HPMC Capsule: The Complete Guide in 2025

The administration of therapeutic medicine is a frequent and vital therapeutic procedure. The oral route of administration is a widely accepted method due to its advantages, particularly in young and elderly patients. A capsule that retains active ingredients in its sealed gelatin acts as a potential oxygen barrier, protects sensitive ingredients, and masks the unfavorable taste.

Capsules are solid dosage forms available in hard and soft shells. There are unaccountable diversities in capsules shapes, sizes, colors, single or multiple active ingredients, and mode of action.

Recently, after thousands of tests and trials Hydroxypropyl methylcellulose (HPMC) is introduced into the world of capsules. HPMC is a well-established form of a capsule that successfully replaced gelatin and is preferable used all over the world.

Have you ever questioned how your choice of drug is manufactured?

Or have you ever chosen a dosage form with your choice? (Capsules or tablets).

Are you conscious of whether a drug is originated from animal or plants sources?

In this guidance blog, we will give you a thorough overview of HPMC capsules extracted from verified sources.

So, we recommend you read the entire blog to know more about HPMC capsules.

Let's get into it!

1.What are HPMC capsules?

HPMC or vegetarian capsules are plant-derived capsules that have been derived from the cellulose of plants since 1998. HPMC capsules are a physically stable polymer that is highly resistant to extreme environmental conditions, possesses low moisture content, and is resistant to moisture-sensitive ingredients. In simpler words, they are acting as an insulator (block heat) against temperature or moisture. Hydroxypropyl methylcellulose or HPMC capsules are obtained from the cellulose of plants by hydrolysis and manufactured by the etherification process. These capsules are preferred worldwide in the food and pharmaceutical industries with extensive utilizing applications.

As HPMC capsules are labeled as vegetarian or vegan, people with dietary restrictions are preferably consuming them as they assume good and natural about it. These capsules do not contain any material extracted from animal sources hence they are regarded as 100% pure natural form.

Thus, HPMC capsules are not only a bonus for vegetarians but also the best product for many consumers who are concern about product stability, and solubility. Because HPMC capsules are not perceived with any potential disadvantages yet. Hence HPMC or Hypromellose is considered the safest drug for human consumption.

2.Do you know the difference between gelatin capsules and HPMC capsules?

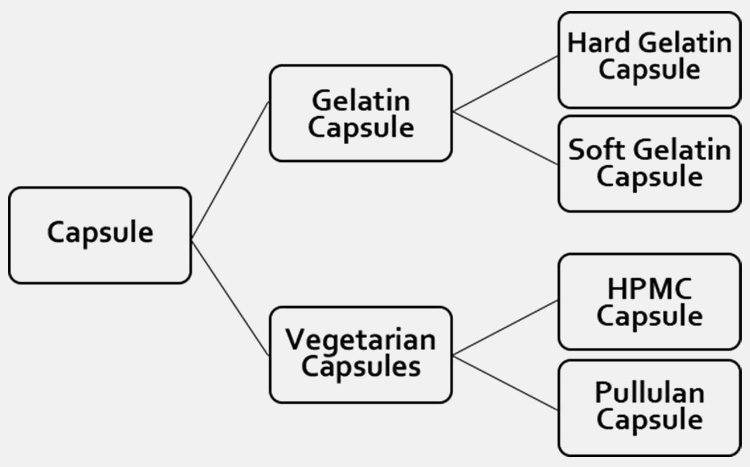

Diverse ranges of capsules are manufactured and developed to support the welfare of humans and other living organisms. For instance, gelatin capsules and vegetarian capsules (HPMC, pullulan, hard gelatin, soft gelatin, etc).

Sorting of capsule categories

The difference between gelatin and HPMC capsules are as followed:

1) Characteristics

HPMC capsules are highly stable as it retains a low moisture content up to 3-7%. whereas the stability of gelatin capsules is lower due to higher moisture content up to 13- 15% and more sensitivity toward extreme environmental factors such as temperature and humidity.

2) Cross-Linking

Formation of crosslinking is absent in HPMC capsules. Whereas cross-linking formation in gelatin capsules is very normal that lowers the solubility of capsules. The formation of crosslinking is induced by some specific filling substances, light, humidity, and extreme weather.

3)- Ratio of Tolerance toward Filling Material

HPMC capsules having a high tolerance for a variety of filling substances, for instance, those substances with the aldehydic group. Gelatin capsules are suitable for dry and powdery substances and may not be compatible with liquid or semi-liquid material for instance oil, or substances with aldehydic groups.

Liquid filled HPMC capsules

4)- Degradation of Capsule by Light

HPMC capsules are capable to remain stable in the presence of extreme weather and light. Although gelatin capsules have a tendency of degradation in the presence of light.

5)- Degradation of Capsule by Heat

HPMC capsules are capable maintain stability up to 80°C whereas gelatin capsules are stable approximately above 60°C.

6)- Oxygen Permeability

HPMC capsules have high oxygen permeability ratio whereas gelatin capsules have lower oxygen permeability.

7) Risk of Transmissible Spongiform Encephalopathy (TSE)

TSE or prion disease are infectious proteins that progress brain neurodegeneration. One of the reasons to get this disease is to consume animal products that are already infected with prions disease; thus, it can transmit and cause brain infection.

There are no chances of getting TSE transmission in consuming HPMC capsules whereas, gelatin capsules extracted from bovine sources may require all necessary certifications to ensure gelatin is free from TSE infection.

The choice is in your hand!

Despite the difference, both kinds of dosage formulations are widely accepted and beneficial in their ways. If you store them properly you can consume them for many years without any contamination. Both of them are versatile and diversified forms of formulations with various shapes, sizes, and colors. If you do not have any dietary or religious issues, then we recommend you opt for gelatin capsules as they are more cost-effective. If you’re more concerned about stability, solubility, and avoiding animal products, vegetarian products are the ideal to use.

3.What are HPMC capsules made of?

The HPMC capsules are made up of the following ingredients.

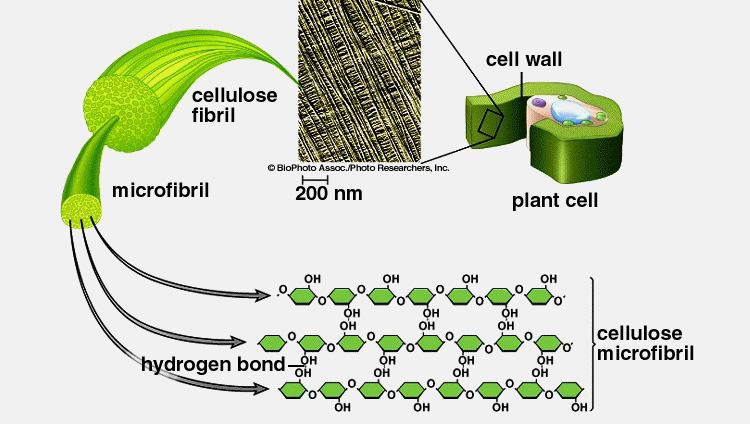

1.Hydroxypropyl-methylcellulose (HPMC)

HPMC is the main ingredient used in the manufacturing process originated from the wood pulp of softwood trees such as Pine and Spruce. HPMC is associated with the group of cellulose ethers where the hydroxy group is substituted at one or more hydroxyl groups in the cellulose ring.

A cellulose Microfibril

HPMC is a solid presence in off-white colors, it forms colloids when incorporated in water. HPMC is non-toxic and prone to combustions and oxidation. HPMC is a biocompatible polymer with a diverse range of applications in therapeutic drug delivery systems, paints, cosmetics, coating, etc.

2.Plasticizers

Plasticizers are used to reduce rigidity in capsules shell, induce flexibility and make it extra pliable such as sorbitol and glycerine. The ratio of plasticizers in hard gelatin capsules is approximately lower than HPMC capsules (0.4:1).

3.Water

Purified water is added depending upon storage conditions and manufacturing requirements.

4.Opacifiers

Opacifiers are used in the capsules manufacturing process in order to get an opaque system, for instance, titanium dioxide (TiO2). Opacifiers are extensively used in making paint, glass, plastic, and pharmaceutical dosage formulations such as capsules. Another important property of using an opacifier is to conceal and protect the filling content used in the capsule shell against biodegradation as well as photodegradation.

5.Colorants

Colorants are used to impart various colors to capsules. The addition of colorant may improve patient compliance and lowers the risk of errors during dispensing and administering a drug. For instance, dies, lakes, minerals, pigments, or mica.

4.How are HPMC capsules gaining momentum on the industrial platform?

Recently, HPMC capsules have gained high momentum on an industrial platform such as:

1) Nutraceutical Industry

The health and nutrition region has constantly been a highly competitive sector in the market. In this regard, consumers play a key role in deciding the right option. In this competition, innumerable players offer an extensive range of innovation, benefits, and awareness related to natural products.

In nutraceutical products, moisture content plays an essential role. Almost every nutraceutical product is sensitive to humidity and prone to reduce effectivity in critical moist conditions. Therefore, HPMC capsules are considered as suitable for this purpose.

Probiotics which upon administration yields beneficial effects to the host. Furthermore, probiotics are living organisms hence their incorporation needs careful consideration. HPMC capsules are excellent for target drug delivery systems such nutraceuticals that allow protection of formulations.

For more than two decades of encapsulation of various nutraceutical products, now they are moving away from using gelatin capsules. Recently this movement is primarily opted for HPMC capsules driven by user’s demand. Because many nutraceutical consumer are health conscious. Thus, primary target of nutraceutical companies for encapsulation of vitamin and supplement prefers HPMC capsules. Therefore, the health market trending toward HPMC capsules.

2) Pharmaceutical Industry

HPMC capsule offers a highly flexible and extensive platform capable of solving multi challenges that are currently faced by pharmaceutical industries. Furthermore, HPMC capsules have solved the problems of filling materials that have established supremacy overusing gelatin capsules. HPMC capsules are an ideal form of dispensing for those therapeutic substances that require a temperature control environment, rapid dissolution, and hygroscopic products.

3) Cosmetics Industry

The advancement and innovation in HMPC capsules have boosted up their industrial application on a wider platform. In recent years, HPMC capsules are extensively introduced in cosmetic industry as it meets all mandatory regulations of safety, stability, and emulsifying agents. They are ideal to dispense those cosmetic powders that are hygroscopic in nature such as collagen.

4) Unani Medicines

The Unani System of Medicine is one of the oldest and traditional methods used for the treatment of various diseases associated with organs of the human system.

Unani medicines are broadly expanded fields based on medicines extracted from natural sources. Therefore, they’re considered a natural source of treatment. To dispense various formulations (dry, semi-solid, liquid) in their original form without worrying about degradation. HPMC capsules are widely used.

5) Ayurvedic Industry

Similar to modern medicines in Ayurveda therapeutic substances are also dispensed in capsules. Previously it was filled in gelatin capsules which were refused by many individuals. How far it is true many vegetarians did not prefer this source of dispensing. Therefore, after the successful emergence of HPMC capsules, people ideally start taking Ayurveda medicines.

5.What are the different sizes of HPMC capsules?

HPMC capsules are available in 000 to size 4, while the ability of capsules to hole the weight is based on the density of powders. Powder in fine form has a lower density, therefore, assessing the quality of the powder is mandatory before the filling process. Furthermore, you can add fillers when dealing with a small number of active ingredients.

HPMC capsules are available in following sizes:

1) Size 000

Size 000 HPMC capsules have the ability to hold approximately 163mg.

2) Size 00

Size 00 HPMC capsules can hold approximately 118mg.

3) Size 0

Size 00 HPMC capsules have the ability to hold approximately 95mg.

4) Size 1

Size 1 HPMC capsules have the ability to hold approximately 75mg.

5) Size 2

Size 2 HPMC capsules can hold approximately 60mg.

6) Size 3

Size 3 HPMC capsules have the ability to hold approximately 47mg.

7) Size 4

Size 4 HPMC capsules have the ability to hold approximately 38mg.

Different sizes of HPMC capsules

6.Why do you prefer HPMC capsules?

There are innumerable advantages of HPMC capsules. The prime benefits of HPMC capsules are as followed:

HPMC Capsule

HPMC capsules are available in the form of empty shell that

allow you to use them for filling herbal supplements or any desirable ingredients.

HPMC capsules just require filling with active ingredients without requiring glue, filler, or coating etc. This is vegan friendly and easy to swallow as no one would prefer to consume capsules manufactured from boiled bones of the bovine or other animal sources.

HPMC capsules have no taste, smell or, colors. Some manufacture may add colorant according to choose of consumers.

The dissolution time of HPMC capsules is bit faster than the gelatin capsule. they often dissolve in five to ten minutes. Bovine gelatin capsules and tablets may take a longer time in the stomach, such as more like twenty minutes for capsules and, tablet disintegration involved minutes to hours.

HPMC capsules are the preferred dosage form for those who wish for non- GMO and are free from unwanted preservatives, or allergen, gluten, or and starch content in their medications.

HPMC capsules are beneficial for probiotic supplementation. As you already know, probiotic is living bacteria also termed as beneficial bacteria. But their activity may lose during the production, transportation, and storage process. In this regard, HPMC capsules are ideal that owing relative low moisture content and significantly advantageous.

HPMC capsules are a highly stable dosage form that is capable to overcome environmental fluctuations such as humidity, temperature, light, etc. Hence due to these properties, it renders longer shelf life of approximately five years.

HPMC capsules are Kosher and Halal certified dosage forms, available in a broad range of colors, sizes, and improved brittleness.

HPMC capsules are chemically stable that ultimately improves their dissolution profile.

7.What are the disadvantages of using HPMC capsules?

Overall, the profile of HPMC capsule is of great interest. With a lot of benefits, HPMC capsules have some limitations or disadvantages, but they are insignificant over a bunch of benefits.

The cost of an HPMC capsule is generally much higher than gelatin capsules.

The manufacturing of HPMC capsules requires high technology and complicated steps than gelatin capsules.

HPMC capsules have weaker shell- walls than gelatin capsules.

8.How to manufacture HPMC capsules in the industrial sector?

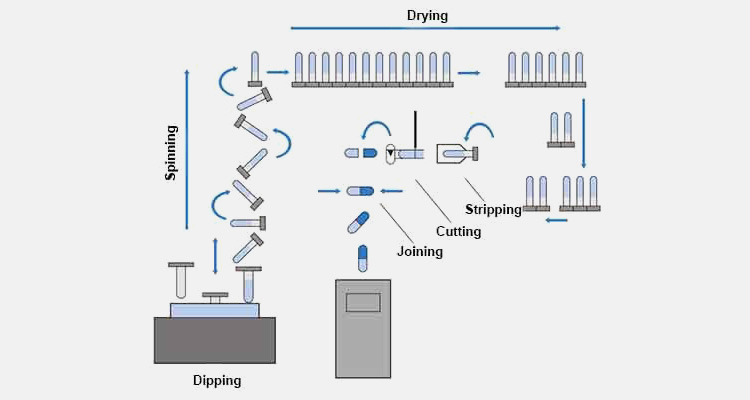

The manufacturing process of HPMC capsules is adapted from hard gelatin capsules. The manufacturing process of HPMC capsules involved similar steps such as dipping, mold, rotation, drying etc.

Let’s have a brief look!

Preparation of the Gelation System

The general preparation of the scheme of HPMC capsules includes mixing a polymer with purified water content with approved colorants as needed.

During manufacturing of HPMC capsules, certain intermediate steps distinguish HPMC capsules from gelatin capsules in the term of processing. For instance,

Gelation

In gelatin capsules, a homogenous film of gelatin is formed at a low temperature accompanied by cold-set gelation. Whereas an aqueous solution of HPMC is known to gel by heat-set gelation. This gel is completely reversible such as they are formed by heating while liquifies upon cooling. Hence, the degree of gelling strength depends upon the degree of methyl and hydroxypropyl substitution.

The strength of the gel is time-dependent and depends on the nature of additives.

Gelation

Gel Promoters

Lower gelling strength of HPMC film necessitates the addition of proper gelling promoters during the manufacturing system. Hence, different natural polymers are investigated such as the incorporation of carrageenan (kappa and iota) has been demonstrated great induction of gelation of HPMC at room temperature. This combination of the gelling system efficiently dissolves gastric fluid. Furthermore, gellan gum, EDTA, sodium citrate are important examples of the gelling promoter of HPMC capsules.

Gel Promoters- Carrageenan

Temperature Control

The manufacturing of hard-gelatin capsules comparatively required low temperature of dipping pins that should be maintained between 45 °C to 55 °C. For manufacturing of HPMC capsule, the dipping pin or molding temperature should be maintained at 70 °C. This temperature should be unaltered till the drying and stability of the film in order to attain an assigned shape of the capsule. This is noteworthy to suggest that moisture content is not considered an essential standard for HPMC capsule shell production.

Thus, a concentrated solution of HPMC is prepared by considering above mentioned ingredients and temperature. The process is carried out in jacketed pressure vessels which helps in maintaining temperature and removing air bubbles due to the application of vacuum to the solution.

In this step, you can also add colorant, pigments to attain the beautiful appearance of capsules. Now gelation is ready to transfer into controlled storage tanks where it is continuously deposited into dipping dishes.

2) Dip- Coating

HPMC capsules shell are manufactured under controlled conditions followed by dipping pairs of assigned steel pins that are arranged in a row of a metal bar. The entire process is maintained at 70 ° C so HPMC solution will be capable to stick the pins. As mentioned earlier, the reason for maintaining temperature is to get a decent homogenous film because temperature fluctuation may result in liquification of film on molds. The arrangement of dipping pins is arranged so that one row may form caps of HPMC capsules while another row may form bodies of the capsules.

Process of Capsule Formation

3) Rotation of Coated Pins

After achieving optimized stability of HPMC film on the surface of the mold. The bars contain pins are removed followed by rotation repeatedly to ensure an even distribution of HPMC solution around to get a uniform appearance and thickness of body and cap.

4) Drying

Once the HPMC solution is properly distributed on the mold, a blast of cooled air is allowed to set a solution on the mold. At this time, the solution is fully dried and optimum moisture content is achieved. It is noteworthy to mention that the moisture content of HPMC capsules is relatively lower than gelatin capsules.

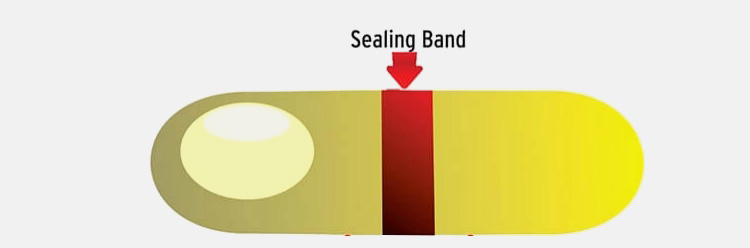

5) Sealing and Banding of HPMC capsules

Sealing of HPMC capsule facilitates high degree of protection against leakage of liquid material ultimately makes them tamper resistant, promotes stability and reduces the chances of oxygen permeation inside the capsules. Moreover, sealing of HPMC capsules also helps in masking the strong odor that is generated from filling material within its shell.

Banding of HPMC capsules is done at the sealing site of two parts of the capsules (body and cap).

Banding is most often achieved by using ethanol 50% w/w although ethanol is considered flammable and toxic due to its residual particles. However, in order to improve performance HPMC capsules are treated with gliding agents that overcome irregularities in sealing and banding edges. Moreover, ethanol-free banding is done using an HPMC water solution with little quantity of gelling agent (carrageenan).

6) Printing

Printing is done to improve identification, manufacturer logo, dosage details of the HPMC capsules.

Furthermore, printing also helps in reducing the risk of product mishandling, or errors by users include patients, caregivers, pharmacists etc.

9.Can filling material affect the stability of the HPMC capsule?

HPMC capsules are considered the gold standard for filling dry powder, oil, lipid, etc. Moreover, it is challenging to sustain the stability of the HPMC capsule shell with filling ingredients. Therefore, proper handling and storage conditions should be maintained to attain significant outcomes.

It is very challenging to encounter liquid filling material in hard-gelatin capsules as a shell of gelatin capsules have an affinity to react with filling content. In the case of HPMC capsules, you may easily fill liquid substance without compromising the stability of the shell. That’s why many pharmaceutical and nutraceuticals ideally opt for HPMC capsules to expands the shelf life of the filling material and capsules.

HPMC Capsules

Oil and lipid are conveniently filled in HPMC capsules if they are in a ‘liquid’ state and available below 35 °C. Furthermore, at this temperature lipids transformed into a semi-solid mixture. The formulation up to 80 °C can be encountered with HPMC capsules.

When you fill ascorbic acid in gelatin capsules, the capsule shell becomes brown. Although this problem did not occur when you fill ascorbic acid in HPMC capsules even at a higher temperature.

When salicylic acid was filled in HPMC capsules, 2% degradation was observed with HPMC capsules under 25 °C.

While the percentage of degradation of salicylic acid is higher in gelatin capsules.

For semi-solid excipients such as PEG, cottonseed oil, sesame oil etc, gelatin capsules shell can be a break for most of them. While propylene glycol is the only excipient that can lead to softening of the HPMC capsule shell.

10.What is another type of vegetarian capsule?

Vegetarian capsules are specialized capsules that are not manufactured from animal sources. These capsules are a highly demandable product among those people who prefer vegetarian sources instead of consuming animals’ by-products.

Thus, vegetarian capsules open a large horizon for vegetarians. vegetarian capsules are available in a diverse range with vast applications.

There are two main types of vegetarian capsules: HPMC and pullulan.

A capsule base cellulose is the most preferable substance that has gel composition.

Additionally, these capsules do not exert potential health risks even consumed for the long term because they are obtained from natural sources and nontoxic.

Pullulan capsules

Pullulan capsules are composed of pullulan and purified water.

Pullulan is a water-soluble mucopolysaccharide. Due to the good filming properties of pullulan, it is considered an ideal substitution for gelatin. Pullulan capsules demonstrate excellent features of natural vegetarian capsules. These capsules are fermented naturally by tapioca that meets high consumer demand across the globe. Pullulan capsules have extremely low moisture content with significant toughness. therefore, these capsules are considered ideal for dispensing water-sensitive drugs.

11.What are the basic types of HPMC capsule filling machines?

Various types of HPMC encapsulation machines are available in the market that can also utilize for filling of hard gelatin capsules. The selection machine this equipment is based on following criteria:

Nature of capsules

Production batch size

For encapsulation of HPMC capsules following categories of machines are used:

1) Hand operated HPMC Encapsulator

2) Semi- Automatic HPMC Encapsulator

3) Automatic HPMC Encapsulator

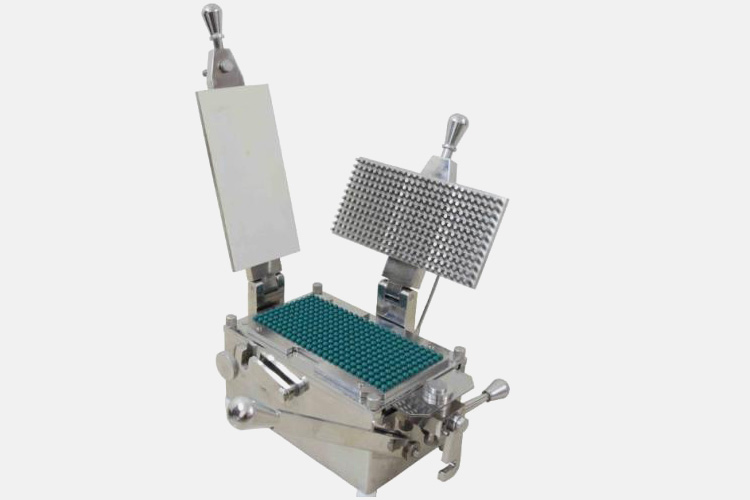

1) Hand operated HPMC Encapsulator

A hand operated, manual or tablet top HPMC capsule filling machine is ideal for pilot and small-scale filling procedures. This equipment is comprised of three hundred holes that are constructed using stainless steel conforms with GMP requirements.

Hand operated HPMC capsule machine is capable to run capsule filling of different sizes e.g., 000 to 4 for HPMC and 000 to 5 for hard gelatin capsules.

The entire assembly of this machine is flexible and easy to dismantle for cleaning procedures. Furthermore, as manual capsule filling machine carries all major procedures manually therefore, their operation requires highly skilled personnel.

Manual Capsule Filling machine

This machine is used in small laboratories, R&D, academic institutions, herbal as well as a nutraceutical, Ayurvedic, Unani preparations, and for pilot batch manufacturing. There are certain events that takes place during operation of manual capsule filling machine.

Load empty capsules: on loading tray and place into the shell hopper of machine.

Rectification: The orientation of capsules should in such as way that all must be in downward direction.

Separation:Caps must be removed from bodies of capsules. Pour and spread a pre-measured powder on powder tray. Then lower the tamper and secure it.

Joining:after filling caps must be re-joined with bodies to secure it.

Ejection: Capsules are ejected from capsule filling machine and stored in proper container.

2)- Semi-Automatic HPMC Encapsulator

A semi-automatic HPMC encapsulator is partially automatic machine. This machine is very simple to operate with high accuracy and lesser chances of errors.

This equipment is used on large scale production on industrial platform. Semi-automatic HPMC encapsulator machine is highly robust form of equipment that meets all basic quality standard assigned by international regulatory bodies to ensure hygienic, safe, and trouble-free filling of HPMC capsules.

AIPAK Semi-automatic capsule filling machine

3)- Automatic HPMC Encapsulator

Automatic HPMC capsule filling machine, fully automatic encapsulator or high-speed encapsulator machine is suitable for encapsulation of powders, granules, liquid, or semi-solid preparations. It implements indexing motion with the multi-position filling method. The tamping method of automatic encapsulator includes separation of body and cap, filling with optimum concentration, closing and ejection.

This machine is ideal for filling various capsule sizes ranges from 000 to 4.

AIPAK NJP-5500C Automatic Capsule Filling Machine

It has well-controlled production speed, with advanced designs, structure, safe and reliable for filling procedures.

This machine is ideal to run batch production on a larger scale. Automatic HPMC capsule filling machine is extensively used in nutraceutical, pharmaceutical, cosmetic, Unani and Ayurvedic therapeutic preparations industries.

12.How to store HPMC capsules?

Discussed below are storage conditions that must be followed during packaging, transportation, and storage. Hence by following these measures you can get HPMC capsules in a good condition up to five years from the date of manufacturing.

1) Packaging

HPMC capsules should be packed in food-grade anti-static plastic bags.

Plastic bags should be kept in corrugated boxes.

The corrugated boxes should be sealed packed using BOPP tape from top to bottom of the box.

These boxes should be labeled properly with the following mentioned information about, batch number, batch size, colors, box number, etc.

2) Transportation

The transportation of HPMC capsules should be carried out under a temperature-controlled environment. The dedicated vehicle must have a data logger sheet to ensure the transportation in the vehicle is maintained.

3) Warehousing

When HPMC capsules are not in use, they are stored in unopened condition. The recommended temperature and relative humidity must be between 20 to 35°C with relative humidity between 40 to 65%.

Furthermore, do not store capsules direct in sunlight, nearby hot water, or hot steam pipes. Boxes must be placed on pallets of the ground.

Caution

For any reason, if the capsules bag is opened then must be closed in such a manner that can be impermeable to the access of humidity, heat, or light.

13.Do HPMC capsules conform with international quality standards?

HPMC capsules are manufactured in compliance with the following international standards:

1) cGMP

HPMC capsules are a cGMP-approved product that ensures their consumption is safe and has passed controlled tests during manufacturing, processing, and packing of the product.

2) ISO 9002 Regulations

HPMC capsules are ISO-certified products that ensure this product is prepared under well-documented parameters that assure consumable safety at all levels.

3) FDA

HPMC is an FDA-approved product that ensures these capsules are effective and reviewed by CDER. These capsules do not exert any harmful effects on the body which is safe and work well on human system.

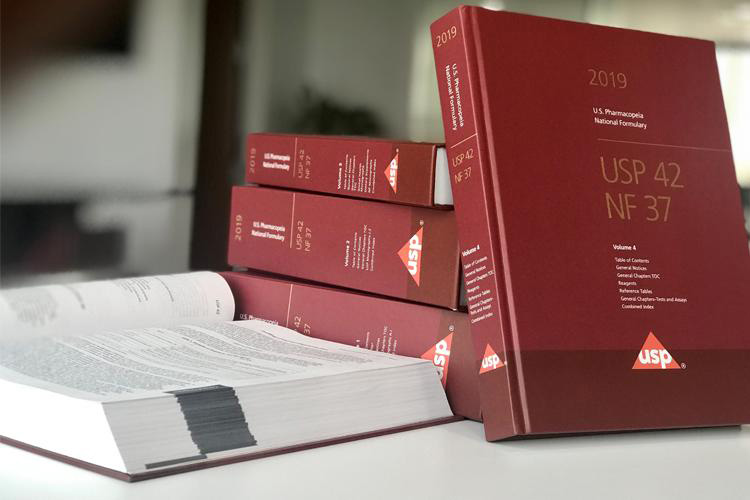

4) United State Pharmacopeia

A dedicated platform that assigns health standards for all FDA-approved drugs for compounding, pharmaceutical setting. Hence, HPMC is a safe product for general health system.

5) Japan Pharmacopeia

A modern pharmacopeia that summarizes practical techniques for drugs, drugs products, and drug formulation. HPMC capsules are Japan pharmacopeia-approved capsules with an established safety profile.

6) National Formulary

HPMC capsules are NF-approved products that are prescribed throughout the particular region e.g., US, British, China, etc. This includes information related to capsules ingredients, selection, administration, dispensing, and broad description.

Points to Remember

Empty gelatin capsules are also available in the market in two basic categories such as gelatin caps and vegetarian form. Both of them serve your needs. It is very important to understand the difference between gelatin and vegetarian capsules. Because it will allow getting potential benefits and the right choice.

If you are taking a capsule supplement, you must be curious to know the source of origination. Gelatin capsules, such as hard or soft are commonly derived from hydrolysis of the collagen of Bovine, swine, or fish.

That’s why, health-conscious, vegans or religious groups who are prohibited from using these products have been highly concerned with this issue.

Fortunately, advancement in medical sciences has substituted animal-based gelatin capsules for vegetarian capsules as a better alternative.

HPMC capsules are manufactured from 100% safe and natural sources with considered as:

- Easy to digest

- Hermetically sealed

- Bioavailable

- Acceptable

- Safe

Conclusion

Despite gelatin as the most widely used capsule, it has many disadvantages. The key challenge is to manage gelatin capsules with respect to undesirable phenomena of cross-linking, humidity, temperature and fluctuation of mechanical strength.

On the other side, HPMC capsules have successfully controlled all major complications. For instance, you won’t find cross-linking of capsules in HPMC due to the absence of amino acids. It exhibits longer shelf life, high mechanical strength in terms of temperature and relative humidity.

HPMC capsules have demonstrated superior properties to gelatin capsules that need to be more improved in the future.

Empty Capsule Related Products

Empty Capsule Related Posts

Empty Capsule Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours