How To Realize The Improvement And Innovation Of Vacuum Drier Machine?

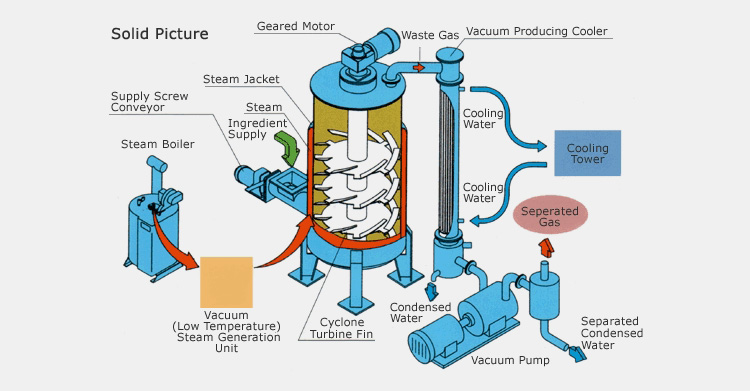

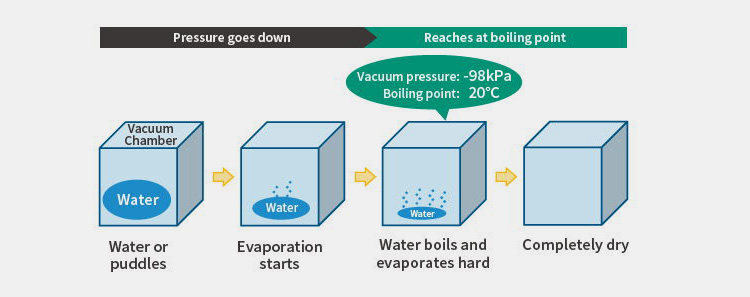

The vacuum drier machine is a vacuum low-temperature equipment that is used for materials’ heating and drying. It can make use of vacuum pumps to extract air and moisture and keep the work piece living in a vacuum state, which is conducive to greatly promoting the drying rate and saving energy.

This machine has many advantages and characteristics and it is capable of saving a lot of energy for you. It is due to the specific advantages drier machine is widely used in the pharmaceutical industry. However, with the change of market demand and the improvement of technical level, there are still many problems to be solved in the vacuum drier machine.

High equipment stability and extended service life

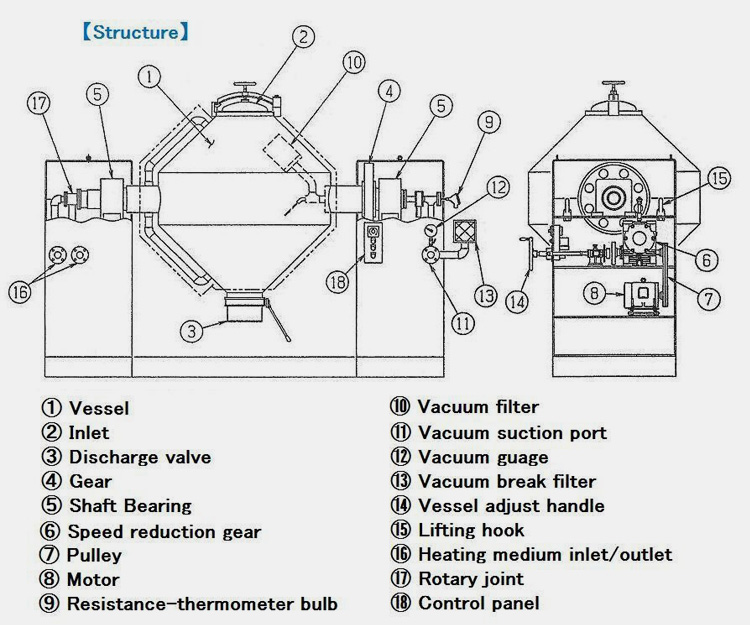

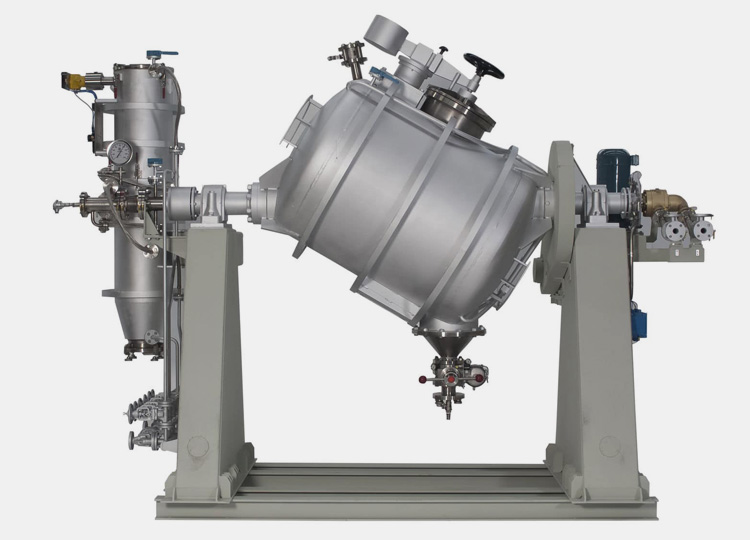

FZG,YZG Squar and round static vacuum dryer

The structure of the vacuum drier machine is firm, the operation is balanced and stable, and the resistance is small. This makes the two ends of the shaft to bear less force. Advanced vacuum drier machine, such as FZG,YZG squar and round static vacuum dryer, its bearings adopt exposed design to reduce use of wearing parts. And the main body of the drying chamber has no wearing parts.

The vacuum drier machine manufacturers introduce that the traditional equipment will bend and lose concentration under the action of its own gravity. When there is a problem with the roller bearing under the drying drum, the drying drum can easily be separated from the roller. Once the drying drum falls down, due to its gravity, it is hard for you to install this part back to its original position.

However, the drying chamber of the newly vacuum drier machine is not rotary but stationary. Advanced production process plus scientific material choosing and strict quality ensure the high quality and high sealing performance of the equipment.

The stability of the static drying chamber is definitely better than that of the traditional rotating type, which saves electricity and prolongs its life. "The vacuum dryer manufacturer said.

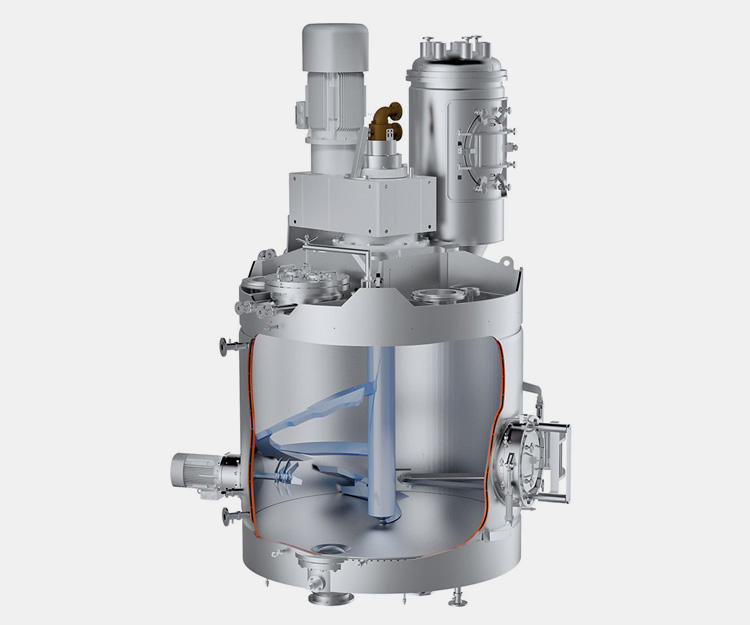

Wide drying range and flexible installation

The advanced vacuum dryer can dry raw materials with a desired moisture content, and the moisture content of the dried finished product can be adjusted to within 5% moisture content by frequency conversion, making the drying range wider and the use range wider.

However, because of the newly vacuum drier machine has characteristics of small size, short length, light weight, more flexible and convenient installation. It efficiently solves the problem of limited space for customers. Saving space and improving the safety factor.

Although the advantages of the vacuum drier machine greatly improve the efficiency of pharmaceutical production and save energy, there are still many problems that are worth discussing and solving by industry insiders. You should know that the vacuum dryers commonly used in the market have the following defects, taking the square vacuum drier machine as an example.

Uneven drying of the material

When the equipment works normally, according to the set time and temperature and reach a certain time, The materials on the upper and lower layers are not uniformly dried.

For example, when water vapor hits the inner wall of the box, it is easy to condense water droplets on the box wall, especially the water droplets on the top plate often drip back into the top material tray, which affects the drying quality of the material.

There is water at the bottom of the box during the drying process

You should know that when some drying chamber is operating. Due to the box being in a vacuum state, it is impossible to drain with negative pressure, and part of the accumulated water at the bottom of the box is re-evaporated for the second time. And the other parts will be excreted after the machine closes. It will lengthen the heating time and have a bad impact on the product’s quality.

Low efficiency of drying

The water vapour evaporated from some vacuum drying materials is moved by the pressure difference in the box formed after suction. Reach to the later period of drying, the speed of water vapor movement in the tank slows down as the evaporation rate decreases.

The moisture accumulated in the upper layer of the material will affect the drying efficiency of the material.

No inert gas protection device

There are no inert gas protection device in some drying chambers, but in actual production, in order to prevent product oxidation, inert gas is required to protect it.

For many years, vacuum drier machines have been widely used such as, mid-body, granular drying of finished products and mixing and solvent recovery; seasoner, dried fruit, drying of food raw materials and mixing of raw materials; drying of synthetic feed, biological protease and additives;

Organic/inorganic, chemicals, pesticides and the drying of powder/particle intermediates such as pigments and dyes. However, with the change of market and improvement of technology, vacuum drier machines need to solve the existing problem as soon as possible and make more improvements and innovations.

Products not only have a important meaning for your enterprise’s development, but also it is a big welfare for customers.

Drying equipment enterprises should take a resource-saving development path, change a single extensive drying type into a combined and intelligent drying type, not only to carry out fundamental transformation from the drying process, but also to carry out comprehensive and multi-level energy-saving technological transformation, vigorously develop the application of renewable energy drying technology for energy and industrial waste heat.

Under the prevailing trend of intelligence, enterprises can inject new life into traditional businesses, actively explore new markets and explore new fields.

Pharmaceutical machine companies need to follow the trend, analyze the risks they face and make actual adjustments according to their own conditions,gradually strengthen innovation, improve technical levels, and develop towards the trend of integration, continuity, automation, formalization, and intelligence. survive in the fierce market competition.

At the same time, we should also pay attention to the cultivation of talents, and talents also play an important role in the development process. Through the establishment of incentive mechanism and welfare mechanism, we can introduce, cultivate and retain talents, so as to maintain the stability of core technical personnel.

Don't forget to share this post!

Drier Machine Related Products

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours