Control system is PLC & Touch screen

Application range is wide

Air distributing plate is special designed

Want A Free Consultation

FL-60 Boiling Fluid bed dryer and Granulator with Spray system for Solid granule infusion Drink Milk Coffee Juice Stevia Powder

AIPAK FG-60 fluid bed drier and granulating is suitable for drying for powder and granules.The principle of action is based on: put the raw material into the fluid bed. The cold air is drawn into the fluid bed through the pre filters and passes through the heating chamber behind the main machine, heated to the desired temperature by the heater. The material is fluidized in the fluid bed regularly . The evaporating moisture is drawn out by the fan.

The advantage of FL fluid bed dryer and granulator rests with maintaining evenness and recurrence of product quality, which reflects an ideal balance between production efficiency and product quality. In the process of fluidization, the materials floats above the air, with surface in full contact with the heated air, and the materials therefore is evenly eated and reaches an ideal state for heat exchange thus to have a high efficiency. Configurated with proper spraying system and through further structural improvement, the fluid bed then becomes a multi-purpose processing facility in combined functions of drying, granulating, solution coating, and powder dressing. Final product usually instant solute granule.

FL-60 Boiling Fluid bed dryer and Granulator Product Details:

FL-60 Boiling Fluid bed dryer and Granulator Application:

- Medicine granulation and coating

- Granulation: tablet granules, granules for granules and capsules.

- Coating: granules, protective layer of pills, color preparation, slow release, film, enteric coating.

- Food Granulation and Coating Sugar, coffee, cocoa powder, butter, powdered fruit juice, amino acids, condiments, puffed food. Pesticide, Pigment Pigment and Dye Granulation. Drying of Powdery, Granular and Block Materials

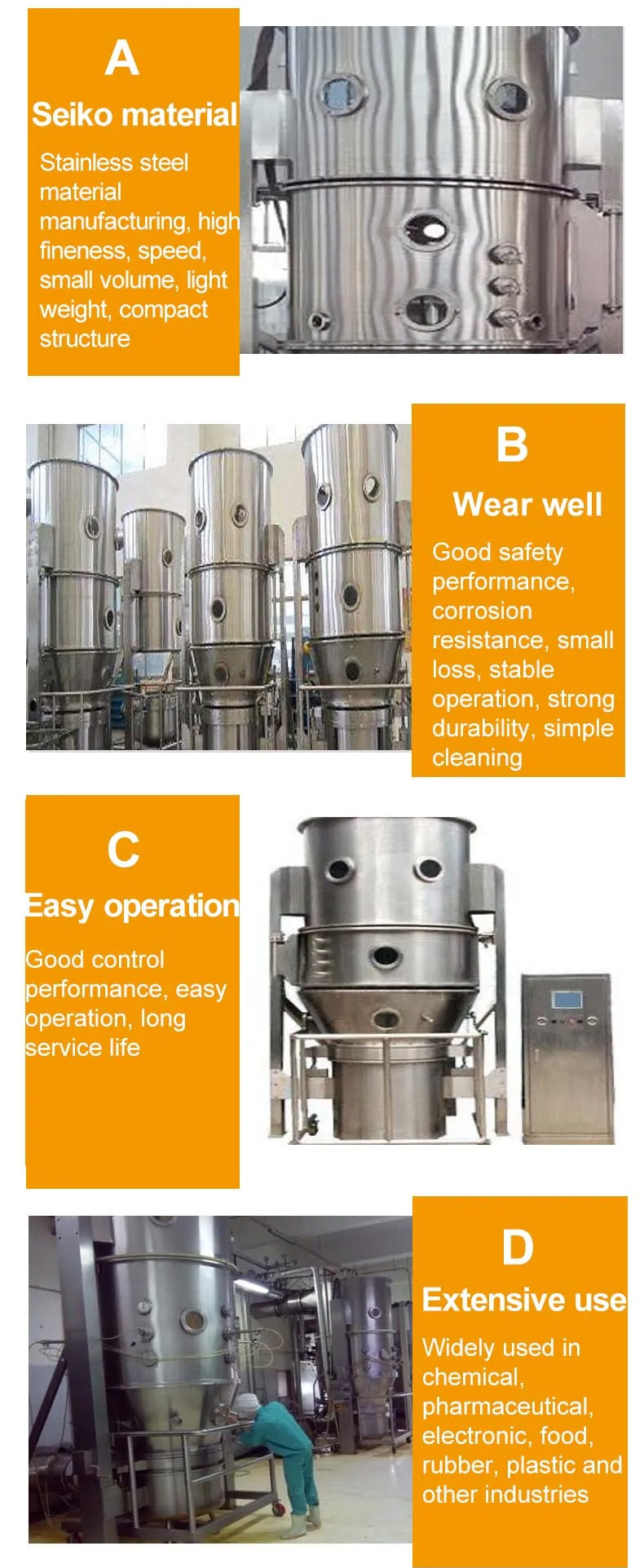

FEATURE

1). Mixing - granulation - drying - in one machine (one step granulation).

2). Adopting double chamber filtering bags system, removing dust completely. Using antistatic filter material, the equipment is safe to operate.

3). The binder nebulizer adopts multi-fluid spray gun, which has uniform spray particles, the content of powder is very low,

greatly improves the qualified rate of finished products.

4). Can choose two bars explosion-proof design

5).The equipment has no dead angle, the loading and unloading material is light, fast and clean.

6). Designed, manufactured and laid out by GMP

DATA SHEET

|

Model

|

5

|

30

|

60

|

120

|

200

|

300

|

500

|

|

Capacity(Kg/Batch)

|

5

|

30

|

60

|

120

|

200

|

300

|

500

|

|

Material yield Rate(%)

|

≥99%

|

||||||

|

Qualified Rate (%)

|

≥85%

|

||||||

|

Container Volume(L)

|

22

|

100

|

220

|

420

|

670

|

1000

|

1500

|

|

Diameter(mm)

|

500

|

700

|

1000

|

1200

|

1400

|

1600

|

1800

|

|

Power of Fan(Kw)

|

3

|

7.5

|

11

|

18.5

|

22

|

30

|

45

|

|

Liquid Feed Power(Kw)

|

0.37

|

||||||

|

Pressure of Steam(MPa)

|

0.4-0.6

|

||||||

|

Consumption Steam(Kg/h)

|

18

|

60

|

120

|

140

|

180

|

310

|

400

|

|

Compress Air Pressure( MPa)

|

0.4-0.6

|

||||||

|

Consumption of Air(m3/min)

|

0.3

|

0.9

|

0.9

|

0.9

|

1.1

|

1.1

|

1.5

|

|

Working Temperature C

|

Room temperature~120C adjustable

|

||||||

|

Noisy(dB)

|

Installed separated with fan

|

||||||

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586