How To Reduce The Heat Loss Of High Speed Mixing Granulator Machine?

Do you know what are the two most critical steps in the production of solid tablets?

One is mixing and the other is granulation.

These two processes are the key to determining the quality of tablets or capsules.

In recent years, the granulation technology has been continuously developed, and the requirements of pharmaceutical companies have also been constantly improved.

Based on this background, the traditional wet granulator machine equipment has been gradually replaced by high speed mixing granulator machine.

What is the specific reason for the rapid development of high-speed mixing granulators?

To be exact, one of the reasons for its wide application is its high efficiency, strong economy and good granulation fluidity.

As for the second reason, it is due to the high-speed mixing granulator not only meets the production requirements of GMP, but also reduces cross pollution to a great extent, and its application range is gradually expanded.

Some people may think that it is just one side of your story.

Never mind, I have another set of survey data here. It shows that in the pharmaceutical industry, high speed mixing granulator machines have accounted for 70% of all solid preparation granulation equipment.

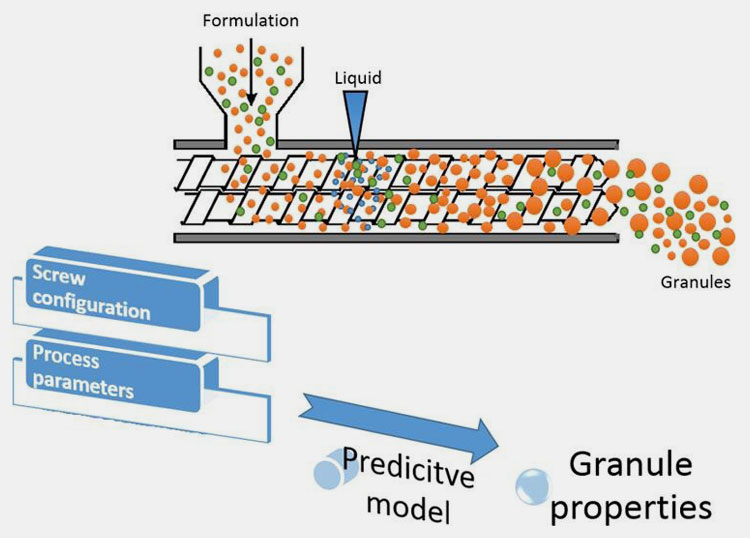

A high speed mixing granulator machine is a new type of granulator integrating crushing, mixing and granulation.

From the working principle, the high-speed mixing granulator includes three main bodies.

One is a support with the body as a whole, the other is a pot as a container, and the third is driven by mixing rotation and cutting flying knife transmission.

The three main bodies cooperate with each other for continuous operation.

So, how do the three subjects work?

First of all, you need to use a stirring paddle to stir the materials, so that the materials can be rolled and mixed evenly in a short time, and then made into particles by the cutting flying knife, and then discharged from the outlet, and then change the speed of the mixing and cutting flying knife, so as to obtain equipment with different sizes of particles.

Then, compared with the traditional granulation process, do you know the advantages of the high speed mixing granulator machine?

Maybe the following points:

The adhesive can be reduced by 25% and the drying time can be greatly shortened.

Each batch of high-speed mixing granulator machine is dry mixed for 2 minutes and granulated for 1-4 minutes. The work efficiency is 4-5 times higher than that of the traditional process.

Although the high-speed mixing granulator machine has many advantages above, a series of problems will occur in the process of use.

With your experience, what do you think is the biggest problem with the high-speed mixing granulator machine?

There is no doubt that it is the heat loss of the high-speed mixing granulator machine during running.

In order to increase the overall economic benefits, pharmaceutical and other enterprises have to take corresponding measures to reduce relevant consumption.

According to industrial professionals,

Generally, there are two ways to reduce the heat loss of high-speed granulator machine.

The first thing you should do is to avoid overload of high-speed mixing granulator machine and optimize heat transfer.

A more effective method is to strictly control the fuel air ratio. If the operation is close to the fuel air ratio, the fuel consumption can also be controlled.

In addition, to reduce the heat loss of the high-speed mixing granulator, machine the existing control equipment can also be used for maintenance. The main operations include the following methods.

Is there any other way to solve this problem?

In fact, you can use the existing control equipment for maintenance. The main operations include the following methods.

Direct heat recovery products.

The technician said that the heat loss of the high-speed mixing granulator machine can be effectively reduced by directly recovering the product.

Do you know why?

This is because once the exhaust gas leaving the high-temperature part can enter the relatively cold feed load, the energy will be transferred to the preheating load, which greatly reduces the energy discharged by the exhaust pipe, thus effectively utilizing the waste heat in the exhaust gas.

You can use waste heat recovery to preheat the combustion air.

It is reported that this method is often used in medium and high temperature industrial furnaces.

The burner using preheated air reduces the amount of fuel required to purchase to meet the requirements of process heat. Preheating combustion air requires a heat exchanger or recycling.

Waste heat boiler

According to the introduction of granulator manufacturers, waste heat boiler is also called waste heat boiler.

It uses the high-temperature waste gas generated by various devices to heat water, generate steam or hot water, and reuse the generated steam or hot water to achieve the purpose of waste heat reuse.

Waste heat boiler is an energy-saving and environmental protection project. It can not only reduce the emission of waste, but also greatly reduce environmental pollution, and also recover heat to a certain extent.

In addition, by using the high-temperature waste heat originally discharged from industrial production to heat the hot boiler, it can not only be used for power generation, but also for heating.

I believe that after knowing these relevant operation details, there will be a better solution to similar problems of high-speed mixer in the future.

In recent years, with the rapid development of the Chinese medicine and pharmaceutical industries and the promotion of environmental protection requirements, high-speed mixing granulator machines will usher in a good development space.

However, it is worth noting that with the continuous improvement of industrial concentration, the market competition has become increasingly fierce.

At present, there are various granulator machines in the market with different functions, which are applied to different segments of the pharmaceutical industry.

In addition, many granulator companies develop and design non-standard products for customers in the process of continuous improvement and innovation, so the manufacturing of high-speed mixing granulator machines should be closer to customer needs.

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine