How to Manufacture Tablet by Direct Compression Method?

Direct compression is a standard and widespread approach of tableting in pharma industries as it is rapid and proficient without having significant production expenses. Direct compression is an efficient method of manufacturing tablets that requires fewest production steps. Apart from process simplicity this method has reduced capital, energy cost and excellent for treating water sensitive active ingredients. Read this informative review that will clear basic sketch of direct compression method.

Table of Contents

Ⅰ.How can you define direct compression method?

Direct compression method is a novel approach in which drug materials and excipients are formed into tablets. It has the steps of blending and compression and there is no need for granulating the powder.

This method does not involve pretreatment of active ingredients as required in granulation and physical nature of ingredients remain unchanged in direct compression.

II.Do you know about kinds of direct compression method?

There are three kinds of approaches employed in direct compression method:

- Direct Compression Excipients

- Die Feeding Type Direct Compression

- Binders Involved Direct Compression

Direct Compression Excipients

These excipients are also termed as direct compressible excipients or direct compression filler. These are non-reactive, non-therapeutic substances, are easily compressed and mixed with active ingredients.

Direct compressible excipients have suitable traits for tableting features and these materials have impact on the distinctiveness of tablets and powder smoothness.

These excipients also have a have an effect on of rigidity and break down features of end products.

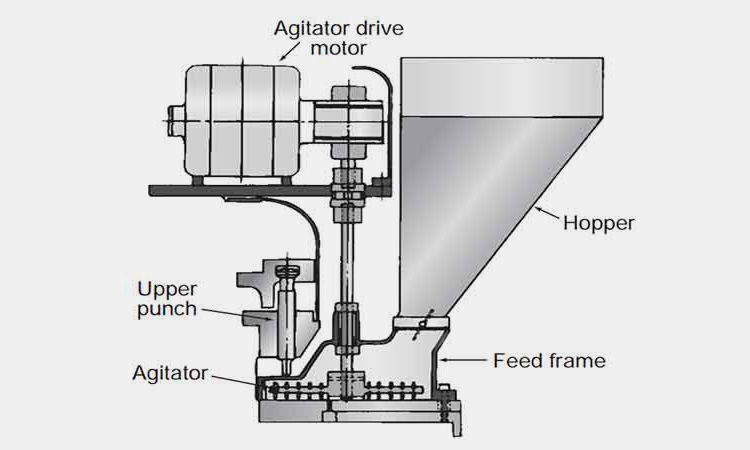

Die Feeding Type of Direct Compression

This technique uses a unique kind of feeder which stops the blend of segregating and boosts the powder passage from hopper part to die component of tableting machine.

Induce feeders also play a significant part decreasing in air trapping within fill materials leading to dense readily compressed powder.

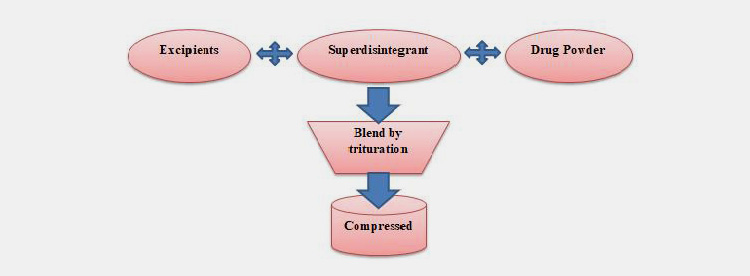

Binders Involved Direct Compression

This technique significantly impacts the compression when drug has lower quantity than filler excipients. The dry binders employed in this compression method have the ability of rapid compression causing the hardness of tablets.

As dry binders have appropriate bulk density so they fill die channel evenly this leads to tablets of consistent weight and this makes high dosage medications.

III.What are the benefits of direct compression method?

There are many advantages of direct compression method. Some advantages of direct compression are stated for your learning.

Stability

Direct compression guarantees the stability of the tablets as the tablets are produced without using water and high temperature.

Alteration in Dissolution Profile

Dissolution profiles of active ingredients remain unchanged upon long term storage as compared to wet granulation.

Low Cost

Direct compression is probably less costly method than other approaches utilized in tablet production due to less steps and equipment involved in direct compression.

Disintegration Characteristics of Excipients

Some excipients employed in direct compression have intrinsic disintegration characteristics.

Rapid Dissolution

The tablets fabricated by the direct compression dissolve into primary particles while the tablets produced by the wet granulation disintegrate into granules so the direct compression tablets have faster disintegration in stomach environment.

Binding Capacity of Excipients

Excipients used in direct compression have high bonding strength so the pressure required to achieve desired hardness is less Due to this direct compression has high manufacturing speed and machines last long.

Wastage and Contamination

Lubrication and powder mixing are carried out in same container resulting in low wastage of product and contamination of mixing vessel.

Growth of Microorganism

There is minimal growth of microorganism in direct compression method.

IV.What are the steps involved in direct compression method?

There are three steps involved in direct compression methods such as

- Pre-milling of Ingredients

- Blending

- Compression

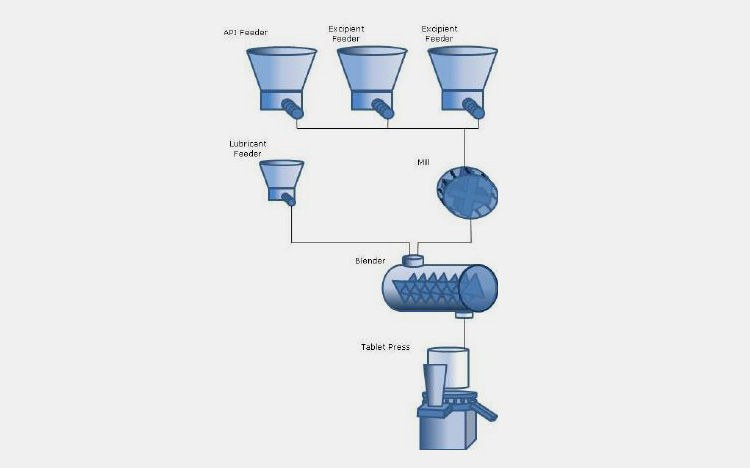

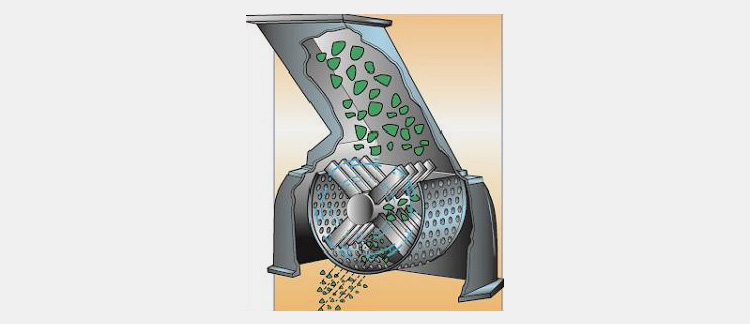

Pre-milling of Ingredients

Pre-milling step in direct compression involves the reduction in the particle size. In this step active ingredients and excipients are mixed together. It comprises of various techniques like crushing, grinding, pulverizing, etc.

It enhances the pharmacological properties of the substances. The purpose of milling is to have uniform particle distribution.

Blending

Good blends make good tablets. Blending involve the mixing of pre-milled materials and excipients such as lubricants and glidants. This process increases the powder flow and improves the uniformity in particle size.

It is a critical step in tablet manufacture as if powders are not blended properly it will result in inconsistent weight tablets.

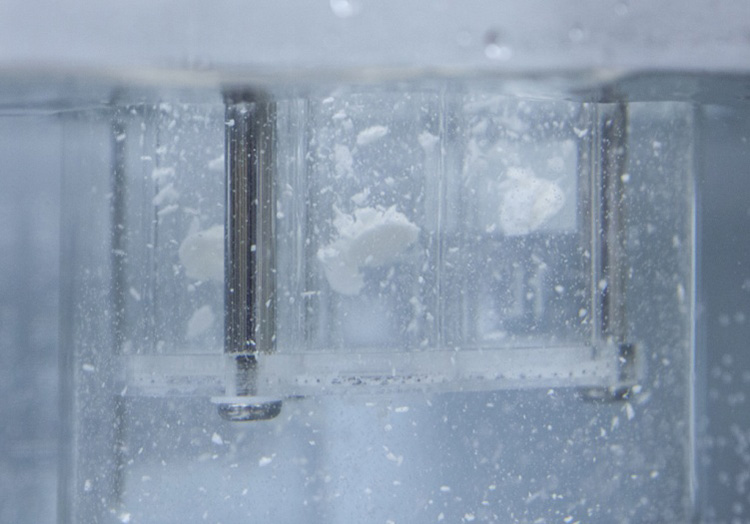

Compression

It is the final stage of direct compression method, in this stage blended powder is compressed into tablet by means of hydraulic pressure. The hydraulic pressure is transformed into static fluid pressure, applied on powder in die cavity by upper punch of tablet compression machine and compresses the powder into tablets.

V.Various excipients used in direct compression method.

Certain grade excipients are used in direct compression for accurate powder flow and compression features. Some excipients included in direct compression are:

- Diluents

- Lubricants

- Glidants

- Disintegrating Agents

- Stabilizers

- Pigments

- Surfactants

Diluents

These excipients give mass to tablets; they assist in flow and compatibility of core drugs. These are also called fillers or bulking agents. These diluents have major proportion in formulations and added to drug to increase their volume or weight. These include lactose monohydrate, anhydrous lactose, etc.

Lubricants

Lubricants such as magnesium stearate are essential in preventing adhesion of tablets in die cavity and decrease the friction between walls of die and tabletsare ejected effortlessly from die without breakage.

Glidants

Glidants or anticaking agents like talc are substances which enhance the flow of powder and added during tablet manufacture to lower the interparticle friction and cohesion.

Disintegrating Agents

Disintegrating agents like disintegrants and super-disintegrants are the excipients and have prime role in rapid break down or dissolution of the tablets into small particles in gastrointestinal fluid. Some examples of disintegrating agents are methylcellulose and sodium starch glycolate.

Stabilizers

These are used to reduce hydrolysis or oxidation depending upon the pH of the drug. These chemicals protect the intrinsic properties of active ingredients.

Colorants

Colorants or coloring agents like dyes and inorganic pigments are included in formulation to achieve the coloration of tablets. These give distinctive appearance to tablets that assist in their identification by the patients.

Surfactants

These are chemicals with both polar and non-polar regions and promote the solubility of the drugs. These are especially used in formulation if the active ingredients are non-polar. Examples are sodium lauryl sulphate.

VI.What are differences between direct compressed tablets and wet granulated compressed tablets?

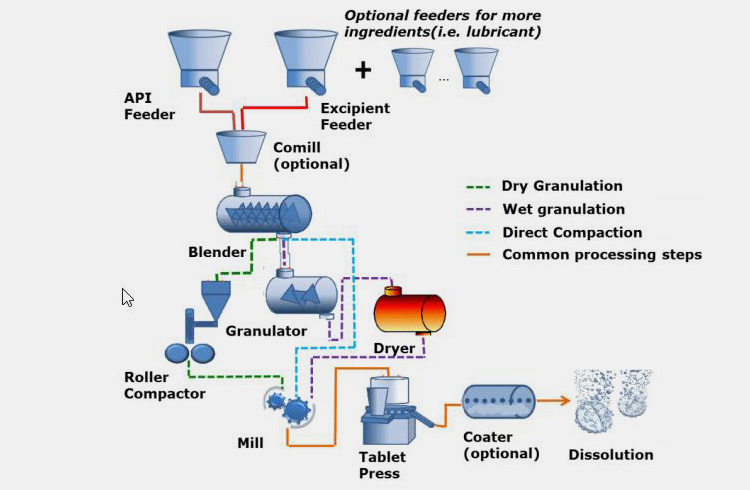

Two most popular techniques in tablet manufacture are: direct compression and wet granulations. Some major differences between two methods are given below:

Process

Direct compressed tablets are manufactured in three steps: milling, mixing, and compression. Wet granulated tablets are produced in six steps: granulation, screening, drying, milling, blending, and compression.

Excipients

Direct compression tablets require special grade excipients, but wet granulation use conventional tablets.

Segregation

Wet granulation ensures uniform mixture and inhibits segregation of the blend during handling process but in direct compression segregation of the mixture occurs.

Cost

The direct compression method has lower cost due to reduced labor, power consumption, equipments, time, and space but wet granulation has high cost.

Material Loss

There is minimal loss of material and cross contamination in the case of direct compression while cross contamination is high in wet granulation.

Dissolution Rate

Disintegration is rate limiting reaction in absorbance of wet granulated tablets as they are made of poor soluble active ingredients, but the dissolution rate of direct compressed tablets is faster. Also dissolution rate of wet granulated tablets reduces with the age.

VII.What are the limitations of direct compression method?

There are few limitations of direct compression method that makes it unsuitable for compression of some ingredients and drugs. These cons include:

Choice of Excipients

Most of the materials are not used as excipients in direct compression method because of these materials do not posses intrinsic binding characteristics.

Expensive Excipients

The excipients included in direct compression of tablets are generally costly than excipients used in other methods of tablet manufacturing.

Segregation

Direct compression mixtures may result in un-blending or segregation during post-blending steps. Blends are deficient of moisture and can cause formation of statistic charges ensuring un-blending. The differences in particle size and density of active ingredients can also cause un-blending.

Tablet Defects

Different defects like capping, splitting, layering etc occur frequently in direct compression because of trapped air during compression.

Interaction between Excipients and Active Ingredients

In some cases, the excipients used in direct compression react with drug ingredients such as the reaction between amine compounds and lactose leading to yellow coloration of tablets.

Nature of Drug Substances

Some drug substances are difficult to compress by direct compression method because of their crystalline or amorphous in nature.

Conclusion

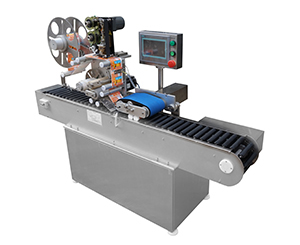

Despite involving fewer process steps, tablet making via direct compression can be challenging that requires intricate product designing to ensure a consistent tablet. AIPAK offers you an extensive range of tableting machines to run this challenging process in a smoother way. AIPAK high speed larger capacity and cost-effective series of tablet press machines with uncountable modern features are crucial for easy and safe production. This will help you to achieve excellent outcomes for your business beyond your wildest dreams. Click HERE to find superb range of AIPAK tablet press machines.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine