Knowledge You Need To Know About Flow Wrap Machine

China’s packaging machinery stats late, after more than 20 years of development, China's packaging machinery has become one of the industries in the machinery industry, providing an effective guarantee for the rapid development of China's packaging industry.

Some packaging machinery can basically meet the needs of the domestic market, and some products are also exported. But compared with developed countries, China is still far behind.

According to analysis, China’s packaging machinery manufacturing industry has problems such as lack of macroscopical planning; lack of capital investment, that is, the average level of investment in research and development by enterprises is less than 1% of sales; lack of professional and technical personnel.

In order to achieve rapid development of China's packaging machinery industry, it is necessary to start from the market and strengthen technological innovation.

From the perspective of product structure, packaging machinery manufacturers should be market-oriented, change the current situation of low-tech content and low-level competition, and eliminate a number of low-efficiency, high-consumption, low-grade, low-value-added, and labor-intensive products.

Strive to develop and produce large-scale complete sets of equipment and high-tech products with low consumption, production and sales.

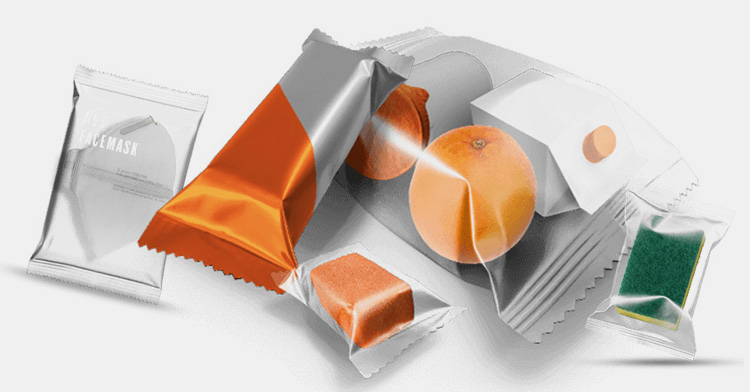

From the perspective of packaging functions, products should be refined and diversified, and packaging machinery products should develop towards the polarized direction of product multi-function and single high-speed.

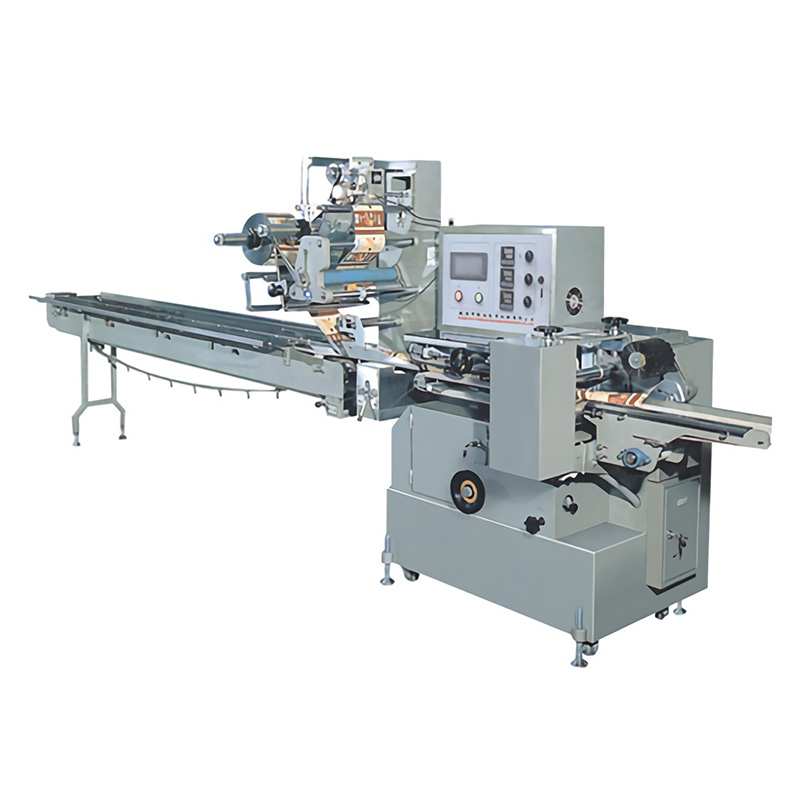

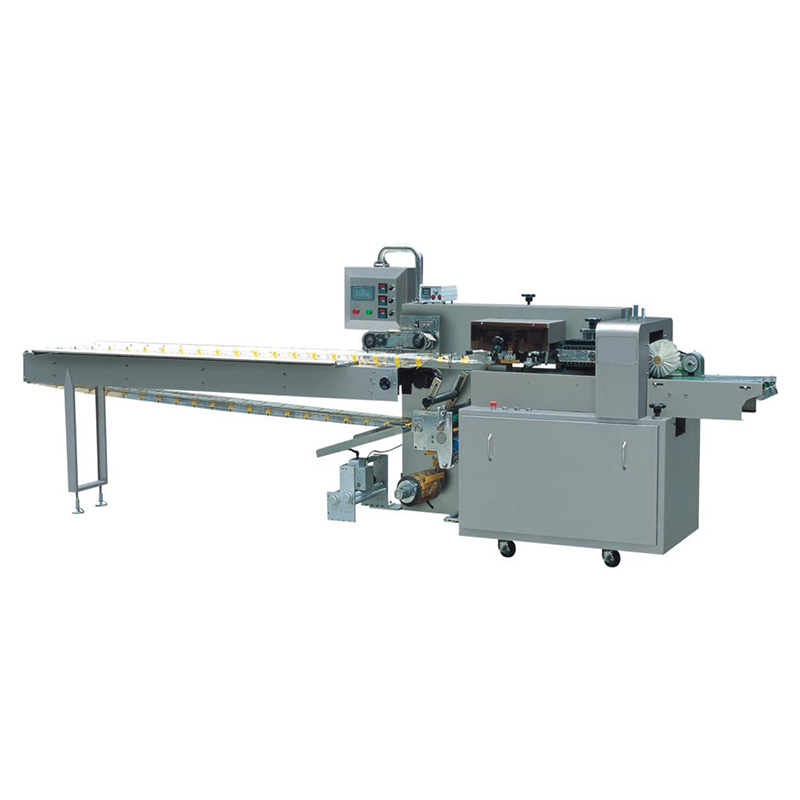

Take the flow wrap machine as an example. At present, most of the flow wrap machines in the domestic food and pharmaceutical packaging production equipment are backward products with low speed and high energy consumption.

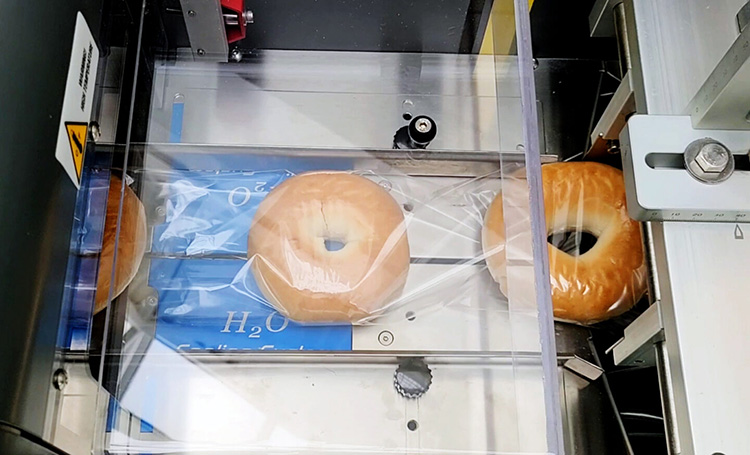

Enterprises must actively develop and upgrade products. The traditional pillow packaging machine must be improved according to the needs of the market. According to the survey of relevant data, the production speed of the flow wrap machine production line should be stable at 40-230 packs per minute, and the detailed data depends on the specific situation.

In addition to improving the speed, companies also need to improve the multi-functionality of the flow wrap machine, so that it can be matched with the metering device, which integrates bag making, filling, printing and counting automatically correct the deviation and automatically alarm and protect, thereby minimizing the loss of the machine.

Nowadays, with the rapid development of flow wrap machine and the market competition becomes more and more fierce, our machines also have a profound change and it has come into being a compete flow warp equipment system, owning a certain technical foundation of this machine.

On the road of future development, flow wrap machine companies need to have independent innovation capabilities, find the right position, and constantly create product images in order to achieve better development.

Professional in this industry said that due to the large demand for packaging in the pharmaceutical and food industries, the working intensity of the flow wrap machine is relatively large.

Therefore, this machine can only be operated, repaired and maintained strictly and correctly. More stable and effective for enterprises to improve production efficiency. The following points need special attention when you are operating the machine.

Check, repair and maintenance work

In the peak production season, companies should regularly check, clean and lubricate each pillow packaging machine, and at the same time, do a good job of heat dissipation and ventilation, and do not put the flow wrap machine in high temperature, humidity, dirty Indiscriminate use can not only prevent product contamination, but also prevent equipment performance from being affected.

In addition, the repair and maintenance of the flow wrap machine must be carried out by professional electrical maintenance personnel when the power is turned off.

Operator

The new operators should operate the machine only after they have a thorough understanding of the correct operation method and a thorough understanding, and in order to improve safety.

It is better to have professional teaching at the beginning, and unauthorized and professional personnel are not allowed to change the data and arbitrarily disassemble the machine.

As long as the flow wrap machine does not stop packaging, the operator cannot leave the post at will, and someone needs to take care of him when he leaves.

Safe question

In the process of packaging and production of pillow packaging machine, because the device for sealing and cutting film is high temperature, it is not allowed to touch the hot sealing wheel, sealing mold and moving parts at will to prevent burns.

It is also forbidden to put your own hair, gloves and clothing into the moving parts of the pillow packaging machine, so as not to be involved in accidents.

For a long time, China's manufacturing industry is mainly concentrated in the middle and low-end links, and the added value of the industry is low. With the development of science and technology, the competition in China's manufacturing industry is more and more concentrated in the fields of technology, equipment, and talents.

Therefore, the transition from low-end manufacturing to manufacturing is the only way for China to build an innovative country.

Nowadays, the traditional manual production mode can no longer meet the needs of the Chinese market. In the fierce market competition, enterprises are also in urgent need of transformation and upgrading. Automated or intelligent machinery and equipment have improved production efficiency and competitive power for enterprises.

In addition, with the prevalence of concepts such as green production, energy conservation and emission reduction, and sustainable development, traditional production methods are gradually being replaced, thus opening up channels for modern, intelligent and digital production.

China also gives great support to intelligent manufacturing. According to the data, the Ministry of Industry and Information Technology and the Ministry of Finance will continue to implement the special intelligent manufacturing project this year, arranging a total of 133 key projects in 25 provinces.

In recent years, China's pharmaceutical machinery industry has developed rapidly. Under the background of national policy support and the general trend of industrial development, intelligence is a wise choice for pharmaceutical machinery and equipment manufacturing.

The strong support of national policies provides the foundation and guarantee for the development of flow wrap machines. For this reason, China's flow wrap machine enterprises must continuously enhance the ability of technological innovation, and constantly learn, introduce and absorb foreign advanced technologies, so that China's pillow packaging machines can obtain Better and longer-term development.

Don't forget to share this post!

Flow Wrap Machine Related Posts

Flow Wrap Machine Related Products

Flow Wrap Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine