Ointment Cartoning Machine: The Complete Buying Guide in 2025

Pharmaceutical packaging is an evolving industry where an ointment cartoning machine is crucial in streamlining the packaging process and maintaining ointment product integrity, compliance, and professional finish. Efficiency, precision, and automation are key to staying ahead in the best ointment cartooning machine.

It automates placing ointment containers into cartons, improving speed, accuracy, and consistency while saving labor costs and human errors. With the advances in recent years, multiple options with innovative features provide enhanced automation, flexibility, and integration with other packaging systems.

Investing in the right ointment cartoning machine directly impacts productivity and the bottom line. While choosing the right ointment cartoning machine, you should carefully consider factors like product capacity, automation level, carton compatibility, and compliance with industry standards.

That’s why, we’re here with a comprehensive guide on an ointment cartoning machine to give an insight before purchasing an ointment cartooning machine. By the end, you’ll have all the details to make an informed decision that aligns with your production targets and business goals.

1.What do you know about the ointment cartoning machine?

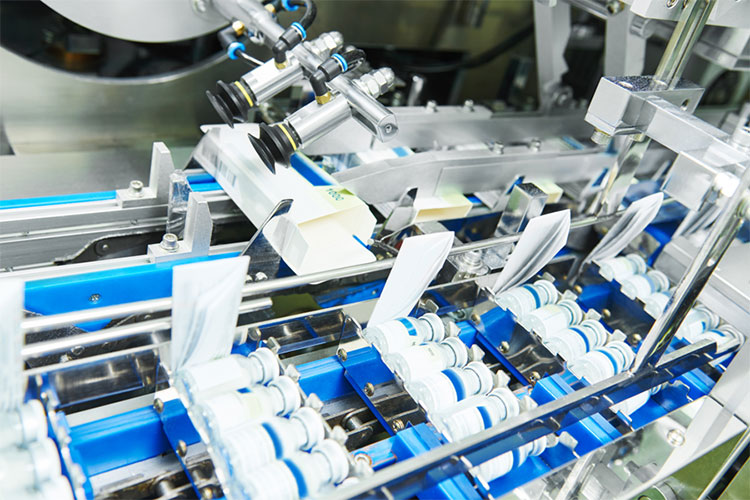

Ointment Cartoning Machine

An ointment cartoning machine is specially designed equipment to automate the secondary packaging of ointment containers in the pharmaceutical industry. It takes the hassle out of packaging by swiftly assembling, filling, and sealing cartons with accuracy. It has versatility, whether you’re handling different tube sizes or production demands. It keeps your process efficient and consistent with every batch.

2.What are the benefits of using an ointment cartoning machine?

Cartoning of Product

Ointment tubes need to be packaged securely because they are fragile. The latest ointment cartoning machine provides contaminant-free and damage-resistant packaging making them important in pharmaceutical production.

Let's talk about how these machines provide various benefits by incorporating into your line of production:

Keep Product Stable and Sterilized

Protection of Ointment Packaging from External Factors- Picture Courtesy: Custom Boxes

Pharmaceutical ointments generally include active pharmaceutical ingredients (APIs) that can degrade when exposed to air, light, heat, or moisture, changing the desired effects of ointment. Some ointments such as eye ointment and burn ointment need to be sterile in order to avoid infections and complications.

This secondary packaging shields ointment from environmental interaction for product stability and shelf life maintenance.

Prevent Tube Leakage and Mess

Cartoning Prevents Physical Damage to Delicate Ointment Containers

Ointments are greasy and semisolid thus leakage is a possibility if not packaged well. The plastic and soft aluminum material of ointment tubes makes them punctured or dented with ease when handled and transported. Such machines can add an additional layer of protection against physical damage and ensure the tube is intact while in storage and transport.

Efficient and Cost Cutting

Ointment Cartoning Machine Reduces Cost- Picture Courtesy: RELEVANT SOFTWARE

Automating the packaging of ointments allows you to increase production and minimize labor. These machines eliminate human errors hence minimizing waste and making the process cost-effective.

Accuracy and consistency

The Ointment Cartoning Machine Gives Uniform Packaging Look

Through the use of these machines on a production line, the ointment containers are accurately set and held in cartons thus avoiding misalignment or damage and giving a consistent packaging look.

3.What industries typically use an ointment cartoning machine?

Ointment Cartoning Machine is Applicable in Various Sectors- Picture Courtesy: EndFlex

The application of an ointment cartoning machine is not limited to the pharmaceutical sector but can be implemented in various other sectors for secondary packaging. Let's take a look at their industrial application:

Pharmaceutical Packaging

Provide Extra Layer of Protection for Pharmaceutical Products- Picture Courtesy: EndFlex

The pharmaceutical sector uses these machines to package ointments, gels, and creams utilized in the treatment of various skin and eye diseases such as infections and burns. Such as the packaging of eye ointments, oral liquids, vaccines, capsule blisters, and tablet blisters, needed to keep them hygienic and avoid contamination.

Cosmetic Packaging

Use for Cartoning of Cosmetic Products

In the cosmetics sector, these carton packaging protect various skin products, such as BB creams, moisturizers, and medicated lip balms. These products are packaged carefully in cartons to maintain quality and protect sensitive formulations from exposure to the environment.

Veterinary Packaging

Box Packaging of Veterinary Supplements- Picture Courtesy: Medica Packaging

The veterinary industry uses these machines to package medicated ointments, vaccines, and pet care products. These products are safely packaged in cartons to preserve sterility and facilitate easy handling.

Food Packaging

Secondary Packaging of Food Products

These machines are less common in the food industry but can be used for packaging consumable creams, flavor gels, and spreads that come in tubes or sachets. These products are put into cartons to increase hygiene, extend shelf life, avoid contamination, and keep the product fresh.

Electronics Packaging

Thermal Paste Secured in Carton Box Packaging

The electronics industry can use an ointment cartoning machine to package thermal pastes, conductive gels, adhesives, and small tools. The secondary packaging provides secure handling and enables accurate labeling of specifications.

Stationary Packaging

Stationary Items Need an Ointment Cartoning Machine for Packaging

These industries also utilized an ointment cartoning machine, for the boxing of pens, erasers, markers, paper products, slime, and play dough. Such products are normally packaged in tubes or small containers and then cartoned to enhance the retail display and secure products.

4.What are the components that together make an ointment cartoning machine?

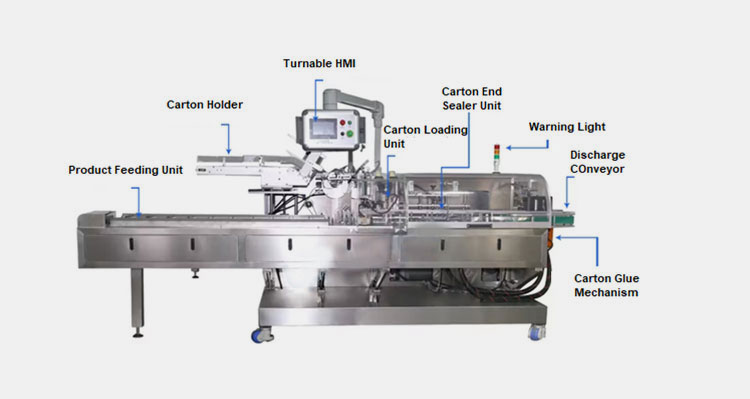

Key Parts of Ointment Cartoning Machine

We have discussed how an ointment cartooning machine streamlines the process from carton forming and product insertion to sealing and quality control. But do you know what exactly makes up an ointment cartooning machine?

Let’s discuss this by breaking down each part and how each of them contributes to smooth packaging:

Product Feeding Unit

Product Feeding Unit

Ointment tubes and other products can enter the machine in the product feeding unit either manually or automatically by the conveyor system.

Carton Holder

Carton Holder

This unit holds flat cartons and moves them into forming mechanisms and product insertion.

Turnable (Human Machine Interface) HMI

Operation Controls by HMI

This turnable HMI is a control panel from where workers can adjust seetings, observe performance, and troubleshoot challenges.

Carton Loading Unit

Carton Loading Unit

This unit pushes the ointment containers into the open containers ensuring proper placement.

Carton End Sealer Unit

Sealing of Carton by Glue

This unit seals the end of the cartons using adhesive glue or mechanical locks according to the packaging demands.

Warning Light

Warning Unit

It alerts about machine status including operations defects, malfunctions, or maintenance alerts.

Carton Glue Mechanism

Adhesive Sealing

If the packaging requires adhesive sealing, this unit applies glue to the flaps before sealing.

Discharge Conveyor

Discharge Conveyor

This is the exit station from where sealed cartons exit the machine and are ready for further processing.

5.What is the basic principle of an ointment cartoning machine?

An ointment cartooning machine makes every step of packaging seamless, where the ointment containers are placed effortlessly into the cartons and smoothly sealed the flaps. Let’s dive into the principle of how this machine works wonders:

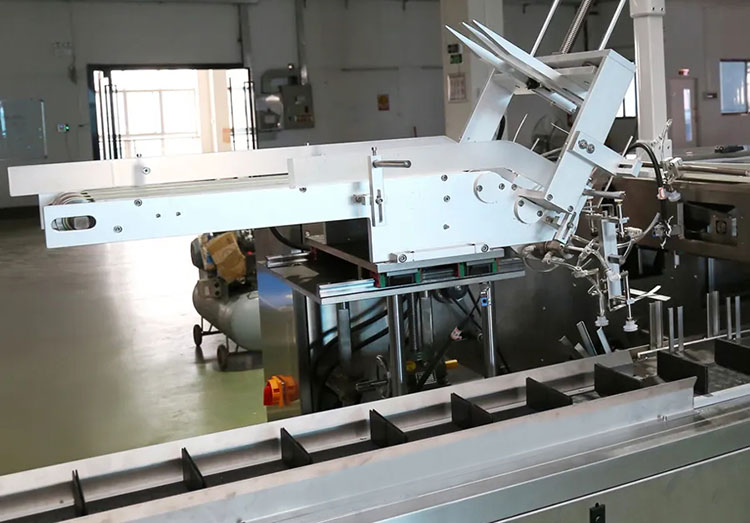

Step# 1: Carton Feeding

Feeding of cartons- Picture Courtesy: Bhagwati Pharma

Pre-scored, flat carton blanks are pulled from a carton holder and placed on a conveyor system. The arrangement sets them up for the subsequent opening process.

Step# 2: Carton Opening

Flat Cartons Turning into Rectangular Form

Flat cartons are then opened into a rectangular shape with the help of a mechanical arm or vacuum system. The cartons are held at a right angle via guide rails and push plates while moving to a loading station.

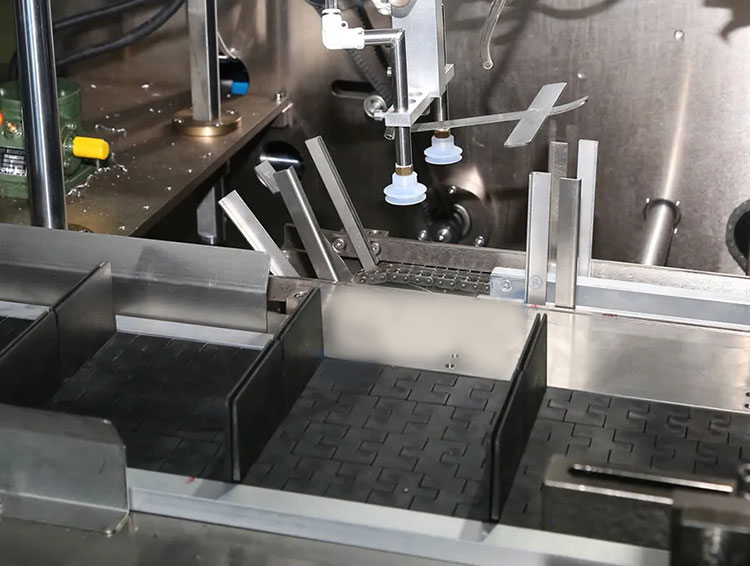

Step# 3: Product Insertion

Product Insertions into Cartons- Picture Courtesy: Jacob White

After reaching the loading area, a synchronized carton loading unit places them into open cartons. This step ensures the accurate placement of the product inside the cartons.

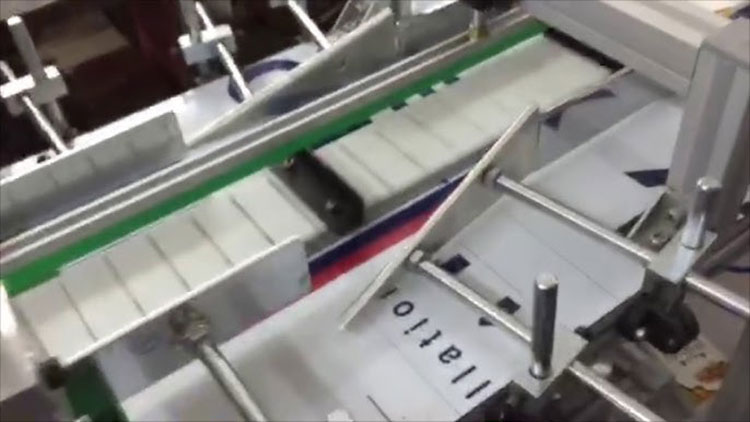

Step# 4: Cartons Closing and Sealing

Sealing of Cartons

Once the product is placed inside the cartons, the machine folds the carton flaps and seals them via adhesive or tucks them in. The product is now enclosed securely and ready for distribution.

6.What are the different types of the ointment cartoning machine?

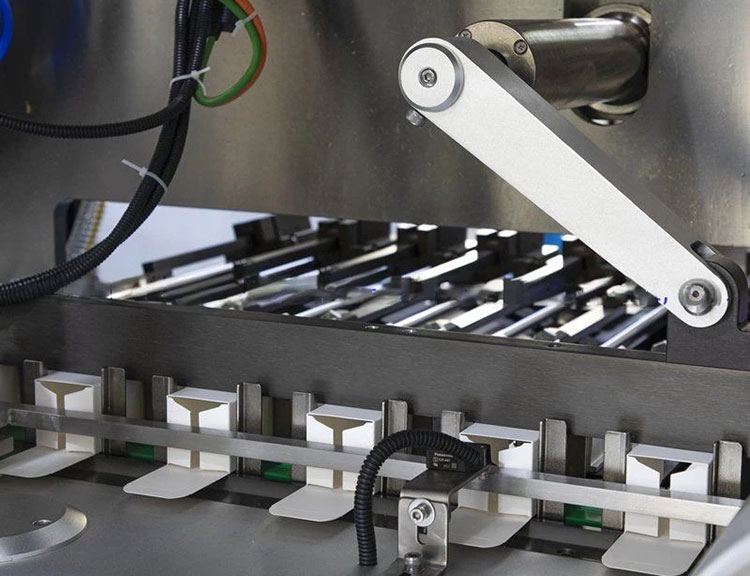

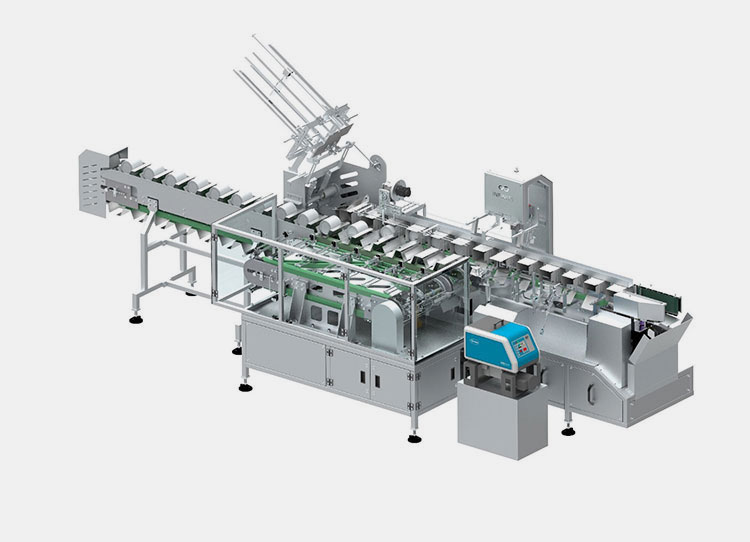

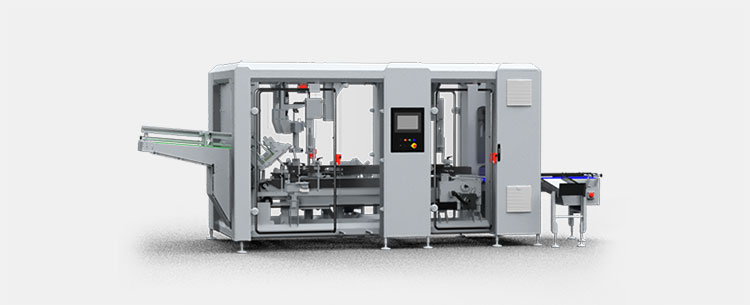

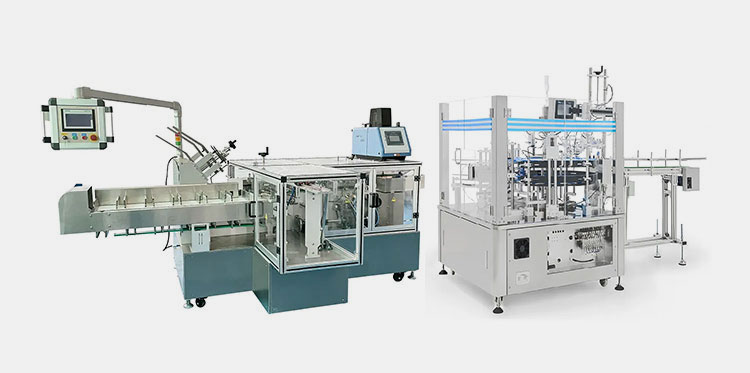

High-Speed Automatic Ointment Cartoning Machine

When it comes to a selection of a best-suited ointment cartonig machine, there are multiple options available in the market to cater to your manufacturing demands. These machines come in different sizes to meet specific production needs.

Whether you need high-speed automation or a machine for cartooning delicate products, understanding the classification of an ointment cartooning machine can guide you in choosing the best one. Let’s explore the various options:

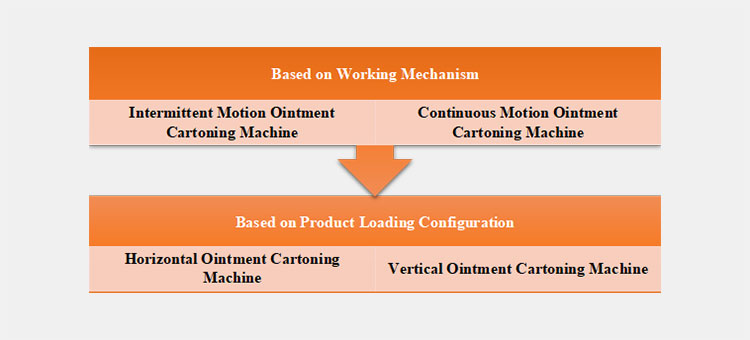

Based on Working Mechanism

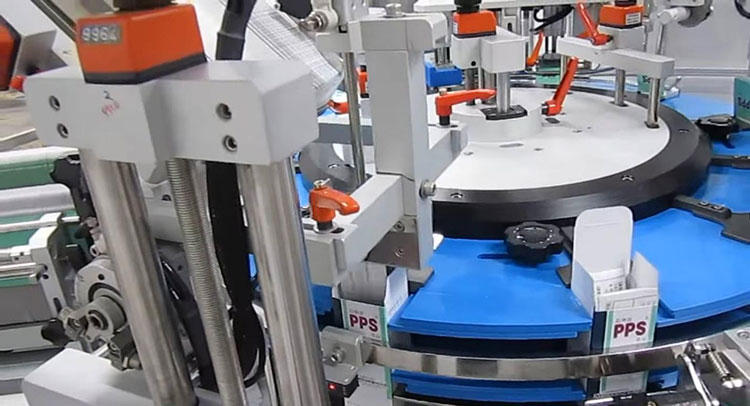

Intermittent Motion Ointment Cartoning Machine

Machine based on Intermittent Motion- Picture Courtesy: Cama

These machines adopt a step-by-step working mechanism, i.e. work in a start-step manner. Here each step of a packaging process (carton erection, product insertion, and sealing) happens one at a time. The machine pauses at each step so that precise product handling can be controlled.

It’s suitable for delicate products like ointment tubes. It operates at moderate speed and is ideal for small to medium-scale production ensuring accuracy in terms of product positioning and carton sealing.

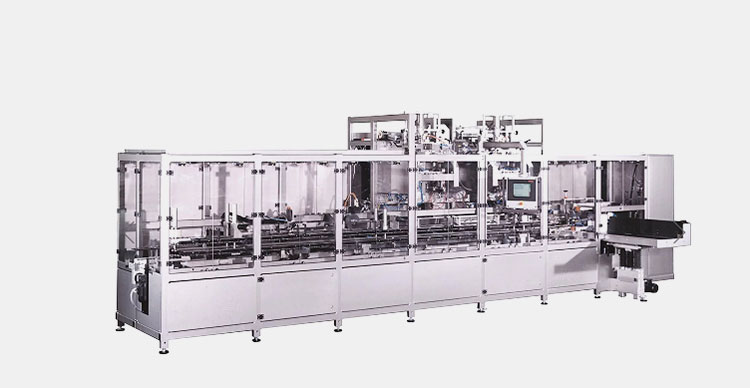

Continuous Motion Ointment Cartoning Machine

Machine Based on Continuous Motion- Picture Courtesy: Cama

In these machines multiple packaging steps are happening smoothly and uninterruptedly. From carton erection to carton sealing all the phases are happening simultaneously as the carton passes through the system.

These machines are designed for high-speed, large-scale manufacturing, ideally for sturdy products that can withstand fast-moving processes.

Based on Product Loading Configuration

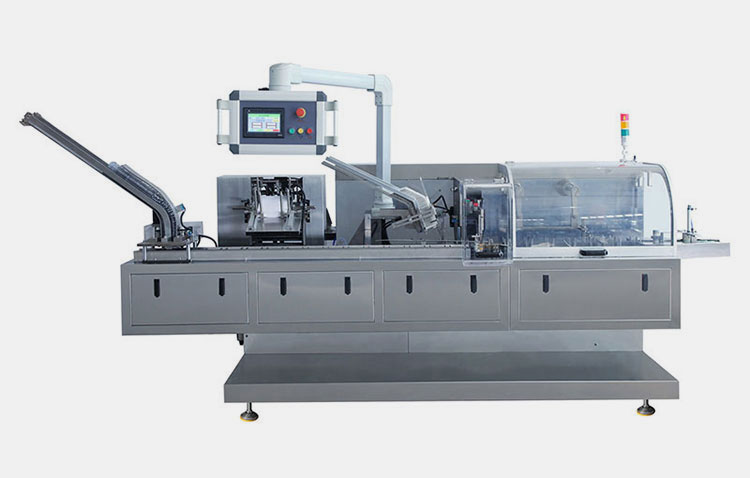

Horizontal Ointment Cartoning Machine

AIPAK Horizontal Cartoning Machine

These machines are also referred to as end-load cartoners. These machines place products from the side (horizontally) as the cartons move along the packaging system. It works well for flexible or stackable items such as tubes or sachets. Provide uniform packaging sizes for bulk production.

Vertical Ointment Cartoning Machine

Vertical Loading Orientation Based Equipment- Picture Courtesy: ROVMEMA

These machines load the products from the top into upright cartons. It’s best suited for products that need careful handling or gravity-assisted insertion like jars, bottles, or vials.

7.What are the common challenges encountered during ointment packaging with an ointment cartoning machine? How can they be resolved?

Troubleshooting of Ointment Cartoning Machine- Picture Courtesy: Newprint

The ointment cartooning machine can face several challenges that affect the efficiency and quality of the process. By understanding the root cause and implementing the right solutions you can address these issues.

| Jamming | |

| Challenge

Production can be delayed by the jamming of the cartons during the packaging process. The cause can be:

|

Solution

|

| Inconsistent Adhesive Application | |

| Challenges

Poor adhesive application can lead to improper sealing, affecting the product integrity. Causes can be:

|

Solution

|

| Product Feeding | |

| Challenge

If a product does not feed smoothly into cartons, it can lead to misalignment or damage. The possible root causes can be:

|

Solution

|

| Failure of carton suction | |

| Challenge

A machine may not pick up the cartons from the magazine. The possible reasons can be:

|

Solution

|

| Material waste and inadequate efficiency | |

| Challenge

Excessive waste of material can increase the cost and affect the efficiency of production. The reasons can be:

|

Solution

|

8.How does an ointment cartoning machine handle various tube sizes and packaging types?

Variation in Ointment Containers- Picture Courtesy: SomeWang

An ointment cartooning machine is versatile in its design as it can accommodate tube sizes and packaging types. Let’s how it can manage this adaptability:

| These machines are designed with adjustable components like conveyor belts, infeed systems, or carton holders. By adjusting these components according to the dimensions of containers, a machine can handle a variation in product sizes and types. |

| Various machines are designed with modular structure which enables integration and modification of different components. With a smooth reconfiguration, a machine can flexibly accommodate different carton sizes, designs, and materials. |

| An advanced ointment cartooning machine is equipped with sensors and an automated system, enabling adjustment according to product sizes. This automation allows adjustment without manual interventions, which ultimately increases the efficiency and reduces the errors. |

9.How will the selection of carton material affect the performance of an ointment cartoning machine?

Impacts of Carton Material Quality

The selection of carton material can significantly affect the performance of the ointment cartooning machine, compromising the efficiency, product integrity, and overall quality of the process. The following are the factors that can impact the performance:

Thickness and Flexibility

Material with excessive thickness can cause jamming during folding or conveying, while material that is too thin can result in improper sealing.

Surface Texture

For using glossy or coated surfaces you may need modification in the suction mechanism for proper handling.

Durability

The carton material should be durable as the fragile material can result in torn cartons affecting the product integrity and packaging efficiency.

10.What kind of packaging materials can be used for ointment in an ointment cartoning machine?

Variety of Carton Material- Picture Courtesy: Sumpap India

High-quality carton material is necessary for providing robust protection against external factors as these act as a barrier, protecting from dampness and bacterial growth during transit. The most commonly suitable materials for cartooning of ointments are:

Folding Boxboard

Folding Boxboard Carton- Picture Courtesy: Ebro Color

They are made of multiple layers of mechanical and chemical pulp. They are lightweight and durable, ensuring smooth folding and sealing and minimizing jamming in the machine.

Solid Bleached Sulfate

Solid Bleached Sulfate Cartons- Picture Courtesy: Netpak

They are made of high-quality fully bleached virgin pulp. They have excellent strength and a smooth surface for printing and moisture resistant. Ideal for high-speed machines due to its stiffness and durability.

Coated paperboard

Clay Coated Paperboard- Picture Courtesy: Print Ninja

They are made of paperboard with a coating of clay or polymer. It enhances printing quality and provides a moisture barrier. Helps in smooth processing in the machine while giving an attractive appearance for branding.

11.How do you decide between a horizontal and a vertical ointment cartoning machine for ointments?

Horizontal VS Vertical Ointment Cartoning Machine

You need to consider certain factors before choosing between a horizontal and vertical ointment cartoning machine. Let’s understand the differences between these two types:

| Factors | Horizontal Ointment Cartoning Machine | Vertical Ointment Cartoning Machine |

| Product Insertion | Products are loaded horizontally into the cartons. | Products are dropped or pushed vertically into the cartons. |

| Container Type | Best suited for tubes, sachets, blister, packs, and trays. | Ideal for any product that needs gentle gravity-assisted loading, including jars or bottles. |

| Production speed and output | It has high speed so ideal for large-scale production. | It has a comparatively slower speed than the horizontal one. Best suited for delicate or controlled loading. |

| Product Stability | Better for stable products that can withstand horizontal pushing. | Ideal for delicate products that can’t handle side pressure well. |

| Machine Footprint | It occupies more floor space. | It takes up less space on the floor. |

| Automation Level | Mostly fully automatic with a continuous packaging mechanism. | It can be semi-automatic or automatic. |

12.What are the principal specifications to seek in an ointment cartoning machine?

Speciation Considerations- Picture Courtesy: Packaging Strategies

Before investing in an ointment cartooning machine, it’s important to consider some principal specifications to ensure efficient performance and compatibility with your production demands. Here are some specifications to evaluate before purchasing:

| Cartoning Speed | Carton Size Range |

| You need to evaluate the cartooning speed, which means how many cartons the machine can process per minute.

Select according to your desired production scale that can align with your overall production process to prevent bottlenecks. |

Most often, industries produce different ointment products, which require various carton dimensions. So, the machine should accommodate a broad range of carton sizes.

This ability to adjust to different carton sizes makes the machine more flexible for multiple packaging products. |

| Material Compatibility | Power Requirements |

| The type of material you use for cartons can affect the packaging quality and the machine’s performance.

Make sure that the machine can process your desired carton material without causing jams or any extensive adjustments. |

The machine requires a stable power supply for optimal performance. Make sure that your facility can support the power requirements of the selected machine.

You can choose a machine with energy-efficient motors which can help you in reducing the operational cost while maintaining the efficient performance. |

| Air Pressure and Consumption | Machine Dimensions and Weight |

| Most of the machine depends on pneumatic systems to operate components such as suction cups and pushers. For that, a consistent and adequate air supply is needed to maintain smooth operation.

Make sure your facility has a well-maintained air compressor system to avoid fluctuations in performance. |

The size and weight of the machine can effectively influence its installation and space.

Make sure that your facility has adequate space to fit within the available floor space for efficient workflow and easy access for maintenance. Keep in mind that heavy machines require stable flooring and proper anchoring to reduce vibrations during the operation. |

| Noise Level | Flexibility for Changeover |

| When you are purchasing a high-speed model, consider that some machines produce high noises, so take noise-reduction measures or operator ear protection as necessary. | Most industries use the same machine for different products, so it needs frequent size changes.

Select a machine with a quick changeover feature to make the transition smooth between different carton sizes or packaging formats. |

13.How does an ointment cartoning machine guarantee product protection and hygiene?

Use of Stainless Steel- Picture Courtesy: Jochamp

These machines are designed to meet high standards of product safety and hygiene during the packaging process. These machines have various key aspects that are incorporated to pack ointment products securely.

| Stainless Steel Design

These machines are made of stainless steel, ensuring durability, facilitating easy cleaning, and preventing contamination. |

Automated System

The machine utilizes advanced automated systems that minimize human contact with the product and packaging material. |

| Secure Sealing

These machines ensure the tight sealing of the cartons to protect them against contamination. |

Regulatory Compliance

These machines follow industry standards to maintain hygiene and product safety. |

Conclusion

Before choosing an ointment cartooning machine you need a careful evaluation of speed, flexibility, hygiene standards, and automation specifications to ensure safe and secure ointment products packaging. AIPAK offers you high-quality GMP-compliant cartooning solutions designs. These machines can accommodate various carton sizes, sealing methods, and automation levels and ensure secure packaging, minimal wastage, and effortless integration into the existing production line. From small-scale production to large-scale production AIPAK provides you advanced technology to meet industry standards.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours