Anti-drip oil filling machine

Continuous capping,efficient&fast

Quantitative filling&accurate metering

Want A Free Consultation

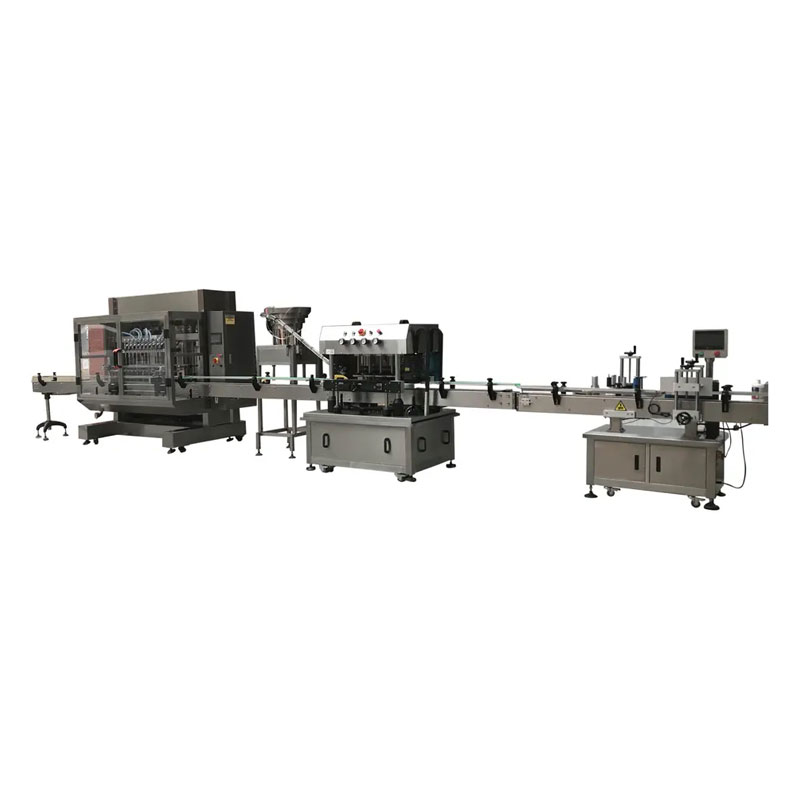

Vegetable Sesame Corn Olive Edible Oil Filling Machine Automatic liquid filling line

AIPAK edible oil filling machine is suitable for filling viscous,inviscid and corrosive liquid.It’s widely applied in plant oil,chemical liquid,and daily chemical industry.It adopts linear type filling,electromechanical&instrucmental intergration controlling.It’s simple and rapid for changing the varieties with unique design and superior capability.It’s appearance accords with the international machinery concept.

Germay SIEMENS PLC and touch screen control make it intelligent protection function.Vacuum anti-dropping device ensures no leaking situation in production.Electric adjusting for volume system,frequency control and photoelectric detecting system(Germany TURCK brand) are applied in this machine.

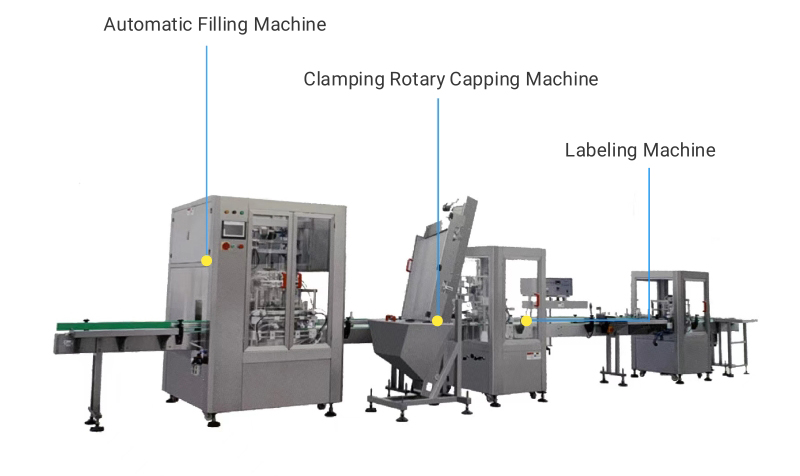

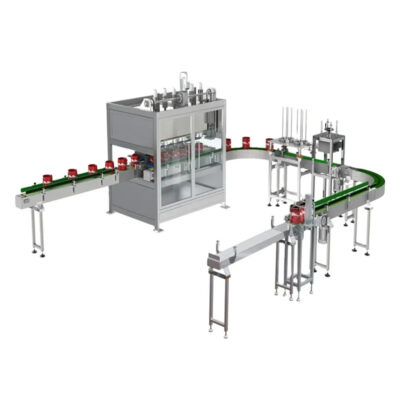

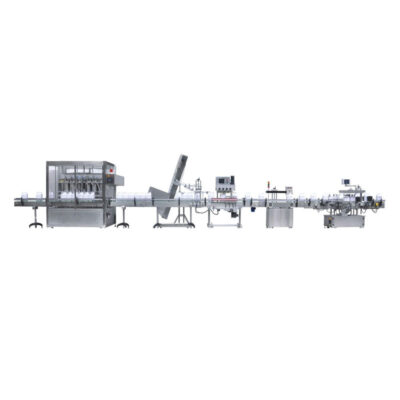

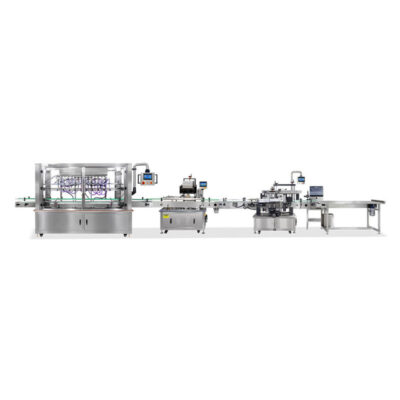

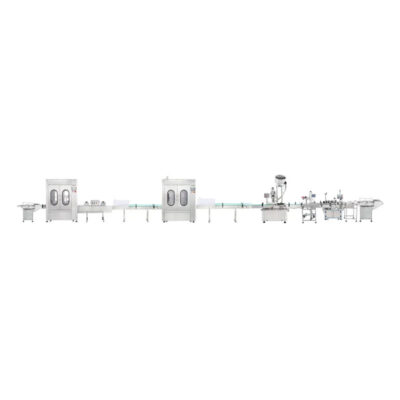

This is a whole Automatic essential oil filling capping machine production line solution. The machine type, number of machines, speed, capacity, size, Etc. The production line would be customized according to the your actual production needs; We can develop a professional integrated filling and packaging production line plan For you.

AIPAK Edible Oil Filling Machine Details:

AIPAK Edible Oil Filling Machine Products:

FEATURE

- Large filling range and high precision

- Compact structure and small body size.

- The actual measurement correction method is used to adjust the filling time, digital display control.

- Easy operation, easy cleaning and maintenance, and low maintenance cost.

- Unique positioning control system can prevent photoelectric miscounting.

- The ball screw dives and moves up and down stably.

- Bottle mouth positioning device to ensure no deviation of the filling head. 8. Automatic fluid replenishment and fluid return without manual intervention.

DATA SHEET

|

Project Name:Automatic Piston / Flowmeter Filling Machine

|

Oil and Fat Products

|

|||

|

Bottle Material

|

Bottle Shape

|

Filling Range

|

Filling Heads

|

Production Capacity

|

|

PET / PP / PE / Glass / Metal

|

Round / Square

/ Unique Shape |

200ml-6000ml

|

4-16

|

700-4000bph

|

|

Filling Valve

|

Each filling valve is controled by servo motor ,realizing segmented high-and low-speed control ; vacuum resorption devices without leakage.

|

|||

|

Cap closing

method |

applicability for both crowning and capping, mechanical instant sealing or servocontrolled sealing

|

|||

|

Bottle components

|

rapid replacement without tools, such as star wheels for bottle infeed and outfeed, and bottleneck clamps

|

|||

|

Filling precision

|

limit deviation: ±2-3g standard deviation: 1.5

|

|||

|

User Ambient Conditions

|

Temperature:10~40℃;Humidity:No dew

|

|||

|

User Electrical Supply Specification

|

Voltage:380V±5%, 3phase; Frequency:50HZ±1%

|

|||

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586