Oral Film: The Complete FAQ Guide In 2025

Tired of popping tablets and capsules!

Now scientists have introduced a novel drug delivery-oral film. This method of drug delivery is gaining tremendous popularity over recent years due to its ease of use. The convenience of oral film swallowability makes it a favorite among children and elderly people. Moreover, consuming oral films does not irritate the stomach which is the norm for oral medication.

If you are interested in learning about oral films then read through this guide “Oral Film: The Complete FAQ Guide In 2023” to discover exciting facts about oral films.

Let’s begin!

1.What Is Meant by Oral Film?

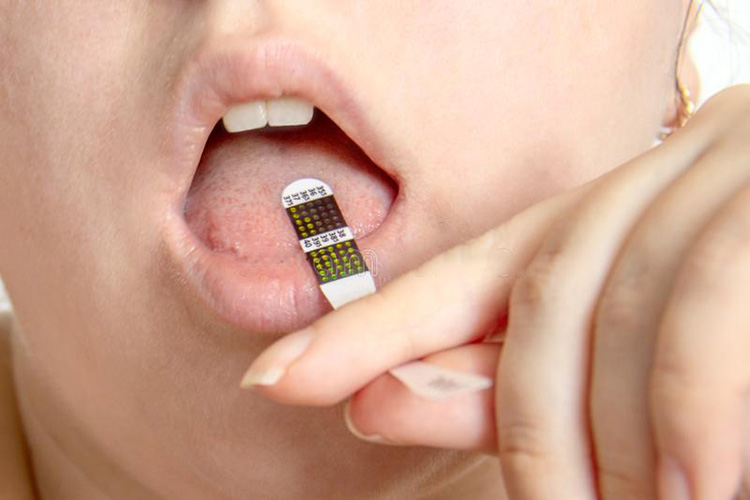

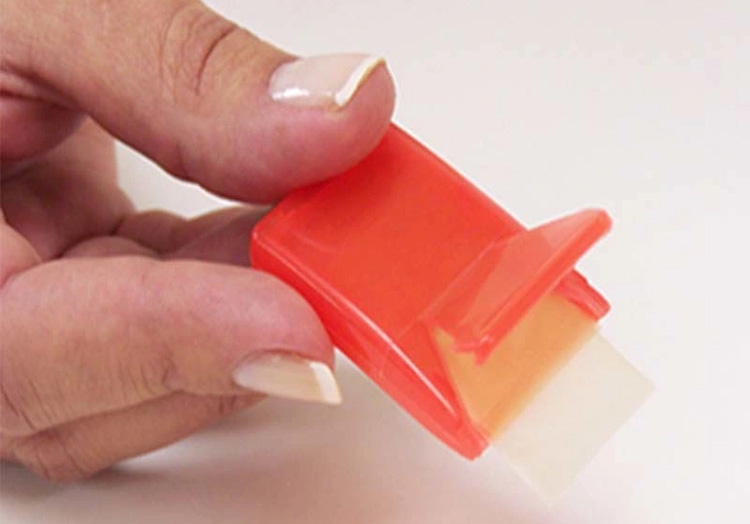

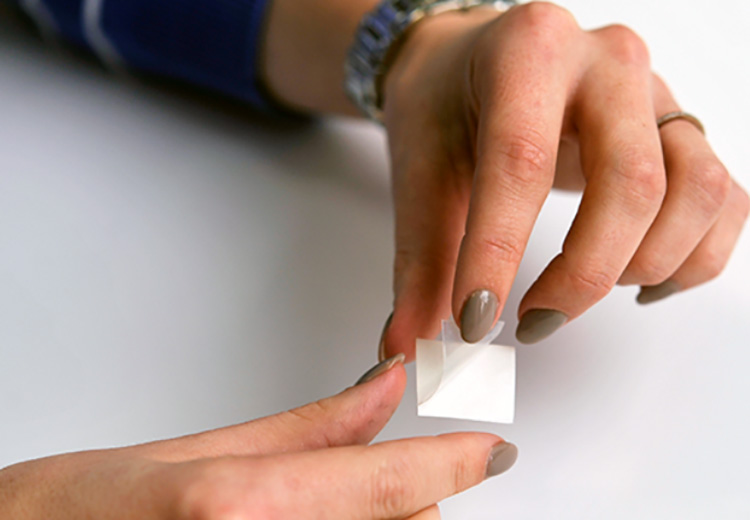

Oral films are one of the most convenient and advanced forms of drug delivery. These are also called oral wafers, oral film strips, and oral dissolving films. These are thin, non-brittle, and flat film strips mostly used for oral drug delivery systems. They are postal stamp size.

These films are alternatives to conventional oral drug delivery methods such as capsules and tablets. There is no need for chewing or drinking water on administrating them in the buccal cavity.

2.What is the History of Oral Films?

These drug delivery systems were first mentioned in the literature in 1960. These therapeutic systems were invented by Richard and Joseph Fuisz, Garry Myers, and Robert Yang. Originally, these oral wafers were used as an oral confection.

Pfizer was the first company to develop a commercial oral film called Listerine in 2001. This oral film was used as a mouth-freshening agent. Then from 2001 to 2005 different over-the-counter drugs (Benzocaine, Chloraseptic) were manufactured in oral film form.

In 2010, the first FDA-approved drug Zuphlenz®, Ondansetron was developed as an oral film. Now several drugs are available as oral films.

3.What are the Benefits of Using Oral Films?

With each passing day, more and more drugs are manufactured in oral film form due to their many benefits on other forms of drug delivery such as:

Patient Compliance

Oral films have increased patient acceptance and adherence due to their convenient consumption and ease of swallowing. These have minimal thickness and break down into smaller fragments on consumption.

No Anaphylaxis

These oral films are perfect and suitable forms of drug delivery for children, the elderly, and emetic patients. These are good for patients with dysphagia problems who face difficulty in swallowing.

Fast Dissolution

Since the oral film has a much large surface area than other oral drugs, therefore, it is rapidly wetted with the action of salivary fluids leading to their fast disintegration in the buccal cavity and dissolution.

Dose Flexibility

These oral films are regarded as precision medicine since they have the capability of dose flexibility. It is easier to change the dose of medication when it is incorporated in oral film form. This is especially important for pediatric applications as children require smaller doses of drugs than adults.

High Bioavailability

Drugs incorporated in oral films are directly absorbed in blood streams and can avoid first-pass metabolism which is a necessary evil with other oral drugs. Therefore, oral films have high bioavailability.

Rapid Onset of Action

As drugs in oral films are instantly moved into blood circulation hence they have immediate onset of action providing relief in a short duration.

Fast and Easy Production

The manufacturing of aqueous-based film is easy and does not need solvents. Oral film production consists of just two mixing steps followed by the casting step while lengthy and complicated steps are part of tablet and capsule production.

4.What Ingredients Are Used for Manufacturing Oral Films?

Some ingredients used for preparing ora;l films are detailed below:

Active Pharmaceutical Ingredients

A standard oral film has 5-30% w/w of APIs. Usually, water-soluble drugs are used in oral films. A nutraceutical oral film has about 10% w/w of multi-vitamin ingredients.

Film Forming Agents

These are the main excipients used in oral film formulation. Film-forming polymers are natural gelling agents such as pullulan, starch, pectin, or cellulose or are semisynthetic such as hydroxypropylmethylcellulose (HPMC), hydroxypropyl cellulose (HPC). These film polymers can be manufactured in industries like carbopol, polyvinyl alcohol, etc.

These are water-soluble and responsible for the physical integrity of oral films. They are not only chosen for their physical properties but can also play an essential role in film breakdown.

Plasticizer

These are the second most important excipients used in oral film formulation. Different kinds of plasticizers for instance castor oil, triacetin, triethyl citrate (TEC), acetyl triethyl citrate (ATEC), etc. can be incorporated in formulation. They provide flexibility to oral film, decrease the brittleness of added polymers, and improve the thermal stability of oral films.

Sweeteners

These are vital components of oral films and their concentration is 3%-6% w/w in oral films. Both natural and artificial sweeteners like xylose, sucrose, aspartame, cyclamate, etc. are incorporated to enhance the taste of oral films.

Flavoring Agent

These agents are commonly included in oral film formulations to mask the bitter taste and unpleasant odor of drug compounds. These also increase the savory taste of films. Flavoring agents can be both natural and artificial such as chocolate, vanilla, peppermint, etc.

Saliva Stimulating Agents

These substances are used in oral film formulation to increase the production of saliva consequently aiding in quick breakdown. Different acids such as citric acid, lactic acid, ascorbic acid, etc. are used as saliva-stimulating agents.

The amount of these materials is about 2%-6% w/w.

Coloring Agents

For boosting the physical appeal of oral films different coloring dyes and pigments are added during film manufacture. These include titanium dioxide natural and custom Pantone or food and drug-approved dyes. Usually, a small concentration (1%w/w) of coloring agents is used.

Thickening Agents

Naturally occurring gums such as xanthan gum, and carrageenan, are incorporated for boosting the viscosity of oral film formulation.

Disintegrant and Surfactant

These excipients are added to increase the dissolution profile and solubility of oral films. These are wetting agents which often aid in the rapid release of drugs from oral films.

5.What Are the Methods of Preparing Oral Films?

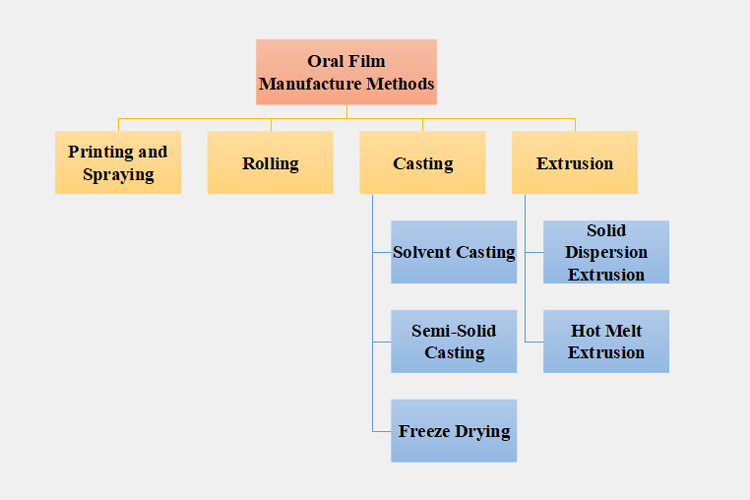

There are various methods of preparing oral films for instance,

Printing and Spraying

It is one of the most modern methods for preparing oral films. It involves 3-dimensional printing (3DP) or inkjet printing, or flexographic method for printing film. In the 3DP method layer by layer polymer film is printed using a liquid crystal display printer. It is mostly used for printing drugs that are denatured by heat.

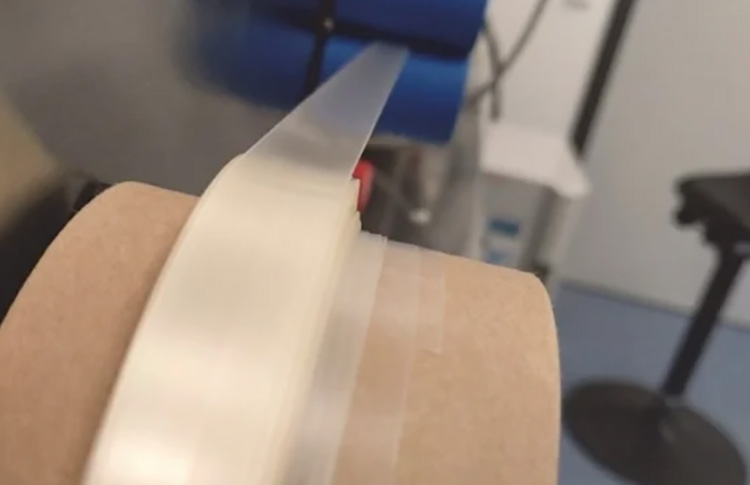

Rolling Method

In this method, a mixture of water or alcohol, or both is prepared for dissolving drugs. Then, this solution or suspension is rolled on carrier devices or rotating rollers for producing oral films. Then the rolled-up film is dried and cut into small strips.

Casting Methods

There are three casting methods of oral film preparation such as:

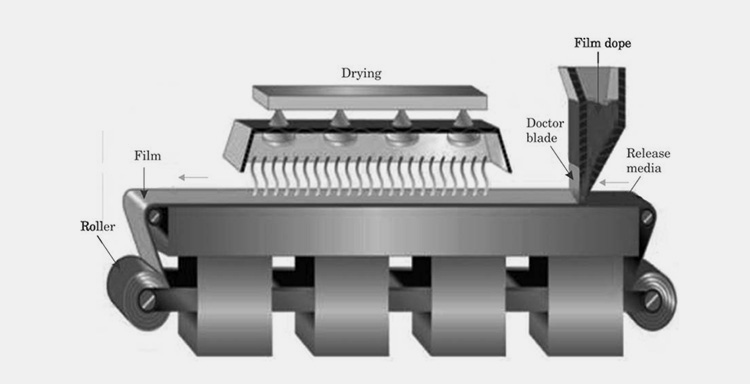

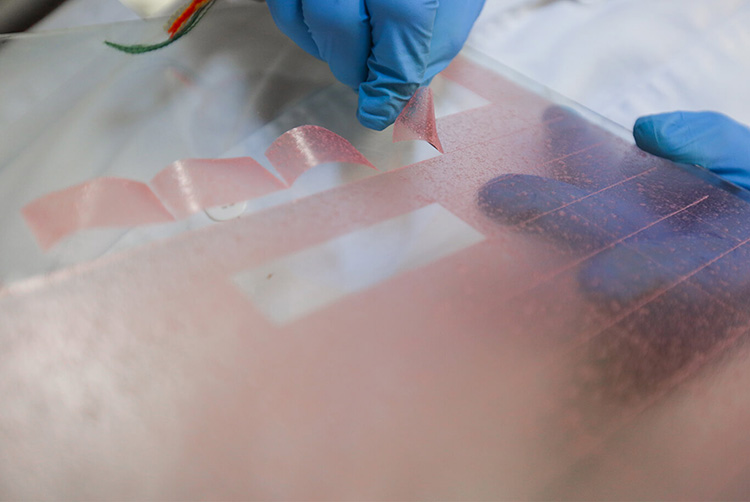

Solvent Casting

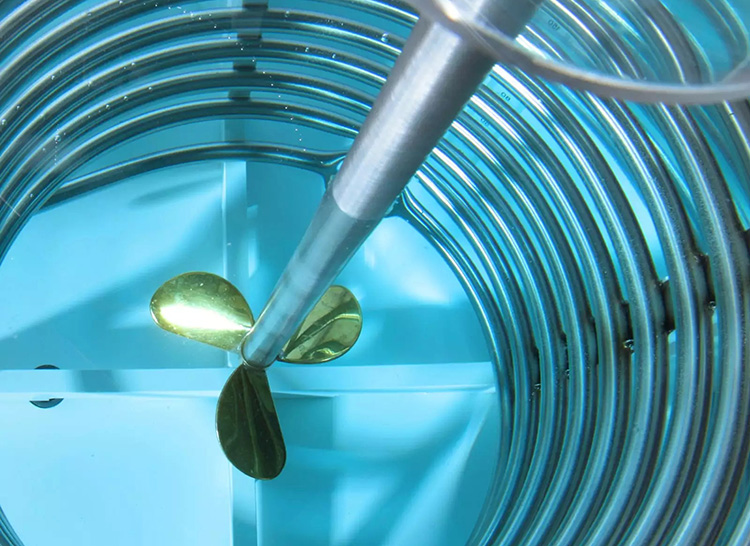

It is a traditional method for manufacturing oral films. In this method, the APIs are first dissolved in a solution containing film polymers, plasticizers, etc. This solution also called film dope is spread by the continuous movement of release media.

Drying devices such as convection chambers are used for evaporating solvents when the film dope is passed through them.

Semi-Solid Casting

For semi-solid casting, the solutions of film polymer and acid-insoluble polymer are prepared in water separately. Then these solutions are mixed. Finally, a plasticizer is added to this mixture to obtain a gel-like consistency. Afterward, this gel-like material is transformed into films or ribbons with the aid of heat-controlled drums.

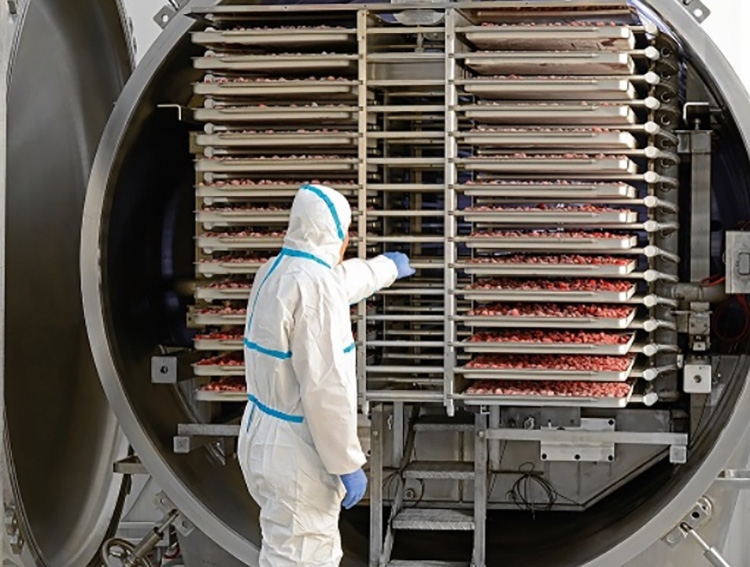

Freeze Drying

This method is also called the lyophilization method and is a novel method for manufacturing oval films. For freezing the solution, a weighing boat containing a solution of ingredients is placed in the freezer at 20°C for 2 hours. Then the frozen solution is placed on the freezer dryer to vaporize solvent under vacuum for 6 hours. Ultimately, the film is extracted from a boat and placed under a desiccator for storage.

Extrusion

There are two extrusion methods for oral films.

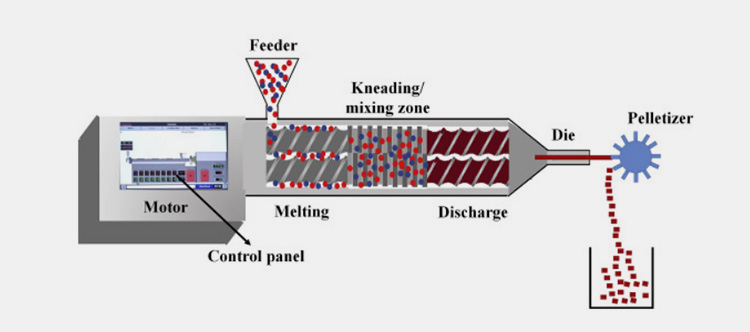

Hot Melt Extrusion

In this extrusion method, film ingredients and solid carriers are heated at high temperatures inside the extruder to melt them. The molten mass is introduced in molds or calendars for pressing it into films. After cooling films are cut and packed.

Solid Dispersion Extrusion

One or more APIs are dispersed into an inert solid hydrophilic carrier. This dispersion is extruded by the hot melt method. After extrusion, this solid dispersion is transformed into films via dies.

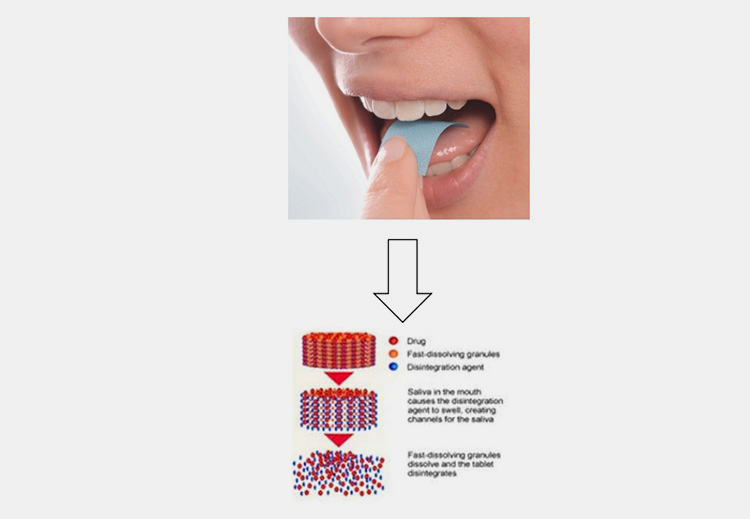

6.How Does the Oral Film Delivery Function as a Drug?

Oral films are a combination of polymers, plasticizers, and drugs. Generally, oral films are employed as a form of medication because of their rapidly disintegrating properties. These thin films can contain approximately 600mg of a single drug dose.

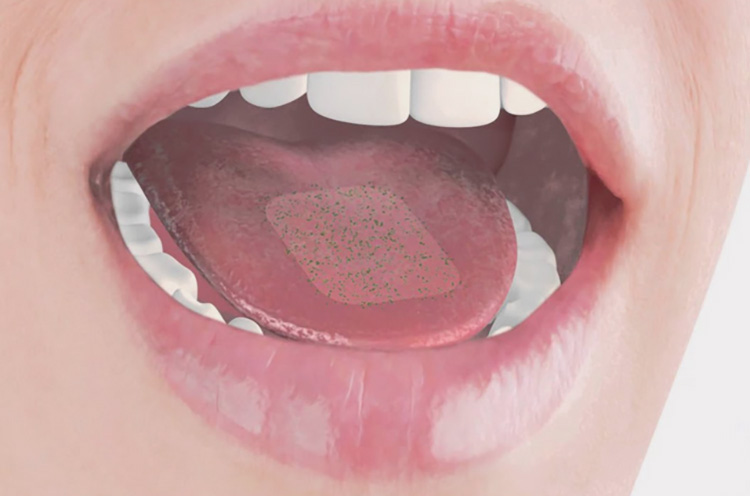

The natural watery fluid (saliva) in the patient's mouth reacts with polymers and these polymers in oral films upon encountering wet conditions in the buccal cavity, the films break down into smaller pieces. These pieces adhere to the buccal cavity and release their drugs into the bloodstream.

Sometimes, these fragments of oral films are swallowed by patients and move to the digestive system where drugs are absorbed in the stomach and intestine.

7.How Are Oral Films Classified?

Oral films are classified into different types which are given below:

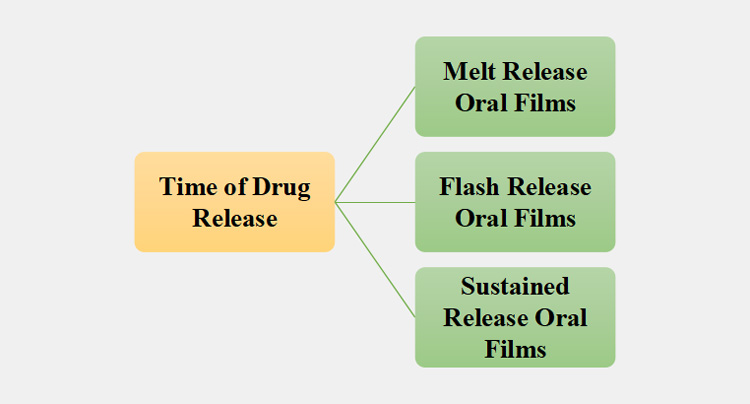

Classification Based on Onset of Drug Release

Melt Release Oral Films

It is a single or multilayer oral film in which the drug phase is either a solid solution or suspension having drug particles. It is composed of water-soluble polymer excipients. These films are placed in gingival or buccal regions. It takes a few minutes to dissolve and usually forms a gel-like mass upon disintegrating.

Flash Release Oral Films

These are also called quick-release oral films and are made from highly soluble hydrophilic excipients. The drug phase in these films is usually a solid solution. They are single-layer systems and quickly dissolve upon contacting salivary fluids on the tongue.

Sustained Release Oral Films

They are composed of poorly-soluble excipients that take longer to dissolve. Due to their composition, these films gradually discharge drugs and provide a sustained action over an extensive period. They are placed in a gingival area of the oral cavity.

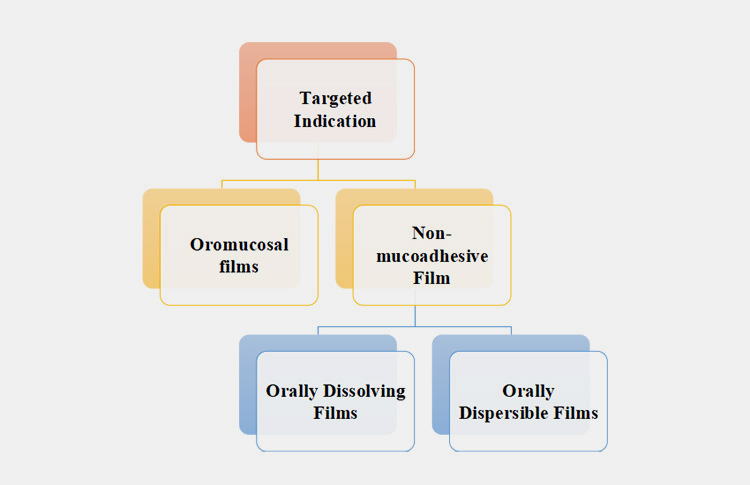

Classification Based on Targeted Indication

Oral films are classified into two major types based on the targeted indication.

Oromucosal films

These are mucoadhesive films and are designed for sticking to the inner oral cavity. These release drugs progressively across the mucous tissues which directly go to the systemic circulation. These are fast acting because they tend to evade hepatic metabolism.

Non-mucoadhesive Film

These do not adhere to the buccal cavity and are designed for swallowing purposes. These are categorized into two types:

Orally Dissolving Films

These films are non-adhesive and are made of water-soluble drugs and excipients therefore, they quickly break down and dissolve in the salivary solution. Hence are partially absorbed into systemic blood circulation.

Orally Dispersible Films

They are usually composed of water-insoluble drugs and these films collapse into smaller fragments which are swallowed. These film pieces travel to the stomach for complete dissolution and absorbance.

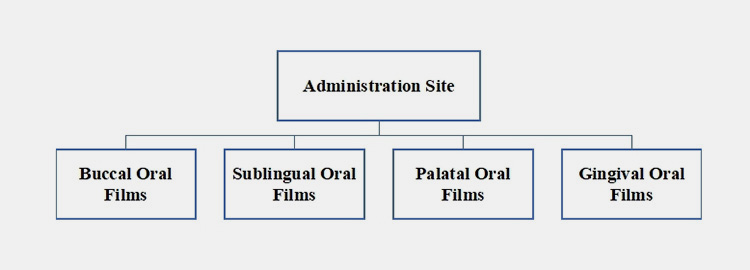

Classification Based on Administration Site

There are four classes of oral films based on the administration site.

Buccal Oral Film

These oral films are placed inside the buccal cavity and release their drug ins the mouth.

Sublingual Oral Film

They are placed under the tongue and their drug is immediately absorbed by blood vessels present under the tongue.

Palatal Oral Film

This type of oral film is administrated on the palate from where the drug goes to blood circulation.

Gingival Oral Film

This is placed at the gums and releases drugs to systemic circulation right away or can have sustained release.

8.What is the Mechanism of Action of Oral Films?

Oral films are thin, elastic strips made of APIs (hydrophilic) and excipients (polymers, plasticizers). Generally, oral films are administrated in the buccal cavity.

- When these films are placed in the buccal cavity, they immediately get wet by the action of saliva and disintegrate into smaller pieces because of the presence of water-soluble polymers. These pieces are swallowed or they dissolve and release their drug in either local or systemic circulation.

- Blood vessels present in the buccal cavity pick up the drug and deliver it to the site of action. The higher bioavailability of drugs in oral films is due to the skipping of liver metabolism.

- However, the swallowed pieces of oral films move to the gastrointestinal tract and release their drug either in the stomach or small intestine. These drugs are transported to the liver for metabolism.

- Sometimes, oral films stick to mucosal tissues in the mouth and slowly disintegrate and release their drug in blood circulation to provide a therapeutic effect for a longer duration.

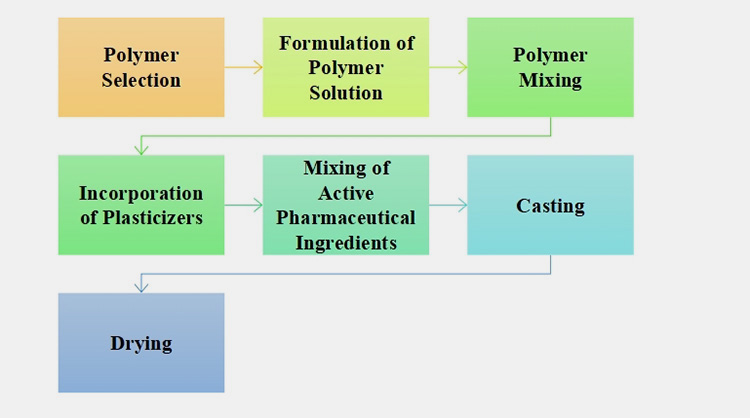

9.How To Manufacture Oral Films?

Manufacturing of oral films is a precise process in which each step is carried out with due diligence to acquire the best quality oral films. Here are some steps involved in making oral films.

Polymer Selection

In the first step, a single or combination of two, or more than two polymers are selected for the film formation. These polymers should have appropriate characteristics to form films of desired properties.

Formulation of Polymer Solution

Afterward, separate solutions of each polymer are prepared by dissolving polymers in suitable solvents such as water, alcohol, etc.

Polymer Mixing

In this step, the solutions of different polymers are mixed in the right proportion as required by formulation. Then solutions are gently stirred to obtain a homogenized mixture.

Incorporation of Plasticizers

For increasing the strength and flexibility of the oral film, the plasticizer is added to polymer solutions. The amount of plasticizer should be around 0-20% w/w of polymer dry weight.

Mixing of Active Pharmaceutical Ingredients

In the next step, APIs are mixed in a polymer-plasticizer mixture. 5-30% of APIs are added to get the required therapeutic action.

Casting

After uniform mixing of APIs and other excipients, this homogenized solution is cast in film or ribbon form. Different devices such as heat-controlled drums, rollers, and release media are used for film casting.

Drying

In the final step, the resultant film is dried in an oven drier or vacuum drier to remove excess solvents. The selection of an appropriate drying approach is depended upon the ingredients used for film manufacturing. For instance, heat-sensitive ingredients are not dried using oven drying.

10.What Are the Applications of Oral Films?

Oral films are the latest drug delivery systems and have found their applications in different fields such as:

Pharmaceutical Industry

It is a preferential oral drug delivery method due to its ease of administration and swallowability. It can be used instead of topical creams, ointments, etc. for skin repair, wound healing, and treating burns.

Nutraceutical Industry

These films are exceptionally suitable for consuming vitamins, minerals, and other supplements instead of large pills and capsules. In the nutraceutical and herbal industries, various nutritional formulations are manufactured in oral film form. These films are used as energy boosters, appetite reducers, etc.

Personal Care Industry

These oral films are also used in the personal care industry for personal hygiene. These strips are often used as teeth-whitening agents and as a breath freshener.

Medical Industry

Oral films are often used in combination with medical devices in the medical industry. These films have chemical agents that are slowly released upon exposure to certain biological fluids.

Food Industry

These films are used in food packaging materials for providing antimicrobial or antibacterial properties to packaging.

11.What Medications Are Used as Oral Films?

Several prescription drugs are available as oral films such as:

- Cough suppressant in oral film strips for suppressing cough and decreasing irritation associated with a sore throat, sore mouth, and minor bronchial infection.

- Nicotine oral films for smoke cessation.

- Thin strips for treating allergic reactions

- Pain-relieving oral films containing fentanyl or Buprenorphine.

- They are used for psychological disorders such as anxiety, epileptic episodes

- Oral strips for treating erectile dysfunction

- Thin strips for the treatment of Alzheimer, Parkinson, and stroke.

- Oral strips for providing relief in stomach ulcers.

- They are available as an antidiarrheal vaccine

12.What Is the Thickness of Oral Films?

Thickness plays an important role in the disintegration and dissolution of oral films. Different kinds of oral films have different thicknesses. However, generally, oral films are 50 to 1000 µm.

- Sustained-release oral films have 50 to 250 µm.

- Flash-release oral films are on the thinner side and are usually 7 to 20 µm thick.

- The thickness of melt-away oral films is about 50 to 500 µm.

13.What Is the Dissolution Time of Oral Films?

The dissolution time of oral films is depended upon their thickness, surface area, solubility, and composition. The disintegration of the oral film is usually around a few seconds to hours.

- Flash-release oral films take a minimum of 60 seconds to disintegrate.

- Melt-away oral films instantly break in just a few seconds and form gel.

- Sustained-release oral films have the longest disintegration time and take about 8 to 10 hours for a full dissolution.

14.What Factors Should Be Considered While Designing Oral Films?

For manufacturing mechanically tough yet pharmaceutically efficacious oral films, the following factors should be given due consideration:

Selection of Active Ingredients

It is important to know that not every drug ingredient is the same. Oral films are generally stamp-sized in which polymers occupy a major proportion. So, it is impossible to use large molecule weight active ingredients as well as large doses for formulating oral films.

Different characteristics of drugs like their solubility, stability, flavor, and heat liability should be taken into account before selection. These ingredients must be water-soluble and stable in salivary fluids. Furthermore, these drug substances should have dose uniformity to avoid over or under-dosing of prescription drugs.

Choice of Film Polymers

Film polymers should be selected carefully as mechanical integrity and safety of oral film are dependent upon film polymers. Before selection, literature should be carefully consulted to choose the ideal film polymer for your desired oral film.

An appropriate polymer is hydrophilic, innocuous, and free of impurities. Besides this, it instantly breakdown when exposed to saliva and has an agreeable mouth feel. These polymers are approved for safe use by regulatory authorities.

Usually, a combination of various polymers is incorporated in formulation to impart the required physicochemical characteristics to oral films.

Choosing Plasticizer

It is best to consider the compatibility between plasticizers and film polymers otherwise the final oral film would not have desired stability and strength. Moreover, the plasticizer should have suitable thermodynamic characteristics for imparting elasticity and gloss to the oral film.

Selecting Other Excipients

Selection of disintegrants, mucoadhesive, coloring agents, flavoring agents, etc. must be based on final film properties. Coloring and flavoring agents should be selected which enhance the aesthetic appeal and acceptance of oral films. A good disintegrant is essential in the immediate disintegration of flash-release film while mucoadhesives are good for sustained-release oral film.

15.What Is the Difference Between Oral Films and Pills?

There are huge differences between oral films and normal pills such as:

| Oral Films | Pills |

|

|

| These are available as thin flexible strips | These are in tablet or capsule form. |

| They have higher dissolution due to their large surface area. Moreover, these can dissolve in just one minute thus they take less time to disintegrate than pills. | These have a smaller dissolution rate due to their small surface area and can take hours for complete disintegration. |

| Oral films have more stability and shelf life than pills. | Pills are more fragile and can break during transport. |

| These thin strips have ease of swallowing and hence are more patient-compliant. | Large tablets and capsules are hard to swallow thus pills have low patient acceptance. |

| No risk of anaphylaxis and choking associated with oral films. | These pills have a high choking risk. |

| Only smaller doses of drugs are impregnated in oral films. | Pills are used for incorporating both smaller and larger doses of drugs. |

16.What Is the Future Scope of Oral Films?

Oral films have emerged as a revolutionary drug delivery method. Research and developments have been carried out in this field to bring innovations in oral film technology.

More Prescription Drugs

Currently, there are few prescription drugs available as oral films in the market. Oral films have high patient compliance and adherence thus research has been carried out to develop more and more prescription drugs in oral film form.

Incorporation of Water-insoluble Drugs and Large Doses

Current oral films have limitations as these do not incorporate water-insoluble drugs and large drug doses as these can destabilize systems. However, scientists are searching for ways to manufacture oral films with larger doses and hydrophobic drugs.

Oral Films as Vaccines

The oral film is a novel and alternative way of vaccine delivery needing only a small amount of vaccine due to skipping first-pass metabolism. In the future, various vaccines will be available in oral film form.

Oral Film and Nanotechnology

Different types of nanoparticles are impregnated in oral films to increase bioavailability and uniformity of drug dose. With the latest innovations in nanotechnology, it will be possible to formulate novel drug compounds, hormones, and antibiotics in oral films.

Conclusion

Oral films are revolutionary drug delivery systems and are continuously gaining acceptance across the globe for their practicality, ease of consumption, and high bioavailability. More and more pharmaceutical brands are opting for this technology due to its low manufacturing cost. These oral films are available for buccal and sublingual drug administration. The composition of these oral films is varied and vast. Innovations have been made in this field to incorporate more prescription drugs.

Don't forget to share this post!

Tablet Press Machine Related Products

Tablet Press Machine Related Posts

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine