How To Troubleshoot Common Problems Of Doypack Pouch?

Three common quality problems of doypack pouches

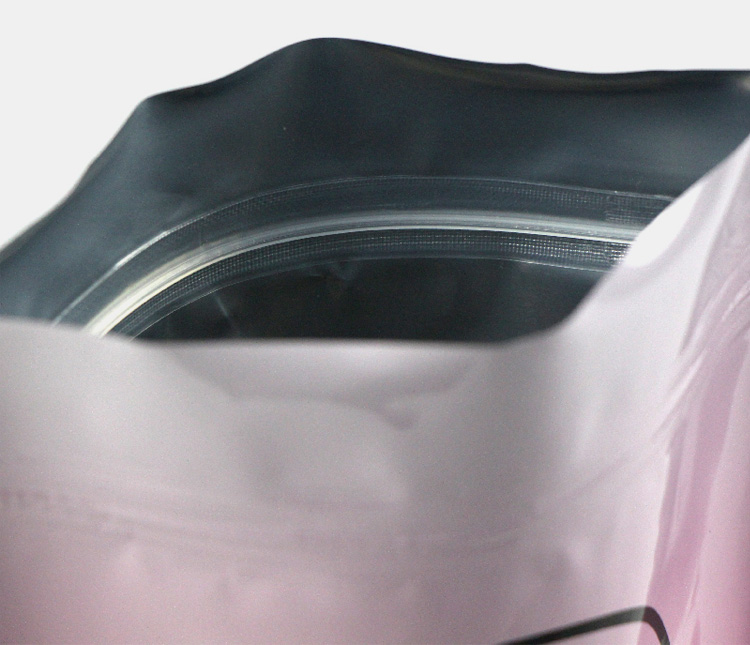

Doypack pouchleakage

The leakage of doypack pouch is mainly due to the selection of composite materials and heat sealing strength.

Selection of materials

The material selection of doypack pouch is very important to prevent leakage. The purpose is to improve the peel strength between the outer layer and the middle barrier layer, between the barrier layer and the heat sealing layer and the heat sealing strength of the pouch.

Therefore, the surface tension of the composite surface of the film must be greater than 38 dyn / cm; The low-temperature heat sealing performance of the inner heat sealing film is better, and the surface tension of the heat sealing surface must be less than 34dyn / cm;

In addition, you should choose inks with good connection performance, adhesives with high solid content and low viscosity, and organic solvents with high purity.

Heat sealing strength

Low heat sealing strength is also one of the important factors affecting the leakage of doypack pouch. During heat sealing, the matching relationship between heat sealing temperature, heat sealing pressure and heat sealing time shall be adjusted.

In particular, pay attention to explore the heat sealing temperature of pouchs with different structures. Due to the different melting points of different kinds of plastic films, the heat sealing temperature is also different; The heat sealing pressure should not be too large, and the heat sealing time should not be too long to avoid macromolecular degradation.

The heat sealing layer is cut by the heat sealing knife in the state of high-temperature melting, so as to reduce the sealing strength. In addition, the four-layer sealing part at the bottom of the doypack pouch is the most critical part. The heat sealing temperature, heat sealing pressure and heat sealing time can be determined only after full test and verification.

In the actual production process, the leakage test shall be conducted for the doypack pouch according to the different requirements of the contents.

The simplest and practical method is to fill a certain amount of air into the bag, heat seal the mouth of the pouch, put it into the basin containing water, and squeeze different parts of the pouch by hand.

If no bubbles escape, it indicates that the sealing tightness of the pouch is good; Otherwise, the heat sealing temperature and pressure of the air leakage part shall be adjusted in time. The doypack pouch containing liquid should be treated with more caution. Extrusion and drop methods can be used to detect whether it leaks liquid. For example, fill a certain amount of water in the pouch, seal the mouth, and detect it according to the pressure test method of GB / t1005-1998. The drop test method can also refer to the above standards.

Uneven bag shape

Flatness is one of the indicators to measure the appearance quality of packaging bags.

In addition to material factors, the flatness of doypack pouch is also related to heat sealing temperature, heat sealing pressure, heat sealing time and cooling effect. Too high heat sealing temperature, too high heat sealing pressure and too long heat sealing time will cause the shrinkage and deformation of the composite film.

Insufficient cooling will lead to insufficient setting after heat sealing, which can not eliminate internal stress and wrinkle the bag. Therefore, the process parameters should be adjusted and the cooling water circulation system should work normally.

Poor symmetry

Symmetry not only affects the appearance of doypack pouchs, but also affects their sealing performance. The most common asymmetry of doypack pouchs is often reflected in the bottom material part.

Due to the improper control of the bottom material tension, the round hole on the bottom surface will be deformed or wrinkled due to the mismatch with the main material tension, and the heat sealing strength will be reduced.

When the four layers are deformed, the tension of the hot sealing layer shall be increased at the bottom of the hot sealing layer, and the hot sealing time shall be reduced when the hot sealing layer is deformed.

In addition, the asymmetry of pouch shape is also related to photoelectric tracking, feeding, cursor design, rubber roller balance, stepping motor or servo motor synchronization and other factors. This problem should be solved in specific operation according to different products and different bag making equipment.

Don't forget to share this post!

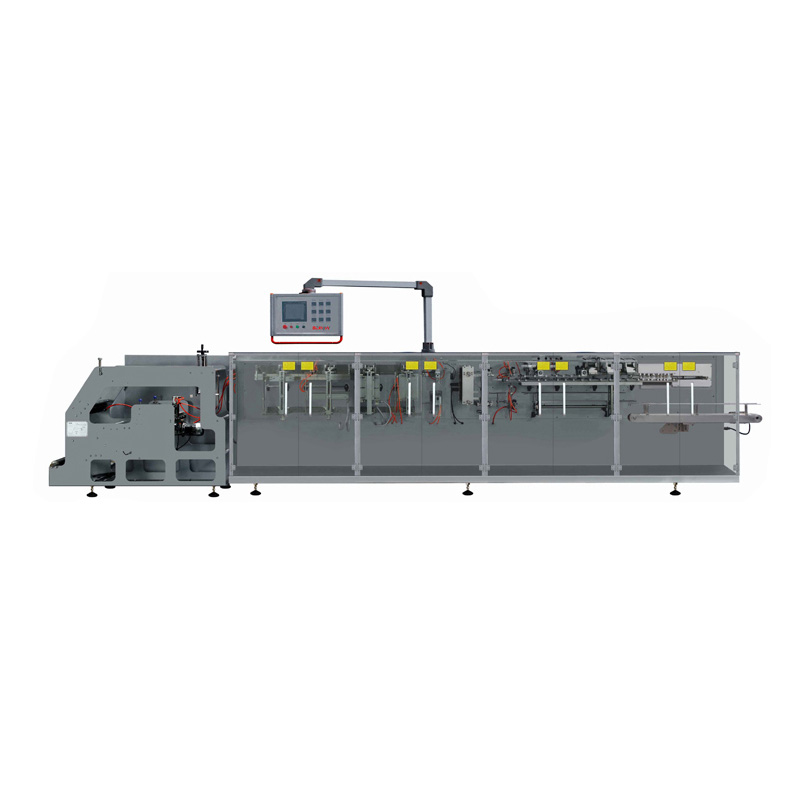

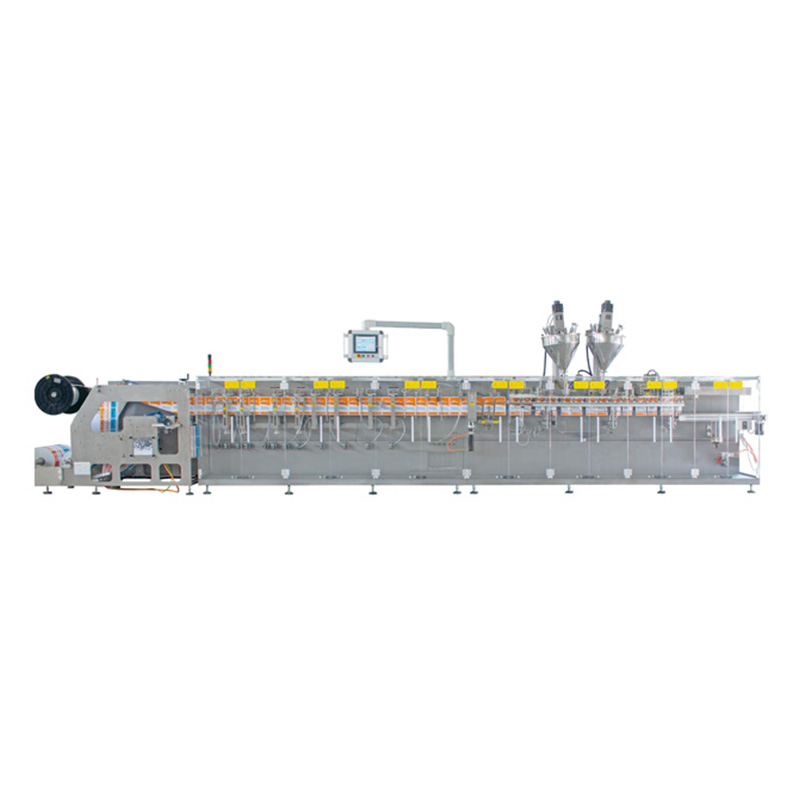

Doypack Machine Related Posts

Doypack Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine