How To Realize Safe And Pollution-free Integrated Production Of Eye Drops Filling Machine?

In recent years, with the strengthening of people's awareness of health, more people have joined the ranks of eye care. Whether it is a student party, an office worker, or an elderly person at home, carrying a bottle of eye drops with you can relieve visual fatigue in time.

But as far as I know, most of the traditional eye drops contain preservatives, if used for a long time or the human eyes will have a negative impact. Therefore, preservative-free daily-dose eye drop packaging will become the target of the market.

Because all countries in the world clearly stipulate that all kinds of ophthalmic preparations should meet sterility requirements, ophthalmic preparations must be produced according to aseptic technology, and the final product should be sterile.

Therefore, it is necessary to strengthen the sterility requirements of ophthalmic preparations. Ensuring that ophthalmic preparations meet sterility requirements and ensuring patient medication safety are issues of high concern to registration applicants and drug review departments.

The industry professionals also point out that eye drops must meet quality requirements such as sterility, isotonicity and appropriate pH during preparation. The traditional production process of eye drops includes many links such as bottle making, filling, capping and capping, and these production links have to be in direct contact with the air.

Objectively speaking, in order to maintain the sterility of the drug, it is also necessary to add preservatives. Therefore, how to break the difficulty of preservatives is a major problem that the development of the eye drops industry must face.

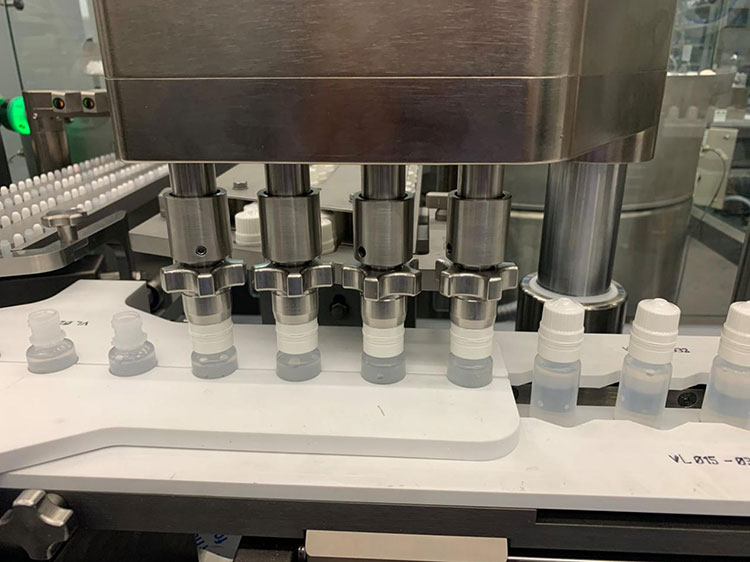

At present, the eye drops filling and capping machines on the market are basically controlled by PLC touch screen and peristaltic pump filling. They are mainly suitable for eye drops and similar small-dose liquid filling and capping, and are provided by imported cam dividers. , to ensure the accuracy of filling and capping, with the advantages of less liquid pollution and strong sterilization.

The new technology has led to the improvement of equipment performance, and the bottle unscrambler, filling machine and capping machine related to the production of eye drops are also constantly improving the efficiency and quality of the equipment in order to stay on the ground.

Take the eye drop filling machine as an example. At present, the shadow of the eye drop filling machine can be said to be ubiquitous. It is widely used in pharmaceutical, chemical, food, light industry and other industries. It is a device for vacuum negative pressure and self-priming liquid filling for glass, plastic, metal and other containers.

For example, plastic bottles of oral liquid, fengyoujing bottles, eyedrop bottles, cosmetic perfume bottles, etc. That people are familiar with every day all need to use the eyedrop filling machine to carry out negative pressure suction and maintain a vacuum stat.

With the development of automation technology, the eye drops filling machine equipment has also been transformed and upgraded. The automatic eye drops filling machine integrates the principle of automation, which makes the filling speed faster, the stability of the filling volume is improved, the sterility is guaranteed, and the overall efficiency is greatly improved.

It is suitable for the modern and rapidly developing market demand, solves the defects of manual filling or traditional filling, turns the tedious into simple and convenient, and saves a lot of costs for companies.

With the continuous improvement of GMP standards, the rapid development of the eye drops industry and the continuous progress of the pharmaceutical machine industry, all-in-one machines and production linkages have gradually appeared in people's field of vision.

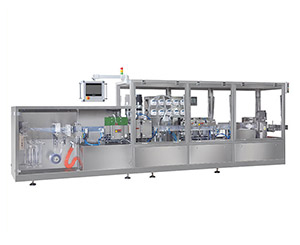

You have to know that the eye drops filling production linkage line is composed of automatic bottle unscrambler and robotic eye drops (eye drops) filling and capping machine, which can automatically complete the bottle unscrambler, filling and stoppering of eye drops (eye drops). , capping and other actions, optional aseptic hundred-level laminar flow hood, to achieve the purpose of aseptic production.

So far, there are many eye drops manufacturers have introduced filling and production linkage lines for more aseptic production, which has improved the overall efficiency and safety of production.

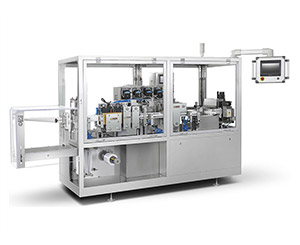

There are also some eye drop filling machine companies that mainly develop the eye drop filling, inner plug, and outer cap integrated machine, which is suitable for the filling, inner plug, and outer cap operations of eye drops, red syrup, iodine and other small-dose products.

The machine adopts disc positioning multi-station type, compact structure, small footprint, high production capacity, and has become the choice of many eye drops manufacturers.

Eye drops are regarded as sterile preparations, which directly work on the eyes to play a therapeutic role, and their quality is related to the health and safety of human eyes. As the key equipment in the liquid medicine filling process, the eye drops filling machine must meet the requirements of aseptic and safe filling of the liquid medicine.

All over the world, it has been clearly stipulated that various ophthalmic preparations should meet sterility requirements has clearly stipulated that all kinds of ophthalmic preparations should meet sterility requirements, ophthalmic preparations must be produced in accordance with aseptic technology, and the final product should be sterile.

Nowadays, the eye drops industry has broad prospects and the market competition is becoming more and more intense.

If a production enterprise wants to stand out in the competition, it must improve the quality and production level of its products, and the relevant production equipment will also become an important "weapon". Only by polishing these "sharp tools" can the production of eye drops be made safer and more stable.

In recent years, with the expiration of various blockbuster drugs one after another, it is an opportunity for companies to launch new products through improved dosage forms to seize the market.

As an indispensable filling equipment, eye drops filling machine equipment will play an important role in the market. Companies must keep up with the needs of the pharmaceutical industry and develop high-quality product equipment to ensure the sterility and pollution-free of medicines and help the better development of the pharmaceutical industry.

Don't forget to share this post!

Eye Drop Filling Machine Related Posts

Eye Drop Filling Machine Related Products

Eye Drop Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine