Products achieve good uniformity, mobility, and solubility

High-speed drying

Simplified&convenient operation control

Want A Free Consultation

LPG25 High Speed Milk Powder Spray Dryer

AIPAK LPG25 milk powder spray dryer is suitable for spray drying of solutions, suspensions and other liquids containing dry matter. It is a vertical parallel flow upward exhaust pressure spray dryer. Materials are sprayed into the tower from the middle of the tower top air equalizer through a high-pressure pump or a peristaltic pump through a high-pressure pipe. The droplets are atomized through a nozzle with an atomization angle of 55~65 °. The droplets contact with hot air with very low relative humidity, and a strong heat exchange occurs between the two instantaneously.

The heat energy of the hot air supplies the droplets to evaporate their moisture.

The materials are dried into powder particles with moisture content meeting the requirements, the evaporated water is taken away by the hot air and discharged into the atmosphere by the exhaust fan through a two-stage cyclone separator. The fine powder taken away from the exhaust duct of the tower body is collected once by the primary cyclone separator, and then again by the secondary cyclone separator. The collected powder is collected into the powder receiving bucket, and the waste air is discharged to the atmosphere through the exhaust fan.

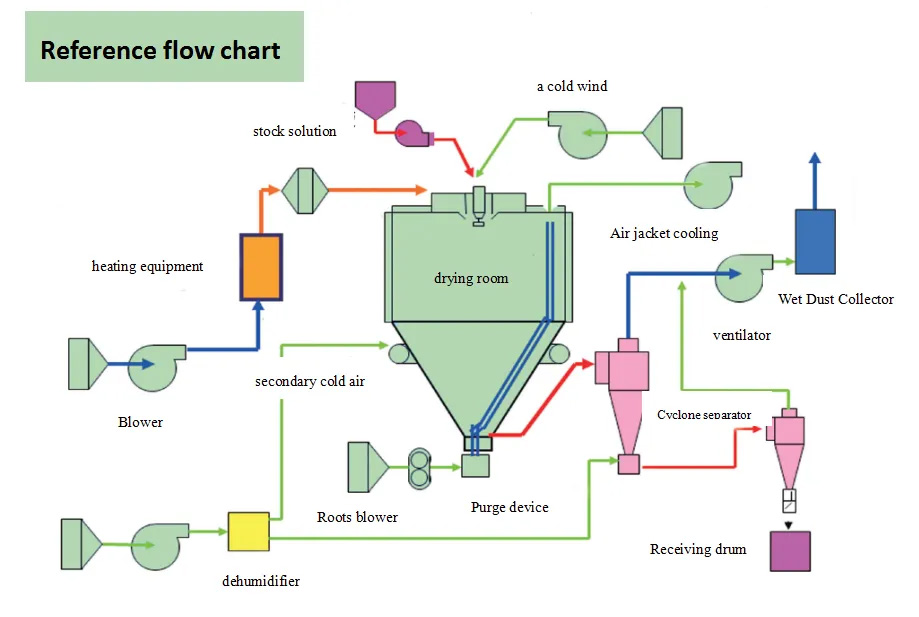

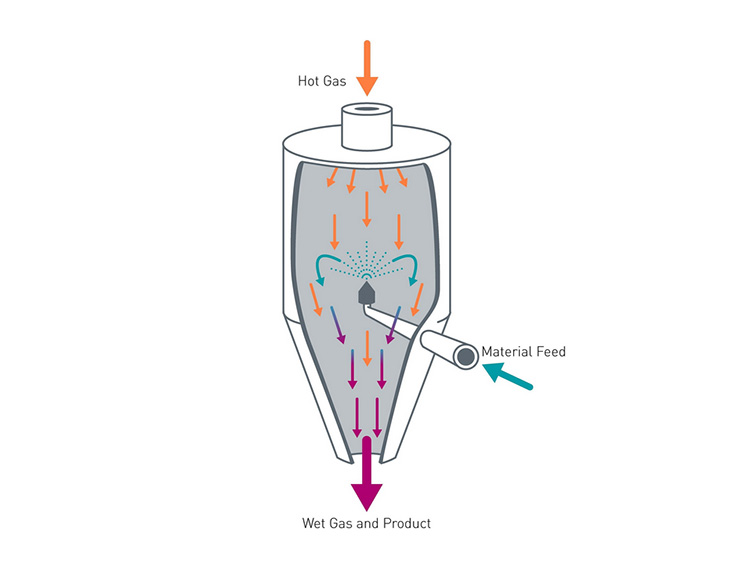

LPG25 Milk Powder Spray Dryer Working Principle

AIPAK LPG25 milk powder spray dryer adopts a new type of air flow structure with upward air intake, which greatly protects the protein, improves the freshness of the product, and reduces the denatured protein of the product. The spiral wind sweeps the tower wall, resulting in less powder accumulation inside the tower.

The hot air box has a new type of air distribution structure, which requires no adjustment to ensure uniform air intake.

The tower top is equipped with a cold air coil to avoid the problem of coke powder on the tower top.

The tower wall is equipped with an air hammer controlled by a pulse controller and a related compressed air system.

The operating pressure can be adjusted within 1-3 bar, and the tapping frequency can be adjusted.

The tower wall is automatically cycled to avoid powder accumulation on the tower wall. The operation adopts automatic

control,equipped with frequency converter, temperature sensor, PLC program control, and a set of manual control buttons, which is simple to operate and easy to control.

Air intake system

(1) The intake air filtration system adopts a sub high efficiency filter.

(2) The air inlet heating system adopts the method of electric heating.

(3) The air intake unit is modular, making it easy to disassemble and clean all components.

(4) The temperature of the hot air inlet can be adjusted within the range of 160~190 ℃.

Exhaust system.

(1) The method of two-stage cyclone separation is used for powder capture. Cyclone separation is a commonly used gas solid separation method, and the waste air is converted into clean air for discharge.

(2) The exhaust outlet temperature is adjustable within the range of 80 to 100 ℃.

Spray system

The material is quickly atomized and sprayed into the tower through a spray gun and nozzle. (1) High pressure pump and volute type M-type nozzle are used for atomization in the production of sticky materials and products requiring high bulk density and fine particles.

(2) When producing non viscous materials and products requiring low bulk density and large particles, peristaltic pumps, two fluid nozzles for atomization, and secondary polycondensation are used.

Drying system

(1) The inner wall of the tower maintains a 2B plate surface, and the welds are polished to reduce fine powder adhesion on the tower wall.

(2) The angle of the cone portion of the equipment is appropriately reduced, thereby accelerating the flow of

materials on the cone.

(3) The equipment is equipped with a quick opening cleaning interface and a sewage outlet, which is convenient for cleaning.

(4) Each section of the equipment is equipped with an anti-static device, which can guide the static

electricity generated by materials into the ground in a timely manner, protecting the equipment and operators.

(5) The inner wall of the drying tower is made of 2mm stainless steel plates, which can withstand a negative pressure of 4000Pa and will not be damaged in the event of incorrect operation. The outer wall is made of 1mm stainless steel plate

Control system

The control system adopts a touch screen+PLC, with a high degree of automation, which can store data, and parameters such as temperature and pressure can be digitally displayed, with an overtemperature alarm.

LPG25 Milk Powder Spray Dryer Application

Food industry: whole milk powder, cocoa milk powder, milk replacer powder, oats, chicken juice, instant tea, seasoning meat, soybean, corn starch, glucose, fruit pulp, etc.

Pharmaceuticals: Chinese medicine, medicinal glue, vitamins, etc.

Detergent: washing powder, soap powder, baking soda, whitening agent, etc.

Chemical industry: catalysts, vulcanizing agents, etc.

FEATURE

- LPG25 Spray dryer is used to disperse the material into mist by using high speed centrifugal atomizer, and the drying device of powder finished product is formed when it is fully exposed to hot air.

- Equipment installation of refrigeration dehumidification device can be in the process of material drying, can make the material in the primary cyclone discharge was immediately after cooling, won't make the material after drying in the condition of remaining agglomerate harden, after cooling of the material collected in cyclone separator, tail gas by cooling tower circulation fan back.

- The equipment installed HEPA filter, so that the air into the air purification of 100,000.

- The inlet air temperature is controlled automatically, which ensures the color, aroma and taste of the material will not be damaged.

- In the tower body, the pipe is equipped with quick cleaning holes and blow-down holes, so that the cleaning is convenient and conforms to the GMP operation specification.

- Due to poor material fluidity, the equipment is in the main tower cone and cyclone cone equipped with air hammer, so that the dry powder will not adsorb on the wall.

- The receiving system adopts two stage cyclone separation to improve the yield of materials.

- Unique inlet screw distributor, is the company's patent, to ensure that the tower in the circumference, the air volume is absolutely uniform down, to minimize the material sticky wall.

- The spray tower is large, it can adjust to the drying of various kinds of materials, the inlet air temperature and the temperature setting of the wind can be controlled by manual, automatic transformation, and the scope of work is wide.

DATA SHEET

| Model | LPG-25 |

| Inlet air temperature | ≤ 350°C |

| Outlet air temperature | 80-90°C |

| Evaporate capacity (kg/h) | 25 |

| Atomizer type | mechanical drive |

| Rotary speed | 22000 |

| Diameter of atomizer disc (mm) | 120 |

| Heating source | Electricity/LPG/Natural gas/Oil/Steam |

| Electric-heating power (kw) | 36 |

| Dry powder yield (%) | ≥ 95 |

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586

The Buyer's Guide

Milk Powder Spray Dryer:The Complete Buying Guide in 2024

In the production world, there are limited dryers that accept material in fluid form and produce powdery material after treatment. The milk Powder spray dryer is one of the best machines that can treat milk and produce powder milk with qualified material size with an acceptable range of moisture content in it. Due to this unique property, milk powder spray dryer is extensively utilized in various industrial sector for flexible operation. If you’re planning to invest in a milk powder spray dryer; this article is for you. Let's read on and find out what amazing features it offers to boom up your business.

1.What is Milk Powder Spray Dryer?

The milk powder spray dryer is a technical equipment used to dehydrate moisture content in milk feed and also to form high-quality dry milk powders. This equipment disintegrates concentrated milk feed into tiny droplets for drying by hot air.

The milk powder spray dryer is part of the production line where skimmed milk powder, instant milk powder, and whole milk powders are processed.

The entire phenomenon takes place at the fastest pace to minimize the risk of rancidity in milk and preserve healthy constituents in it.

2.What are the Industrial Applications of a Milk Powder Spray Dryer?

A milk powder spray dryer can be used in fields such as food, biology, chemicals, pharmaceuticals, and metals. Some of the applications of this technology are discussed below for your understanding.

Milk Production Industry

This machine process various kinds of milk powders such as nonfat milk powders, instant milk powders, baby milk powder, etc. It is energy efficient and easy to use. Milk powder spray dryer removes water content which can help to kill microbes and hence prevent it from spoiling. This method is known for the ESL (extended shelf life) of milk and infant formula. A milk powder Spray dryer is crucial in the production of nutritionally balanced infant milk formula.

Food industry

A milk powder spray dryer is suitable for the processing of both heat-sensitive and heat-resistant food. The technology is suitable for a variety of food materials, provided they are pumpable. This machine is widely used for producing dried eggs, dried fruit juices, powdered flavors, and many more. It is also used in the production of baked goods, confectionery, desserts, etc.

Dairy Industry

The milk powder spray dryer is an integral part of the dairy industry because it improves the storage stability of dairy products. Production of dairy products was one of the first applications of a milk powder spray dryer and it started in the 19th century. It helps in making buttermilk powder, creamer powder, and various other specialty dairy powders.

Pharmaceutical Industry

The milk powder spray dryer has extensive use in the pharmaceutical industry. It converts liquid emulsions and suspensions into dry form. This helps to achieve precise attributes in pharmaceutical powders such as particle size, morphology, and stability. Milk powder spray dryers are employed in the preparation of poorly soluble oral and inhalable drug formulations.

Biochemical Industry

Milk powder spray dryer technology has become a part of routine operations such as the production and isolation of peptides, proteins, and monoclonal antibodies in the biochemical and biopharmaceuticals industry

Nutraceutical Industry

This machine is employed in nutritional supplement production. It is helpful in manufacturing protein powder, vitamin powder, and meal replacements. Milk powder spray dryer ensures the preservation of essential nutrients and increases their shelf life.

Animal Food Industry

Nowadays dried and readily available food is also used to feed domestic and pet animals. Therefore milk powder spray dryer is used in this industry widely. The proper formulation of animal feed is necessary for the development of young ones, which can be achieved by using a milk powder spray dryer. It provides a concentrated and easily digestible source of nutrients.

3.What are the advantages of a Milk Powder Spray Dryer?

A milk powder spray dryer is a versatile machine with a huge range of benefits. Some of these advantages are penned below:

Rapid Drying

Milk powders spray dryer is central equipment in milk processing lines due to its quick drying. The spraying of milk mist boosts the surface area of liquids for evaporation leading to fast drying.

Ease of Use

There is no need for additional equipment with a milk powder spray dryer such as a crusher or sieve. The moisture content of milk is reduced in a single pass in this machine. Moreover, the milk powder spray dryer is equipped with state-of-the-art computerized systems that assist in the easy adjustment of program parameters.

Refined Purity of Products

Milk powder spray dryers are customized with efficient spray nozzles to spray liquid milk and cyclone dust collection devices to filter milk powders from the exhaust air. This results in the production of superior quality ultra-pure milk powders with high shelf life.

Particle Size Control

It has full control over the particle size of milk powders. There are no variances in particle sizes of end products with milk powder spray dryer. Moreover, this machine produces milk powder particles having sizes in a range of 30-500 µm.

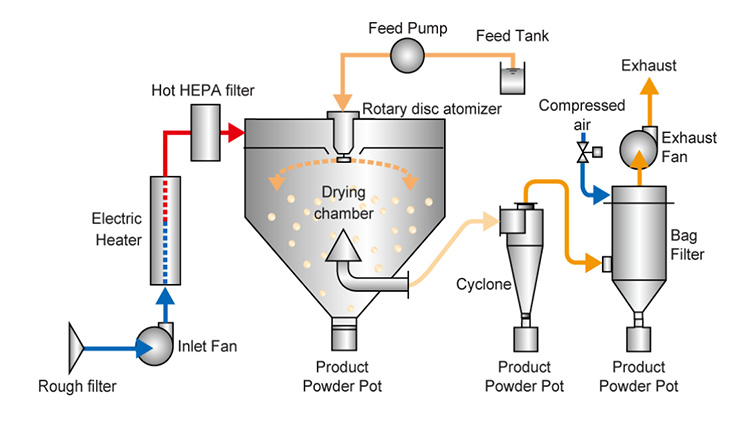

4.What is the Working principle of a Milk Powder Spray Dryer?

Some important steps in working of spray powder spray dryer involve:

Preparatory Stage

In the first step, the liquid milk is concentrated before it is filled inside the feed tank. This step is beneficial in amplifying the number of solid particles consequently reducing the volume of liquids for evaporation. Wet feed then goes to the product inlet where it is carried to the atomizer nozzle.

Liquid Atomization

This step act as the heart of the milk powder spray dryer working. Nozzles in milk powder spray dryer apply pressure or centrifugal force for the disintegration of milk into tiny droplets.

Air-Droplet Exposure

Heated air is introduced inside the drying chamber and after atomization droplets are exposed to air. This intimate contact of spray and drying medium leads to heat transfer which in turn causes the evaporation of moisture from the droplet surface.

Evaporation

It starts immediately after contact between droplets and drying air. There are two steps for drying particles. The first step also called the constant rate period, involves the steady migration of moisture from the interior of a droplet to its surface from the former is vaporized. The evaporation occurs at this constant rate till there is enough moisture left for drying.

But after some time, the quantity of moisture decreases in the droplet and a thin layer of solid crust starts forming on the droplet surface This crust thickens with time ultimately reducing the drying rate. This stage is called the falling rate period.

Separation

After drying, solid milk powders are separated by two means. In primary separation, the piled-up milk powders are removed from the base of a drying tower utilizing screw conveyors.

However, in secondary separation, exhaust air with dispersed milk powder particles is passed to gas-treatment systems where a cyclone separator, bag filter, and precipitator fully separate powders and purify the air.

5.What are the Parts of a Milk Powder Spray dryer?

The milk powder spray dryer is comprised of different parts, each playing its role in the drying process. Some basic components of a milk powder spray dryer include:

Pre-Air Filter

It removes the impurities and microorganisms such as bacteria from compressed gas coming from outside. It is a type of coarse filter.

Blowers

They are the supplying fan that direct the atmospheric air to electric heating systems.

Middle and High Effect Air Filter

This section meant to assure fairly cleared process with no chances of contamination by trapping impurities using ultra high air filters.

Electric Heaters

These are employed in milk powder spray dryer for heating hot air. This type of heaters also recover heat from exhaust gases and lower carbon emission.

Feeding Pump

These pumps provide the necessary pressure for the transport of viscous milk slurries to the atomizers located at the upper part of the drying chamber.

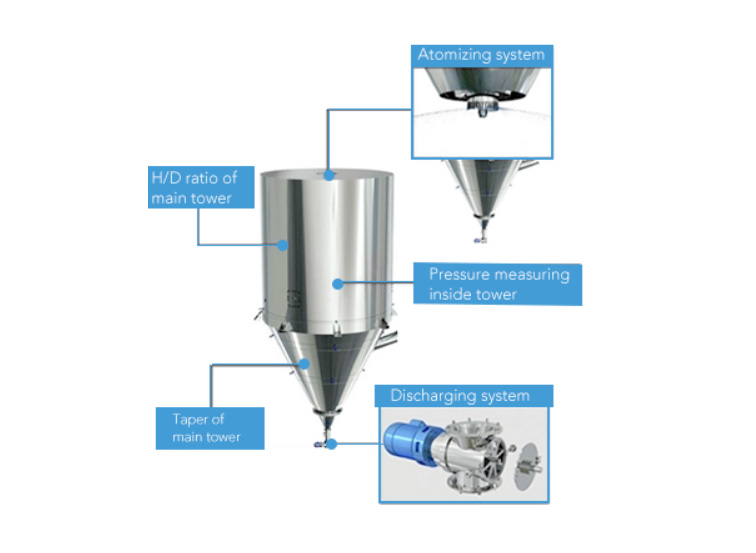

Atomizer

It is the fundamental part of the milk powder spray dryer that uses high pressure, kinetic energy, or centrifugal force for dispersing milk feed into smaller drops. Rotary atomizers (spinning disk atomizers), pressure nozzles, and hydraulic nozzles are employed in the milk powder spray dryer for atomization purposes.

Drying Tower

It is the main component of a milk powder spray dryer where drying takes place. Liquid milk is introduced through nozzles in this chamber and the moisture from liquids is evaporated through the contact of hot air.

Cyclone Separator

It is the commonly employed dust collection device in the milk powder spray dryer. Gas with particles is tangentially flown inside the cyclone separator and by centrifugal force, heavy particle settles at the edge of walls while air is sucked upward.

Draught Fans

The milk powders spray dryer consists of draught fan that utilizes high pressure to force and remove the hot air from the system.

Duster

It removes the impurities, dust, or inflammable particles from the exhaust air. Bag filters are an important component of off-gas treatment systems in the milk powder spray dryer.

Fan of Cool Air

It is device that uses high voltage to produce cool air towards the milk powders. The milk powder particles are attracted toward collecting plates when cool air with milk powders is introduced inside the precipitator.

6.What are the Types of a Milk Powder Spray Dryer?

There are different ways to classify a milk powder spray dryer. The classification of milk powder spray dryer is detailed below for your understanding.

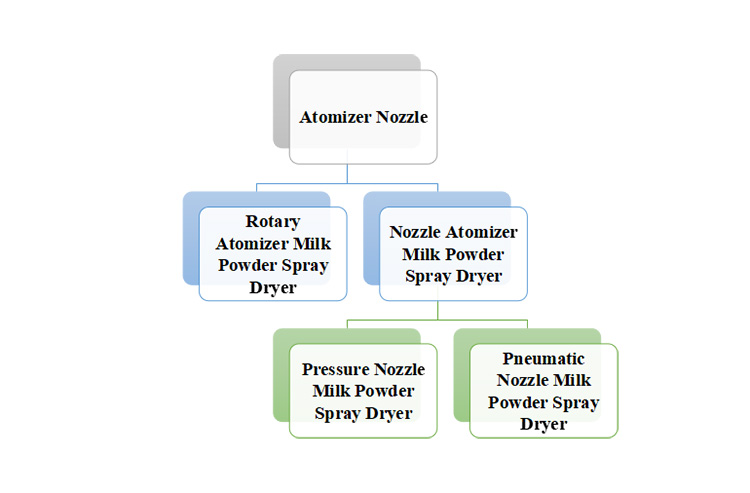

Classification Based on Type of Atomizer Nozzle

There are two major classes of milk powder spray dryer based on the type of atomizer nozzle installed in them.

Rotary Atomizer Milk Powder Spray Dryer

It is also referred to as a centrifugal milk powder spray dryer because centrifugal force is the main culprit that breakdown the milk into atomized droplets in this type of milk powder spray dryer.

It has a horizontal rotating disc and liquids for atomization are loaded at its center. By rotating force, the milk particles scatter towards the edge and are disintegrated by centrifugal force as they pass through the nozzle. Rotary atomizer milk powder spray dryer produces powders of about 20-200 µm.

Nozzle Atomizer Milk Powder Spray Dryer

This type of milk powder spray dry is further classified into two types. These are:

Pressure Nozzle Milk Powder Spray Dryer

It is also called one nozzle or hydraulic nozzle milk powder spray dryer. The milk feed is disintegrated into tiny droplets via pressure generated by the pump in the pressure nozzle milk powder spray dryer. When feed is forced through a nozzle orifice, it disintegrates into smaller drops. Pressure nozzle milk powder spray dryer generates droplets of about 120-250 µm size.

Pneumatic Nozzle Milk Powder Spray Dryer

It is also known as a two-nozzle or kinetic nozzle milk powder spray dryer. The pneumatic nozzle milk powder spray dryer has two nozzles-one for liquid feed and the other for hot gas. The milk on exposure to compressed air break down into atomized spray by the kinetic energy of the gas.

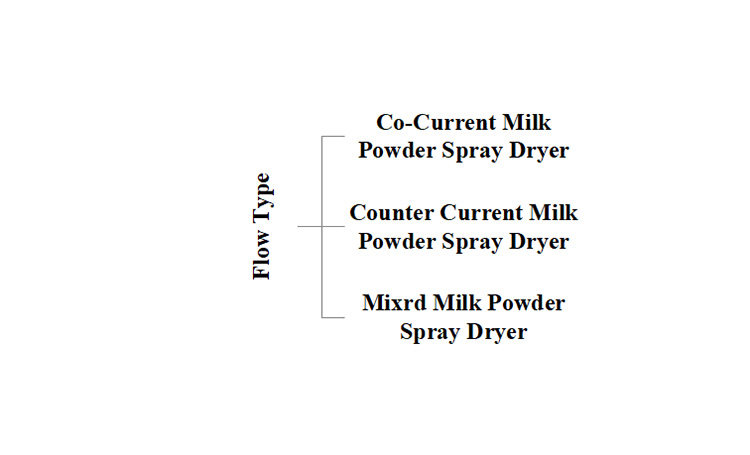

Classification Based on Flow Type

There are three classes of a milk powder spray dryer based on the direction flow of feed and gases.

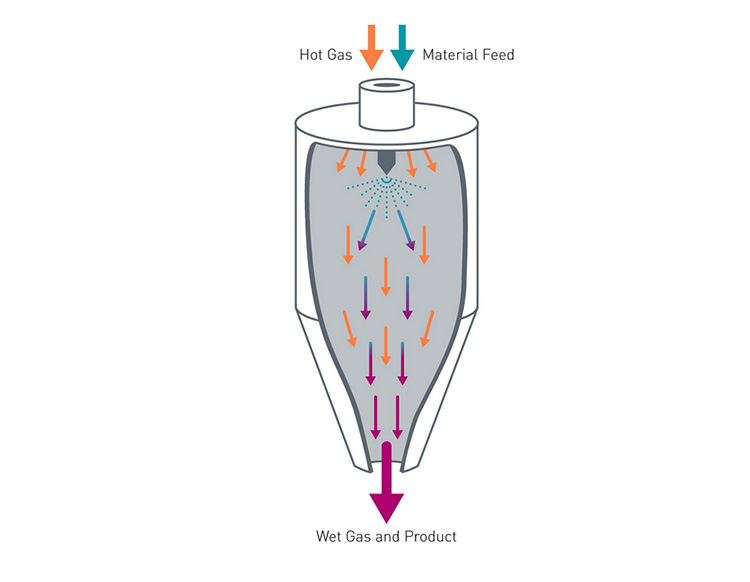

Co-current Milk Powder Spray Dryer

Both milk feed and compressed air are introduced in the drying chamber from nozzles present at the top of the drying chamber hence, they also flow in the same direction. This type of milk powder spray dryer is named after the co-current flow pattern.

The drying time is shorter due to fast evaporation.

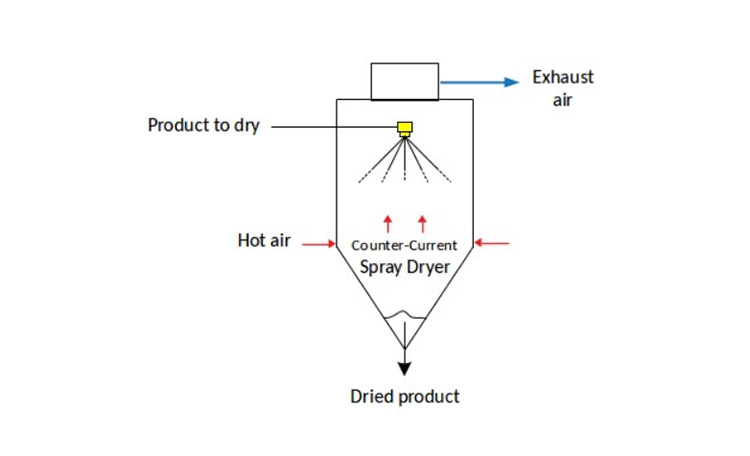

Counter Current Milk Powder Spray Dryer

The liquid feed is loaded inside the drying tower from the top while the compressed air enters the drying vessel from the bottom in a counter-current milk powder spray dryer. The movement of feed and air in opposite directions. Overdrying of particles occurs when they are first exposed to hot air.

Consequently, this system is not recommended to dry heat-sensitive powders.

Mixed Milk Powder Spray Dryer

The working principle of this type of milk powder spray dryer is based on both co-current and counter-current milk powder spray dryers. Milk feed is introduced inside the chamber from the nozzles located at the bottom of the drying chamber while the compressed air enters through the top inlet.

First, the feed droplets flow in a counter-current manner but when they get dispersed inside the air, the latter moves them in a co-current manner.

Classification Based on Application Type

There are two major types of a milk powder spray dryer based on application type.

Laboratory Milk Powder Spray Dryer

It is a small portable benchtop milk powder spray dryer that is typically used in a laboratory in an experimental setting. It has a minimal working capacity with a small footprint of about 1m2. the laboratory milk powder spray dryer produces low noise and is exceedingly advantageous because of its high milk powder recovery.

Industrial Milk Powder Spray Dryer

It is a large-scale milk powder spray dryer having multiple nozzles and off-gas treatment systems. It occupies more space and usually has a working capacity above 4000 ml/h. Industrial milk powder spray dryer is employed in massive processing plants for drying large loads of milk feed.

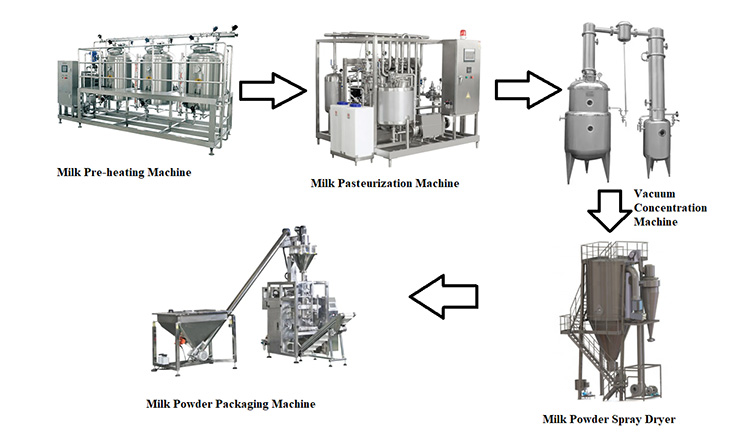

7.What is the Production Line of a Milk Powder Spray Dryer?

Milk powder spray dryer production lines are automated having different machines that carry out sterilized production and processing of milk powders. Some of these machines are detailed below:

Milk Pre-heating Machine

This machine is the first machine in the milk powder processing line and heats the milk to 35-38°C and then centrifugally spins it to separate the cream from the milk.

Milk Pasteurization Machine

It homogeneously mixes the raw milk at the temperature of 60°C and pressure of 20Mpa. After uniform mixing, the milk is heated at a temperature of 85-87 °C for removing bacteria and other microbes from the raw milk.

Vacuum Concentration Machine

This machine concentrates the raw milk by evaporating the liquid content to obtain 45-55% dry content in milk feed. Vacuum concentration machine is employed before a milk powder spray dryer to acquire high-quality milk powders with longer shelf life.

Milk Powder Packaging Machine

Different kinds of milk powder packaging machines fill the milk powders in different containers such as cans, tins, sachets, pouches, etc. This packaging protects milk powders against environmental elements and other harmful agents.

8.What is the Role of an Atomizer in a Milk Powder Spray Dryer?

The atomizer is a central part of a milk powder spray dryer and is responsible for the atomization of the liquid milk. It is a nozzle-type device used for chopping or cutting liquids into fine mist. It divides the feed into tiny droplets to increase the surface area of milk for evaporation.

The atomizer devices use either pressure or centrifugal forces for disintegrating the liquids. Atomizer is the main part that distinguishes a milk powder spray dryer from other drying machines.

9.What is Single Stage and Two- Stage Milk Powder Spray Dryer?

Single-stage and two-stage milk powder are part of normal milk powder production and packaging lines.

Single Stage Milk Powder Spray Dryer

This milk powder spray dryer removes the maximum moisture content from the milk. It is composed of only one dryer machine-spray dryer. After completing the drying cycle in a single-pass milk powder spray dryer only 2% to 5% moisture content is left in the dry milk powders.

It is best for producing spherical and round milk powders.

Two-Stage Milk Powder Spray Dryer

As the name indicates, the drying of milk occurs in two stages in this type of milk powder spray dryer. Two-stage milk powder spray dryer has an integrated fluid bed dryer in addition to a normal spray dryer. The milk powders on leaving the two-pass milk powder spray dryer have a higher range of moisture about 5% to 10%.

Hence, the powders are moved to a fluid bed dryer where moisture in milk powders is reduced in the second drying stage. A two-stage milk powder spray dryer operates at low temperatures and consequently is best for drying heat-sensitive milk feed.

10.What is the Temperature of a Milk Powder Spray Dryer?

Since milk powders are composed of delicate heat-sensitive components such as proteins that may denature at high temperatures. So, for processing and drying of milk, a liquid feed is atomized at the inlet temperature of about 180-220 °C. while the temperature of exhaust gas or outlet temperature is in the range of 65-85 °C

11.What is the Drying Time of the Milk Powder Spray Dryer?

The drying time of the milk powder spray dryer is extremely low. Since only a few seconds are required for atomizing liquids into droplets. Moreover, due to the high surface area, the drying of moisture from liquid milk is also extremely rapid. The normal residence or retention time of milk powders in a drying chamber is usually about 12-30 seconds.

12.How to Extend the Shelf Life of a Milk Powder Spray Dryer?

A milk powder spray dryer costs large capital thus manufacturers are always looking for ways to increase the operational life of this instrument. Some approaches for extending the shelf life of a milk powder spray dryer include:

Scheduled Maintenance

It goes a long way in extending the shelf life of a milk powder spray dryer. Regular inspection of nozzles, drying towers, cyclone separators, pumps, bag filters, etc for wear and tear helps in decreasing downtimes and replacement of parts.

Cleaning

Accumulation of milk powders in different parts of the milk powder spray dryer comes with a price of fast drying of milk feed. However, investing in clean-in-place technology is recommended to clean hard-to-reach parts. Regular cleaning of the nozzle and drying tower increases their efficiency and also decreases their deterioration.

13.What are the Problems and Solutions of a Milk Powder Spray Dryer?

Brand owners processing milk powders often face problems in their equipment leading to increased downtimes and periods of poor productivity. However, the problems in milk powder spray dryer can be easily troubleshoot by following simple guidelines which are discussed below:

| Problems | Reasons | Solutions |

| Minimal Product Purity

|

Raw materials have powders impurities

The air filter system is not properly working Mixing of debris in the end products |

Filter the milk powders before drying.

Properly position the air filter system Replace or clean the air filter system |

| Reduced Atomizer Speed

|

Defective or damaged atomizer nozzle | Inspect the nozzle for damage and repair it. |

| Reduced Evaporation Rate from Milk Powders

|

Minimal airflow

Decrease the inlet temperature of a gas. Leakage in pipes or tower of milk powder spray dryer |

Increase airflow for proper drying

Adjust the inlet temperature of a gas Reweld or replace pipes or towers if there is leakage in the system |

| High Moisture Content in Dried Milk Powders

|

The outlet temperature is low | Reduce the volume of liquid milk slurries to increase the outlet air temperature |

| Poor Filtration of Milk Powders in Cyclone Dust Separator

|

High collisions cause damage to the cyclone separator leading to failure in powder separation

Blocking of walls and discharge outlet of cyclone separator due to debris build-up |

Purchase and install a new cyclone separator for accurate milk powder separation from air

Properly clean walls and discharge outlet |

| Insufficient Fluidity of Raw Feed

|

Blockage of openings of atomizers due to dust accumulation

The high viscosity of materials |

Wash and clean the atomizer

Process the right viscosity materials according to the machine manual |

14.What is the Future Prospect of Milk Powder Spray Dryer?

In 2022, the market size of a milk powder spray dryer was calculated to be about US$ 5.59 billion in 2022. The market size of the milk powder spray dryer is continuously expanding and is projected to reach 8.95 billion by the end of 2030, showing a CAGR of 6.1%.

A surge in demand for this equipment has been observed due to a variety of factors such as urbanization, population expansion, and lifestyle changes. Encapsulation, the biggest advantage of milk powder spray dryer has introduced value-added nutritionally beneficial milk powders.

To fulfill the consumer demand for ready-to-use milk powders, manufacturers are always in pursuit to develop an innovative milk powder spray dryer that will have increased thermal efficiency as well as minimal pressure requirement.

Modern milk powder spray will have low maintenance requirements. Moreover, it will have reduced off-gas treatment and thus will be more environmentally friendly. It will consume less fuel leading to a lower carbon footprint.

Furthermore, the forthcoming milk powder spray dryer will be mobile with a small footprint and will be used for processing smaller batches of sample powders.

Conclusion

A milk powder spray dryer is a versatile equipment with robust control and fast drying capabilities. It is a highly sought machine in various industries, especially the dairy industry. Milk powder spray dryer is available in different design configurations depending upon drying stages, flow type of feed and air as well as atomizer designs. You can customize this device according to your needs. For further queries related milk powder spray dryer, you are always welcome to contact our helpline.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951