Milk Powder Filling Line: The Complete Buying Guide In 2025

Isn’t milk powder filling is challenging? This is a delicate formulation with sensitive to various factors. Therefore, to provide accurate and safe packaging, a milk powder filling line is used.

This is an important mode of filling which is required for various large companies to protect and pack their formulation for local and international supplying.

For appropriate knowledge, have a look at this blog, because here you will find important information essential to bring milk powder filling task effectively.

1.What is the milk powder filling line?

A milk powder filling line is a major section of the dairy industry which is composed of a series of units enabling promising filling and securing of milk powder. This is ideal for milk powder of various categories including skimmed milk, infant formula milk powders and so much more.

Therefore, when you open the can of milk powder, it assures fully nutritious milk powder that your manufacturer has carefully packed to delight you. The milk powder filling line is basically based on the units such as bottle unscrambler, milk powder filling machine, capping machine, induction sealing machine, etc in one complete solution.

2.How significant a milk powder filling line is?

Just imagine how tiring it would be if the milk powder was filled with your own hands. Of course, it is not only time-consuming, but it will cost you more in terms of requiring several technicians, along with so many risk factors such as cross-contamination, oxidation, etc.

That is why a milk powder filling line in your facility smoothly manages the process with the cutting of so many risky factors. See below the primary significance of the milk powder filling line:

Saving your money

Saving your money- Picture courtesy: Alphafoodie

When you are spending your money on the procurement of a milk powder filling line; it might cost you more in the first attempt. But when you are planning for high-quality material production, then indeed it is a wise step. The investment in this unit is fruitful.,

You are saving your time, minimizing the expenditure on labor, reducing the chances of product wastage, etc. So how is it not profitable to install a milk power filling line?

Extra safety and cleanliness

Extra safety and cleanliness

If you see the construction of the milk powder filling line, you will realize that its entire structure is based on food-grade materials. That helps in sustaining and preserving hygiene throughout the work process., The machine aims for minimum contact with your product and allows lesser chances of product lumpiness on the surface of the machine. Hence, it is quite easier for you to clean it if in case any material or residue is left over.

Catering Packaging Material with Various Sizes

Packaging Material with Various Sizes

The powder filling line is very ideal for catering to packaging material of different sizes, and shapes, and with an unlimited number. Therefore, the unit is completely diversified for dealing with broad-spectrum packaging materials without requiring your large investment in change over the tooling.

Remarkable Filling Consistencies

Remarkable Filling Consistencies

The milk powder filling line is an excellent solution for managing the variable volume and concentration of filling milk powders with astringent uniformity. For example: if one can is composed pack of 100 grams of milk powder, then the entire production batch would be with similar weights and accurate quantity.

Hardly ever face any production error where some inconsistency in the filling of material has occurred. However, there are 99.9% chance of high exactness in terms of filling. Therefore if you want to create high consumer trust in your brand, then we will suggest setting up for milk powder filling line for business workflow.

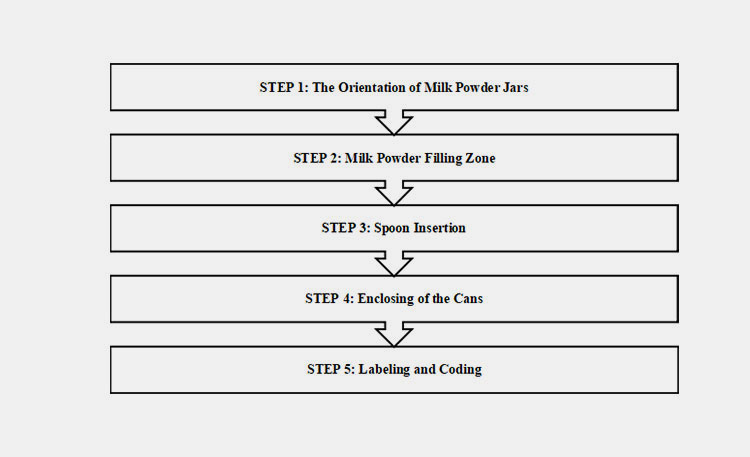

3.How does a milk powder filling line work?

The working principle of the milk powder filling line is based on sequential units that work one by one to complete the filling procedure of powder milk. We have described the following steps with the provided illustration to ensure that you have fully understood the method.

STEP 1: The Orientation of Milk Powder Cans

Orientation of Milk Powder Cans

Generally, the milk powders are filled in specified jars or cans. But these jars have to be fully oriented and in an upright position. You cannot subject the random order rather so it must be in a correct position. For that, the first step of the milk powder filling process is the positioning of the jar to smoothly transport them throughout the units.

STEP 2: Milk Powder Filling

Milk Powder Filling

This is the major step where you need to pour the powder into the specified jars. They are coming toward the section in an oriented direction. Once the machine identifies its presence, a specified quantity of milk powder is directly poured into it.

The process is taking place in a way that there is no chance of dust formation, spillage, or wastage of formulation. Therefore an accurate and safe milk powder is filled respectively.

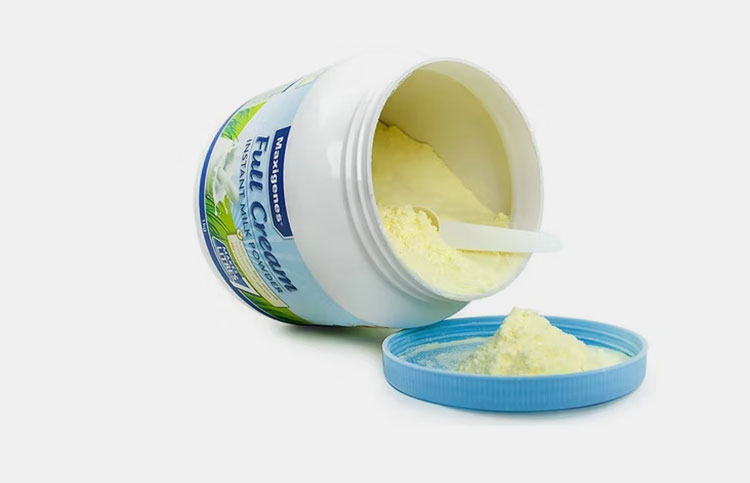

STEP 3: Spoon Insertion

Spoon In Milk Powder – Picture courtesy: Coor products

Your manufacturer always cares for accuracy; that’s why this step is mainly included with the insertion of a feeding spoon in the milk powder. For correct doses, you can use the spoon available inside. Once the milk powder is filled, the spoon is automatically dropped in the jar to make the correct milk formulation.

STEP 4: Enclosing of the Cans

Enclosing of the Cans

Once the product is filled, it is hermetically sealed in a vacuum seamer to extend the potency of the formulation. Here, simultaneously gas flushing takes place with lid placement so milk powder is sealed airtightly. It is evidence that the product is original without any tampering. Besides this, capping is done to enclose the jar. By the application of force, they are firmly fixed around the jar's neck.

STEP 5: Labeling and Coding

Labeling and coding

The milk powder cans are subjected to labeling and coding section. The purpose of this section is to provide useful information in the form of labels that are applied all around the can. Plus, coding is necessary to provide useful information related to the manufacturer, its barcode, manufacturing batch, manufacturing date, etc. So in case, you are required to trace the specific formulation, the provided code can directly approach the following production formula.

4.Where is the milk powder filling line required?

Not only dairy industry but with unlimited benefits and reliable services, a milk powder filling line is widely accepted in various manufacturing production companies.

This is because the machine offers a tremendous filling approach for the formulation of various other categories. We have described them just right below.

Pharmaceutical Industries

Pharmaceutical Industries

Due to the accuracy and safety features present in the milk powder filling line, every pharmaceutical industry is referring to this solution in the packaging and production line. It will not only cut the manufacturing cost but also be suitable for safe pharmaceutical preparation. It is included with dry powder chemicals, oral medicinal powders, health-related supplements, topical antiseptic powders, and bulk medicinal powders, such as cellulose magnesium oxide magnesium carbonates, etc.

Food and Beverage Industry

Food and Beverage Industry- Picture courtesy: Cargill

A milk powder filling line is commonly required in food and beverage industries for the exact portioning and dispensing of various formulations. Today whenever you are picking any food or beverage item from the shelves of the market; you may observe that the specified quantity with the mentioned volume packaging is consistent to maintain the market value of the specified brand.

There are many examples of food and beverage products such as spices, seasoning powders, chocolate powders, bakery ingredients, etc all of them are served to you by utilizing this filling line.

Nutritional Industry

Nutritional Industry- Picture courtesy: Spee Dee packaging

When someone is using nutriceutical products, they aim to get a healthy physiology and attain the useful benefits from the specified formulation. You have used various nutriceutical products like flavored milkshakes, milk powders, beneficial enzymatic powders, energy-boosting supplements, anti-ageing, and anti-oxidant powders, etc.

Many of these products are carefully designed with useful constituents extracted from plants or natural sources. Therefore, a milk powder filling line is an integral tool to preserve the potency of your formulation from safe and effective packaging.

Cosmetics Industry

Cosmetics Industry- Picture courtesy: the French Beauty Academy

Not just food and health-related products, but the milk powder filling line is very important for dealing in the management of nonfood related formulations as well. In the world of cosmetic industries, there are so many cosmetic products that are formulated and supplied to you in the powder packaging presentation.

For example: dusting powder, loose powder, compressed powders, and talcum powders, in the specified packaging materials. For this purpose, a milk powder filling line is an absolute choice for gaining amazing packaging properties.

Chemical Industry

Chemical Industry – Picture Courtesy: Nature’s Brand

In the chemical industry, you deal with moderate, toxic, nontoxic, acidic, and neutral powdery substances. Believe me, if you are planning to fill and pack them using manual handling would not be only risky for the filling and packaging of your material but also harmful for the worker. That is why, the milk powder filling line is an excellent gateway to deal with the filling and packaging of your product most safely and securely.

Veterinary Industry

Veterinary Milk Powder – Picture Courtesy: Aussie Vet Product

This is the fastest-growing industry, especially in the Western world, this is mainly associated with health care and diet-related care of your pet. Therefore, the formulations related to the treatment of the animals for example anti-allergy powders, topical formulations, anti-bacterial, and anti-fungal powder products are mainly formulated in the form of powders and are packed in specified jars.

Furthermore, animal food-related items such as powdered milk, probiotic powder, dried grains, rice, and meals are mainly packed in boxes, and jars by using a milk powder filling line.

5.What is the composition of the milk powder filling line?

The milk powder filling line is composed of the basic machines that are discussed below:

Bottle/Jars/Cans Unscrambler

AIPAK Can Unscrambler Machine

Your cans are needed to be subject for the filling machine must be in an oriented position. For that, an excellent solution is provided in the form of cans unscrambler. This is the machine that helps in the positioning of random cans with the help of a rotary tray and a high blower system.

These two properties allow the random jars to jumble over the rotary plates. The presence of pockets allows the fixation of cans into them. Therefore, it leaves the once-acquired proper direction.

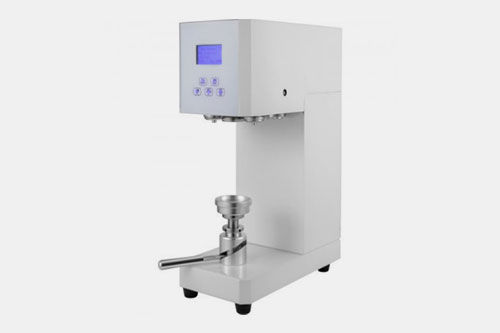

Milk Powder Filling Machine

AIPAK Milk Powder Filling Machine

The machine is integrated with a jar unscrambler unit, therefore when the correct position can come directly toward the filling nozzle of the milk powder filling machine, it detects the presence and notifies the machine to dispense the specified volume of the milk powder inside the individual container. If there is no can, there won't be any filling process.

There are many other types of milk powder filling machine. All of them are designed related to users' requirements. For example:

Volumetric Milk Powder Filling Machine

This is the machine that is used for large production batches. Here the specific volume of the formulation is fed inside each can. In terms of accuracy, this machine is not an ideal option but yes if you require to attend to high production needs then it is suitable for this purpose.

Net Weight Milk Powder Filling Machine

Net Weight Milk Powder Filling Machine

This is the machine where the required weight is entered into the software of the machine. Therefore, the net weight is measured and dispensed. Once it reaches the limits the powder pouring stops. This type of machine is mainly used for large or bulk amounts of milk powders and is very simple in structure.

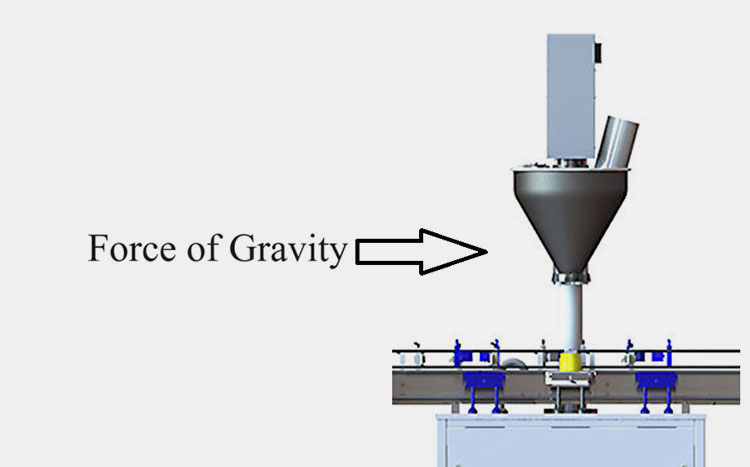

Gravimetric Milk Powder Filling Machine

Gravimetric Milk Powder Filling Machine- Picture courtesy: ALL Fill

This type of machine is where the flow of milk powder is entirely based on the force of gravity. The machine principle and its features are entirely based on automatic technologies, though it does not require generating high power to bring the dispensing process.

Spoon Dropping Machine

Spoon Inserting Machine

The spoon dropping machine is mainly responsible for falling spoons in the filled containers. The scoops or spoons with random positions are inserted into the machine’s hopper. The machine can sort them and upon identification, it drops each spoon into an individual jar. However, the phenomenon stops if there’s no jar present over the conveyor.

Vacuum Seaming machine

Vacuum seaming machine

The vacuum seaming machine provides high security with a nitrogen flush to eliminate the presence of oxygen inside the jar and create a vacuum. A thin layer of aluminium lid is positioned that creates a strong bond with the edges of the can which results in airtight sealing. The security lid can only be broken down once you pull the foil. The purpose behind this machine is also to offer a highly potent and fresh product by preventing the degradation process.

Types of Can Seamer Machine

There are different types of can seamer machines that you can pick depending on your needs and choices.

| Automatic Can Milk Powder Seamer Machine | This machine works entirely using automatic characteristics. For the large production batches, this is a suitable option. Here, you do not need human involvement rather set of cans comes across the unit for sealing. |

Automatic Can Milk Powder Seamer Machine |

| Semi Automatic Milk Powder Can Seamer Machine | This is ideal for small to moderate production batches that need the involvement of humans. You need to start the machine and place the can. At this time, the machine can identify and seal the object. So you can remove the sealed can. |

Semi Automatic Milk Powder Can Seamer Machine |

| Rotary Milk Powder Can Seamer Machine | This is a fast-acting machine that induces the seaming effects over a set of cans that rotates around the fixed axis.

This machine features multiple head seamers that can help in the sealing of large batches at one time. Hereby, it is best known for dealing with large production batches. |

Rotary Milk Powder Can Seamer Machine |

Capping machine

AIPAK Milk Powder Screw Capping Machine

The capping machine is used to apply the cap on the milk powder cans to secure the formulation inside. The machine hopper which is stacked with a bunch of caps, loads up the cap over cans upon their presence. By applying pressure using screw caps methods, flipping the cap, and other your milk powder jar is fully secured against the external environment.

Labeling

AIPAK Milk Powder Labeling Machine

A milk powder labeling machine is capable of identifying the exact position and application of various sizes of labels with quality checking. The machine is capable of performing the task steadily. The label roll is adjusted in the machine, and it unwinds the machine and gives the command to the PLC system. The reel starts opening and automatically positioning and pressing of the applied label takes place. As a result, the professional effect with smooth textured labels can be achieved.

6.What types of milk powder are catered with milk powder filling line?

Various types of milk powder mainly require a milk powder filling line for its production sector. The following types are described below.

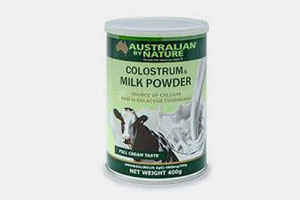

| Cow/Goat Milk Powder

|

This milk is mainly originated and extracted from the cow or goat’s milk. It is used as a replacement supplement for babies feeding milk.

Because cow milk after modification has a similar composition and constituent to human breast milk. Consequently, it is considered to be a suitable solution for the nutritional growth of infants who are unable to digest or attain their mother's milk. |

Australian by Nature |

| Soy-Based Milk Powder

|

This is another good solution for infant supplements who are suffering problems such as glucose intolerance or are unable to take human milk as well as cow milk.

This milk is considered the safest option for the nutritional fulfillment of infants as they are derived from natural and plant-related sources offering complete nutritional requirements. |

|

| Hydrolysed Protein Formula

|

This type of milk is mainly formed by utilizing modern biotechnology methods This means that the protein available in the milk is segmented into smaller fractions; which makes you digest and tolerate it easily and this is also known as the best supplement in order to replace cow milk or other to manage an infant’s allergies or digestive problems. |  |

| Specialized Formulas

|

This type of milk powder is mainly created by intervention of your dietary needs.

Such types of milk are mainly prepared by the involvement of protein building blocks such as an amino acid chain. The type of milk is mainly designed to reduce the frequency of lactose intolerance as well as milk-related allergies. Moreover, such type of milk is mainly suggested for babies who are premature or have low birth weight. |

|

| Skim Protein Milk Powder

|

This type of milk is prepared by removing the fat content present in the milk. Nowadays a greater prevalence of using skim milk is observed commonly. This is all because of its high nutritional benefits related to health. |  |

| Whole Milk Powder

|

This is also known as cream fat milk powder which is composed of enriched creamy content that favors the preparation of various dairy products. Additionally, this milk is highly nutritious and delicious. That is why various food formulations such as yogurt cheese and flavorful sweet desserts are prepared using whole milk powder. |  |

| Flavored milk powder | There are various milk powders used for health supplements and are presented in different flavors and extracts. This can also be filled and packed by using a milk powder filling line, for example, strawberry milk, chocolate milk, vanilla milk, soymilk powder, etc. |  |

7.How to attain an efficient response from the milk powder filling line?

Milk Powder Filling- Picture courtesy: Maxigene

A milk powder filling line is a valuable asset in pharmaceutical, dairy, nutraceuticals, and other industries. When you are looking for it carefully by close maintenance, it will give you an extended and smooth operational work life. You can prevent many mishaps and accidents with more and more excellent performance just by following the mentioned steps:

Conduct scheduled cleaning of the units

You understand the logic behind the regular cleaning of the powder filling line and its high efficiency. The milk powder is sticky and a non-free-flowing powder. This means that it tends to stick and clog rapidly. Therefore, whenever you subject the machines to their dispensing task, after the process routinely clean them.

It is included with per day cleaning to remove the presence of particles or excess milk powder, weekly as well as monthly cleaning. Both of these schedules should be based on deep cleaning including inside and outside parts.

Monitoring & damaging of damaged components

Never ignore any unusual sounds, they might be indicating something happening wrong. You can keep an eye on the parts of a machine and keep replacing them with alternatives to enjoy uninterrupted work.

Never forget Lubricating the machines

Friction and dryness are the culprits behind the machine’s inefficiency and inaccuracies. You need to stop them by all means. This is possible by regular application of lubricating oil especially those sections that are involved in the generation of movement. For example, rotary disc, conveyor, and related components. Avoid using excessive oiling as it will also result in terrible outcomes.

Say YES to calibration

Whenever the system is overloaded, it becomes inefficient. The provided data and produced results don’t show sharp matching. Therefore, to save your time and attain amazing performance, calibrate your machine regularly.

Conduct Training Workshops

When you subject the milk powder filling line to trained personnel, they will surely operate and manage the system well. Therefore, it is essential to conduct scheduled training sessions, either monthly or depending on your needs. This will help technicians deal with production lines and related technical pitfalls rapidly without causing any downtime or cost.

8.How to tackle the problems with milk powder filling line?

There are certain challenging problems that every manufacturer faces when associated with milk powder filling. Just check below to find out:

Prone to Interact with Moisture

Interaction with moisture

When dealing with milk powder filling, you are having high risk for the product’s interaction with moisture, humidity, or external environment. It directly affects the freshness, progresses clumping, and starts the process of microbial growth.

Solution

Focus on airtight sealing and appropriate sealing of the can that offers tremendous barrier properties therefore directly reducing the moisture content involvement, and other unwanted hazards.

9.How to stop Oxidation?

Oxidation

The prime reason behind the fast rancidity of milk powder is oxidation. The oxidation is a cause behind the degradation of nutrients and results low potent formulation.

Solution

To solve this problem, opt for an aluminum foil sealing layer that strongly inhibits oxygen entrance inside the packaging. To improve the filling process, always look for a machine featuring ‘modified atmosphere packaging (MAP)’ or properties for oxygen displacement with the vacuum that can reduce the risk of oxidation.

10.How to deal with filling inconsistencies?

Filling accuracy- Picture courtesy: Nestle baby

Sometimes the milk powder filling line can not fulfill goals and results in inaccurate dispensing. This problem results in poor quality, and batch failure, and affects consumers’ trust.

Solution

To address the issues, check the basic points, whether your machine is calibrated or not. Check the movement of the conveyor, and correct the settings if the filling speed is higher than required. By monitoring and correcting these points, and trying a test run, we assure the problem will be resolved.

Conclusion

After reading the article, you will be able to understand the basics of the milk powder filling line. Therefore, it is the right time to choose the excellent way for our production line. Yes, by selecting the right equipment depending on your production capacity, budget, and material is integral for boosting your industry in the competitive world. With the AIPAK team, you will find an absolute solution related to a milk powder filling line that will affordably fulfill your needs. Do you want to try communicating with us? Why not! Just message us to get in touch with our experts.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine