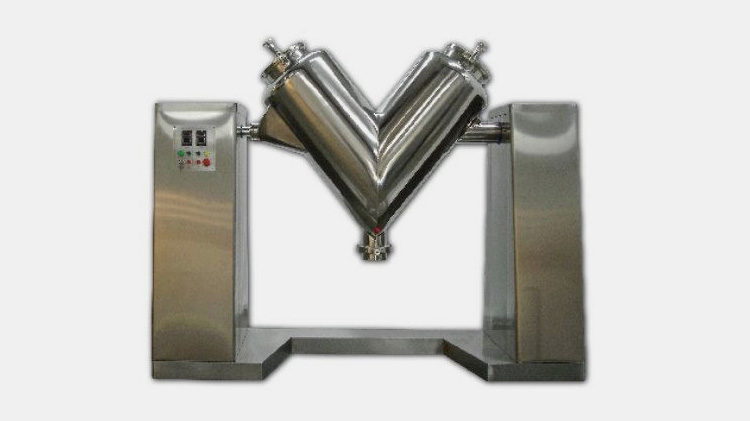

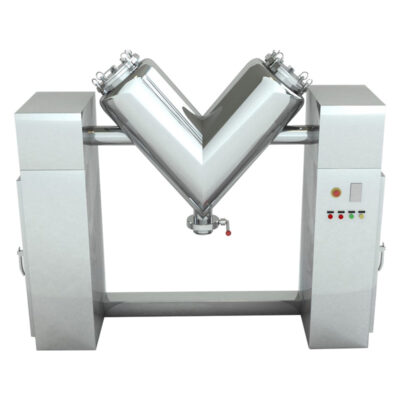

Knowledge Of High Speed Bin Mixer Points That You Can’t Miss

High speed bin mixer is a kind of mixing machinery equipment which is widely applied at present. This kind of machine with high efficiency mixing characteristics is favored and liked by many customers and manufacturers. For example: the application of raw material coloring, drying mixer.

In order to reasonably improve the production efficiency, the production of feeding method is more important. High-speed mixer belongs to a vertical mixer. The feeding mouth of the machine and equipment is generally higher than 1.5 meters above the horizontal plane. So what aspects should customers pay attention to when choosing the feeding method? There are several methods you can take as a reference.

First, screw feeder feeding. After the high speed bin mixer is installed in place, the screw feeder is used to feed the mixture pot, the height of the storage hopper of the general feeding machine can be freely designed and made. The height of the storage hopper is generally designed and made for 650-700mm in the industry. This height can effectively reduce the working intensity of the workers when feeding.

This method of feeding raw material powder, particles and other state materials, through the screw feeding. According to the size of the high-speed hybrid model, the feeding amount can be controlled by the level meter or time relay. Screw feeding machines with the features of fast, easy to operate, safety and other characteristics.

Second, vacuum feeding machine feeding. This is through the negative pressure vacuum feeding method. It is composed of a vortex air pump, suction pipe, suction pipe, vacuum bucket and electrical control cabinet.

Especially for powder feeding, it can effectively suppress dust spillover, and has the characteristics of fast feeding speed, small footprint and high degree of automation. Vacuum feeding machines can be placed according to the site situation, easy to use.

Third, manual feeding. Manual feeding is obviously time-consuming and laborious. It is necessary for the actual operator to climb onto the base of the mixer and open the lid of the pot to implement the feeding operation.

Screw feeder feeding, vacuum feeder feeding, manual feeding. These methods are high-speed bin mixer feeding method, friends can choose to use according to their own conditions. Screw feeding machine and vacuum feeding function to achieve automation. Relatively speaking, the overall high speed mixer application input cost is slightly higher.

After knowing the feeding methods, the most significant thing for customers is to learn the precautions for safe operation steps of high-speed bin mixer, which avoids unnecessary danger due to improper operation during the use of the machine.

First, you should carry out an empty operation to test the machine before using it. Before testing the machine, the fastening degree of all connecting parts of the high-speed bin mixer should be checked first, and the integrity of electrical equipment. Then, the main power switch should be closed, and the power supply should be passed to the empty operation to test the machine.

Second, hold down the safety switch by hand, then press the green start switch pay attention to the motor steering(clockwise rotation). If the direction is reversed, please press the red switch to stop and turn off the power and swap the wiring of any two phase lines.

Third, an empty run test machine. The high speed bin mixer can be put into production only if there is no abnormal noise, or the bearing gear is heated, and the temperature of the reducer is increased.

Fourth, in the process of use, if you need to scrape the material in the barrel wall of the high-speed bin mixer, use wood or plastic tools, do not use hands, so as not to cause hand injury accidents.

Fifth, in the use of the machine, if you find vibration or abnormal sound, you should immediately shut down the high-speed bin mixer for a comprehensive inspection.

Sixth, remember do not use too much load. In general, the load of high-speed hybrid electromechanical motor is measured. The heavy load current of 380V motor when mixing plastic is normal, which does not exceed the rated current of the motor. If the load is exceeded, the mixing capacity should be reduced.

Seventh, the management personnel must be familiar with the technical performance, internal structure, control system and application principle of the high-speed bin mixer. Do not leave the work site during operation to avoid machine failure and damage to parts, and ensure safe production is the premise.

In addition to the safe operations, there is another necessary thing for you after using the machine, Yes, that is the cleaning and maintenance work of the high-speed bin mixer.

During the use time of the high speed bin mixer, if you want to get the use effect, then you need to be able to do a good job of the daily maintenance of the equipment when using the equipment, so as to bring efficiency protection to the whole production. Many people in the use of equipment is because of the inability to do these things, because this leads to the entire production process can not get production efficiency.

The first step to do is to check whether there is a gas injection device in the grease adding pipe of the mixer.

The second step is to check whether the screen in the filter tank of the mixer is damaged.

The third step is to check whether the nozzle is blocked, adjust the angle of the nozzle, as far as possible not to let the oil spray on the wall panels and blades at both ends of the mixer.

The fourth step is to properly control the heating temperature of the oil to prevent the oil from being sprayed into the material and producing oil.

In the fifth step, the inspection screen of the finished product after mixing is added to the process, and the mixed oil mass is beaten and removed.

Many people do not do a good job in the daily maintenance of the high-speed bin mixer when using the high-speed bin mixer, so they can not get help in the process of using the equipment.

Do a good job in the daily maintenance of the high-speed bin mixer can make use of it to make the equipment keep a good state, which is certainly a good benefit, because once you can master the state of these equipment, it is bound to be able to get help when using these equipment.

Don't forget to share this post!

Bin Mixer Related Products

Bin Mixer Related Posts

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine