Perfect Choice For Stable Homogeneous Emulsions,Suspensions

Freely Assembled,Modularized Dispersing Head,Easy To Maintain

Concentrated Particle Size Distribution With Only One Treatment

Want A Free Consultation

APKZRJ Bottom Homogenizer Vacuum Emulsifying Mixer

Production Description

AIPAK Vacuum Emulsifying Mixer is suitable for emulsification of the pharmaceutical. Cosmetic, fine chemical products, especially the material having high matrix viscosity and solid content. Such as cosmetic, cream, ointment, detergent, salad, sauce,lotion, shampoo, toothpaste and so on.

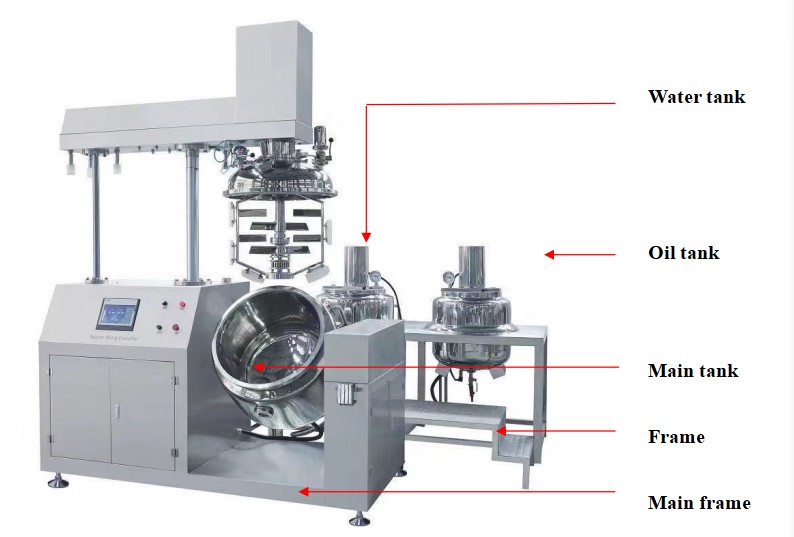

Structure

- Usually the oil pot is used for dissolving some solid that the product can just only be dissolved into oil, then the dissolved solvent will be sucked into the emulsify pot by soft pipes.

- The function of water pot is the same to the oil pot.

- The emulsify pot is used for emulsifying the products that suck from the oil pot and water pot.

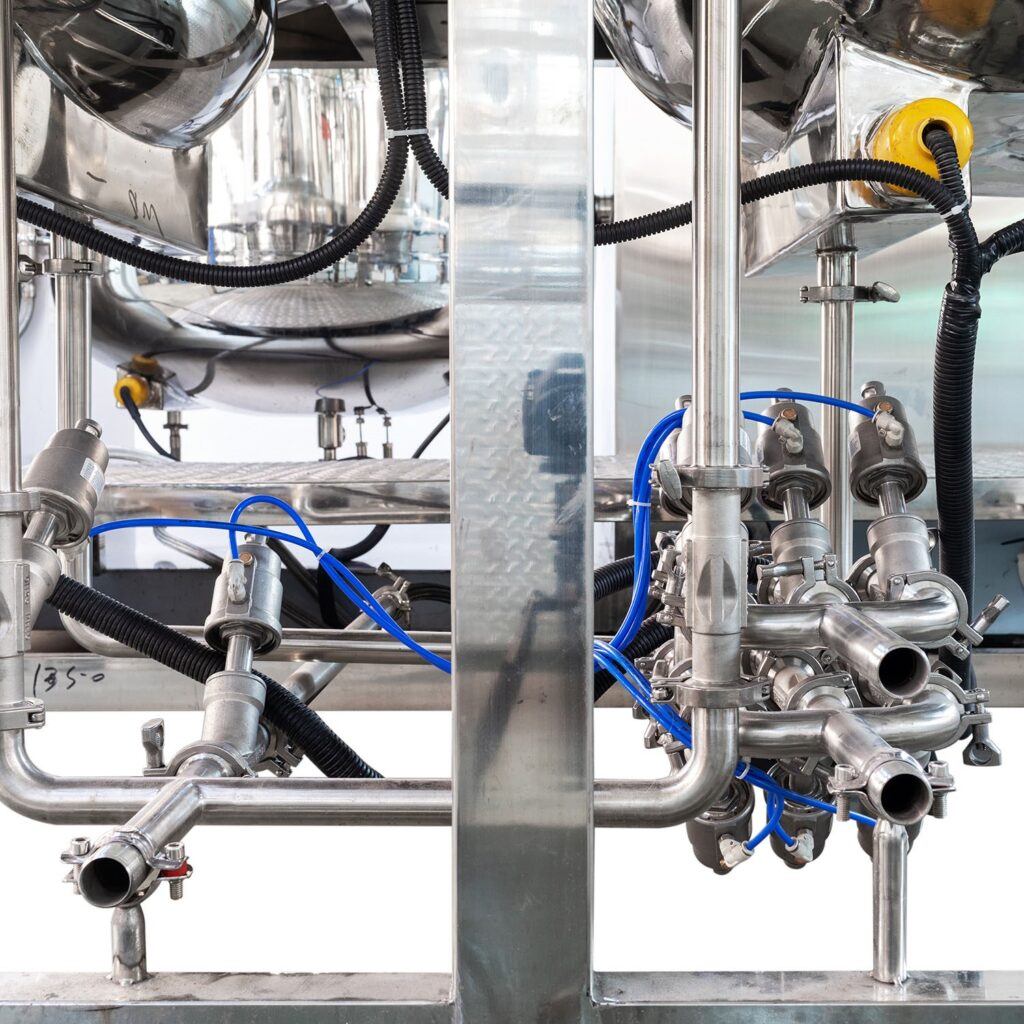

Main frame: including emulsify pot, lifting system, discharge system, vacuum system, electric control system, rotate system, mixing system.

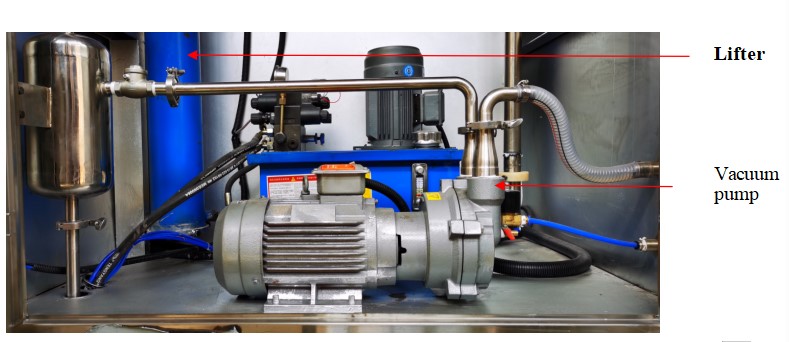

Vacuum pump is connected by two soft pipes, one is connected the water tank by soft pipe which is used for sealing when the pump is operating; the other connected to main emulsify pot through pipes and gas—liquid separator, so that the pump can make the main emulsify pot under vacuum condition. The gas—liquid separator is separating the gas and water, because the steam is sucked into vacuum pump when it is working, the steam through gas—water separator, some of steam become into water which flow out at the bottom of the separator.

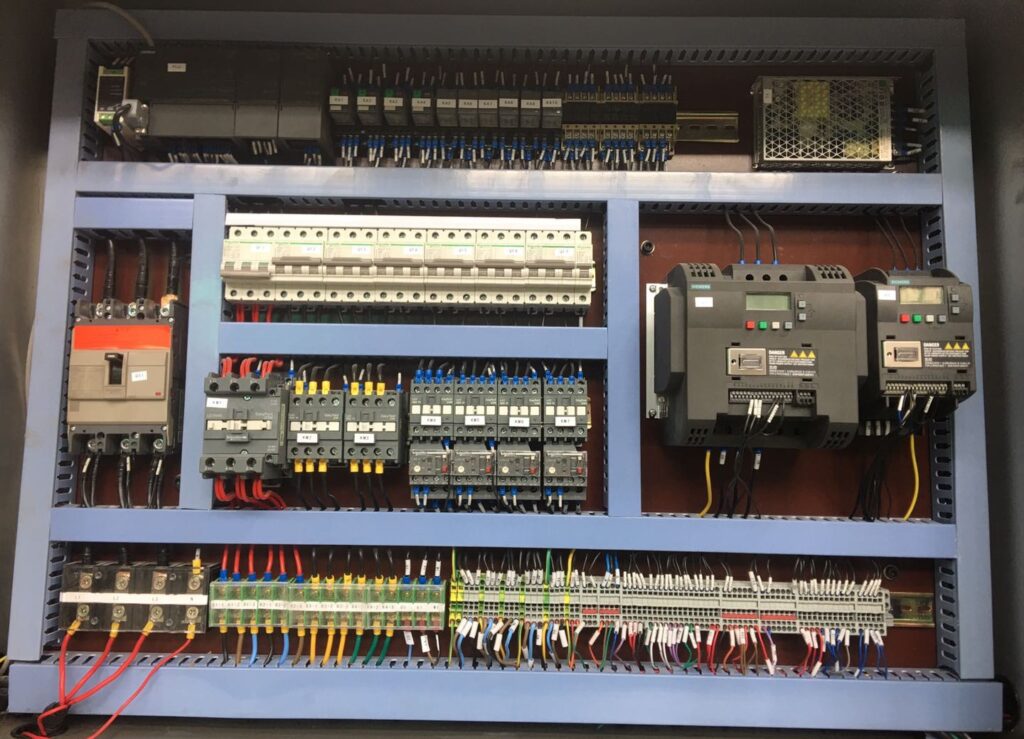

Electric control system

The vertical motor is high speed motor which can rotate between 0—3500 rmp/min

You can demolition the motor by open the screws and one wire.

Mixer: it include low speed mixer and high speedy mixer (homogenizer)

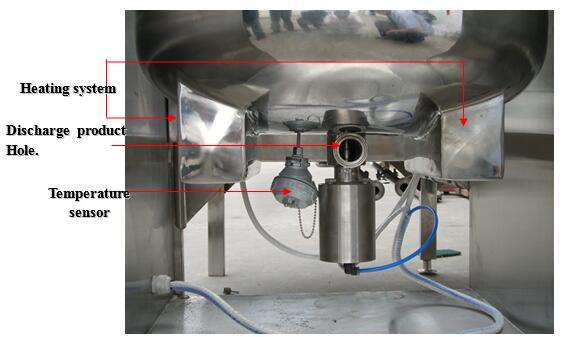

- Emulsifying pot:including cover, pot, bottom valve, temperature sensor, heating system.

This machine is heated by electricity, you just fill water into jacket, then turn on the heating system, the water is heated by electricity according to your requirement.

2. This machine also can be heated by steam, you just connect to steam producer when you heat the machine by steam.

Discharge hole: it is used for discharging the product just open the valve by pressed air.

Temperature sensor: it is used for check the temperature the product inside pot

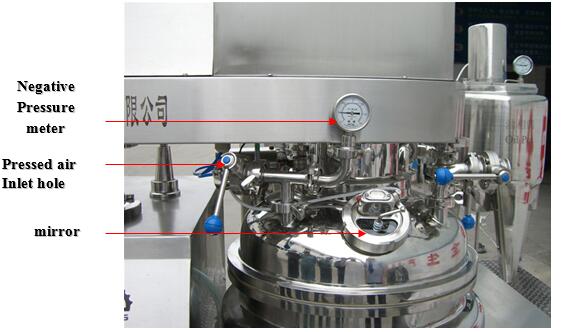

Accessories on the cover: including vacuum protection system, pressed air inlet hole, negative and plus pressure meter, mirror, CIP that for washing, break vacuum hole, material inlet hole, prepare hole for inlet perfume, automatic control vacuum valve and so on.

Negative pressure meter is used for check the pressure inside pot.

Pressed air inlet hole: it is connected with Air Compressor by blue soft pipe. it can press the product by air when the product is finished so that the product will be discharged under the plus pressure.

Mirror: you can see inside pot by turning on the light

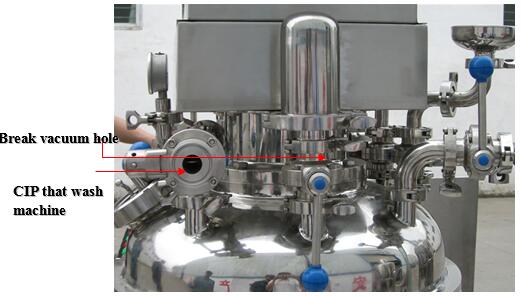

Break vacuum hole: it can break the vacuum inside pot by turning the valve, there is air filter inside valve. The product can not be discharged under vacuum condition, it just can be discharged without vacuum.

CIP: it is used for cleaning the inside pot by connecting tap water

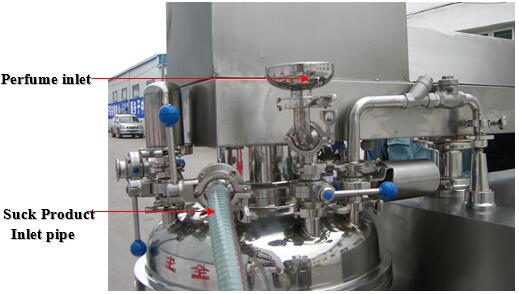

Perfume inlet: it is prepare hole for put perfume into the pot.

Suck product inlet pipe: it is used for sucking product from the oil pot and water pot.

You also can suck the product from oil pot and water pot to emulsify pot by vacuum through the stainless steel pipe.

Safety system:

Water inlet system and cooling system

Finished Products

FEATURE

- Control by computer touch-screen, integrated operation, with beautiful generous;

- Work continuously large quantity, circulating homogeneous discharging, especially suitable for single products continuous production.

- Easy operation, perfect homogeneous emulsification

- Capacity : 100-2000LHelical ribbon mixing, internal-external circulating homogenization.

DATA SHEET

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586