Ointment Filling Machine:The Ultimate Importing Guide In 2025

Ointment, cream, lotions are semi-solid formulations used for medicinal and cosmetic purposes. These products are available in different container including tubes: which are filled using a tube filling machine also known as ointment filling machine. State of the art design not only allows accurate tube filling but also sealing and packing in the final container.

If you want to know more about tubes, how they are filled and packed, which ointment filling machines are popular or you are interested in buying an ointment sealing machine than we recommend you to read this blog. Bringing you “OINTMENT FILLING MACHINE THE ULTIMATE GUIDE IN 2021”. This blog covers:

Let’s go!

1.What are ointments and how to prepare them?

Ointments are formulations prepared for application on body usually skin. Their appearance is “semi-solid” as they have an oily or greasy consistency. Most ointments are usually prepared with substances that act as a drug on the area it is applied to usually skin and/or get absorbed into the blood to act systematically.

Petroleum jelly is often used in their preparation and hence the greasy nature, and many dyes and aromatic substances are added to make them acceptable for human use.

The main purpose of using ointments out of all the skin product is to achieve an occlusive effect, which not only drives the medication into the skin more rapidly but also provides more protection against loss of moisture, as they tend to remain on the skin for longer durations than a solution or cream base, since the common ingredients used in the preparation is often mineral oil and petroleum.

2.What materials are used to make ointment tubes?

The first collapsible tubes were made of a number of materials including tin, zinc and lead. These tubes were sometimes coated with wax from inside to avoid material adhesion. Now a days you will find aluminum tubes more often used in various industries because of its property as a perfect container.

As to why aluminum is a perfect container there are certain points. For instance aluminum does not have a leeching effect i.e. it does not contaminate the product by releasing its residues making it safe, it can withstand high fluctuation in temperature thereby increasing shelf life of the product and many more.

Apart from aluminum, tubes are also made in plastic such as polyethene. Majorly plastic tubes are used in cosmetic and food industries. Unlike aluminum tubes plastic tubes retain their shapes when squeezed with unique decoration that’s appealing to the buyer from marketing and sale point of view.

3.What is an automatic ointment filling machine?

You are now aware that ointments are semi-solid dosage forms and these are packed mostly in collapsible tubes. Now the question is how they are packed? Well you can simply weigh and fill the product in an empty tube, use a hand held sealing tool and seal the tube or you can avoid all the laborious work and buy an automatic ointment filling machine.

AIPAK Automatic ointment filling machine

It is said that the first automatic ointment sealing machine was invented by a German company named IWK at the turn of 20th century. Automatic ointment filling machine is a complex mechanical invention that can perform tasks like loading, filling, sealing and packaging tubes with ease and does not require huge space for working. It is easy to operate and maintain and is available in various models having different specifications.

This whole blog is about automatic ointment filling machine. Continue reading! If you want to know more about ointment filling machine, its components, important features and many other related questions.

4.What are the industrial uses of ointment filling machines?

Pharmaceutical Industry

It’s a common fact that the formulation intended for topical purposes meaning these are required to be applied on the skin are dispensed in containers that are easy to use and does not result in wastage of product. That is why antibiotics, steroids and pain killers are available in tubes for topical application. An ointment filling machine has now become an indispensable part of the pharmaceutical industry because of its important role in topical products.

Cosmetic Industry

The cosmetic industry has transformed into one of the biggest industries of the modern world and has become a part of daily lives of billions of people. This industry has a range of countless products including lotions, creams, lipsticks, foundation to name a few. The ointment filling machine can be employed in the packaging and labelling of these products other than ointments and is therefore have a significant part meet the demands and upkeep of this industry.

Food Industry

From ketchup to peanut butter and unique products used in space, mankind including you have now seen agricultural revolution followed by industrial revolution. These diverse food products are often packaged and shipped all around the world, and the ointment filling machines are used in the packaging and processing like feeding, filling, metering and bagging.

Daily Products Industry

With the use of ointment filling machines not only accuracy but the packaging of any products is achieved with zero errors, saving great monetary costs. Household daily products include toothpaste, shampoos, body gels and lotions to name a few, can be accurately filled and packed using an ointment filling and sealing machine.

5.What are manual, semi-automatic and automatic ointment filling machines?

It is all about your needs and requirement, whether you are a small business owner or a manufacturing industry there are different choices available for you in the market that can meet your demands. Based on your work load you can opt for either a manual hand held ointment sealing tool, a semi-automatic filling machine or a fully automatic ointment filling and sealing machine. These are;

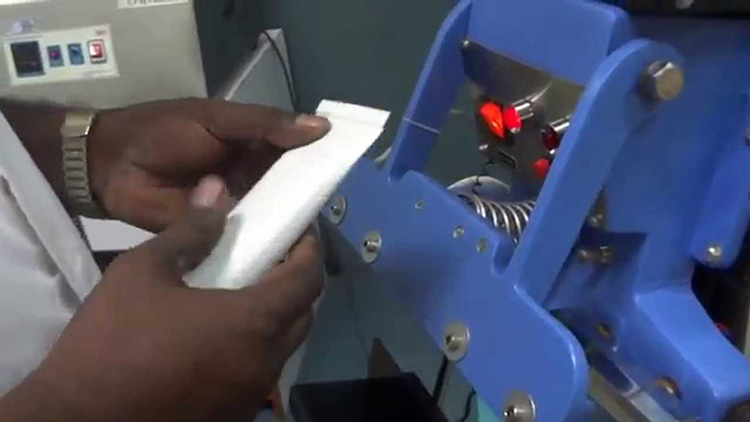

Manual ointment tube sealing tool

Manual ointment tube sealing tool can be used by you to manage small to medium work load with accuracy and efficiency. A simple easy to use unit, this tool can also be used as a backup device to perform sealing operations. Manual sealing tool is operated after the tubes are filled with desired product and the tails are sealed between two arms of the tool.

Manual tube sealing tool

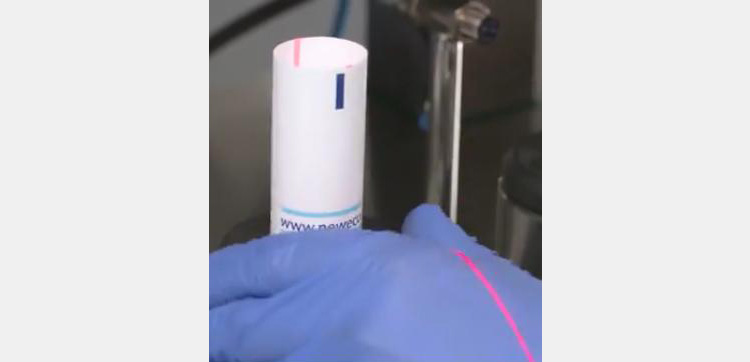

Semi-automatic ointment filling machine

This machine is best employed in research and development laboratories and small businesses. The main body is made up of stainless steel. Semi-automatic ointment filling machine is provided with a pneumatic unit that delivers accurate dispensing of material.

Semi-automatic tube filling machine- Picture- Courtesy- YouTube

With a push of a button you can convert this machine into manual dispensing unit. However, semi-automatic ointment filling machine cannot seal the tubes you will need an ointment tube sealing tool separately for sealing.

Black knob converts from semi-automatic to manual dispensing- Picture- Courtesy- YouTube

Automatic ointment filling and sealing machine

Automatic ointment filling and sealing machine comes with an additional feature of filling tubes along with sealing and packaging in given containers. You don’t need to buy a separate units for filling, sealing and packaging automatic ointment filling and sealing machine can do that for you. It is a highly advance machine with latest filling and sealing technology equipped with top notch electronics and fail-safe features.

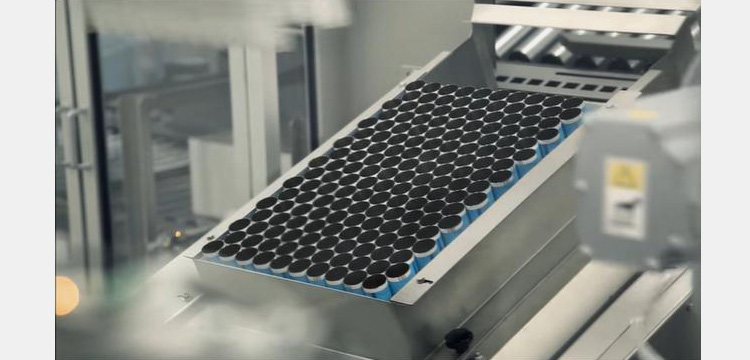

Automatic tube filling machine with two tube buckets- Picture- Courtesy- shenzen

6.Highlighting the advantages of an automatic ointment filling machine?

State of the art design: Rest assured that you have purchased an ointment filling machine equipped with advanced electronics and latest technology in tube filling and sealing. Its compact design facilitates entire operation in very short duration. The parts which come in direct contact are made entirely of stainless steel thereby, reducing cross contamination.

Artistic automatic tube filling machine- Picture- Courtesy- AM

Filling accuracy: Automatic ointment filling machine uses a filling valve that can be adjusted to provide accurate volume and filling of the product. The filling nozzle can also extend into the tube which ensures effective filling and avoid adhesion and spilling of the material.

Ease of maintenance: This machine is designed in such a way that it can be assembled and disassembled easily. The tube bucket and filling head can be removed instantly for cleaning, disinfecting and maintenance work without a hassle.

Customization: If you want to customize your machine there are certain features that can be added to the automatic version that further improves the working efficiency of ointment filling and sealing machine. One such unit is air blowing device; this unit is highly efficient in filling highly viscous product with ease.

Automatic speed adjustment system: Standard version of the machine is equipped with speed adjustment unit that automatically adjusts the machine filling speed and fulfills a high production demand.

Speed adjustment- Picture- Courtesy- You Tube

GMP compliance: Automatic ointment filling machines comply with good manufacturing practices in order to fulfill different regulatory requirements. So majorly these machines are used by food and pharmaceutical industries.

7.An outline of an automatic ointment filling machine technical specifications.

The major factor that plays the most important role in buying a machine is the amount of money you are willing to invest. You should look for a machine that’s could cater all your need even if the cost is high. Buying a machine that does not fulfill your requirements 100% will need a changeover if your production increases in the future and in the long run and it will cost you.

Automatic tube filling and sealing production line- Picture- Courtesy- You Tube

Below mentioned are specifications of an automatic ointment filling machine that you need to look into when buying ointment filling and sealing machine.

Power supply: This machine is equipped with a 5KW three phase motor which requires a power supply of 220V and 20A rated current.

Speed of production: You can produce 40 tubes in a minute with this machine although, this feature can be customized to match your requirements.

Production line- Picture- Courtesy- You Tube

Tube dimensions: One of the best feature of this machine is its adaptation to different types and sizes of tubes. Whether tube type be plastic or aluminum as long as the diameter of tube is in the range of 10-50mm and length 100-210 your machine will efficiently fill and seal them.

Tubes of same specifications aligned for filling- Picture- Courtesy- You Tube

Hopper: The standard version is equipped with a hopper having a capacity of 40L. This capacity can be customized to meet the buyer demand.

Stainless steel hopper- Picture- Courtesy- You Tube

Temperature: The sealing of tubes are performed using a heating unit that can provide a maximum temperature of 450OC.

Filling volume and accuracy: Your ointment filling machine can fill tubes with varying volume that lies in between 5-250mL for a single tube with an accuracy of ±1%.

Filling nozzle inside tube- Picture- Courtesy- You Tube

Air pressure: The standard version of automatic ointment filling machine is equipped with a pneumatic unit that can generate air pressure of about 0.5-0.7 MPa.

Dimensions: An automatic ointment filling machine weighs about 750Kg having an outline dimensions 1900x850x1900mm.

Water consumption: At 2 bar hydraulic pressure the machine consumes about 2 liter water in a minute.

8.Working principle of an automatic ointment filling machine.

“Without self-knowledge, without understanding the working and functions of his machine, man cannot be free, he cannot govern himself and he will always remain a slave”. George I. Gurdjieff.

You can relate to the working principle of an automatic ointment filling machine in a single sentence i.e. it is easy to understand. Below mentioned are the key points of working principle of ointment filling machine.

- Following arrangement of the tubes in the tube bucket, the tube feeding unit will automatically feed the cup seats.

- The rotary table will rotate and bring the tubes to different work stations.

Rotary table moving tubes to respective units- Picture- Courtesy- You Tube

- Adjusting the filling volume using volume dial can deliver desired volume in the tubes.

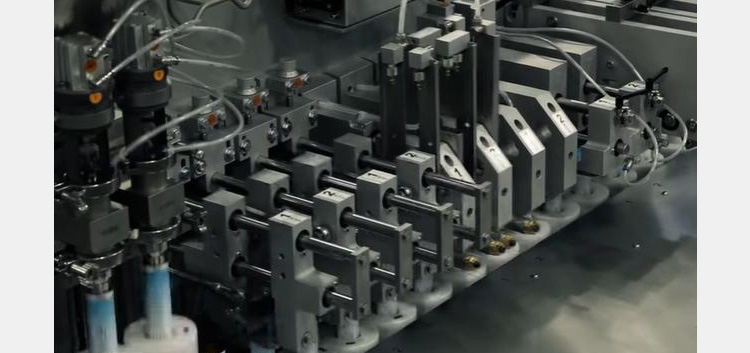

- The tubes will be automatically be filled with the product in the hopper through plunger type filling valve connected to the hopper.

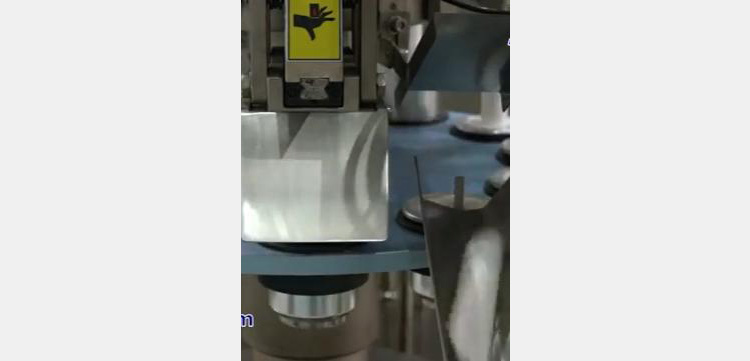

- Once the tubes are filled with the ointment, the rotatory table will rotate and bring the tubes to the sealing unit. The tubes will be sealed instantly in between two mechanical clamps.

- Different types and composites of tubes such as plastic and aluminum can be sealed by the heating unit with a simple change of mold.

- Once the sealing is completed the coding unit will print automatically the manufacturing date, batch number and expiry date on the tail of the tube.

- After coding the tubes are sent to the collecting unit for packaging through a discharged chute.

Emergency stop button- Picture- Courtesy- You Tube

9.Construction of an automatic ointment filling machine; a brief overview

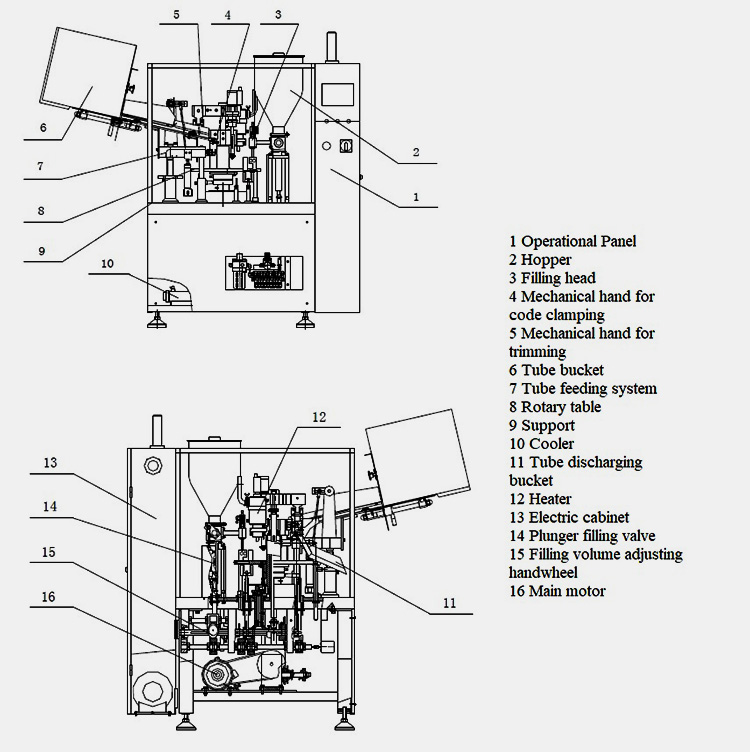

An automatic ointment filling machine can be divided into following major parts;

1) Operational Panel,

2) Hopper,

3) Filling head,

4) Mechanical hand for code clamping,

5) Mechanical hand for trimming,

6) Tube bucket,

7) Tube feeding system,

8) Rotary table,

9) Support

10) Cooler,

11) Tube discharging bucket,

12) Heater,

13) Electric cabinet,

14) Plunger filling valve,

15) Filling volume adjusting hand-wheel and

16) Main motor

1) Operational panel: It includes the control panel and emergency button on the left pillar. The entire operation is carried out according to pre-entered instructions on the operational panel using user friendly interface.

2) Hopper: Made entirely of stainless steel, the hopper has a capacity of about 40L of products. You can customize the capacity to meet your requirements.

Operational panel and hopper- Picture- Courtesy- You Tube

3) Filling head: Includes a piston type filling valve, filling head ensures accurate filling of product in the tubes.

4) Mechanical hand for code clamping: Used for color coding, automatic ointment filling machine can imprint both horizontal and vertical color codes.

5) Mechanical hand for trimming: After sealing the tubes are trimmed by clamping between mechanical hands.

6) Tube bucket: Empty tubes can be properly aligned and stacked in tube bucket.

Tube bucket- Picture- Courtesy- You Tube

7) Tube feeding system: The tubes are transferred from tube bucket by tube feeding system to the rotary table where they are filled, sealed and discharged.

Tube feeding system- Picture- Courtesy- You Tube

8) Rotary table: The ointment filling machine is equipped with the rotary table that rotates and brings tubes to respective units for appropriate treatment.

Rotary table- Picture- Courtesy- You Tube

9) Support: The entire machine is placed on a stainless steel support or the main body which is easy to maintain and clean. Use of stainless steel in the main body ensure there is no chances of cross contamination between products.

10) Cooling unit: This machine is also equipped with a cooling unit that utilizes water as a coolant to regulate temperature for proper and reliable seal.

11) Tube discharging bucket: The tubes after filling and sealing are discharged through chute to collecting unit for packaging.

Tube ejection after filling and sealing- Picture- Courtesy- You Tube

12) Heating unit: Heat is employed for sealing tubes. This unit is used for sealing the tubes once they are filled with product.

Tubes sealing units- Picture- Courtesy- You Tube

13) Electric cabinet: The electrical components and connections of the entire machine are situated inside the left column of the main body and can be accessed from behind the machine.

14) Plunger filling valve: This machine utilizes plunger filling valve for accurate filling and dispensing of product.

15) Filling volume adjustable wheel: You can adjust the amount of product filled in a given tube according to the dimension of the tubes by using filling wheel.

16) Main motor: Automatic ointment filling machine is powered by a 5KW three phase motor. The motor can operate at a voltage of 220V, however these requirements can be customized to meet your demands.

10.How to operate an ointment filling machine?

Operating an automatic tube filling machine- Picture- Courtesy- You Tube

Standard ointment filling machine is equipped with a digital control panel. You can operate your machine using this user friendly interface. All the instructions are entered beforehand by the operator. After starting the operations the automatic ointment filling machine performs the task from filling to sealing without much human efforts. Given below is a simple way to operate your machine.

User friendly interface

Control panel of an automatic tube filling machine- Picture- Courtesy- You Tube

- After connecting the machine to the main power supply switch on the main power switch and control panel. Touching anywhere on the screen will bring you to the main menu display. Clicking OPERATION buttons will display operation interface and activate operations.

- By clicking MENU button operation parameters can be entered. These include temperature settings, number of tubes per minute, door protection setting, time delay and as well as angle of clamps.

- Clicking NEXT page will display coding parameters.

- Pressing the DEBUGGING button will display inching operation and inching code searching.

- There is also an ex-factory setting which can be restored by pressing DEFAULT DATA button.

Of course there can be minor changes in different versions of machine, for details please check user manual.

Adjustment of machine according to individual tube specification

Before pressing the debugging button you need to make sure that the cup seat, plate (turning), cooling ring, heating sprayer, code searching and tube pressing hammer, filling nozzle and material cylinder are adjusted according to the length and diameter of the tubes. Here is how you do it.

- Place the cup seats with the tubes into the holes of rotary disc. Rotate the pulley manually. Adjust the height by loosening the screws of rotary table and turning the handle of the table. This will make the bottom of the internal blade 3-5mm away from the tail of the tube.

- After rotary table adjust the heating ejector pin. For a convenient debugging remove the cooling protection ring. Move the cup seats with tubes to the heating unit by manually rotating the pulley. Loosen the screws of the heating ejector pin to facilitate manual ejection of heating pin. At this point the tail end of the tube will be 3-5mm away from the holes of heating sprayer. Tighten the screws to lock the settings.

- Adjust the pressure of clamp according to the size of the tube.

- Loosen the nuts of ejector pin to raise the ejector pin to a height 10mm higher then the cup seat. Once adjusted tighten the screws.

- Now finally you have to adjust filling and lifting ejector pin height, color code and tube feeding.

- Turn on the chilling unit by opening cold water valve and start debugging.

11.What are failure solutions of an ointment filling machine?

You will come across certain situations where the ointment filling machine will not perform efficiently despite following strict working and maintenance SOPs. Well no need to panic! It is called troubleshooting. A little tweak here and there will resolve your issue and bring the ointment filling machine to its optimum working output.

Given below is a short insight on how to deal with most common problems, refer to user manual for details about your particular model.

- Improper sealing with scald:This problem is related to the cooling ring and heating device. You will have to check whether the cooling ring properly holds the tube and the heating unit is aligned vertically to the center of the hole of the rotary table. You will also have to adjust the heating ejector pin and increase the auxiliary jig at the side of the scald.

Proper sealing of tubes- Picture- Courtesy- You Tube

- Material contact and heating holes blocked: It occurs when the tubes are filled with excess material and adherence of the material with the wall of the container. Adjust the air blowing unit and the volume of material according to the capacity of the tube.

- No tube ejection from cooling ring: This issue can be resolved by adjusting cooling ring, heating temperature and increasing the distance between the tube and the heating unit to more than 5mm.

Adjusting tubes- Picture- Courtesy- You Tube

- Sharp edges at one or both side: Alignthe heating device vertically to the center of the hole of the rotary table. Adjust the volume of cooling water. Reduce the heating temperature and clamp pressure.

- Color code position is not right: Adjust the position of the tube before adjusting color code unit followed by adjusting the angles of the detector. If the problem not resolved check the height of the tubes.

- Vertical and horizontal code adjustment: Adjust the light emitted by the detector to avoid overlapping.

- Transparent tube adjustment: Insert a code searching hammer in to the tube diameter. It will shade the light emitted by the detector.

12.How to perform cleaning and maintenance of an ointment filling machine?

Proper cleaning and maintenance will increase the working life of an ointment filling machine. You should employ proper in-house cleaning and maintenance SOPs. It is recommended by the manufacturer that the cleaning and maintenance should be performed by highly skilled staff trained in handling cleaning and maintenance of machines.

Cleaning parts of ointment filling machine

For cleaning use a solution of detergent first than wash with hot water and application of alcohol to the inner wall followed by drying in the air. Disassemble the machine in the following manner.

- After removal of the hopper, loosen the screws of the valve.

- Remove the air piper and take out the filling part.

- Remove the material cylinder by loosening its screw.

- After removal of material cylinder loosen the ferrule of the nozzle and remove the nozzle.

- Once the filling nozzle is removed the dust cover is taken out followed by removal of valve spool

Clean the disassembled parts using detergent, warm water and alcohol and air dry before assembling them in the reverse order.

General maintenance of ointment filling machine

You need to make sure that following points are part of your maintenance SOP. For further information please refer to user manual provided with your machine.

- After operating ointment filling machine cut off the main power supply and allow the machine to cool down for 15 minutes.

- Use soft wipes or cotton dipped in alcohol on filling nozzles, cup seats, rotary table, sealing and printing arms to remove any visible dust particles.

- Lubricate moving parts every week and apply fresh grease every six months on the moving machine parts. These include main drive, cam shaft and chain.

- Always make sure that the oil in the machine is above the half mark, add suitable engine oil recommended by the manufacturer if the level is lower than the half mark.

- Before starting the machine, if it has not been used for a long time, check for loose connections and screws and secure the machine. Replace the oil if the machine was not in use for more than three months.

13.Advanced features of an automatic ointment filling machine.

Advanced electronics: Your machine is smarter than you think! Electronic sensors are employed not only to facilitate ointment filling and sealing operation but also to avoid any uncalled situations that could lead to improper filling and sealing of product. These sensors stop the production line if they detect no tubes in the tube bucket.

Advanced electronics utilized in an automatic tube filling machine- Picture- Courtesy- You Tube

Minimum user input: This machine detects any fault during operations and removes them without much aid of the operator. Once such feature includes removal of faulty sealed tubes from the production line.

Minimum user interference- Picture- Courtesy- You Tube

Alarm system: Your machine is smart enough to let you know if something is not right. This machine is also equipped with overloading and overheating alarm system. These parameters are determined at the start of the operations. If for any reason the limits are exceeded the machine automatically sounds an alarm and halts the operation until the cause is identified and removed.

Safety of user: Your safety comes first! In order to avoid occupational hazards the machine is equipped with advanced safety features. For instance, if during operations the doors are opened the machine will halt its working to avoid potential injury.

User safety- Picture- Courtesy- You Tube

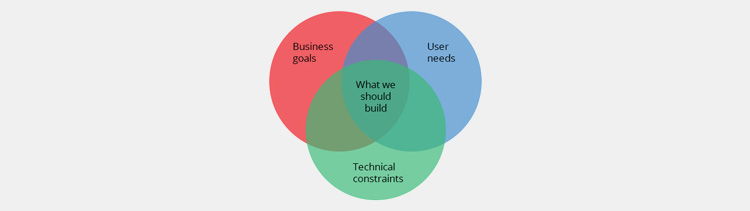

14.Parameters to consider when buying an automatic ointment filling machine.

When buying any machine you should research, do a thorough market survey on the available product and make sure that the machine fulfill your requirements. Following are some of the important points that should be considered before buying a machine.

Requirement

First thing‘s first! Are you running a small business? Or as an internationally acclaimed manufacturer you plan to increase your units worldwide. Identifying your production needs is the first step to buy any machine. Also you should take into account your future plans because if a machine can be upgraded to meet your future demands why buy a new one?

Cost

Of course! One of the main things to look into is the cost of the machine. If cost is not an issue you should definitely opt for an Automatic ointment machine that can fill, seal and pack tubes in one go, without much user interference and meets local and international regulatory requirements. Keep in mind that automatic machine in the long run with all its advanced features will prove to be an inexpensive bargain for you.

Automation

“To err is human”. Alexander Pope. Humans make mistakes and are less efficient when high productivity is required it’s a universal truth. A little automation will always help you out and increase your productivity with less chances of errors.

Latest technology

Ongoing latest trend and latest technology is a must when you are looking to invest in machines. Firstly they will meet the requirements of the regulatory authorities as with the passing of time the regulations are getting stringent. Secondly you need a machine that can work with you for next ten to twenty years and can be upgraded to meet your demands because no one likes a short investment.

Availability of parts

After buying the product the first things that comes to mind is the availability of parts and after sale service. When machine is working continuously and meeting supply and demand there will be some cost incurred in terms of maintenance. Availability of spares will keep machine in top notch condition that is why major manufacturer recommend to have spares in advance.

Customization

A machine which is specifically tailored for you cannot be compensated with easily available machine that has standard features and cannot be customized or cater user’s demand. Well fret not! Automatic ointment filling machine can be customized in the way you want. Just go through multiple options and select the machine that fits best to your need.

Quality and safety

You are well aware of the fact that entire working agenda of regulatory authorities is to keep checks on quality and safety of the products. Buying a machine which is recognized by regulatory authorities will ease the registration of the product anywhere in the world.

Conclusion

Hope this blog has piqued your interest in ointment filling and sealing machine and covered all the topics that you were searching for. The blog was specifically written to make the reader understand ins and outs, pros and cons of an automatic ointment filling and sealing machine and self-assessment and analysis of one’s own needs. Now you are in a better position of selecting the best ointment filling machine from the market according to your needs and requirements. HAPPY HUNTING!

Tube Filling Machine Related Products

Tube Filling Machine Related Posts

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours