How To Troubleshooting Common Problems Of Tablet Manufacturing Defects

In life, have you ever paid attention to whether the tablets you take have defects in appearance and function? How are the defects on these tablets caused? If you are a tablet manufacturer, do you have the same troubles and want to solve them?

Tablets are the most widely used dosage form among solid dosage forms. If you want to improve your tablet production technology, you must learn to check and control the problems encountered in tablet production and provide corresponding solutions.

This post is about teaching you how to troubleshoot common problems of tablet manufacturing defects. Through in-depth study and research, you can achieve a smoother tablet manufacturing experience and higher quality products. Let's find out together!

1. What Is Tablet Manufacturing?

What Is Tablet Manufacturing-sourced: sigmaaldrich

Tablets are one of the most widely used oral solid dosage forms in the world. Tablet manufacturing refers to the process of manufacturing tablets through tablet machinery such as granulation, compression, and coating. You need to choose the right manufacturing method and the right formulation excipients.

Tablet manufacturing is carried out by mixing, compressing, coating and other steps of active pharmaceutical ingredients and some fillers, binders, disintegrants, lubricants, colorants and taste modifiers.

2. What Are The Common Problems Of Tablet Manufacturing?

During the tablet manufacturing process, you may encounter some problems. Here are the common problems that may happen during the tablet manufacturing.

Common problems about the granulation process:

Common Problems In The Granulation Process-sourced: fabtechnologies

Granulation plays a very critical role in your entire tablet preparation process. Because the effect of granulation will directly affect the quality of subsequent processes. Let’s learn about the problems encountered during the granulation process!

Tablet Particle Size Does Not Meet Requirements

Tablet Particle Size Does Not Meet Requirements-sourced: researchgate

- When your tablet particles are thicker and the fluidity becomes poor, the weight difference of the extruded tablets will become larger;

- When the particles are too fine, the hardness of the extruded tablets will be smaller, and the tablet press vacuum will pick up too much dust, and your output rate will decrease.

Possible Reason

- When you make tablets, adding too much or too little binder will make the tablet particles coarser or finer in size.

Tablet Viscosity Does Not Meet Requirements

Tablet Viscosity Does Not Meet Requirements-sourced: topickaquarium

- During your tablet making process, you may encounter problems with tablets that are too viscous or too tacky.

Possible Reason

- The dosage of the tablet binder is not well controlled, or the speed and time of the tablet production process are not well controlled.

Uneven Content of Drug Ingredients In Tablets

Uneven Tablets-sourced: andarupm

- When the content of drugs or active pharmaceutical ingredients in tablets is uneven, the efficacy of the tablets will be inconsistent, which will damage the activity of the drug.

Possible Reason

- The method, time and dosage of lubricant you added are incorrect. After the lubricant is added, the equipment speed and time during mixing are not adjusted properly.

Tablets Do Not Contain Enough Water

Tablets Do Not Contain Enough Water-sourced: pharmasciences

- The water content in the tablet is also very important. Tablets with insufficient water content will have poor disintegration, which will affect the absorption of medicinal effects and greatly reduce the quality of the product.

Possible Reason

- If your tablets don't contain enough water, there may be a problem with the addition of the lubricant. The method, dosage and timing of adding lubricant are incorrect.

Common problems in the tablet compression process:

Tablet Compression Process-sourced: hassalesk

Tablet compression refers to the process of compressing filled and mixed drug granule powder into tablets to obtain complete tablets. It prepares your tablets for subsequent coating.

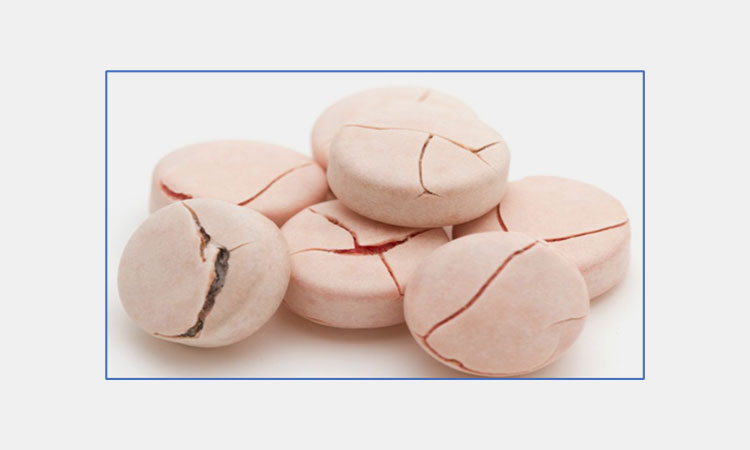

Tablet Cracking

Tablet Cracking-sourced: colorcon

- If your tablet breaks or cracks, it will be rejected. Being eliminated as substandard products will greatly increase your production costs and thus affect your production efficiency.

Possible Reason

- The ambient temperature and humidity of the tableting environment are too low;

- Insufficient dosage of binder or wetting agent causes the viscosity of the particles to deteriorate;

- There are too many oil ingredients in your prescription and the particles contain too little water, resulting in poor particle viscosity;

- If the particle size difference is large or there are too many fine powders, the hardness of the upper and lower parts of the pressed tablets will be different;

- It may be that the pressure of yourtablet press is too high or the speed is too fast, causing the air in the particles not to be discharged in time.

Tablet Flakes

Tablet Flakes-sourced: freemantech

- When your tablets are formed, if the hardness is too low, they will break with just a pinch of your fingers. When the tablets are bagged later, if they are shaken slightly, burrs or chips may occur.

Possible Reason

- Tablet granules contain too little water;

- You are not using enough adhesive or wetting agent;

- Yourprescription contains a lot of volatile oil ingredients;

- The particles have poor fluidity and the filling amount in the mold hole is insufficient;

- If the pressure of yourtablet press is too small or the speed is too fast, the tablets will loosen;

- If there are larger clumps or particles blocking the granulator and discharge port, which will affect the filling amount of raw materials, it will also lead to loose flakes;

- If the punch dies of your tablet press are of different lengths or some punch dies are too tight, the tablets will be subject to different pressures, which will lead to loose tablets;

Rough, Uneven, and Dented Tablets

Rough, Uneven, and Dented Tablets-sourced: ipharmachine

- A thin layer or a small part of the surface of the tablet is easily removed by the punch, which can easily cause the surface of the tablet to be rough, uneven or dented.

Possible Reason

- The granules in the tablet contain too much water;

- Insufficient or uneven amounts of lubricant in your formula;

- There are oil stains or water stains on the surface of the punch of the tablet press you are using;

- The proportion of fine powder in the particles is too high, resulting in high friction with the punch.

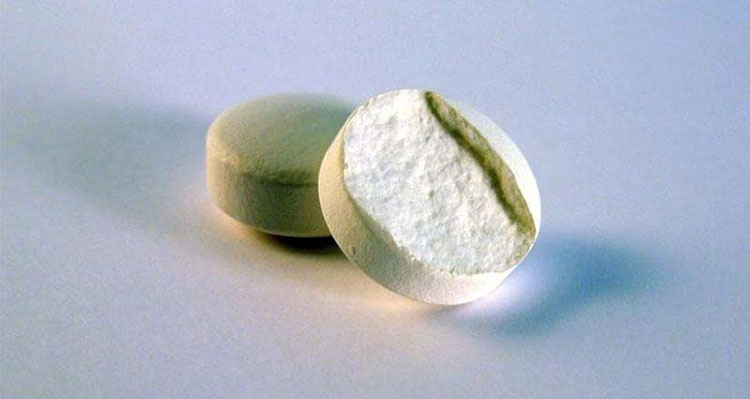

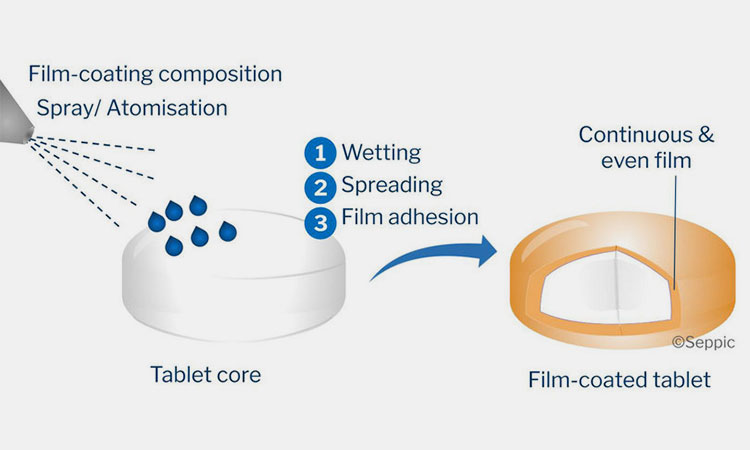

Common problems about the coating process:

Tablet Coating-sourced: syntegon

Tablet coating refers to using excipients to evenly wrap the surface of tablets, granules, pellets and other solid preparations to form a stable coating. This can help you improve the stability of the drug, covering the bad taste of the drug, controlling the release of the drug.

Coating Film Rupture

Coating Film Rupture-sourced: colorcon

If you use too much coating solution and the final drying is affected, the coating film will concentrate on the tablet surface, causing the coating mucosa to rupture.

Possible Reason

- When tablets are being dried, the air inlet volume is too low and the coating film is formed slowly;

- The drying temperature is too low, which affects the drying speed of the coating film;

- The rotation speed of the coating pan is too low, so that the coating film cannot completely wrap the outer surface of the tablet;

- The coating spray flow rate is too fast, the coating liquid cannot completely and evenly wrap the outer surface of the tablet;

- The distance between yourspray gun and the tablet bed is too close, which affects the coating range of the coating solution.

Coating Film Is Too Rough

Coating Film Is Too Rough-sourced: colorcon

- Due to the poor atomization effect of the coating and the sticky coating, the sprayed droplets are unevenly heated or concentrated, causing the coating film to be rough.

Possible Reason

- If the concentration of the coating solution you use is too high, the coating film will be too rough;

- The atomization effect of yourcoating liquid is not good.

Coating Film Peels Off

Coating Film Peels Off-sourced: pharmaeducation

- If the quality and dosage of the coating liquid you use are not properly controlled, it may easily cause the final coating film to fall off after it is dried.

Possible Reason

- The atomization effect of the coating liquid is not good;

- The mechanical strength of the coating film is too great;

- Yourengraving on the tablet surface is too complex, too fine or too shallow;

- There are too many hydrophobic ingredients in the tablet core prescription.

Uneven Coating Film

Uneven Coating Film-sourced: tech-publish

- Some of your film-coated tablets that are not properly controlled will have uneven colors, causing quality control problems.

Possible Reason

- Your colorant selection is incorrect;

- The coating machine you choose has poor mixing effect and dead spots;

- The rotation speed of the coating pan in the coating machine is too low;

- The atomization range of the spray gun is inappropriate;

- The covering power of the coating material is not good.

3. How To Troubleshooting Common Problems Of Tablet Manufacturing Defects?

Let's explore possible solutions. This will make it easier for you to make corresponding improvements when you encounter similar problems later.

Solutions to common problems in the granulation process:

Following the solutions below, you can get your best tablets quality with good appearance.

Standardize Your Tablet Particle Size

Standardize Your Tablet Particle Size-sourced: goerlich-pharma

- When your tablet granules are coarse, you can reduce the amount of binder added or the granulation speed and time;

- When your tablet particles are too fine, appropriately increase the amount of binder added or extend the granulation time.

Increase Or Decrease Your Tablet Viscosity

Increase Or Decrease Your Tablet Viscosity-sourced: tdptabletpresses

- If the tablet is too sticky, you need to reduce the amount of binder added or reduce the granulation speed and time;

- When the viscosity of the tablet is too low, you need to increase the amount of binder or extend the granulation time.

Add More Water Into Your Tablets

Add More Water Into Your Tablets-sourced: verywellhealth

- If the moisture content of the tablet is too low, you need to appropriately reduce the tablet drying temperature and time;

- When the moisture content of tablets is too high, you need to appropriately lower the drying temperature and time.

Add Lubricants In Tablets

Add Lubricants In Tablets-sourced: pharmaeducation

- Adjust the method and dosage of lubricant addition, and adjust the mixing speed and time.

Solutions to common problems in the tablet compression process:

Tablet Compression Process-sourced: pharmtech

There are good solutions to solve your tablet compression problems with easy operation and adjustment.

Solutions For Tablet Cracker

Solutions For Tablet Cracker-sourced: biolinscientific

- Reduce yourtemperature or time of the tablet drying process;

- Appropriately increase the amount of adhesive or wetting agent;

- Appropriately reduce the pressure or slow down your machine speed;

- Adjust your prescription, substitute or increase the dose of absorbent;

- You can properly sift some of the relatively coarse particles and fine powder;

- Properly increase the temperature and humidity of the air conditioning system.

Solutions For Tablet Flakes

Solutions For Tablet Flakes-sourced: pitchcare

- Appropriately increase youramount of adhesive or wetting agent;

- Reduce the temperature or time of the tablet drying process;

- Increase your tablet press pressure or reduce operating speed;

- Re-granulation or removal of large particles and clumps;

- Check the quality of the punching die and clean your die hole in time;

- Adjust your prescription and add absorbent;

Solutions For Rough, Uneven, and Dented Tablets

Solutions For Rough, Uneven, and Dented Tablets-sourced: pharmtech

- Adjust your drying time or temperature appropriately;

- Appropriately increase the amount of lubricant or adjust the mixing parameters;

- Increase the amount of lubricant appropriately;

- Clean the punch surface;

Solutions to common problems in the coating process:

Once the coating problem is solved, you can obtain complete and high-quality tablets.

Solutions For Coating Film Rupture

Solutions For Coating Film Rupture-sourced: seppic

- Increase the rotation speed of the pot;

- Reduce yourspray flow rate;

- Increase the distance between the spray gun and the film bed;

- Increase yourdrying temperature appropriately;

- Appropriately increase the air inlet volume;

Solutions For Rough Coating Film

Solutions For Rough Coating Film-sourced: pharmtech

- Reduce the amount of coating powder in the coating solution;

- Increase the atomization pressure, reduce the spray speed, and increase the distance from the spray gun to the film bed;

Solutions For Coating Film Peels Off

Solutions For Coating Film Peels Off-sourced: thomasprocessing

- Choose a coating solution formula with strong adhesion;

- Increase the atomization pressure or reduce the spray speed;

- Adjust lettering;

- Increase hydrophilic ingredients in prescriptions;

Solutions For Coated Tablets With Uneven Color

Solutions For Coated Tablets With Uneven Color-sourced: setylose

- Adjust the type of colorant, often using non-water-soluble colorants;

- Improve the structure and distribution of coating guide plates;

- Increase the rotation speed of the liquid-encapsulated pot;

- Adjust the spacing of the spray guns to ensure that the atomized areas do not overlap;

- Use coating materials of appropriate color for pre-coating;

Conclusion:

The tablet manufacturing is a process that needs continuous improvement. By constantly learn how to troubleshoot the common problems of tablet manufacturing defects, you can prescribe the right medicines and strive for excellence. If there are more you want to know, just come to us now!

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine