How To Win The Planted-based Gummy Game?

Gummy provides consumers with a funny and convenient dosage form. When it refers to the consumers’ daily supplement projects, gummy can achieve higher compliance.

Gelatin is the most common and fundamental ingredient in gummy, and it is still the most common polymer that is used in these formulas. However, modern consumers become more and more fastidious. The product they want should be suitable for the specific lifestyle and the limitation of the food.

Over 75 million people obey the vegan, jew or muslim diet, so manufacturers must provide some supplements that without animal by- products(such as, gelatin) to satisfy these consumers’ requests.

It is vital to choose the correct plant hydrophilic colloid, because your choice of hydrophilic affects the sensory and cosmetic properties of the final gummy. However, making vegan gummy may be difficult. It is because of the flavor of the gelatin gummy---- the taste experience that consumers know and love---- it is hard to duplicate by using plant ingredients.

Plant-based hydrophilic colloids such as pectin, starch, carrageenan, AGAR, and gum Arabic are common alternatives to gelatin. Depending on the desired texture and sensory properties, these water hydrophilic can be mixed and used individually. Pectin was the most commonly used gel-forming agent: from 2020 to May 2021, every two servings of dietary supplement gummy contained pectin.

Preparing non-gelatin gummy also brings extra challenge in manufacturing and processing. Next, I will point out the common problems with which the formula designers are confronted when they change the vegetable gum, and how to overcome these problems.

The viscosity of the formulation may increase

In spite of removing the gelatin, the percentage of these polymers in formula is most likely to decline, but the distribution of the rest polymer’s may be different.

One of the most useful methods for decreasing gel stuck is to make sure your cooking and transfer equipment have adequate jacket and rated value to deal with the higher temperature demand for planted-based formula.

During the whole process, the range of recommended temperature of the typical planted-wasted is at least greater than 85°. Before changing the formula, it is critical for you to ensure that your equipment can reach and maintain this temperature.

The different in formula temperature demand

Add the heated gelatin is important in facilitating hydration, but make ensure the polymer’s (such as pectin) hydration is more significant. In order to achieve proper pectin hydration and the consistency of the final texture between batches.

It is vital for you to let the pectin and water mix under at least over 85°C at the initial hydration stage. Before proceeding with the change in formula, it is crucial for you to make sure your equipment can reach and keep this temperature.

The sensitivity in acid ingredient

The majority of planted-based polymers are sensitive to acid ingredients. High ester pectin depends on pH control mechanism to gelation. S o if you add acid ingredients in the manufacturing process(such as ascorbic acid or citric acid) to lower the pH of the gel prematurely, the pre-gel may destroy the batches.

In addition, when using seaweed extract and other polymer, gel may degrade due to the long time exposure and finally it will become weak and unstable. In order to eliminate the potential problems in the pre-gelation or gel’s instability, you should take special care to ensure that components may reduce the pH of the gel are as added as close as possible to the deposition step.

Keep the ideal pH value

As mentioned above, high ester pectin is the most common planted-based substitute for gelatin. It relies on the pH trigger mechanism to form the eventual colloidal texture, which is in contrast to gelatin and seaweed extract’s thermal gel mechanism.

As described above, you should pay attention to make sure that you add any acid ingredients as close as possible to the deposition step, buy you should take extra care to make sure an appropriate buffering system, such as sodium citrate to guarantee the PH valve of the final products keep an ideal range(about 3.2-4.0, it depends on ingredients in formula) during the whole shell life.

Gelatin can be remelted if it does not solidify properly, while inconsistent gelation in pectin can result in the entire production being scrapped. The variability of gel parameters needs to be tightly controlled to minimize production waste and delays, which can be very expensive and wasteful for manufacturers.

While deposition temperature and solid percentage are easier to control, controlling pH can often be overwhelming -- especially in the presence of flavoring agents, colorants, or active agents that differently affect the pH in a formulation. More control over pH can be achieved with buffer salts that stabilize the pH within a set range.

Additionally, the pH of the system may change when transitioning from gelatin to pectin. Therefore, it is important to access whether there are any potential stability challenges for active ingredients at this lower pH.

The setting temperature may be different.

One of the benefits is to enhance the final gummies’ thermal stability when using planted-based gel hydration to substitute gelatin. However, with the extra thermal stability, the extra technology is needed to promote the higher temperature required for deposition.

During the whole process of mixing, stewing and depositing, proper temperature control is the key to ensuring that gels are not exposed to temperature variations and will not lead to the problem of gel adhesion and batch failure.

In addition, you may need to optimize the dryer condition, because the planted-based gummy may solidify faster so that it will decrease the time of drying and adjusting.

You can make it.

Switching from gelatin to planted-based gum formulations is not without challenges, provides an excellent opportunity to expand your customer group and meet the needs of modern consumers.

This is also mainly because many people are turning to a vegetarian lifestyle because they want to live in a way that does not harm animals or the environment. While these are lofty goals, it's hard to find vegan foods that taste as good as animal-based alternatives. Therefore, the improvement and development of planted-based formulations are crucial for the entire society.

Don't forget to share this post!

Gummy Making Machine Related Posts

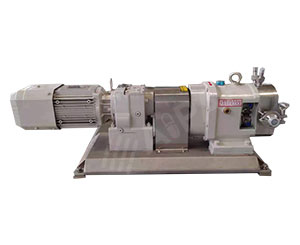

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine