Important Points about Tablet Press Machine: the Complete Buying Guide in 2025

In fact,tablet is not unfamiliar in your daily life,furthermore,tablet press machine has a history of decades,and as time goes on,this technology is getting more and more mature.Until nowadays,table press machines have been used in many fields.

This article is to give a complete presentation of tablet press machine,I’ll introduce this machine from different aspects.If you happen to be interested in tablet press machine,just read on.

1.What is a tablet press machine?

Actually,tablet press machine is a device which can compress powder or granular materials into uniform tablets,which means that the tablets are in the same shape,size and weight.Tablet press machine can be used in large-scale production industries.

Tablet press machine is first appeared at the last century,and with the development of technology,there are more advanced tablet press machines have been created.

2.Why do you need a tablet press machine?

As well as known,nowadays,machines can help human do many things because the technology is develop rapidly and the production demand is getting higher and higher,that’s the reason why you need a tablet press machine.

In other words,instead of saying why do you need a tablet press machine,you can understand it as how can you benefit from using this machine,and the benefits are as follows:

High-speed

It is no doubt that the tablet press machine is quite efficient that it can finish the production task quickly.When you use a tablet press machine,you can produce lots of tablets in a short time.

High Pass Rate

As is mentioned above,the tablet press machine can compress materials to uniform tablets,it is hard to achieve by manual production.Generally, the pass rate of the tablets which are produced by tablet press machine is very high, and it is not easy to appear many unqualified tablets.

Sanitary

The tablet press machine is up to the standard of GMP,and in the process of tablet production, the material will not touch too much environmental elements,which can keep the finished tablet sanitary.

3.What are the requirements for the material to be pressed by the tablet press machine?

There are two types of materials can be pressed into tablets:powder or granular,however,not all kinds of powder and granular can be pressed by tablet press machine,the machine also has its own requirements for the materials.

First of all,the material need to be dry,the drier the better,it must not be moist.Perhaps you will ask why,well,if the material is moist,there is high possibility that it will sticks to the components of the machine,which results in blockage and wear.

Similarly,the material need to have a certain amount of mobility,to make the filling and pressing process more smooth.

Moreover,the material need to be in uniform thickness,and can not be too thick, or it will cause damage to the working components of the tablet press machine.

4.What are the applications of tablet press machine?

According to the market requirements,tablet press machine is widely applied in many aspects,you will find that it is closely related to your daily life.The tablet press machine is mainly used in the following fields:

Pharmaceutical Industry

As a matter of fact,the tablet press machine is commonly used in pharmaceutical industry,you can observe your medicines,many of them are in a form of tablet.But,why need to produce medicines into tablet form?

There are two reasons,on the one hand,the dosage of the tablet is accurate,the error of the drugs content is small;on the other hand,tablet is convenient to be carried and delivered.

Food&Health Care Products Industry

Probably,food tablets and health care tablets are not strange for you,either,such as compressed biscuit,dextrose candy,effervescent tablets,calcium tablet,vitamin tablet and so on.

The advantage is evident,these tablets are easier to storage,they are hard to be metamorphic,and they can be absorbed by your body quickly.

Chemical Industry

Besides,the tablet press machine can be applied in chemical industry,to produce some products which can make your life more convenient.As an example,laundry sheets,they can help you wash your clothes quickly and simply.

And there are other chemical tablets such as powder art, camphor aroma balls and pesticide tablets,etc.Likewise,they are all familiar in your daily life.

Electronics Industry

And another application field of the tablet press machine is the electronics industry,for instance,the button batteries.Button batteries are used in tiny electronics,if you wear a watch regularly, you're familiar with them.

Compared to the traditional batteries,the size the button battery is very small,it can be installed in small electric products which the traditional batteries can not enter,so that the electronics industry also need to use the tablet press machines.

5.How many categories of tablet press machines are there?

Generally ,there are four types of tablet press machines:single punch tablet press machine,flower basket tablet press machine,rotary tablet press machine and high speed tablet press machine.

Single punch tablet press machine

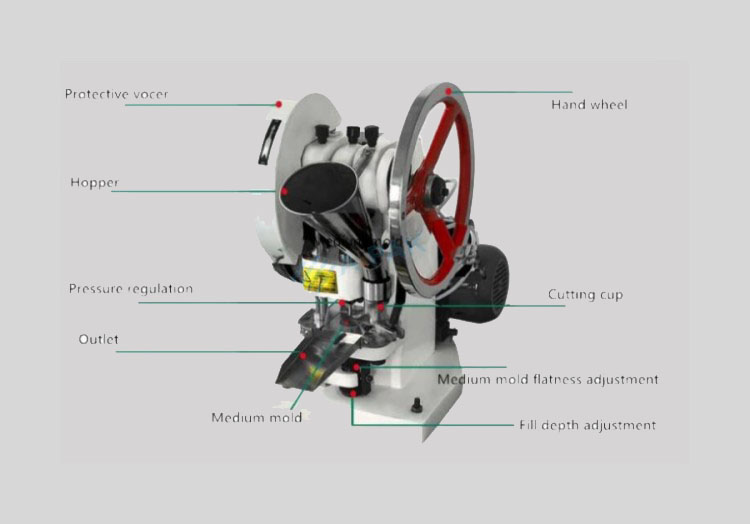

Aipak TDP-6 Single Punch Press machine

The single punch tablet press machine is a type of small size machine which compresses granular into round tablets.This machine is suitable for small-scale production demands such as pill tablets,candy tablets and calcium tablets.

Flower basket tablet press machine

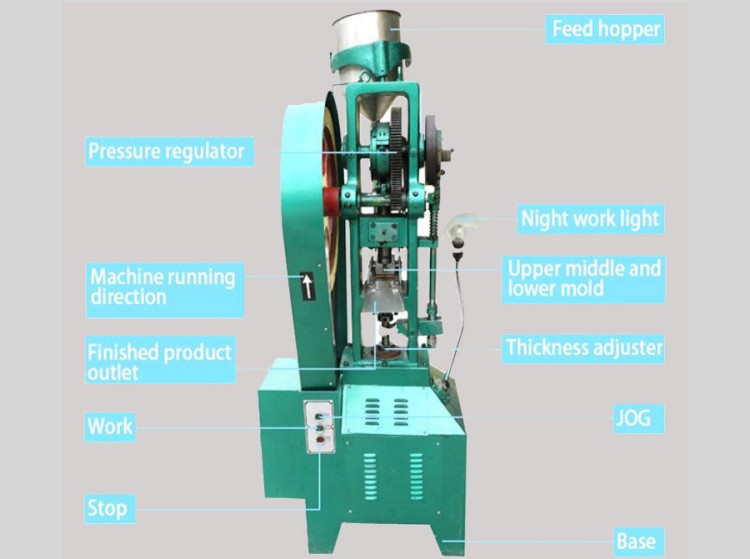

Aipak THP Flower Basket Tablet Press Machine

Flower basket tablet press machine is more multi-functional,it can produce various irregular shaped tablets,as a result,it plays an important role in tablet production and it is widely used in chemistry,food,pharmaceutical industries.

Rotary tablet press machine

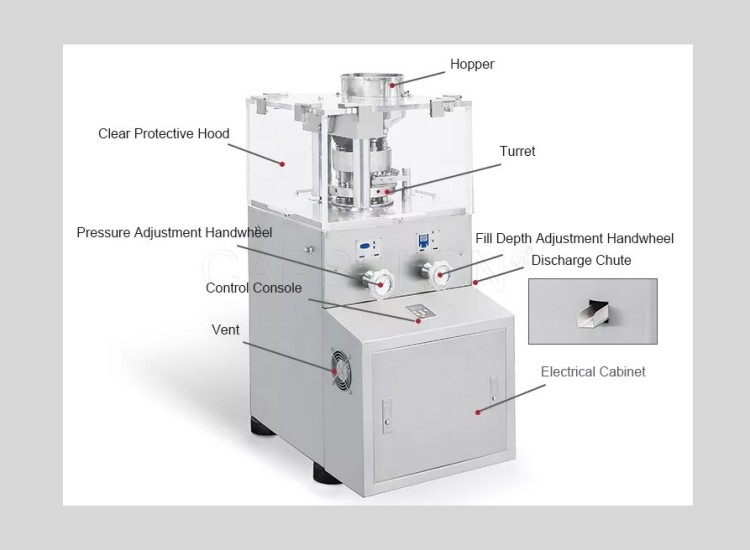

Aipak ZP21B Rotary Tablet Press Machine

Rotary tablet press machine is a small size electric continuous tablet pressing equipment,the tablets which are pressed out with this machine have even thickness and high gloss.

High speed rotary tablet press machine

Aipak High Speed High Capacity GZPS660 Series Rotary Tablet Press Machine

High speed tablet rotary press machine adopts a double pressure construction,which means that it can compress more tablets per cycle.On the basic of its structure,the production speed is pretty high,so it is suitable for large-scale tablet production.

6.What are the components of single punch tablet press machine?

As the picture shows,the structure of single punch tablet press machine is very simple,the main components of it are as the next:

Hopper

You can regard this part as the entrance of powder or granular materials,the original materials are filled into the hopper,and then entering the other parts.

Die cavity

Next is the die cavity,or you can say it is a mold of the tablet, materials are filled into it and then being shaped.This part determines the size and shape of the finished tablets.

Punches

For the purpose of compressing power or granular into tablet,punch is the vital part of the single punch tablet press machine.There are two punches,the upper one and the lower one,they press the material which is in the die cavity,to make it become tablet.

Cam truck

The function of the cam truck is to guide the movement and position of the punches,let them remove on an established trajectory.

Tablet adjuster

The tablet adjuster can control the volume of the material which is going to be compressed,in other word,this component can decide the weight of the finished tablet.

Ejection adjuster

As the name implies,when the production process is completed,the ejection adjuster will eject out the finished tablet from the die cavity.

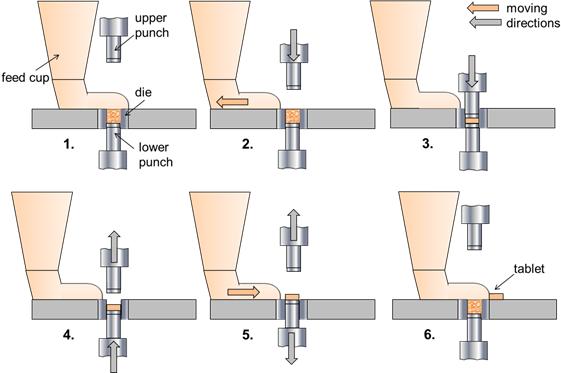

7.How does a single punch tablet press machine work?

Filling

At the beginning,the upper punch raises up and the lower punch drops down,to prepare a space for die cavity.And then the material in the hopper will fall into the die cavity,the filling process is finished.

Compression

At this stage,the punches will squeeze the original material which is in the die cavity continuously,under the action of pressure,the material finally becomes tablet.

Ejection

Next is the final stage,when the tablet pressing process is finished,the upper punch will retract while the lower punch is raising,as a result,the tablet is ejected out.

8.What are the advantages of single punch tablet press machine?

After knowing the structure and working process of the single punch tablet press machine,you may consider about the advantages of this machine.Well,they’ll be referred to below:

Firstly,as you can see that the single punch tablet press machine is in a small size and the structure of it is quite reasonable.As the saying goes:although spadger is small,it has all inner organs.That’s one of the advantages of single punch tablet press machine.

Easy to operate

Similar to the previous one,the single punch tablet press machine has a simple and easy-to-understand structure,so you can operate it without any problems,which reduces a lot of troubles.

Suitable for small-scale production

Sometimes,you don’t need to produce so large amount of tablets,then the single punch tablet press machine is an ideal choice for you,it’s suitable for small -scale tablets production and it will not occupy too much space.

Low noise production environment

Different to some large size equipment,the single punch tablet press machine can keep a low noise condition during its working process.It’s evident that such a production environment is more friendly to the operator,so there are some people prefer to choose the single punch tablet press machine.

9.What are the functional parts of flower basket tablet press machine?

The same as the single punch tablet press machine,the flower basket tablet press machine is also simple in its design,it just have six main functional parts which include:feed hopper,pressure regulator,tablet mold,outlet,thickness adjustment device and switch.

Feed Hopper

Obviously,this is the part which the material fill into the machine,the hopper is made of stainless steel,which means it is very hard,meanwhile,it is sanitary and it is confirming to the GMP standard.

Pressure Regulator

As the picture shows,the pressure regulator is under the feed hopper,it plays a role in adjustment,it means that it can control the pressure which is added to the tablet.

Tablet Mold

Next is the tablet mold,this is the place where tablet is shaped.According to different table production requirement,the tablet mold can be replaced to different sizes and shapes.

Outlet

After the tablet is completed,it needs to be pushed out,you can see that the outlet plays this role.It is under the mold so that it is convenient for tablet to be ejected when it leaves the mold.

Thickness Adjustment Device

Another important functional part is the thickness adjustment device,the function of it is to adjust the thickness of the finished tablets.

Switch

You can look at the picture,there are three switch buttons on the body of the flower basket tablet press machine.The three buttons respectively refers to jog,work and stop,they will help you operate your machine easier.

10.How to use a flower basket tablet press machine?

Totally speaking,the operation of the flower basket tablet press machine is not difficult,after reading the next content you will learn how to use this machine.

At the first,you need to turn on the power of the flower basket tablet press machine,then click the button of work,let the machine start working.Furthermore,pay attention to the direction of movement,if it is the same as the arrow of the body of machine,it is the right direction,in opposite,the direction is wrong.

If the moving direction is wrong,don’t worry ,you just need to adjust any two live lines to let the direction go back on track.

The second step,you need to install the mold,put the lower mold on the top material screw,and then put the cavity mold on the working plate,let it inside the lower mold,after that,put a cloth in the cavity mold and put upper mold into it,then tighten the screw.

Don’t forget to check whether the position of the mold is correct,if it is normal,then you can start the compression.

Next,click the button,let the machine start pressing,at the same time,you need to check whether the weight of the of the products is conformed to the requirements.

Then check the height of the top of the product,adjust the upper and lower molds,the top of the lower mold needs to be matched to the working plate. Then click the button,check whether the pressure is accord with the requirements.

The next step is to adjust the feeder,you have to rotate the gear,let the lower mold lift to its highest place,and then tighten the screw,repeat several times to check whether the feeder can push products successfully.

When you complete the steps above all,you can start your tablet pressing process.

11.What are the strengths of flower basket tablet press machine?

Why the flower basket tablet press machine is widely applied in many fields,it is because that it has many strengths,which are as follows:

Large Pressure

One of the strength is that the flower basket tablet press machine has a large pressure,which can make the materials form to tablet quickly,and guarantee the quality of the products.

What’s more,because the large pressure,this tablet press machine can compress large tablet to small capacity.

High Accuracy

Simultaneously,according to the different molds,the flower basket press machine can compress the material precisely,you can say that this machine has a high accuracy.

Stable Tabling Process

The movement of principal axis of the flower basket tablet press machine is driven by belt and gear rotation, so as to achieve continuous tablet pressing process.The whole tabling process is quite simple and stable.

Good Performance

It is no doubt that the flower basket tablet press machine has a good performance,the parameters of this machine are in a good standard.As a result,this machine can perform perfect during the working process.

High Yield

On the one hand,the cost of the flower basket tablet press machine is lower than other large machines;on the other hand,the speed of the machine is fast,so it can produce more tablets in the same time.In summary,the flower basket press machine is of high yield.

12.What are the components of rotary tablet press machine?

As is known,the rotary tablet press machine is also named multi-station tablet press machine,the structure of it is more complex than the two types machines which are mentioned above.

But,you may find that the components of the rotary tablet press machine are a little similar to the single punch tablet press machine,it has seven main components,they are as follows:

Die

The die is the mold of the tablet,this component can determine the size and shape of the tablet,and the die can be replaced casually,to meet the different production demand.

Turret

The turret plays a crux role in the rotary tablet press machine,when it turns for a cycle,it can take the die pass through the feeding mechanism,filling mechanism,pressing mechanism and ejecting mechanism,to achieve the process of continuous pressing tablet.

Feeding Mechanism

This part consists of the hopper and the moon shaped feeder,the hopper is on the top of the machine,and the shape of it is similar to funnel,the function of feeding mechanism is to storage the original material and feed it into the dies.

Filling and Adjustment Mechanism

This part is formed of feeder and filling track,It controls the amount of the material which is falling into the die.

Punches

Similar to the single punch tablet press machine,the rotary tablet press machine also has its upper punch and lower punch.During the pressing process,the punches give pressure to the dies which is between them,to let the material becomes tablet.

The Guide Track of the Upper and Lower Punches

Both the upper punch and the lower punch has its own guide track,the meaning of the guide track is to control the movement of the punches,therefore,they can press on the dies precisely,which also improves the efficiency of pressing.

Pressure Adjustment Mechanism

The pressure adjustment mechanism refers to the upper and lower pressure wheels,they are the real enforcer of the pressure,when the dies pass by the lowest point of the wheels,the pressure is at the maximum value,at that moment,the tablet is shaped.

13.What is the working principle of rotary tablet press machine?

In fact,the working principle of the rotary tablet press machine is on the base of the working principle of single punch tablet press machine.In addition,the rotary tablet press machine improves the problem of extracting air,the pressure is increasing and reducing gradually,so that the completed tablets are high-quality.

When the machine begins working,the original material will flow from the hopper through the feeder into the die which is placed in the constantly rotating platform.

The working principle of rotary tablet press machine is that when the upper punch and the lower punch rotate between the two pressure wheels,they compress the material into tablet.

This machine adopts a filling method of filling the track,which can reduce the difference of the each tablet’s weight.

14.What are the virtues of rotary tablet press machine?

This question is to introduce the virtues of the rotary tablet press machine,please read the next several paragraphs.

Save Cost

By the help of the turret,the rotary tablet press machine can quickly complete a series of operation with high efficiency,which means that you can invest limited cost,and gain high productivity.In other word,it means that you can reduce your cost.

Automatic Production

Moreover,the working process of the rotary press machine is highly automatic,it doesn’t need too much manual intervention,which can save the investment of labor.

Reduce Waste

Sometimes,the powder or granular material is expensive or rare,then the the advantages of the rotary tablet press are reflected,because of the high accuracy of the machine,the waste of the material is reduced,which can ensure that your material are well applied.

Meet High Requirement

The rotary tablet press machine can control the weight and hardness of the tablet,the error between each different tablet is very small,so that this machine can meet high production requirement to the tablet.

15.What is the construction of high speed rotary tablet press machine?

Relatively,the construction of the high speed rotary tablet press machine is the most complicated in the four types machines,and the components of it are more than others,they are as to below:

Upper Pressure Wheel Safety Device

The upper pressure wheel is installed in the left and right groove of the upper cover,and it is set on the crankshaft.Under the eccentric moment action of the crankshaft,the spring is compressed,and the distance of the upper and lower pressure wheels are increased,then the pressure is reduced.

This device is to protect the safety using of the components of the machine.

Upper Track Guide Device

The track guide plate is disc-shaped, and there are heat-treated guide plates around it, which are tightened by screws.The groove of the tail part of the upper punch will move along with the convex side of the track guide,to do lift and down movement regularly.

Turntable Device

There are 33 vertical holes on the turntable,each hole has a die in it,the whole turntable is covered on a fixed vertical axis.While the machine is working,the turntable will rotate clockwise.

Turntable Outer Cover Housing Device

There is a transparent enclosure around the turntable, on the one hand, it is convenient to observe the running situation during the working process,;on the other hand, it can prevent dust, and ensure the hygiene of tablets.

Feeding Device

There are two sets of hopper and feeder,the front feeder is to supply the left pressing wheel, and the back feeder is to supply the right pressing wheel

Lower Pressure Wheel Adjustment Device

This device is to control the thickness and hardness of the tablet.The lower pressure wheel is installed in the groove on the two sides of the main body, and it is set on the crankshaft. The crankshaft is equipped with helical gear and worm which are connected. When the worm is rotated,the gear slow down and the crankshaft will rotate.

When the eccentricity of the crankshaft is upward, the pressure wheel rises and the pressure increases, the completed tablet is thin, on the opposite,the complete tablet is thick.

Filling Adjustment Device

The filling adjusting device is in the interior of the main body, and the moon-shaped filling track can be observed on the plane of the main body. The filling track raises and falls by the action of the spiral,to achieve the purpose of controlling the amount of filling.

And the filling track is divided to the front track and the back track ,the front track controls the amount of tablet pressing of the left pressure wheel, and the back track controls the amount of tablet pressing of the right pressure wheel.

Engine Base and Motor Device

The engine base is a three-dimensional square box, and the motor is mounted on the movable board of the engine base.

Powder Absorb Device

This device is at the right side of the engine base,there is a blower in it,and under the blower is the powder storage chamber.The function of powder absorb device is to deal the flying powder which is created during the production,to prevent the powder from falling into the turntable.

16.What is the working principle of high speed rotary tablet press machine?

Even if it seems that the high speed rotary tablet press machine has a complex structure,its working principle is simple.

The spindle rotation drives the pressure plate which is fixed on the upper and lower ends of the spindle,the punch on the pressure plate rotates with the pressure plate under the constraints of the upper and lower guide tracks.

There is a group of pressure wheels at the left and right ends of the spindle, and each group of pressure wheels is composed of a pre-pressing wheel and a main pressing wheel.

When the punch rotates to the place where the pressure wheels are,the pre-pressing wheel and the main pressing wheel gives pressure successively,under the influence of the pressure,the tablet is shaped.

17.What are the advantages of using a high speed rotary tablet press machine?

Of course that the high speed rotary tablet press machine also have many advantages,next,they will be elaborated one by one.

The first one is that the transparent glass cover of the high speed rotary tablet press machine can guarantee the safety of the operator,and it also can prevent pollution from the working environment.

The second point is that the high speed rotary tablet press machine has advanced LCD touch screen which can make the operation and adjustment easier for you.

In addition,the high speed rotary tablet press machine has a safety-cut-off mechanism,if there are any errors occur during the working process of the machine,it will give you a warning message.

And the high speed tablet press machine have a special pre-pressing function,the pressure is pretty high,it can compress tablet with a high efficiency.

What’s more,the machine has its own lubrication system,which can maintain the machine’s normal working,avoid the possibility of broken-down.

18.What are the common faults and solutions of tablet press machines?

In some cases,when you use your tablet press machine,there may be some faults,you need to make it clear that which part of the machine occurs problems,then you can find methods to resolve them. The common faults and solutions include:

For example,when the guide track is worn,there are three possible reasons.The first reason is that maybe the oil is lack or the quality of the oil is bad.You need to choose engine oil to lubricate,and pay attention to the operation,use a clean cloth to wipe the rest oil,and then use a brush to add a layer of oil evenly.

The second reason is that the material is too thin or too moist,if it is too thin,you need to add material gently to avoid the dust;if it is too moist,you need to dry the material and add lubrication to the guide track.

And the third reason is that the punch is dirty,the solution is simple,you just need to clean the punch until it can slide freely.

Besides,the pressure wheel is also easy to occur fault,the most common problem is that the pressure wheel is worn or the pressure shaft is damaged.If the pressure wheel is worn seriously,you need to change it.If the pressure shaft is damaged,you need to change it and adjust the material and pressure.

Otherwise,if the die is worn or the head of it is curving,you need to replace it.

And there is another situation that the feeder is worn or installed improperly,if the feeder is worn,you need to adjust its place,let it keep a certain distance to the working table.If it is installed improperly,you need to adjust the screws which are at the two side of the feeder,and then adjust the height of hopper.

Or,if the machine is vibrative in the pressing process,first you can check whether the cushioning pad is or the screws are loose,if it doesn’t the matter of them,you can check the rotation speed of the machine and adjust it.

However,these are just part of the problems which may occurs,you also need to consider the problems according to the real situations.For the purpose of avoiding problems,you’d better to maintain your machine regularly,check the components each one or two months.

19.How to choose a good tablet press machine?

Until now,believing that you have a knowledge about the tablet press machine,if you want to choose the most appropriate machine,there are some factors you need to think about.

At first,the most basic one,you need to consider the performance of the tablet press machine,that is to say,whether the machine is high-quality.But,it doesn’t means that you must choose the best machine,it just need to meet your production demand.

Then you have to consider the cost performance,blindly expensive or cheap are both unreasonable, you need to consider your costs and benefits and choose the best machine within your budget.

Next,your requirement of production capacity is also a necessary factor to be considered,if you just need small-scale production,the single punch tablet press machine and the flower basket tablet press machine is suitable for you.

If you need to produce large amount of tablets,maybe you need to look at the rotary tablet press machine or the high speed tablet press machine.

And another relevant factor is the floor space of your production place,how large is your workshop,the size of the tablet press machine need to conform to the size of space.

Certainly,the most important factor is your reality demand,this is just to give a suggest to you,finally you need to decided by yourself.

Conclusion

In a word,the tablet press machine is an important device which is used in pharmaceutical,food,electronics,chemistry and other fields,and it help you achieve high automatic production.If you have other problems about the tablet press machine,welcome to contact us.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours