Discharging finished product in right order

Automatic collection of bad products

Auto rewinding of strap material to ensure easy collection

Want A Free Consultation

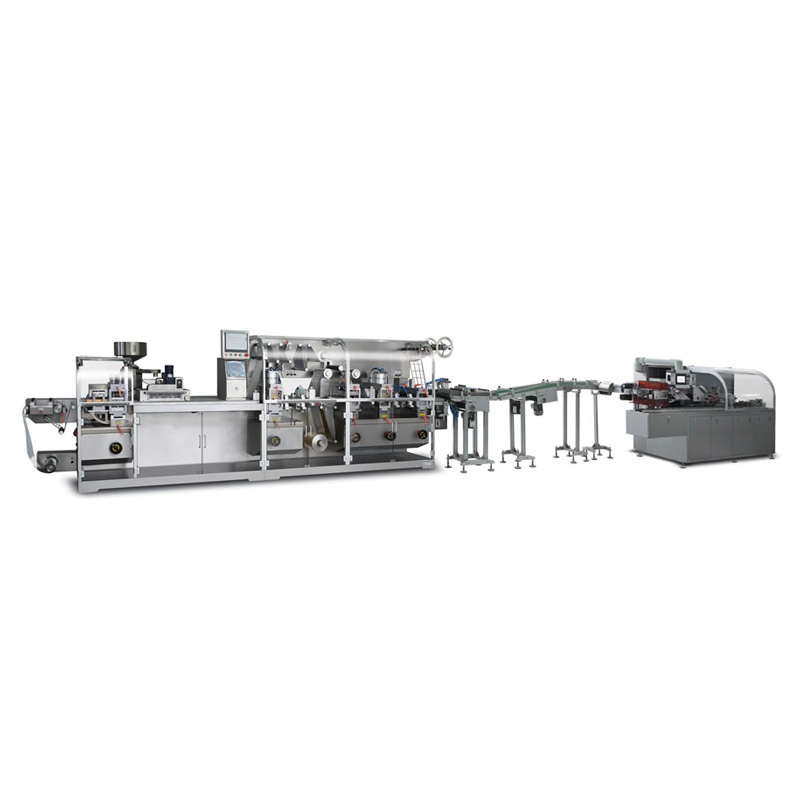

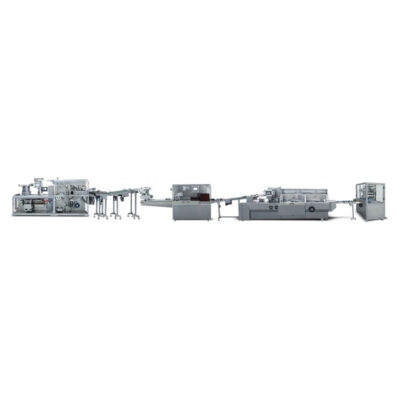

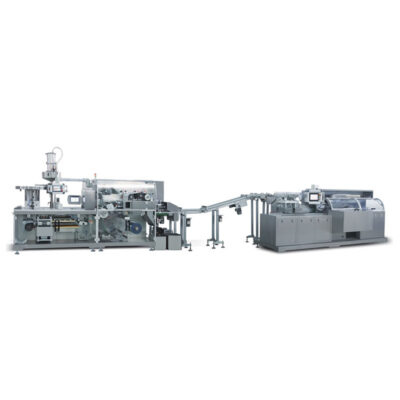

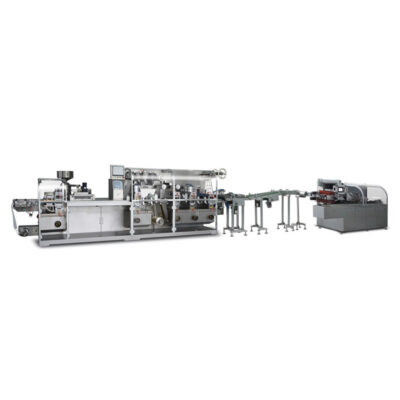

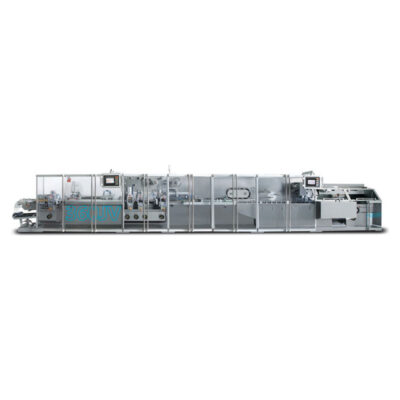

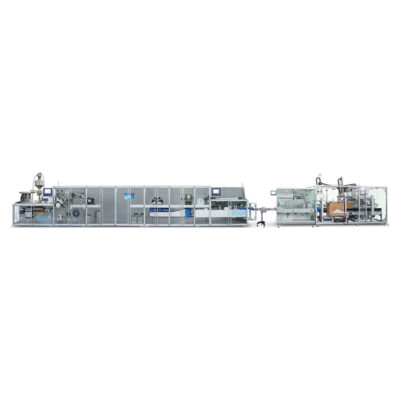

DPB270/350JL-ZHJ150 Cantilever style flat-plate blister packing machine and automatic cartoning machine production line

AIPAK DPB270/350-ZHJ150 cantilever style flat-plate blister packaging automatic cartoning machine production line can be used for packing and packing of all kinds of capsules, tablets and other drugs (aluminum-plastic/aluminum-aluminum) with bubble caps. It can be connected with baling machine, inspection machine, packing machine and other subsequent equipment to form a complete and efficient drug packing production line.The design structure of the production line meets the requirements of GMP and GMP standards and the principles of ergonomics. It adopts advanced servo intelligent drive and PCL man-machine interface control.feeding camera detection, lack of material detection, etc., to ensure the qualified rate of finished products.It can be separated into the elevator and the purification workshop after decoration.

FEATURE

1..The production line uses a separate control system for equipment operation, maintenance, maintenance is very convenient;

2.Adopts imported servo motor traction device that improves the running stability performance, and automatically forming, feeding, checking, sealing, batch number (indentation) and punching, testing and rejecting qualified products through the input system into boxing servo feeding system, automatic cartoning machine detection kits, brochures, version after the drug into the box before they were to meet to ensure that products passing rate of 100%;

3.Hardware, software, user-friendly design, the whole production line automation adjustment, saving the waste of resources, improve production efficiency;

4.The device transitional soft connection, the production floor space flexible layout, efficient use of space.

5.Equipment split packaging, transportation, use of the site is more conducive to handling and installation.

DATA SHEET

Main Technical Parameter (Alu pvc blister packing machine)

| Model | DPB-270JL | DPH-350JL | |

| Punch Frequency | 10-35times/min | 10-35times/min | |

| Max. Forming area | 120×260mm | 120×350mm | |

| Max. Forming depth | 13mm | 13mm | |

| Traction stroke | Punch:20-120mm | ||

| Blister specification | Standard:80×57、95×65、103×43(Customized allowed) | ||

| Packing material | Standard PVC hard sheet | 0.15-0.5 × 270mm | 0.15-0.5 × 350mm |

| Standard PTP Aluminum foil | 0.02-0.035×270 mm | 0.02-0.035×350 mm | |

| Tropical Aluminum foil | 0.09-0.15×270 mm | 0.09-0.15×270 mm | |

| Average hole diameter of roll | 70-76mm | 70-76mm | |

| Air consumption | ≥12 m3/h (Self-contained) pressure:0.6-0.8Mpa | ||

| Mould ooling | tap water or recycle water 60L/h | ||

| Total power | 12KW | 12KW | |

| Main motor | 2.2KW | 2.2KW | |

| Overall dimension (L×W×H) | 5360×850×1750mm | 5360×950×1750mm | |

| Weight | 4000Kg | 4500Kg | |

Main Technical Parameter (Automatic cartoning machine)

| Cartoning speed | ≤130(ctns/min) |

| Carton size | Max.190×90×60mm(L×W×H) Min.55×20×15mm(L×W×H) |

| Leaflet size | Max.260×180mm(L×W) Min.115×100mm(L×W) |

| Power | 380VAC, 50HZ, 3KW |

| Main motor | 1.5Kw |

| Air pressure | 0.6-0.8Mpa |

| Air consumption | ≥10m3/h |

| Overall dimension | 3300×1200×1900mm |

| Weight | 1300kg |

VIDEO

CONTACT

Get in touch with an expert

We´re looking forward to find the suitable solution for your product. Please contact:

We´re looking forward to find the suitable solution for your product. Please contact:

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951