Do You Know How To Troubleshoot Common Problems Of Tube Filling Machine?

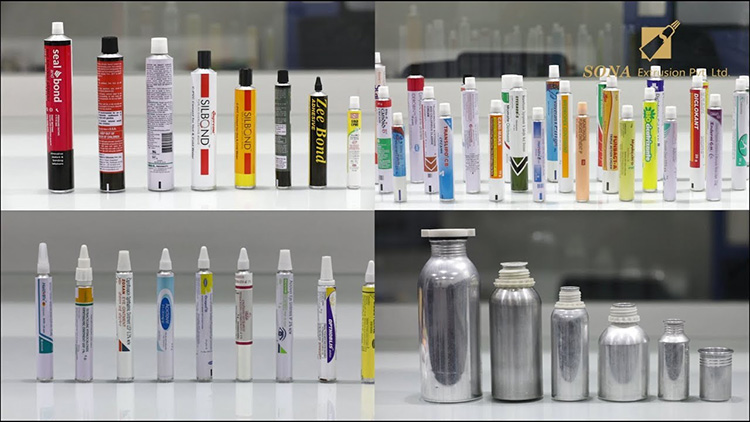

The tube filling and machine is suitable for filling hose, aluminum plastic pipe products, suitable for food, cosmetics, pharmaceutical. Chemical industry and many other professions, because of the wide range of application, beautiful finished products, high degree of automation, by the majority of customers.

With the tightening of the environmental protection policy of pharmaceutical profession, pharmaceutical machinery enterprises are closely following the policy trend, and quickly upgrade and innovate pharmaceutical machinery products. The tube filling machine as an important part of the pharmaceutical packaging profession, its green development will be the trend of the times.

The tube filling machine can smoothly and accurately inject all kinds of paste, viscosity fluid and other materials into the hose, and then finish the heating, sealing and batch number, production date of hot air inside the pipe. It is widely used in medicine, food, cosmetics, daily chemical products and other occupations of large diameter plastic pipe, composite pipe filling, is an ideal, practical, economic filling equipment.

Generally speaking, the tube filling machine adopts closed and semi-closed filling paste and liquid, sealing without leakage, filling weight and capacity consistency is good, which plays a very important role in the pharmaceutical packaging profession.

The transmission part is closed below the channel, which is safe, reliable and pollution-free. The filling part of the tube filling machine is installed above the channel, and the outer frame without static electricity can be seen in the cover, which is convenient for the operator to observe, operate and maintain. The tube Filling can also be selected PLC control, man-machine dialogue interface, the vane driven by CAM, faster speed, higher precision.

Problems in tube filling machine

First, the compressed air hedge transformer is blocked or improperly installed.

During normal filling, compressed air passes through two 1mm holes to form an air passage. When the set weight is reached, the measuring lever is lifted up, and the connecting rod baffle in the center of the transformer blocks the gas path and stops filling.

If the impurities in the compressed air completely block the transformer. It can not form air passage, LPG can not be filled. When the transformer is blocked but not completely blocked, the gas flux becomes smaller, so that the pressure valve behind cannot reach the requirements, resulting in slow filling. The filling is not immediately stopped, resulting in overweight.

The instrument transformer is installed on the high side, so that the measuring lever can be lifted higher and exceed the balance point of the scale, so that the baffle plate can block the gas path, resulting in the reaction lag of the scale and overweight filling.

The instrument transformer is installed on the low side, so that the measuring lever is lifted low and the balance point of the scale is reached at the end, and the baffle has blocked the gas path, resulting in the reaction advance of the scale and insufficient filling.

The instrument transformer is not properly installed, so that the measuring lever is lifted, and the baffle and the instrument transformer rub against each other, causing the lever to be lifted too slowly, resulting in overweight filling.

The solution is to remove the impurities inside the transformer and install it correctly.

Second, the pressure valve is too dirty or its air flux conditioning is improper.

Because the impurities in the compressed air enter the pressure valve and accumulate to a certain extent, it will block the internal gas pathway, the gas flux becomes smaller, the pressure valve can not reach the working pressure, the response is slow, stop filling is not immediate, resulting in overweight.

When the gas flux regulation of the pressure valve is too large or too small, it will cause the pressure valve to react too fast or slow, resulting in insufficient or overweight filling.

The solution is to remove the internal impurities of the pressure valve and adjust its gas flux correctly.

Third, the pressure valve leaks air.

Pressure valve internal rubber diaphragm aging loss of elasticity, diaphragm perforation, diaphragm installation error, will cause air leakage in the pressure valve.

When it is serious, all the compressed air from the stop button will leak, then press the start button, the filling display pressure gauge will show "fill air", and the compressed air will open the diaphragm valve and begin to fill air.

However, after releasing the finger, the pressure valve has no controlled air source, and a large amount of internal air leakage, the pressure will drop to zero. Diaphragm valve closes and filling stops. Make filling insufficient.

When the air leakage is not too serious, press the start button to fill the air. However, when released from the finger, the pressure valve slowly leaks air, and the pressure of the pressure gauge slowly drops to zero. Diaphragm valve closes and filling stops.

If the air leak is small, the cylinder can be filled before the air leak. It has little effect on the filling accuracy. If the air leakage is large, the cylinder will be stopped before filling, resulting in insufficient filling.

The diaphragm of the pressure valve is tightly mounted and not easy to remove. If forcibly removed, most will be destroyed, so the fault can only be completely solved by replacing the pressure valve.

Fourth, the start or stop switch is damaged

Damage to these two switches will cause the cylinder to be unable to fill or the filling to stop, respectively. That is, it causes insufficient or overweight filling. Only by changing the same parts can you solve the problem.

In order to reduce the impact of the above four problems, it is necessary to dehydrate the compressed air in time, remove oil and remove impurities: at least once a day to drain the water separator in the scale; Remove the above pneumatic component at least once a month for incomplete decomposition, check their internal conditions, clean up impurities, and ensure correct installation.

Although the troubleshooting time of the machine is accidental and unpredictable, in fact, these problems can also be effectively prevented. The most important thing is to do a good job in the repair and maintenance of the machine every day.

First, All lubricated parts should be filled with sufficient lubricant to prevent wear of parts.

Second, in the process of operation, the operator should standardize the operation, do not allow to touch the machine is running parts, in order to avoid personal injury accidents. If abnormal sound is found, it should be stopped in time for inspection until the cause is found out. After troubleshooting, it can be started up and run again.

Third, machine oil must be added to the oil atomizer (including the feeding unit) before each start of production.

Fourth, release the water of the pressure reducing valve after shutdown at the end of each production (including the feeding unit)

Fifth, clean the inside and outside of the filling machine. It is forbidden to clean with hot water higher than 45℃ to avoid damaging the sealing ring.

Sixth, after each production, clean the machine and turn off the power switch or unplug the power plug.

Seventh, check the sensor sensitivity regularly.

Eighth,tighten all connecting parts.

Ninth, check that the electric control circuit is connected and tightened with each sensor.

Tenth, check and test whether the motor, heating system, PLC and frequency converter are normal, and clean and test whether the coefficient parameters are normal.

Eleventh, check whether the pneumatic and transmission mechanism is good, and do a good job of adjustment and change the lubricating oil.

Twelfth, Equipment maintenance items shall be handled by the operator and maintenance records shall be made.

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine