Knowledge You Should Know About Cartoning Machine

Recent years, with the continuous development of domestic pharmaceutical industry, the number of drug types is increasing, the dosage forms of drugs are constantly enriched, and the requirements for drug packaging are also constantly increasing. The drug packaging machines’ market has won good development opportunities.

After the drug is packaged by itself, it also needs to be packaged as a whole.Cartoning machine is a kind of machinery used for overall packaging, including automatic cartoning machine, medicinal cartoning machine, etc.

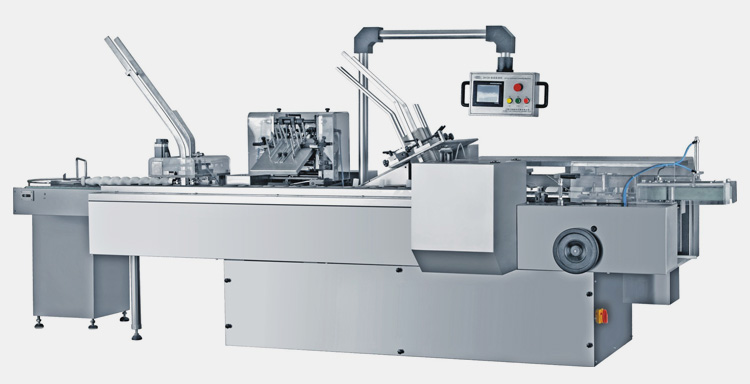

The high-speed cartoning machine is suitable for the cartoning of pharmaceuticals, tubes, ampoules and similar items. Compared with the traditional cartoning machine, the high-speed cartoning machine is more efficient because it adopts frequency conversion speed regulation and human-machine interface PLC control.

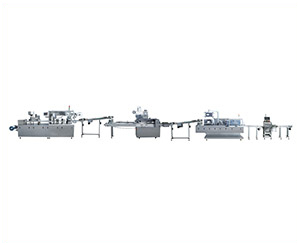

It can automatically complete the folding of the manual, the opening of the carton, the boxing of the plate, the printing of the batch number, and the sealing.The equipment can be used alone at present, and can also be connected with blister packaging machines and other equipment to form production lines.

Problems with high-speed cartoning machines

In terms of domestic machines, there are some universal problems for the high-speed cartoning machine in the market.

First, the quality of the carton is below the standard,which may cause some troubles in packaging. It is reported that many cartons are made of substandard materials, using inferior materials, or mixing low-quality materials, which may easily cause the packaging to be difficult to smooth.

Second, the structural design of cartoning machine is unreasonable. The process of machines’ parts are not standard and the assembly is not in place. Improper debugging, unstable operation, and failure to reach the scheduled production capacity.

Third, it is because most of the high-speed cartoning enterprises adopts small workshop production that the supporting facilities of their machine are poor. It hard for customers to purchase the parts.

Fourth, the variety of packaging for boxing is complex, and it is difficult to adapt to boxing. At present, the varieties of medicines on the market are becoming more and more diverse, and the corresponding cartoning machines also need to improve adaptability.

Fifth, the manufacturers of equipment requiring front-end and back-end connections are increasingly integrated, and the connection increases the difficulty of work. Integrated production has increasingly become a production model for pharmaceutical companies to increase rates and reduce labor costs, which also poses challenges to cartoning machine companies.

How to solve these problems?

First, improve the models, and gradually classify them into standard models.

Second, form large-scale production, and use tooling, molds, and inspection tools to create industrialization.

Third, high-speed cartoning machine companies should seize the market demand, increase investment in scientific research, and develop the integration of cartoning machines to meet the needs of users for integrated production and reduce corporate costs.

Fourth, the industry believes that pharmaceutical factories cannot rely solely on paper to reduce consumption, but should increase the rate from speed and use paper that meets the requirements to ensure speed benefits.

Fifth, improve the standardized design of pharmaceutical factories. The same specifications are packaged in different specifications, which is easy to waste the cost resources of both parties. In this regard, the industry suggests that the country should introduce relevant standards and unify the packaging specifications.

In a word, in the modern era of rapid development and fierce industry competition, high-speed cartoning machines can not only save a lot of time and labor intensity for enterprises, but also greatly improve work efficiency.

In addition, the production and use of high-speed cartoning machines can complete many people The work that cannot be done by hand has helped pharmaceutical companies to solve many problems, and the high-speed cartoning machine market will surely achieve better development in the future.

Facing the new market opportunities and challenges, manufacturing companies also need to break through the current bottlenecks in several aspects, strengthen R&D innovation, and create higher-quality, high-stability high-speed cartoning machine products to help pharmaceutical companies better meet.

With the rapid development of high-speed cartoning machine, there are many high-speed cartoning machines on the market. For you or your company, how to choose a suitable high-speed cartoning machine is a big problem. In this aspect, the industry shares several factors to consider when you choose a high-speed cartoner.

The stability of the equipment

Only properly designed, solid and durable equipment can better withstand external forces and vibrations and adapt to different production environments. When purchasing a high-speed cartoning machine, it should be ensured that the cartoning machine manufacturer uses high-quality parts. Ask about the type of parts it uses, as well as the name of the manufacturer.

Customized Service

You can choose a manufacturer that can provide customized automatic cartoning machines according to their actual situation. The advantage is that, after minor changes to the design, it can meet the real needs of users.

The credibility of the manufacturer

You should consider the reputation of the manufacturer in the cartoning machine industry, and ensure that after the equipment is used, the manufacturer can provide timely support and help during the future maintenance period.

Sensitivity of the device

The market is constantly changing, and future packaging needs may also change. Therefore, when choosing a cartoning machine, the sensitivity of the equipment cannot be ignored.

It is recommended in the industry that if you estimates that the size of the carton or product will change in the future, then it is necessary to ensure that the equipment purchased can be modified, or whether it can handle cartons of different sizes.

In addition, you must find out whether the speed of the cartoning machine to be purchased can meet the current production and future speed requirements.

The area of the space occupied by the equipment

When choosing a manufacturer, first look at whether he can provide a variety of cartoning machines, so as to find a suitable model of packaging consumption line. For example, if a user buys a front-end product disposal device that occupies a relatively large area, he can choose a cartoning machine that occupies a relatively small space.

The cartoning machine is generally located at the middle end of the production line, and it should be ensured that the selected cartoning machine can be connected to the upstream and downstream equipment. Since a consumer line also includes various other machines, such as upstream bagging machines and wrapping machines, you need to ensure a manufacturer-specific integrated consumer line.

Delivery time

After determining the solution given by the manufacturer, you also needs to ensure all the production steps, including the process of design, procurement, assembly, testing, wiring and programming, supervise the completion and delivery time of their projects, and ensure that they have sufficient time to put into production.

Technical support

After the equipment is installed, the manufacturer should continue to provide technical support and after-sales service. Users can choose a supplier that can provide 24-hour service. If they are in different areas from the supplier, make sure that their location is within the service coverage area of the other party’s service.

In the end, the heavy responsibility of the development of cartoning machines still falls on the cartoning companies.

In order to invest more high-quality and high-tech automatic cartoning machines, cartoning equipment companies must not only consider technical factors, but also comprehensively consider all aspects of the problem from the perspective of the system.

For example, it is necessary to consider not only the product itself, but also the impact on the system and the environment; it is necessary to consider not only the technical field, but also economic and social benefits, both the current and the long-term development.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine