How To Solve The Raw Material Absorbing And Low Uniformity Of 3D Mixer?

Do you know 3D mixer? It is the upgraded machine applied for the various mixing work. In the manufacturing process of 3D mixer, there may exist the absorbing problem and low uniformity. What a trouble! How to make the best work of this talented and wonderful 3D mixer?

How to solve the raw material absorbing and low uniformity of 3D mixer? What are the main 3D mixer type? What should be considered for your mixer selecting? What are the future developing trend of 3D mixer? Congratulation! You find the most comprehensive post to solve the all questions! Come on and have a reading!

1.What Is 3D Mixer?

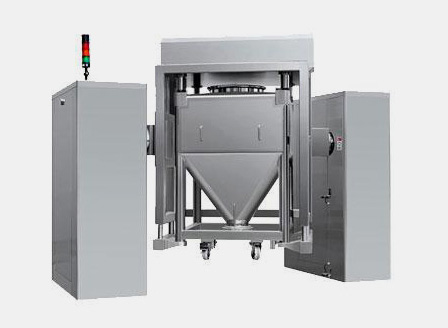

AIPAK 3D Mixer

3D mixer can make the quick and even mixing of various powder and particles. It can make a series of work like swinging, moving, rolling and so on. The three-dimensional working of this machine makes the high efficient work and its special name. It is the essential equipment for many powder and particle types.

It can make the stable, quick and outstanding mixing. The different function and its scientific design make the even blending of its various work. It has the wide application of various particle size and is suitable for both big and small scale production.

2.What Industry Can 3D Mixer Be Applied?

3D mixer is the helpful and efficient machine. And in many industries, it has the great application.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:matconibc

Pharmaceutical industry has the wide application of various powder or particles. The even and high qualified mixing is the premise of the reliable and great medicines. 3D mixer is widely used in pharmaceutical industry for its wide application and efficient work.

Food industry

Food Industry-Sourced:armanifood

There are various powder applied for food products manufacturing. The quality standard and hygienic standard of powder in food industry is high and you should apply 3D mixer for the efficient work. This machine avoids lump and other unqualified condition for your further work.

Cosmetic industry

Cosmetic Industry-Sourced:filtra

Cosmetic industry also makes the frequent use of 3D mixer. There is the great need of fine and even powder in cosmetic industry to give the efficient and careful caring for your cosmetic products. You may find your various cosmetic products which applied the machine.

Supplementary industry

Supplementary industry is booming in current market. You may find the various supplementary products type like powder, capsule, tablets and so on. The supplementary industry also needs the 3D mixer for the various material mixing.

3.How To Solve The Raw Material Absorbing And Low Uniformity Of 3D Mixer?

There may be raw material absorbing and low uniformity in 3D mixer work. For the problem solving, you may need the knowing of below causes and solution.

Causes

Material issues of equipment

Material Issues Of Equipment-Sourced:apecusa

The strong adsorption properties of 3D mixer may easily adsorb raw material particles. Certain metal surfaces may have tiny pores or rough structures which absorb the materials. This phenomenon is more evident when the raw materials are sticky or have surface-active properties.

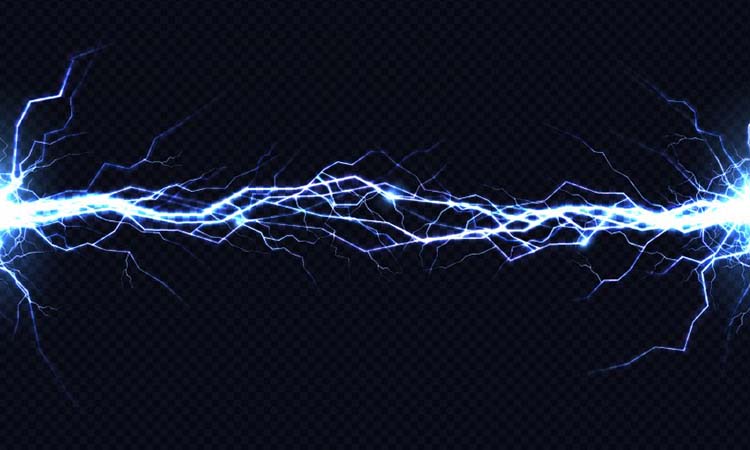

Electrostatic effects

Electrostatic Effects-Sourced:vectorstock

Static electricity comes from friction between the raw materials, the equipment walls and the particles. This static electricity charges the raw material particles. The increased adsorption force between the materials and the equipment causes the sticky of raw material and the content uniform.

Improper mixing process parameters

Improper mixing process parameters are varied. The short mixing time, unevenly mixed material can also cause the absorption problem of material by equipment. Besides, the high mixing speed can also cause some raw materials to be thrown onto the walls and absorbed.

Raw material property differences

Raw Material Property Differences-Sourced:foodandwine

There are significant differences in properties such as particle size, shape, density, and moisture content between different raw materials. The smaller particle sizes are more likely to fill the tiny gaps and be adsorbed. Besides, the material with higher moisture content is more easier to be stock by equipment.

Inadequate equipment cleaning

The residual materials or impurities from previous operations which comes from the previous cleaning problem may interact with the current batch of raw materials and increase the likelihood of adsorption. It can also affect the determination of content uniformity.

Solution

Optimize equipment material and design

Optimize Equipment Material And Design-Sourced:buntyllc

Change Materials

You may apply materials with weaker adsorption properties to manufacture the internal components of the mixer. Smooth stainless steel or PTFE linings are your great choice for the reduce of the adsorption sites for raw materials.

Improve Structure

You should optimize the mixer’s structure to reduce internal dead corners and gaps. It makes the better flowing of your material and reduces the absorption.

Eliminate static electricity

Install electrostatic eliminators

You should install static eliminators on the mixer, like ionizers, to neutralize the static electricity generated. It can also reduce the chances of raw materials adhering to the equipment due to static.

Increase humidity

You should increase the humidity in manufacturing places. The relative humidity between 40%-60% can help reduce static electricity.

Adjust mixing process parameters

Adjust Mixing Process Parameters-Sourced:vecteezy

Set optimal mixing time

The optimal mixing time ensures the thorough mixing of raw material and avoid low content uniformity which may come from insufficient mixing time.

Optimize mixing speed

You should adjust the appropriate mixing speed according to raw material characteristics and mixer performance. The fast or slow speed is bad for mixer manufacturing. Different speeds can be tested to find the optimal speed for uniform mixing and minimal adsorption.

Raw materialspre-process

Raw Materials Pre-process-Sourced:pishrochem

Adjust Raw Material Properties

You should adjust particle size, moisture content and so on to make their properties more uniform. You may sieve raw materials with large particle size differences or dry materials with high moisture content to reduce adsorption.

Add Anti-adsorption Agents

You should add appropriate anti-adsorption agents to the raw materials, such as talcum powder or magnesium stearate. These substances can form a film on the surface of raw material particles. The contact between the raw materials and the equipment is cut off.

Strengthen equipment cleaning and maintenance

Strengthen Equipment Cleaning And Maintenance-Sourced:aise

Regular cleaning

The strict cleaning protocols for equipment can ensure thorough cleaning of the mixer. The no residues of material in equipment can reduce the affect of raw material on your 3D mixer.

Inspection and maintenance

Regular inspecting and maintaining the mixer is essential. You should promptly detect and repair surface wear, scratches, or other issues to prevent uneven surfaces from increasing the likelihood of raw material adsorption.

4.How Does 3D MixerBenefit You?

3D mixer is widely applied in the various industries. Have you ever wondered the reasons. How does 3D mixer benefit you ?

High efficient

High Efficient-Sourced:33vincent

3D mixer is highly efficient. The machine can make the great work in making the even and great blending in a short time. For various particle type, your 3D mixer can make the great and highly efficient work.

East to operate

The machine is easy to operate. The entering of some simple parameter help your 3D mixer begin the operating for various particles and powders. The machine is friendly for user and the operator can begin the work with simple training.

Quality prove

Quality Prove-Sourced:jonble

With the help of the 3D mixer, you may have the high qualified powder or particle products. And the high qualified products is the premise of your great product sales. You can have your products quality proved with the efficient and powerful machines.

High flexible

This machine is highly flexible and for the various products, it can make the great handle. For pharmaceutical products, cosmetic products, supplementary products and food products, 3D mixer can make the great handling.

5.What Are The Main 3D Mixer Type?

3D mixer is the efficient and useful machines. And there are different types of 3D mixer with different features.

3D inverted swing mixer

3D inverted swing mixer is highly efficient which uses its two arms for the even blending work. The two arms and the three dimensional blending make the precise and even blending work.

3D double arm swing mixer

3D Double Arm Swing Mixer-Sourced:shaffermixers

3D double arm swing mixer is the special machine with two arms, bowl and other accessories. It makes the outstanding operating performance and can provide the great work for small scale production.

3D planetary mogul mixer

With three mixing mechanical arms and three dimensional bowls, 3D planetary mogul mixer can make the quick and large scale production with its three arms. The great performance can promote the faster work and larger scale production.

3D multi-motion mixer

3D Multi-motion Mixer-Sourced:alphie

3D multi-motion mixer is the excellent mixer which apply four mechanical arms for the fast rotating of your materials. The performance of this machine is excellent and can handle the most hard mixing. For the large production scale, it makes the nice performance.

3D triple axis mixer

3D triple axis mixer is also the advanced and talented machine which apply three axis for the blending and mixing work. It has also the excellent performance with its three skilled and powerful mixing arms.

6.What Are The Main Parts Of 3D Mixer?

3D mixer is the pretty and elegant machines. And here are the main parts of this machine.

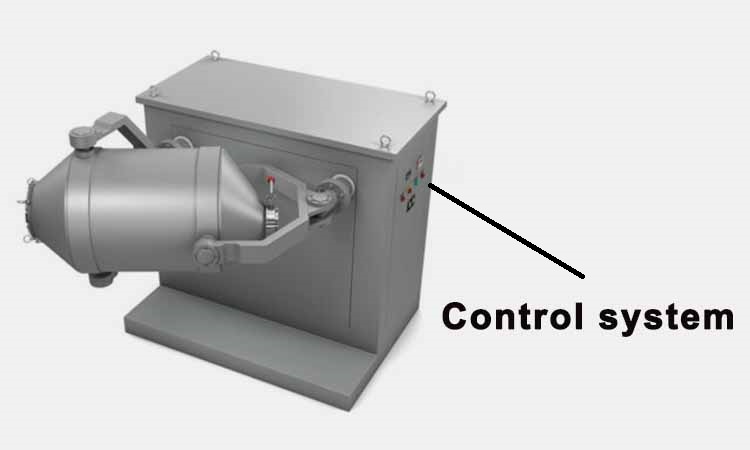

Control system

AIPAK Control System

Control system is like the center of 3D mixer. Control system helps make the connection with operator and machine. With it, you can make the direct connection with the machine and adjust the parameter according to your products’ feature.

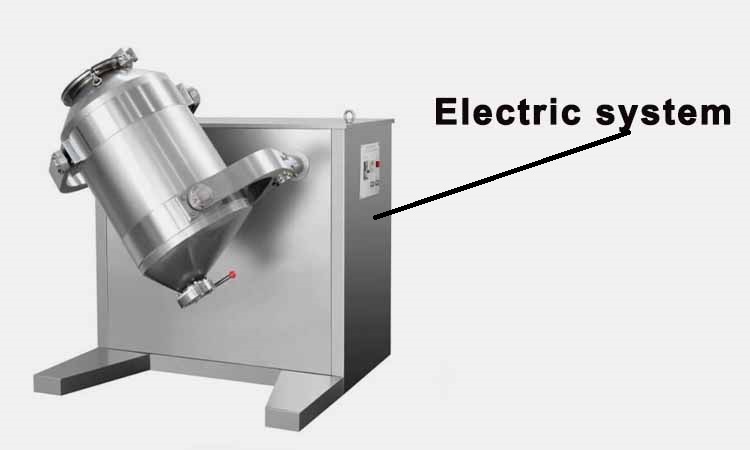

Electric system

Electric System-Sourced:vibrosievingmachine

Electric system provides the basic energy for your machine. And without it, you can’t begin your machines. For different machine size and type, there are different electric system of a 3D mixer. The suitable electric system can make the best work for your machine operation.

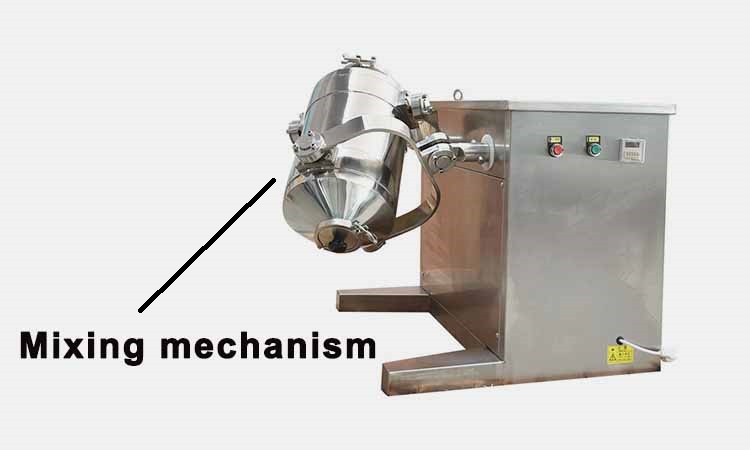

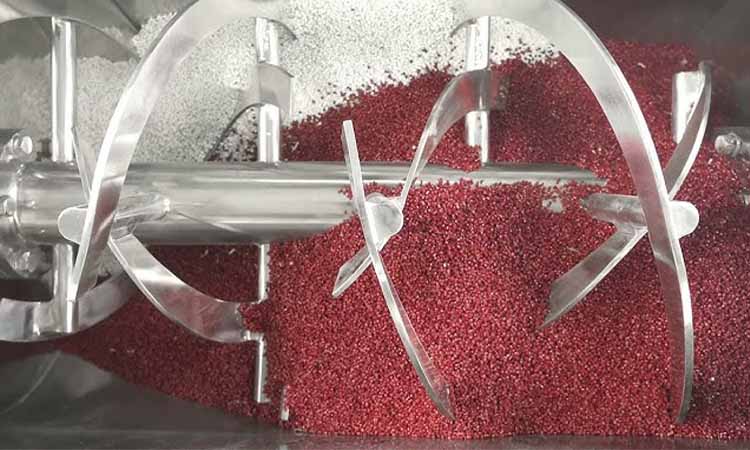

Mixing mechanism

ALLPACK Mixing Mechanism

Mixing mechanism is the center for the efficient and quick work of your various particles and powder. As mentioned above, for different 3D mixer size, there are different mixing type and number. The stainless steel mixing chamber is robust and stable and can handle the various mixing.

Discharge valve

Discharge valve makes the last step of the whole 3D mixer manufacturing process. There are different discharge types and you may find gravity discharge, screw discharge, air-driven discharge and so on. The great discharge valve makes the quick and smooth discharging work.

7.What Is The Working Process Of 3D Mixer?

3D mixer makes the great manufacturing work. Are you interested about the working process of 3D mixer?

Material prepare

Material Prepare-Sourced:rotovia

For the suitable and smooth operating of your 3D mixer, you should first make the careful dealing of the material. You may need make the cutting for your material to suit the particle size of your products. The connecting of 3D mixer with other machines can save you energy and time in preparing material. Besides, you should also make clear the different container of your machine type for the manufacturing.

3D mixer mixing

3D Mixer Mixing-Sourced:permixnorthamerica

After the setting of parameter, you can then begin the 3D mixer. 3D mixer began the mixing work with the two arms rotating. One arm is the driven arm and can make the horizontal rotating. Your products are blending and rotating in the cabinet in the three dimensional way. In the rotating and mixing, your products can be evenly mixed.

Material discharge

Material Discharge-Sourced:fmixer

For the well mixed material, you can them make the further work of discharging. You should stop the machines and them make the discharge. You would better to discharge your products in the clean and great container to see products quality. For any condition of bad quality or uneven mixing, you should make the quick response for the second mixing.

8.What Should Be Considered For Your Mixer Selecting?

For your 3D mixer selecting, you should follow the below tips for your expected and suitable machine.

Machine performance

Machine Performance-Sourced:ALLPACK

You should make the careful investigating about your mixer performance. Its capacity, construction material, blending time, efficiency and so on are all the important considering for your 3D mixer choose. For different production scale and production need, there are different machine for you to choose.

Maintaining difficulty

Maintaining Difficulty-Sourced:flaticon

After the decision of your machine type, performance and so on, you should also consider the maintaining difficulty of your machine. The simple and easy maintaining of your machines are the premise of your later maintaining and cleaning work. This is also the tips you should consider for your mixer selecting.

Budget

Budget-Sourced:freshbooks

How about your budget? How much you would pay for this part of your manufacturing business? You should choose the machines within your budget. There are machines with higher price and higher performance. But the one over your budget can not promote too much for your manufacturers.

9.How To Maintain Your 3D Mixer?

Your 3D mixer should be maintained well for the nice performance and long shelf life. Here are some of your tips of maintaining your 3D mixer.

Regular inspections

Regular Inspections-Sourced:cedarstoneindustry

You should make the regular inspections for your 3D mixer. You would better to make the schedule for your machine inspections. Month inspection or week inspection? It depends on your operating frequency. The regular inspections should be made with great care for the efficiency and benefits of your 3D mixer.

Cleaning after use

Cleaning After Use-Sourced:conspare

For your every use, you should make cleaning for your 3D mixer. You should avoid the residues of particles or powders on machine for it may lead rust for your machine. Besides, the cleaning of your 3D mixer after use can also prove the hygiene for your next round of products.

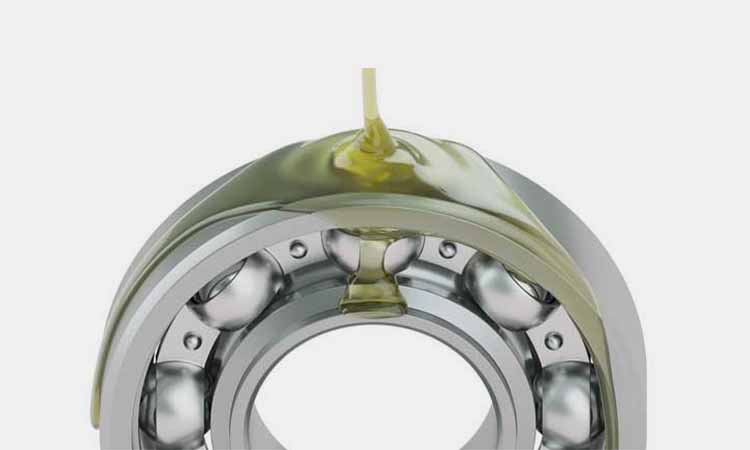

Lubrication for every parts

Lubrication-Sourced:machinerylubrication

You should make the lubrication for every parts of your 3D mixer. The lubrication reduces the friction produced in operation and protects the various parts of your products. Lubrication is essential thus for your operating. You should apply regular lubrication for the prolonging of your products.

Worn parts removal

Worn Parts Removal-Sourced:vibrosievingmachine

You should remove the worn parts of your 3D mixer. The remaining of the worn parts may lead the larger worn parts of your 3D mixer. And the worn parts can also lead the problem of your machine operating and your products quality problem. For any worn parts of your 3D mixer, you should make the quick respond and make the removal.

10.What Are The Future Developing Trend Of 3D Mixer?

3D mixer is the innovative and powerful machines. And with the new innovation, your machine will be more developed and more helpful.

Multiple motors

Multiple Motors-Sourced:mymitsubishisupport

3D mixer with multiple motor equipped is more capable and can deal with various materials. This type of 3D mixer is more efficient and more precise in products mixing. You can adjust the parameter and speed easily with this machine.

Higher automatic level

Higher Automatic Level-Sourced:shutterstock

3D mixer will have higher automatic level in future. The higher automatic level means the less human efforts in machine dealing and higher precise in products dealing. It reduces the cost in energy and time greatly. Besides, the more automatic machine can help you monitor the problem in products mixing process.

Environmental friendly

Environmental Friendly-Sourced:okcredit

The more concern on environment protection promotes the 3D mixer with environmental design. The material applied for machine constructing is more environmental friendly. You may find the recyclable plastic, stainless steel and such energy-efficient material for machine manufacturing.

More intelligent

More Intelligent-Sourced:dreamstime

The 3D mixer will be more intelligent. The digital control and artificial intelligent make your 3D mixer more precise, intelligent and efficient. The intelligent machine can help you make the fully use of material and reduce the waste or your material. The intelligent 3D mixer is the future trend.

Conclusion

How to solve the raw material absorbing and low uniformity of 3D mixer? You may have your own answers. And for the various problem and questions for 3D mixer, you may all have the answers. 3D mixer makes great help for your manufacturing business. And for any problem or question, feel free to contact AIPAK.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine