How To Reduce The Punch Friction of High Speed Tablet Pressing Machine?

How to make the best effect of your tablet pressing machine? The great tablet pressing machine can always help you in a comprehensive way. And there is always way for you to make the better effect for your tablet pressing machine. You may know the way of operating tablet pressing machine, and here is the way for you to get the best efficiency.

How to reduce the punch friction for the increase of operating speed of tablet pressing machine? How to improve the accuracy of your tablet pressing machine? What are the factors which affect the tablet pressing machine operation? Why you need the regular maintaining of your tablet pressing machine? Here come on and have a reading!

1.What Is Punch Friction In Tablet Pressing Process?

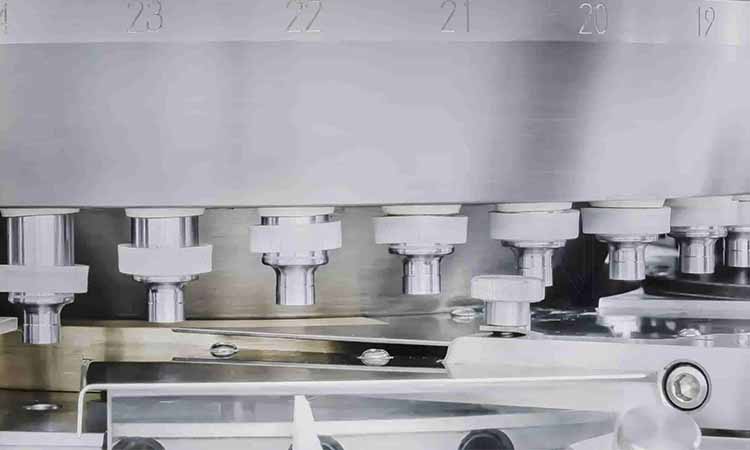

Punch Friction-Sourced:ducsonco

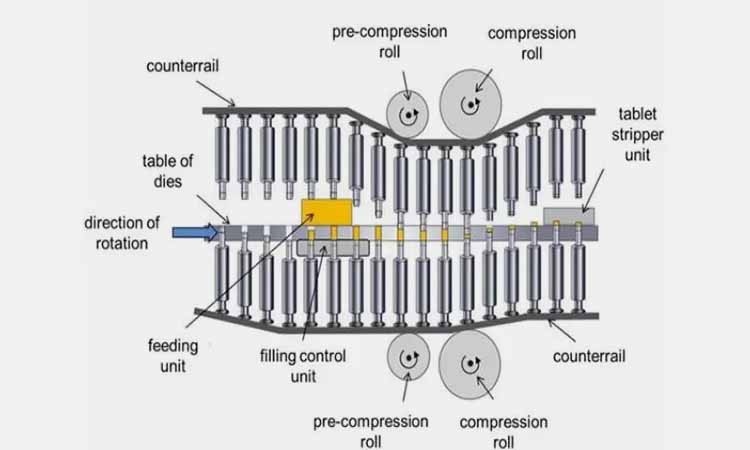

Friction happens in the pressing of your tablets. And in tablet pressing process, punch friction is the most common one which happens with the pressing work of upper punch and lower punch. Punch friction happens in the wear and tear of punch and die wall. Punch friction helps the forming of your tablets but it may also lead the wearing of your material parts.

The different punch friction makes different effect for your tablet pressing work. You may find the balance of it to make the suitable tablet pressing work here. And, you may also reduce punch friction for the higher efficient tablet pressing work.

2.What Are The Types Of Punch Friction In Tablet Pressing Machines?

What are the types of punch friction in tablet pressing machines? Here are the typical punch friction in tablet pressing machines.

Static Friction And Dynamic Friction-Sourced:diffzy

Static friction

Static friction is the friction which happened with no operating of high speed tablet pressing machine. Without any operation, there may be the friction which forbidden the work of punch. And static friction is the friction which forbidden the initial operating.

Dynamic friction

Dynamic friction refers to the friction punch make in the consistent tablet pressing work. Dynamic friction is the main friction road. And in tablet pressing work, there are sliding friction, rolling friction and so on which are all the type of dynamic friction.

3.What Are The Factors Which Affect Punch Friction In Tablet Pressing?

There may exist different punch friction in tablet pressing work. Have you ever wondered the factor which affect punch friction in tablet pressing?

Powder characteristics

Powder Characteristics-Sourced:atslab

Different powder makes different punch friction. You should consider the particle size, flow, cohesiveness and such factors for the affection on punch friction. The powder with poor flow and high stick can improve the friction and make more wear on punch and die parts.

Die and punch design

Die And Punch Design-Sourced:lfatabletpresses

The design of your die and punch should also be considered seriously for your punch friction. The smooth and sleek punch and die mold can help reduce the friction apparently. And the abrasive and rough die and punch can not make the low punch friction work.

Lubrication

You should also apply lubricants for the reduce of friction. The changing of formulation for better lubrication and applying of lubricants on machine parts can help reduce punch friction and maintain the best friction levels for your tablet pressing machine.

Machine settings

You may make the different machine setting and tablet pressing speed, compression force and tablet thickness can all affect the punch friction. The higher speed and compression force can lead larger friction and affect your tablet products quality.

Punch material

Punch Material-Sourced:osdmachinery

How about the material of your punch? There are stainless steel, carbide, coated alloys and so on for you to choose. Different material makes different job for your tablet pressing work and the friction level is also different. The punch with titanum or chrome coating makes the outstanding job in reducing friction.

4.How To Reduce The Punch Friction of High Speed Tablet Pressing Machine?

How to reduce the punch friction of high speed tablet pressing machine? Here are the comprehensive solution for you.

Adjusting the fit gap between the punch and die

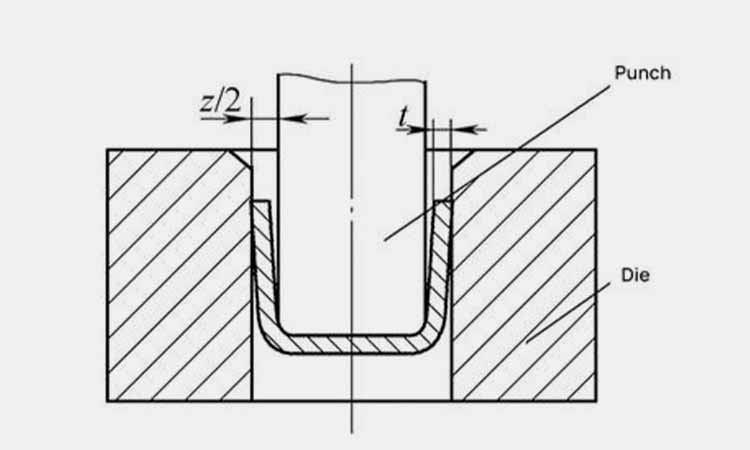

Adjusting The Fit Gap Between The Punch And Die-Sourced:artizono

Check the fit accuracy

The fit gap between the punch and the die should meet the equipment’s requirements. If the gap is too small, it may increase friction, potentially causing the punch and die to seize. Professional measuring tools, such as feeler gauges, can be used to check if the gap is within the specified range. Generally, an appropriate gap is between 0.05 and 0.1 mm, with the specific value depending on the tablet press model and die specifications.

Mold design modification

Try to minimize the contact area between the press wheel and the die to allow the press wheel to pass quickly over the stress surface of the upper die, thereby increasing the equipment’s speed.

Repair or replace worn parts

After long-term use, the punch and die may become worn, causing the fit gap to increase or become uneven, leading to unstable friction. If wear is observed, timely repair or replacement of the punch and die should be carried out to ensure fit accuracy.

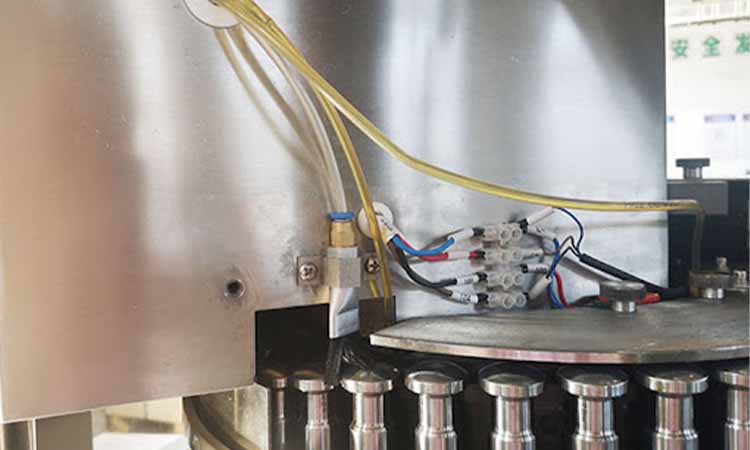

Optimize the lubrication system

Optimize The Lubrication System-Sourced:pharmacy-machines

Choose the right lubricant

Based on the tablet press’s working environment and requirements, choose a lubricant with good lubrication and wear resistance properties. For example, for high-speed tablet presses, a lubricant with low viscosity and good fluidity is preferable.

Adjust lubrication frequency and oil quantity

Increasing the frequency of lubrication and appropriately increasing the oil quantity can effectively reduce friction. However, excessive lubrication may contaminate the tablets or cause oil residue to accumulate on the punch surface, affecting tablet quality. Typically, based on the press machine's running speed and load, the lubrication cycle can be adjusted from once per hour to once every half hour, with each oil injection covering the punch surface with a thin, uniform film of oil.

Control the properties of the tablet material

Control The Properties Of The Tablet Material-Sourced:hosokawa-alpine

Adjust material moisture

If the material moisture is too high, its stickiness will increase, resulting in more friction with the punch. Drying methods can be used to reduce material moisture, usually controlling the moisture content between 3% and 8%, with specific values varying depending on the type of material. For traditional chinese medicine extract tablets, the moisture content is usually controlled between 5% and 8%, while for chemical drug tablets, it is controlled between 3% and 6%.

Improve material particle size distribution

Uneven material particle size distribution may cause poor material flow during the tablet compression process, leading to localized high pressure and increased punch friction. Sieving or other pre-treatment methods can be used to ensure a more uniform particle size distribution. Generally, the material's particle size distribution should range from 80 to 200 mesh, with particles in the 100 to 160 mesh range accounting for at least 70%.

Adjust the tablet press’s operating parameters

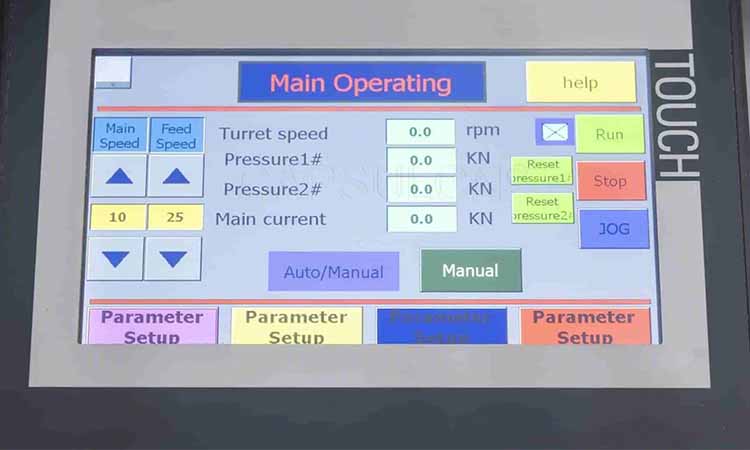

Adjust The Tablet Press’s Operating Parameters-Sourced:huadapharma

Reduce compression pressure

While ensuring tablet quality, appropriately lowering the compression pressure can reduce the friction between the punch and the material. The compression pressure can be gradually reduced, with each reduction of 3-5 kn, while monitoring tablet quality indicators such as hardness and friability, until the optimal pressure is found.

Optimize speed change gradient

When performing speed challenges, avoid sudden increases in tablet press speed. A gradual increase should be adopted, allowing the equipment and material to adapt. Observe changes in upper punch friction, and once friction stabilizes, continue to increase the speed.

When adjusting these parameters, closely monitor the operation of the tablet press and the quality indicators of the tablets to ensure that, while alleviating friction issues, the process validation results and product quality are not negatively affected.

5.How To Improve The Accuracy Of Your Tablet Pressing Machine?

The high accuracy can help you a lot in tablet pressing. How to improve the accuracy of your tablets pressing machine?

Optimize your powder material

Optimize Your Powder Material-Sourced:alpapowder

You should optimize your powder material for high accuracy of your products. And the nice powder should gave great flow. You may make it with even mixing and granulation. The adding of excipients should also be applied for your powder alleviating.

Great compression force

Great Compression Force-Sourced:lntyjx

You should have the great compression force for the high qualified tablet products and high accuracy of your tablet pressing machine. The real-time monitoring is essential for your products pressing process. You should adjust the setting of your compression force for the accurate work of your tablet pressing machine.

Machine condition maintaining

You should make the careful maintaining of your tablet pressing machine and its relative parts for the accurate pressing work. The regular check and lubricating are the important methods for your tablet pressing machine monitoring. The performance of the two work can help you a lot.

6.What Is TheEfficient Strategies To Reduce Cycle Time Of High-Speed Tablet Press Machines?

What is the effective strategies to reduce cycle time in high-speed tablet press machines? Here you may check your answers.

Optimize your machine

Optimize Your Machine-Sourced:ipharmachine

For the high efficient tablet pressing work, you should make the best machine setting. The turret speed, filling time and compression force are all the factors you should consider for your high speed tablet pressing work. You should thus optimize your machine according to your medicine products feature and type for the reduce cycle time.

Improve powder flow

Improve Powder Flow-Sourced:indpro

You should improve powder flow for the smooth tablet pressing work. The particle size, hopper design and relative parts can all make difference for your powder flow. You should improve your powder flow for the rate reducing of tablet weight change and defects.

Apply advanced design and system

You should apply advanced design and system of tablet pressing machine for the reduce of tablet pressing circle. The optimized punch design, mold size and coating technique are all the place you should consider in your advanced design and system.

Make in-time monitoring

Make In-Time Monitoring-Sourced:empmonitor

The in-time monitoring is also essential for your tablet pressing process. You should make the careful and deep monitoring for your tablet pressing work. The monitoring on weight, vibration, and many tablets products date or condition can be monitored for the shorter pressing circle.

Train operator with high standard

The professional and skilled operator can help make the best use of your tablet pressing machine and reduce the pressing circle. The operator may know the operation of machine and safety protocols of machine for the safe and high efficient tablet pressing work.

7.What Are The Factors Which Affect The Tablet Pressing Machine Efficiency?

Do you want to improve the efficiency of your tablet pressing machine? What are the factors which affect the tablet pressing machine efficiency?

Formulation feature

Formulation Feature-Sourced:livenaturallymagazine

Your formulation makes different affect for your tablet pressing machine work. The formulation with fine powder which has great flow can make the stable and smooth tablet pressing work. The great formulation prove the nice flow and high efficiency of your tablet pressing machine.

Machine maintaining and managing

Machine Maintaining And Managing-Sourced:manwinwin

You should make the careful maintaining and managing of your tablet pressing machine. The regular cleaning and maintaining of your machine in the best condition can improve the efficiency of your machine.

Apply high automatic method

The automatic tablet pressing process can make you the smooth and efficient tablet pressing work. Automatic tablet pressing work can simplified your tablet pressing process and prove the high standard of your tablet products.

Pre-compression work

Pre-compression Work-Sourced:yenchen

Pre-compression is the process which applied in tablet pressing work. Before the main compression, it can help improve the speed and prove quality. Pre-compression work is also essential and can help make the consistent and higher pressing speed.

8.Why You Need The Regular Maintaining Of Your Tablet Pressing Machine?

Your tablet pressing machine needs regular maintaining. And do you know the reason of the regular maintaining?

Better production

Better Production-Sourced:thomasprocessing

The regular maintaining of your tablet pressing machine makes better production of your tablets products. The reliable tablet pressing machine can make the tablet products with better quality, safety and feature. The regular maintaining is thus important for your tablet products production.

Higher efficiency

Higher Efficiency-Sourced:huadapharma

The tablet pressing machine with great maintaining can be more efficient. The time applied for machine mistake and machine breakdown is reduced. The machine with little mistake and smoother operation can of course be more efficient.

Loner lifespan

Your machine with better maintaining can have longer lifespan. The long lifespan can save you lot cost and give you excellent ROI. The longer life of your tablet pressing machine is so beneficial for your tablet pressing business.

9.How To Make The Quality Control Of Tablet In High Speed Tablet Pressing Process?

How to make the quality control of tablet in high speed tablet pressing process? To make sure the high quality of your tablet products, here are the quality control you should implement.

Weight variation test

Weight Variation Test-Sourced:pharmabossbd

Weight variation test make the careful test about the uniformity of tablets components. Weight variation test makes sure the accurate dosage of your each tablets. The accurate amount of API and excipients is the base for your qualified tablet products.

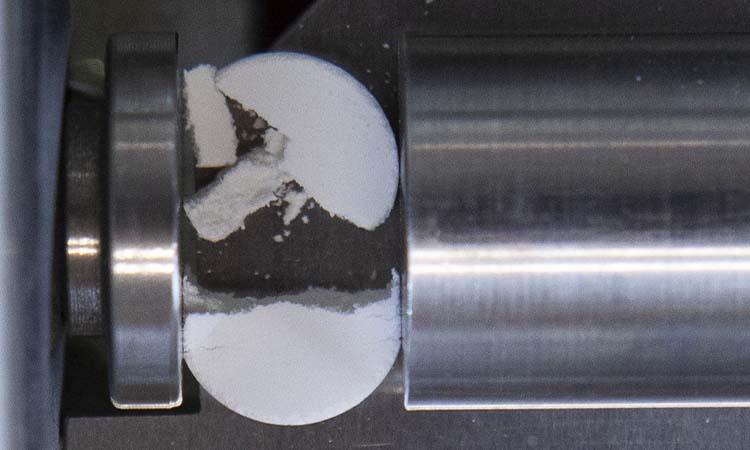

Hardness test

Hardness Test-Sourced:merlin-pc

Hardness test makes the careful test for the pressure tablets can take. The tablets which are not easy to break or crumble is the great tablets. Tablets which pass the hardness test is the tablets which are reliable and pressure resistant.

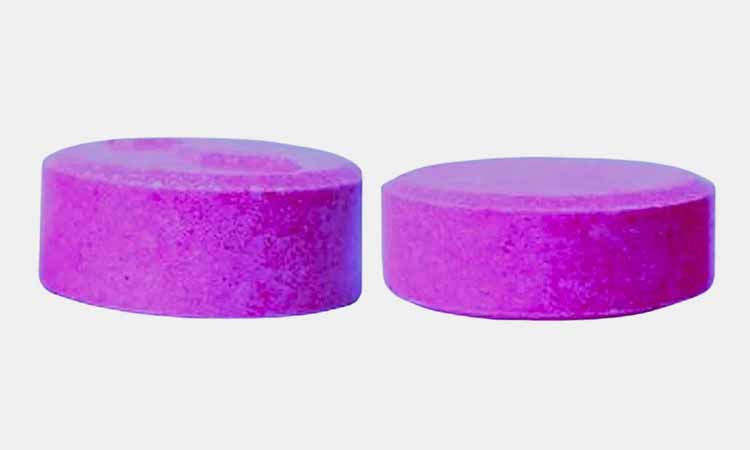

Friability test

Friability Test-Sourced:merlin-pc

Friability test is the reliable test which shows the ability of tablets in defending abrasion. In packaging, transporting and storing process, tablet products should be strong in durability and resistance.

Disintegration test

Disintegration Test-Sourced:raiselabequip

There is also the test about the speed of your tablets disintegrating into small particles. The disintegration rate reveals releasing speed and absorption rate of your tablets products. Your medicine effect concerned to it greatly.

Conclusion

How to reduce the punch friction of high speed tablet pressing machine? Punch friction makes such important role in your tablet pressing work. Do you want to know more about punch friction of your tablet pressing machine or have any question on this part? Contact AIPAK now! There are professor for your problem solution!

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine