How To Troubleshoot Common Problems Of Softgel Encapsulation Machine

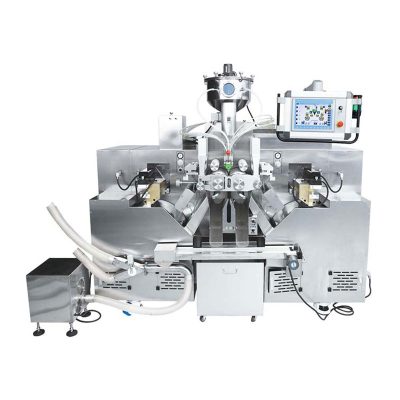

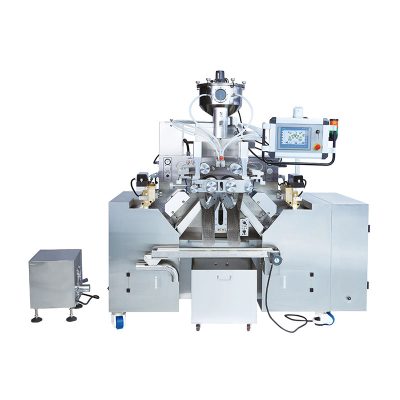

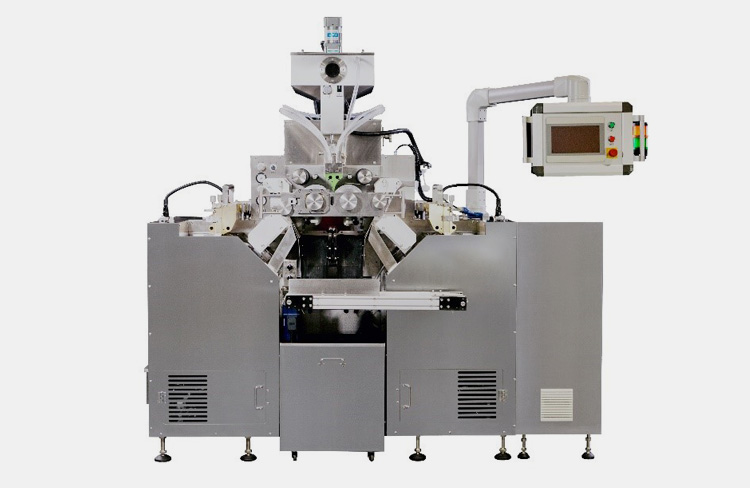

The softgel encapsulation machine integrates mechanism, electricity and gas, adopts microcomputer programmable controller, touch panel operation, frequency conversion speed control, equipped with electronic automatic counting device, the machine is sensitive to action, accurate filling dose, novel structure, beautiful shape, convenient operation, can automatically complete the capsule in place, separation, filling, locking and other actions, reduce labour intensity, improve production efficiency, in line with pharmaceutical health requirements.

It is suitable for filling all kinds of domestic or imported capsules. It is the most economical and practical equipment for filling capsules in the pharmaceutical industry.

Softgel encapsulation machine nowadays is widely used for producing the easy-taking softgel,or paintball,however,it may encounter some problems when using the machine,today I have summarized some of the best solutions to these problems,be careful reading through,which will help you boost your business and again more market share.

One, the capsule shell can not be separated.

Solutions:

- It should be the capsule shell itself,you mayneed to replace the capsule shell.

- Check if the vacuum is too small, you can get that fromthe vacuum table .

Vacuum is too small for many reasons. The reason of vacuum pump itself, find the mechanic to repair, or replace the vacuum pump. The vacuum pump is connected to the bladder shell separated from the air tube broken, you should replace the air tube.

The vacuum pump filter membrane is blocked, you should clean the filter membrane.

There are also reasons such as the water flow is too small, then you should replace the water flow pipe with a larger one.

However,specific problems require specific analysis. I have only listed a few simple ones here.

The gap between the module and the bladder shell separator is too large. Then you need either adjust the height at the bladder shell separator, or there is a problem with the module, or the telescopic rod in the module.

An analysis is needed to find a solution. Here may the powder is too fine or the powder is too sticky is prone the most likely problems.

The module is not aligned properly. You have to adjust the module with the adjustment rod until it falls into place automatically.

The powder is too sticky to block the module, then you should clean the module clean.

Second, the capsule head and tail concave

Sometimes the capsule shell itself is a problem, I have encountered a lot of this before.

This way you should replace the capsule shell on the solution. Then it is to check at the thimble, whether the height of the thimble needs to be adjusted.

Sometimes increasing the force area of the capsule can also solve the problem. Increasing the force area of the capsule is a matter of making a thicker thimble. This is what we heard from the capsule manufacturer, we did not do it at that time.

Third, the capsule rubbing split, this is a very headache, but also often encountered.

It needs to be treated carefully. This phenomenon generally occurs for the following reasons.

It may bethe capsule itself, the capsule cap and the capsule body difference is too large. Then you have to replace the capsule shell.

There is too much residual powder on the module,you also need to clean the module.

When installing the module, the upper and lower moulds are not aligned, you should re-align the module. Re-align the module until the setting lever can automatically fall into place.

In fact, there is a relationship with the size of the powder particles.

In the process of talking to others, they also said that there was a reason for this. I have not confirmed this. If this is indeed the cause, then this item should be added when doing the verification, whether the particle size can lead to the phenomenon of insertion and cleavage, and if it is confirmed that this phenomenon does occur, then you should consider whether it is time to replace the screen when the whole grain.

Whether the thimble is too high at the locking of the capsule shell.

To solve the splitting phenomenon, there is a method to try: shorten the distance between the upper die and the top plate, but of course the distance is too short to work.

The principle is: before the splitting occurs, it will be locked in place. This method does work and is the one I use most often.

On one occasion, I found a split in the lock and no amount of adjustment could fix it. I almost replaced the whole batch of sacs in the new factory, and then I used this method to solve the problem.

Fourthly, the difference in filling volume is too large, there is no fixed method for this.

Readjust the filling rod. This cause is basically directly related to the powder. If it is related to the powder, for the sake of the equipment, please refuse the filling directly and ask the granulation post to rework.

Fifth,the distance between the powder scraper and the dosing tray should be at 0.5 mm, as long as it does not touch the dosing tray.

The distance can be adjusted higher or shorter to directly affect the filling volume. Sometimes the loading volume is low, you can try to adjust the distance upwards. If the filling rod is not pressurised at the the most shortest distance, and the filling volume is high, please ask the granulation post directly to rework.

Sixth, the bearings at the exit of the finished product

The locking place and the rejecting waste sac are blocked, basically because the powder has gone in, then you should clean the bearings in time and apply the right amount of oil, adding butter to these places is better than applying oil.

After cleaning, you should ensure that the bearings have been dried, otherwise, they will immediately be blocked again. The bearings should be removed for cleaning and oiling each time the field is cleared.

Don't forget to share this post!

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine