All Sizes of Capsule Available

High Productivity & Fully Automatic

High Efficient & GMP Standard

Want A Free Consultation

NJP-1200D Automatic Capsule Filling Machine

AIPAK NJP-1200D automatic capsule filling machine produced by our company is the innovative product of the third generation. It not only covers all the functions and effects of the domestic capsule filling machine of the same model, but also has six pieces of innovation, two of which has been issued the utility model patent certificate by the national intellectual property administration, PRC at May 11, 2016. The innovative NJP-1200D automatic capsule filling machine has advantages of higher production efficiency and longer service life, and has been well received by customers at home and abroad.

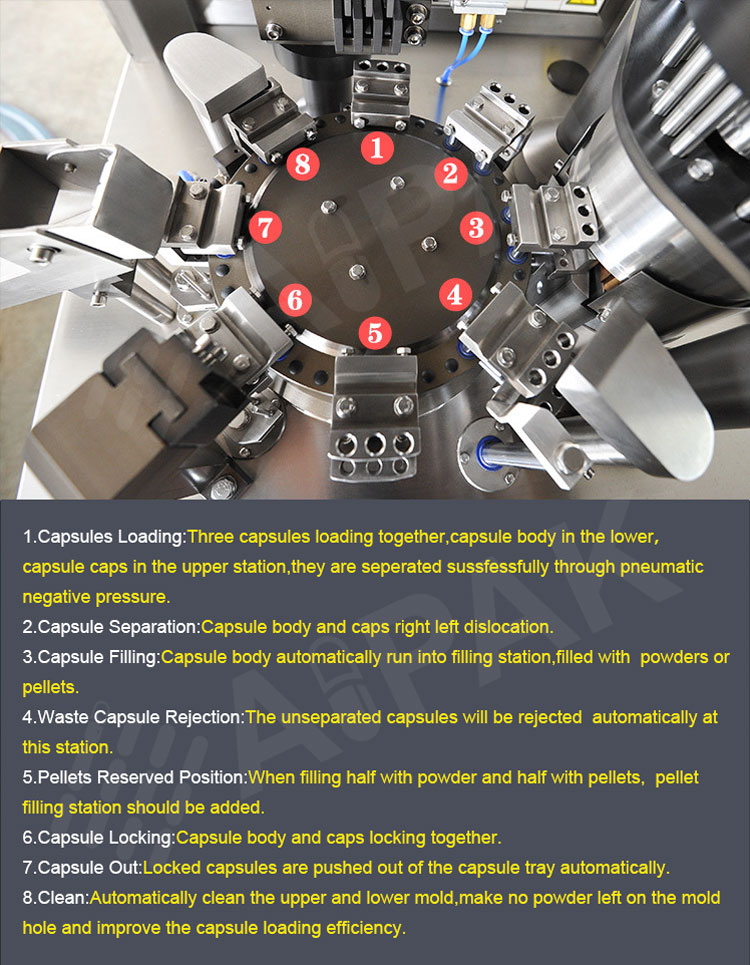

1.Automatic Capsule Filling Machine Working Principle

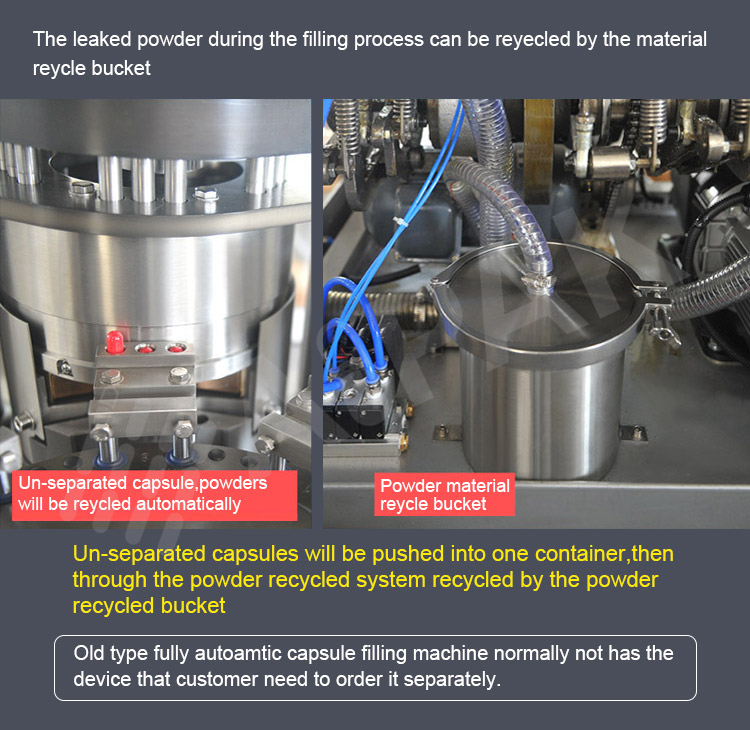

2.Automatic Capsule Filling Station

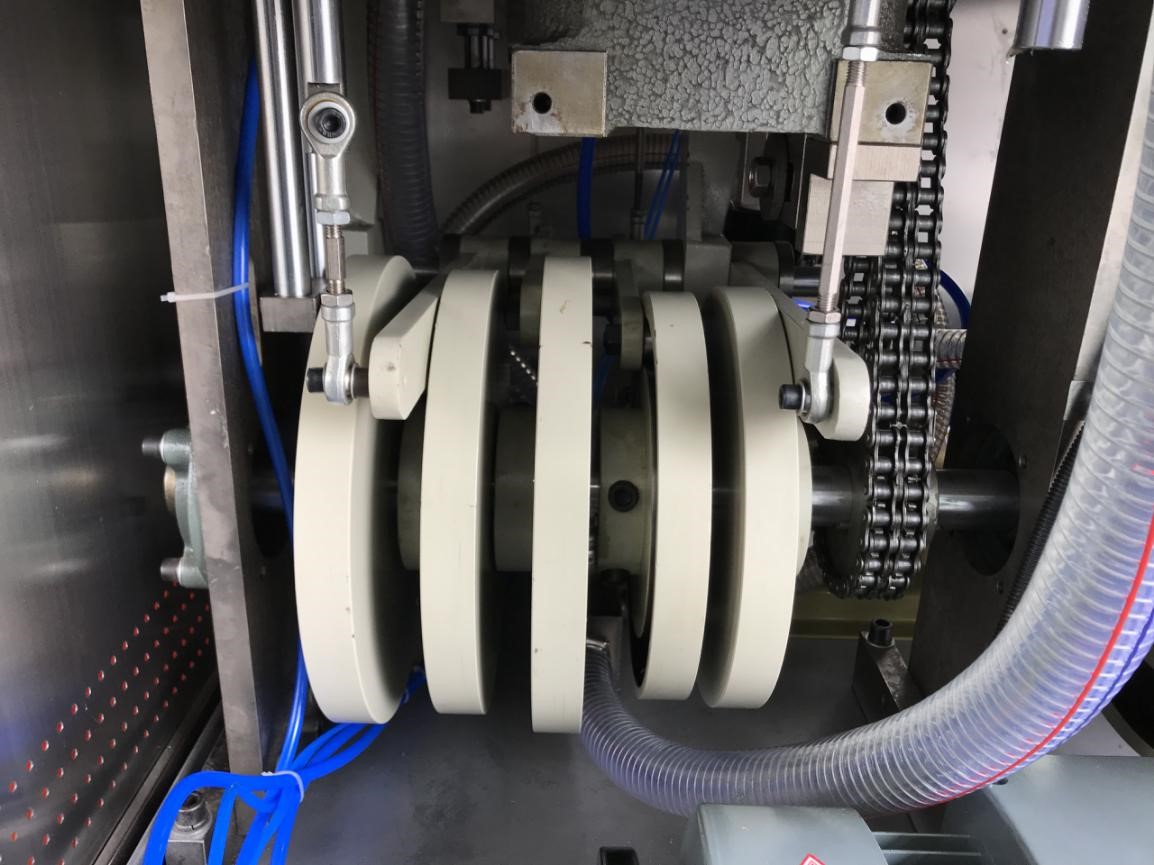

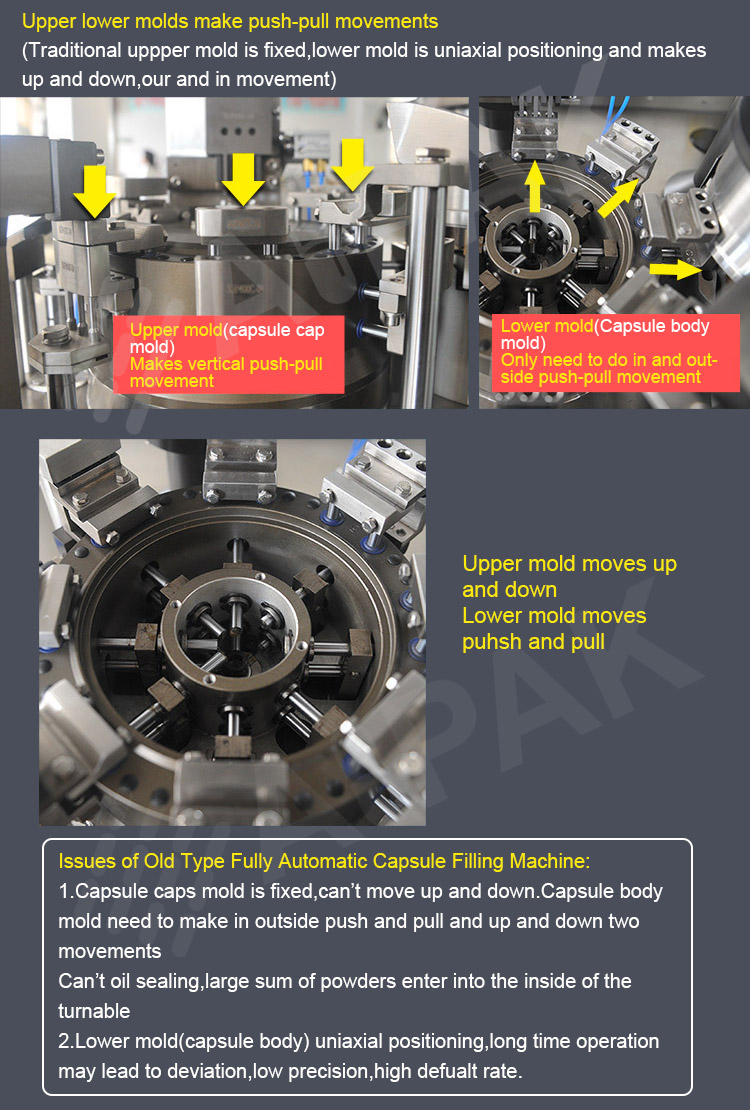

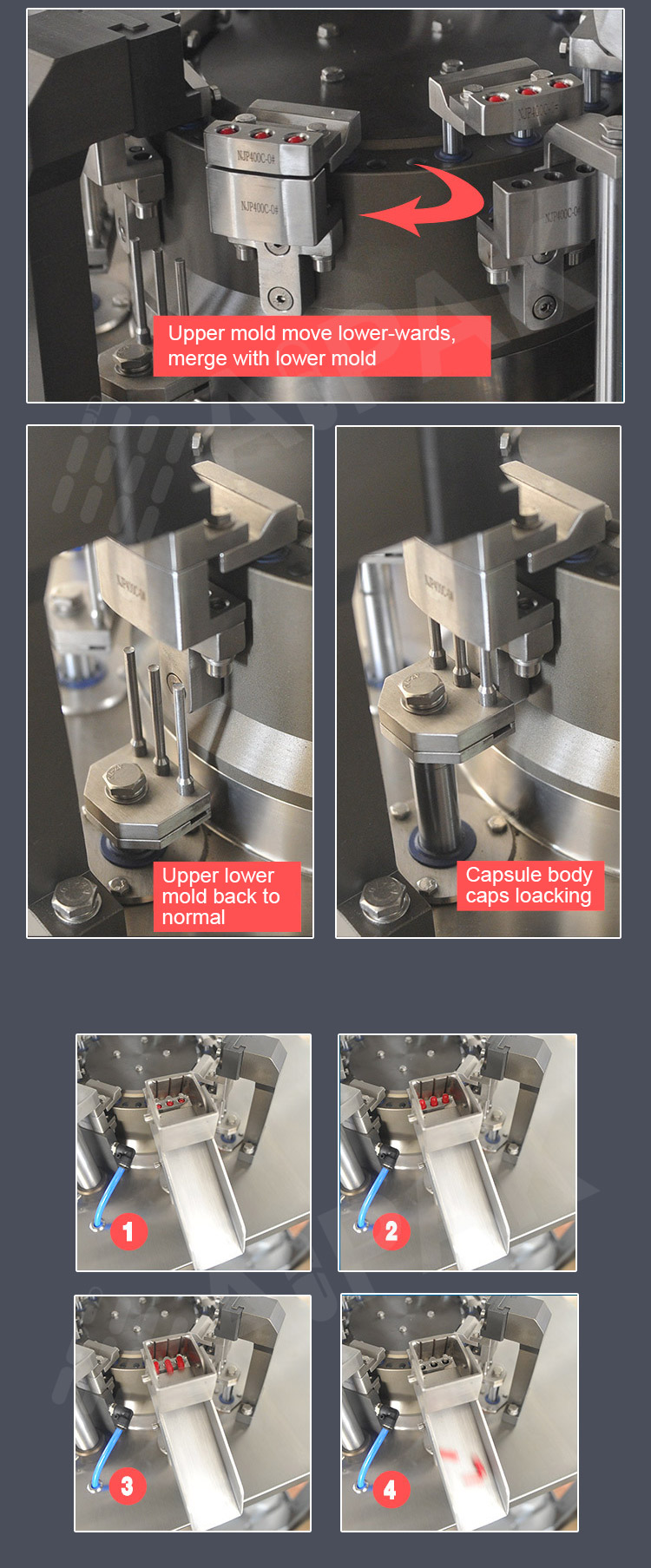

3.Upper Mold Movement

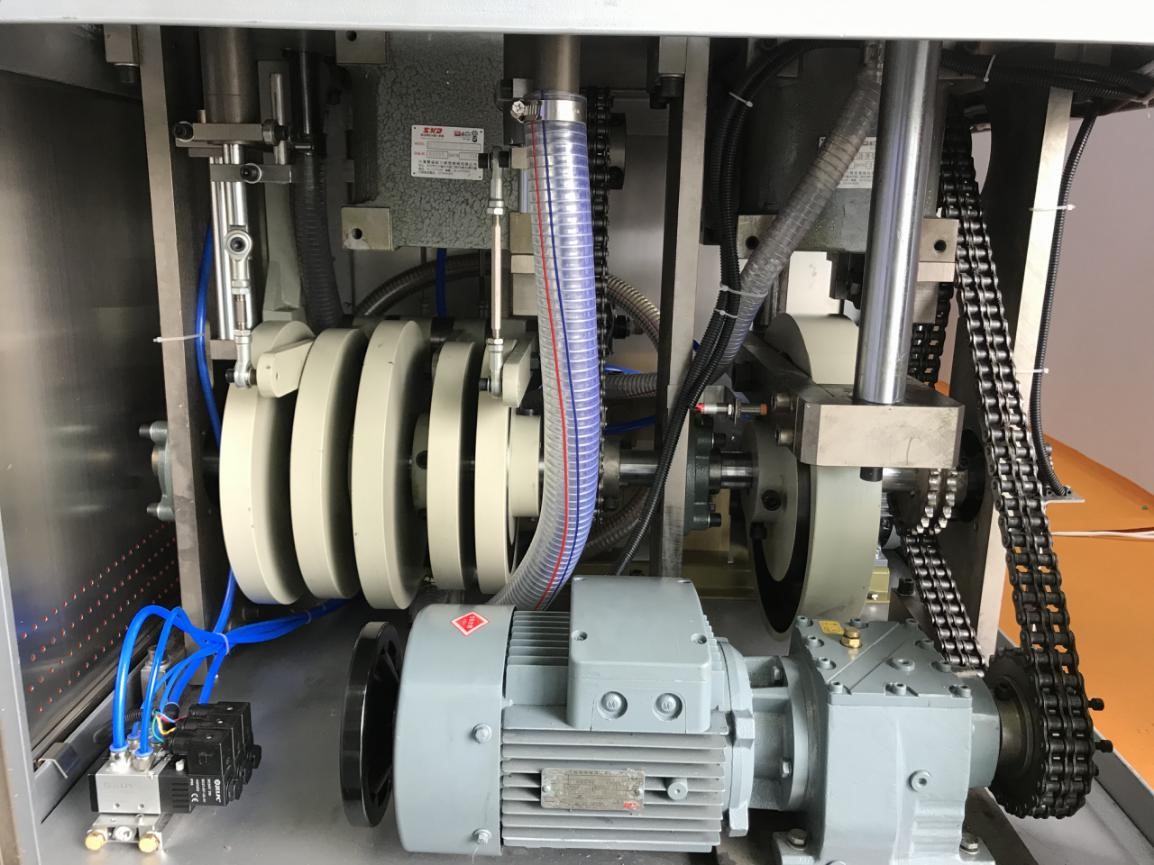

4.Double Shaft Double Oil Sealing

5.Loading Valve

6.Aviation Material

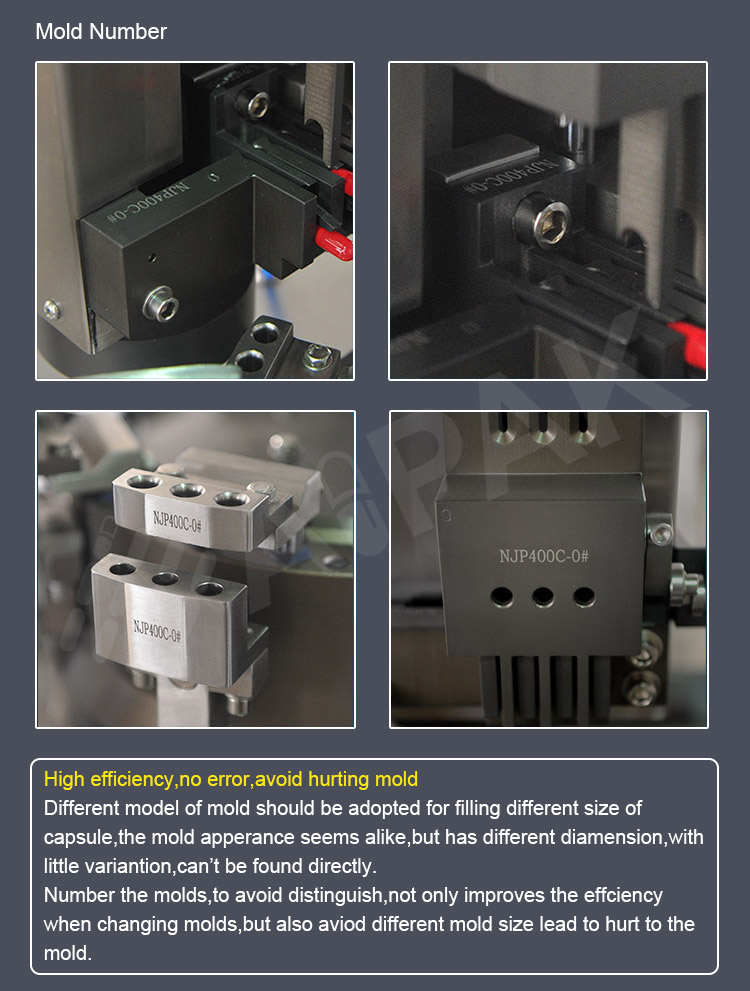

7.Mold No.

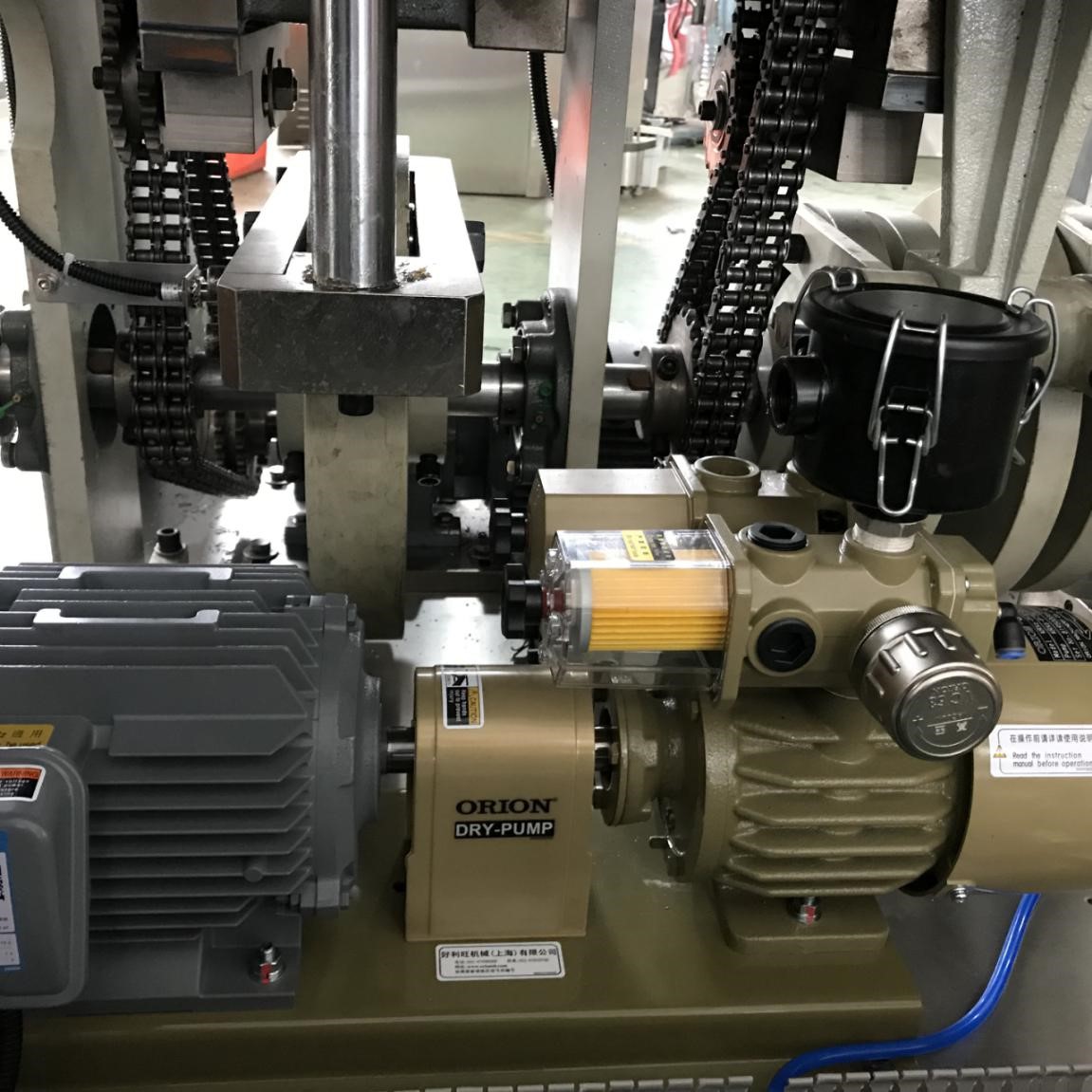

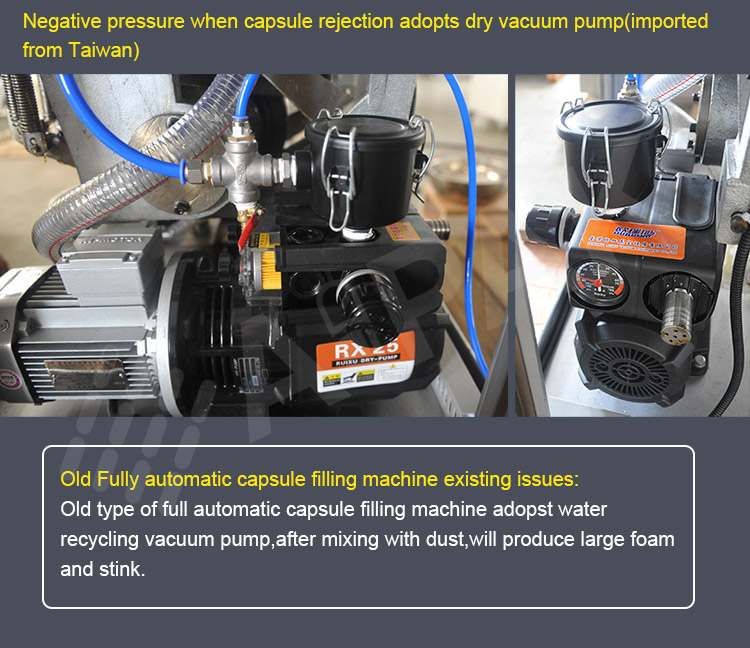

8.Dry Vacuum Pump

9.Safety

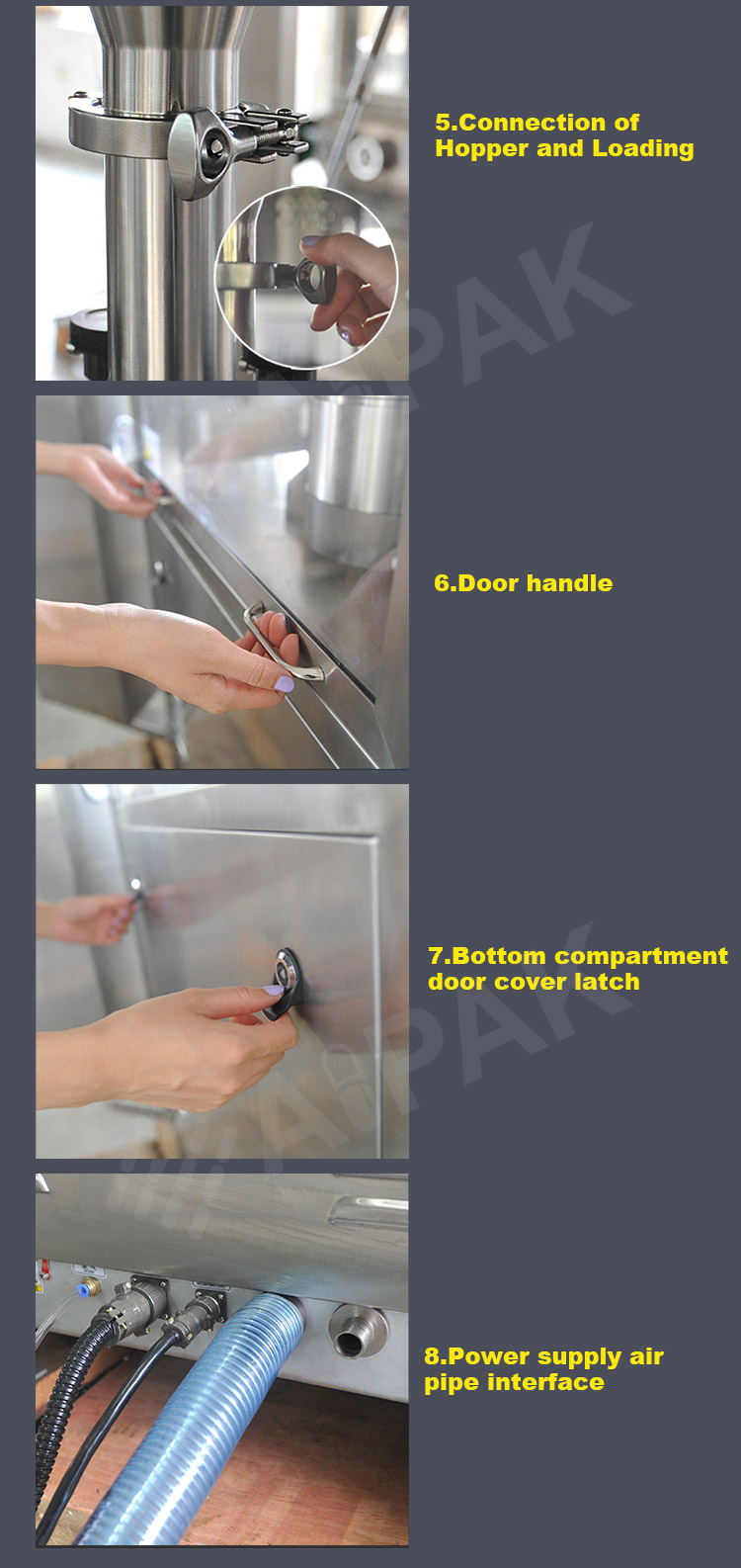

10.Specific Details

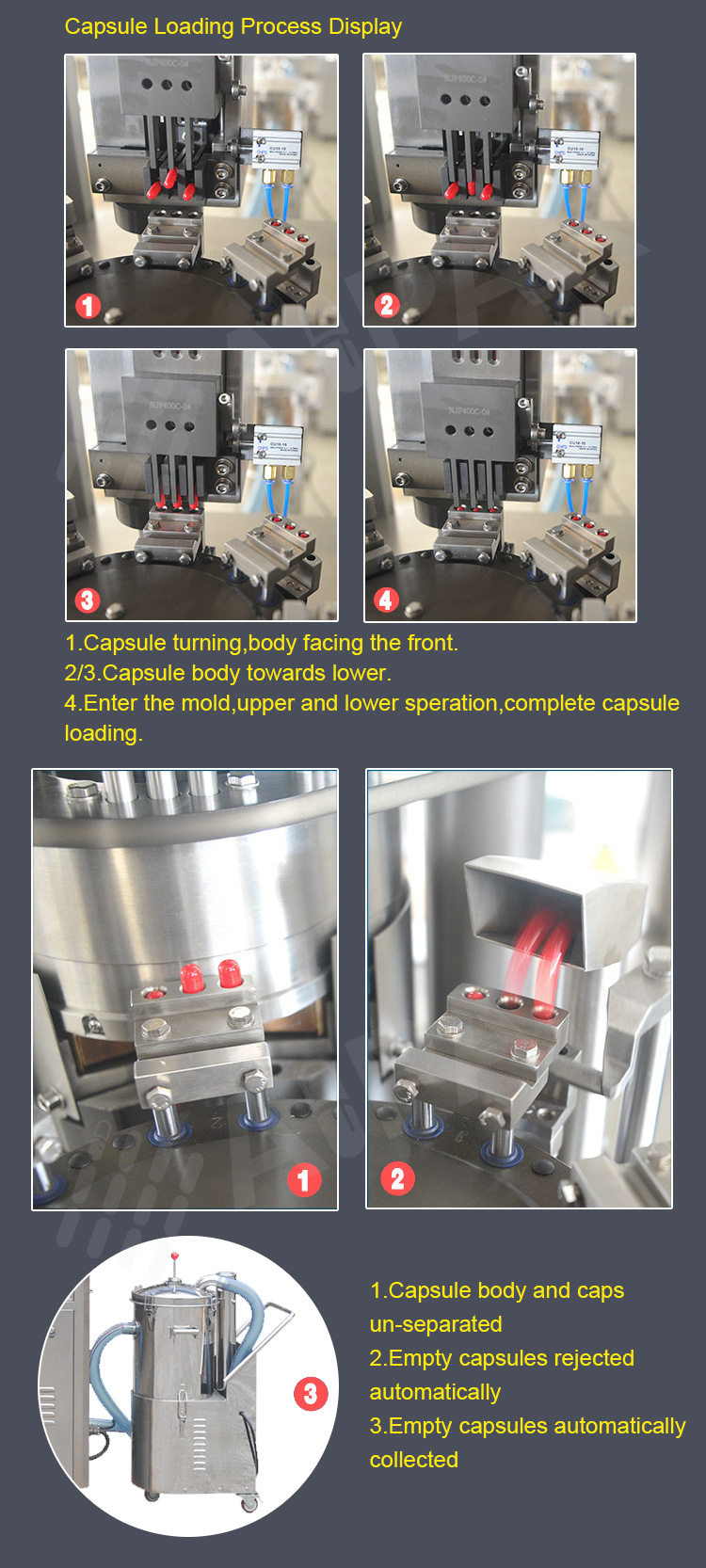

11.Capsule Filling Complete Process

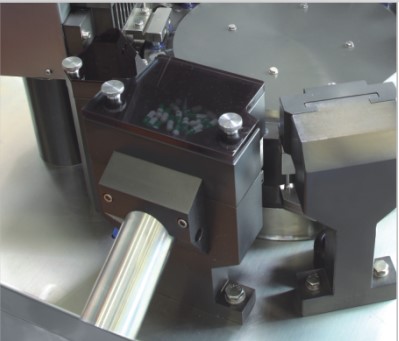

12.Pellet Filling

13.What AIPAK Automatic Capsule Filling Machine Can

FEATURE

- In order to improve the quality and production efficiency of this model, we have made significant improvement on the original 1200Dautomatic capsule filling machine. The overall machine size has been enlarged, where the main machine dimension is changed to1200×1000×2150mm.

- For ensuring the device quality and production effects: we have selected bigger high precision dividing box, which is better than 1200Dautomatic capsule filling machine of the same model produced by other companies in domestic industry, who usually use the configuration of 83DS and 83DS cam dividing box, and whose disadvantage is that the filling speed is limited at about 900pcs capsule per minutes in proper working condition. Forcibly increasing the filling speed to about 1000pcs capsule per minutes and continuing the working condition for these machines may cause breaking of the input and output shafts and the subsequent operation stopping. Unlike other companies, we use cam dividing configuration of 100DS, and we are the first one in domestic market to use the 100DS. Although the production cost increases, we have significantly enhanced the device’s production efficiency and service life. Its filling speed has been raised up to about 1100pcs capsule per minutes. Due to these advantages, it has been widely received by customers at home and abroad.

DATA SHEET

|

Model |

NJP-1200D |

|

Filling capacity |

72000pcs per hour |

|

Weight |

1000Kg |

|

Dimension |

1100×910×2100mm |

|

Power supply |

380/220V 50Hz |

|

Total power |

5.5KW |

|

Segment bores |

9 holes |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Air compression |

Air consumption 5m3/h Pressure 5-7Kg |

|

Operating noise |

<75DB(A) |

|

Filling percentage |

Empty capsule 99.9% filled capsule 99.8% |

|

Capsule size |

00,0,1,2,3,4,5# safety capsule A-E |

|

Filling accuracy |

Western medicine ±3% Chinese medicine ±4% |

|

Suitable for |

Powder, Granule, Pellet, Tablet. |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586