Start-stop of the dryer is quite simple

Easily discharged out of the dryer by harrows

Careful cleaning and observation can be carried

Want A Free Consultation

LPG100 Food Industrial Spray Dryer For Fruit Powder Milk Protein Powder Spray Dryer Equipment

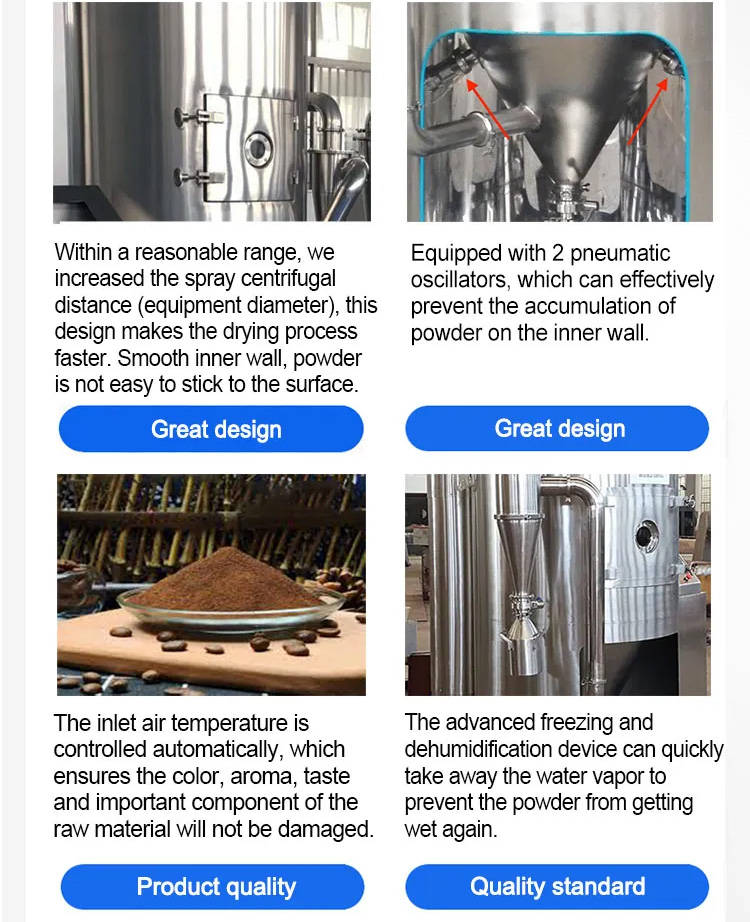

AIPAK LPG100 spray dryer for fruit powder is used to disperse the liquid into mist by using high speed centrifugal atomizer,and the drying device of powder finished product is formed when it is fully exposed to hot air.The key point of the equipment is to pay attention to raw material sticking to the inner wall of the equipment,moisture evacuation,the collection and protection of the final product,etc.

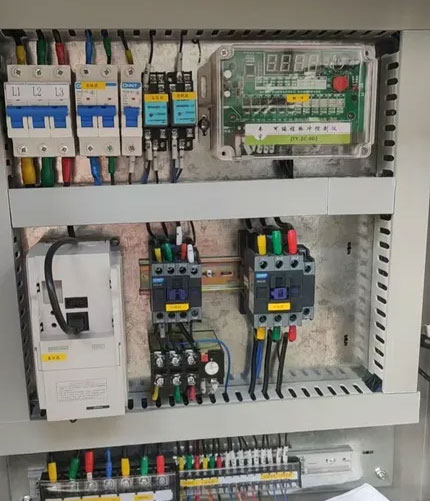

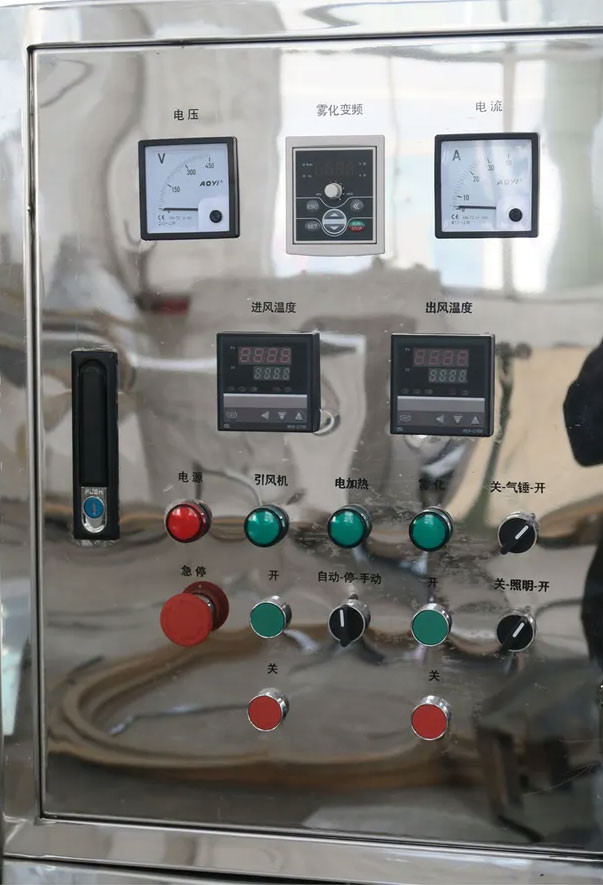

LPG100 Spray Powder For Fruit Powder Deatils

LPG100 Spray Powder For Fruit Powder Advantages

FEATURE

1.Drying speed,the atomized liquid after the greatly increased surface area,in the hot air flow,instantaneous evaporation can be 95%-98%moisture,and only a few seconds to complete drying time,is particularly applicable to dry thermosensitive material.

2.Product has good uniformity,mobility and solubility,high purity products,good quality.

3.Simplify the production process,convenient control.The humidity of 40 to 60 percent(up to 90 percent of special materials)to the liquid into a dry powder products,dried without crushing and screening to reduce production processes,improve product purity.

4.The product size,pine density,moisture,in a certain range by changing the operating conditions can be adjusted,control and management are very convenient.

DATA SHEET

| type | 5 | 25 | 50 | 100 | 150 | 200-2000 |

| Inlet temponlurer(℃) | 140-350 outomamicaly controld | |||||

| Outlet temperatuerc(℃) | 80-90 | |||||

| Max water evaporation capacity(kg/h) | 5 | 25 | 50 | 100 | 150 | 200-2000 |

| Way of atomizing | Compessed ai trand misson | Mechanical tansmission | ||||

| Rotation speed(r, p, m) | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| Dameter of atomizng tray(mm) | 50 | 100 | 120 | 140 | 150 | 180-340 |

| Heant supply | Elecricity | emoyesimam | Electigty+ steam. ftuel o and gas | settied by users themselves | ||

| Max Electhie henting pweraw(Kw) | 9 | 36 | 63 | 81 | 99 | |

| Length(m) x Wdth(m) x Height(m) | 1.8x0.93x2.2 | 3x2.7x4.26 | 3.7x3.2x5.1 | 46x4.2x6 | 5.5x4.5x7 | Decdie aoon Io bee conoele condtors |

| Died powder festoing tate(%) | >95 | |||||

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586