How To Prevent Cracks In Tablet Coating Process?

What is your feeling while taking the coated tablets or pills? The sleek and sweet coating can always help make the great swallowing of your various pills. Coating becomes the important process for tablet manufacturing in pharmaceutical industry. In the tablet coating process, there may exist various problems.

How to prevent cracks in tablet coating process? What industry can tablet coating be applied? What are the main tablet coating type? What are the machines used for tablet coating? How does tablet coating made? The solution of these questions can help you make the great and real qualified coated tablets products.

1.What Is Tablet Coating And Tablet Coating Machine?

Tablet Coating-Sourced:lfatabletpresses

Tablet coating is the important technique which is applied in pharmaceutical industry. It makes the even, smooth and great taste film for your various tablets products. Coating can help you reduce the bad taste of pills and help people with swallowing problem. Besides it can also make the protection for the API of tablets.

Tablet coating machine is the machine which used particularly for tablet coating. Tablet coating machine has the round container for the tablet coating work and the revolving of the container can make sure the even and efficient coating for your coated tablets products.

2.Why You Need Tablet Coating For Your Tablets Products?

Tablet coating is the essential process for your medical products making. Here are the reasons of your purchase of tablet coating machine.

More powerful protection

Powerful Protection-Sourced:vikramthermo

Tablets coating can make the great shield for your tablets products. It makes the better protection for the API of your precious tablets products. It can make great protect against light, moisture and heat. Your coated tablets products can thus have the better protect.

Better taste

Better Taste-Sourced:clevelandclinic

Tablets without coating may have the bad taste or smell which make the great trouble for patients taking. With the sweet and sleek coating, tablets may have the better taste and smell which is helpful for patients swallowing. The great medicine taking process can help improve the impression of your customers.

Improve stability

The great protection of your tablets products can make the great protection for your products. The better protection improves the stability of your tablets products. The stabler tablets products makes the longer shelf life and better products feature.

Better medicine releasing

Better Medicine Releasing-Sourced:krka

Tablets with great coating can also make the difference in medicine releasing. The adjusting of coating formulation can make the affect for releasing property. And for the medicine with special releasing need, coating is essential.

3.How To Prevent Cracks InTablet Coating Process?

In tablet coating process, there may exist cracks in the manufacturing. How to prevent cracks in tablet coating process? Here are the reliable solutions.

Core tablet factors and solutions

Core Tablet Factors And Solutions-Sourced:spangler-automation

Core hardness

Insufficient core hardness can lead to the sugar coating cracking due to external forces or moisture absorption during the coating process. You should ensure that the core has appropriate hardness which typically controlled between 50-100N. You can improve the core hardness by adjusting the formulation, such as increasing the binder amount or selecting a stronger binder.

Core moisture

If the core contains too much moisture, during the drying process of the coating, moisture migrating to the surface will create pressure on the sugar coating, causing cracks. The moisture content of the core should be controlled between 3%-5%. To reduce moisture, the core can be adequately dried before coating. Drying at 60°C for 2-4 hours is the appropriate drying temperature and time

Coating material factors and solutions

Syrup concentration

If the syrup concentration is too high, the dried sugar coating becomes hard and brittle and lead to cracks. If too low, the coating lacks sufficient adhesion, making it hard to form a complete protective layer. The syrup concentration for coating should generally be controlled between 65%-75%.

Adding plasticizers

Adding an appropriate amount of plasticizer, such as glycerin or propylene glycol, to the coating material can improve the flexibility of the sugar coating, reduce brittleness, and minimize crack formation. The amount of plasticizer typically ranges from 5%-10% of the syrup’s weight.

Process parameters and solutions

Process Parameters And Solutions-Sourced:coatingsystems

Drying temperature and speed

If the drying temperature is too high or the speed is too fast, the surface moisture of the sugar coating will evaporate quickly, while internal moisture cannot migrate in time, causing the surface to shrink rapidly and crack. The drying temperature during the coating process should be controlled between 35-50°C, with slightly lower temperatures in the early stages of drying, and gradually increasing in the later stages.

The drying speed should not be too fast. A staged drying approach is recommended. For the first 2 hours of drying, you should control the airflow at 1-2 meters/second. After 2 hours, you should increase the airflow to 2-3 meters/second.

Coating layers

If the number of coating layers is too few, the sugar coating may be too thin to withstand external pressure and stress, leading to cracks. On the other hand, too many layers may cause the thick coating, increasing internal stress and also potentially causing cracks.

The appropriate number of coating layers should be determined based on the size, shape and properties of the core tablet. Typically, a powder coating requires 10 to 15 layers, a sugar coating requires 8 to 15 layers, and a colored sugar coating requires 3 to 5 layers.

Coating pan speed

If the coating pan speed is too high, the centrifugal and frictional forces on the core tablet increase, potentially damaging the sugar coating and causing cracks. If the speed is too slow, the core tablet may not roll evenly, leading to an uneven coating that could also result in cracks. The typical speed of the coating pan should be controlled between 20 to 40 revolutions per minute which is adjusted according to the core tablet’s characteristics and batch size.

Environmental factors and solutions

Environmental Factors And Solutions-Sourced:pharmasalmanac

Humidity control

High environmental humidity can cause the sugar coating to absorb moisture, making it soft and sticky and leading to cracks after drying. The relative humidity in the coating workshop should be controlled between 40%-60%. Humidity can be adjusted by installing dehumidifiers or air conditioning systems.

Cleanliness

Dust and impurities in the environment may mix with the coating material, affecting the integrity of the sugar coating and increasing the likelihood of cracks. The coating workshop should be kept clean and disinfected and equipped with an air purification system to ensure that air meets cleanliness requirements.

4.What Industry Can Tablet Coating Be Applied?

There is the frequent use of tablets coating in pharmaceutical industry. And in other industries, there is also the applying of tablet coating machine.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:ezo

Pharmaceutical industry makes the frequent applying of the tablet coating technique. There are many tablets and pills which need the tablets coating for stabler feature, better taste and protection. Tablet coating is essential for pharmaceutical industry.

Supplementary industry

There are also various products in supplementary industry which seek the help of tablet coating technique. Tablet coating can make the great help in making the easy swallowing and great taste tablets.

Food industry

Food Industry-Sourced:stockfood

In food industry, you may find the applying of tablet coating technique in making the coated sugar or candy. The coated candy has the better taste. Your food can also be protected better with this technique.

Construction industry

There are industrial coating which applied in construction industry. There are coil coating, cladding, roofing and many other construction parts which need the applying of coating technique for the high quality and great feature.

5.What Are The MainTablet Coating Type?

There are various tablet coating type for you to choose. And here are the main tablet coating type.

Sugar coating

Sugar Coating-Sourced:biogrund

Sugar coating refers to the thick sugar syrup layer which covered the tablets products. Sugar coating tastes sweet and its smooth feature gives the great medicine taking experience for patients. Sugar coating makes the thick protection for your tablets and makes the nice appearance of it.

Enteric coating

Enteric Coating-Sourced:making

Enteric coating is the special coating technique which makes the important job in preventing the harm of medicine for your stomach and intestines. Enteric coating makes great help in releasing the API into blood. It helps enhance the absorption of medicine effect. For many medicine which is sensitive to acid, it is the good choice.

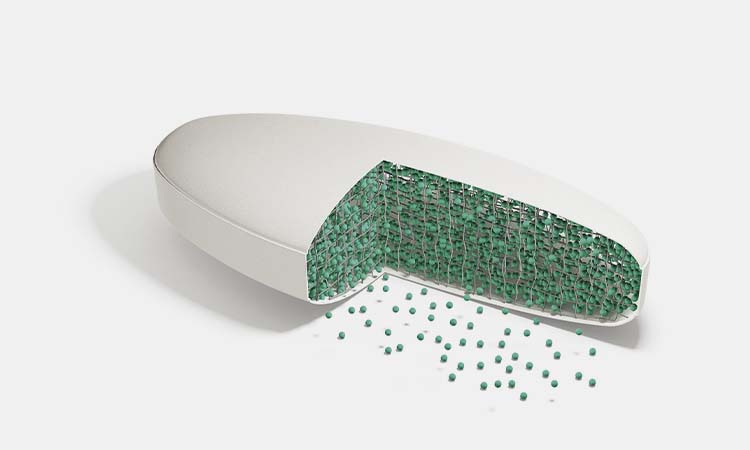

Film coating

Film Coating-Sourced:colorcon

Film coating is the advanced coating technique. The thin film of film coating makes the great protection for your medicine products. The tablets products can thus be more durable and better. You can add color for the film coating formulation for the better look and better sales.

Organic solvent film coating

Organic solvent film coating is the advanced technique which makes the protection for the moisture-sensitive medicines. It reduce the affect of moisture to tablets. For many types of medicines, this is the great choice. But the high price of organic solvent film coating is the thing you should consider seriously.

Aqueous film coating

Aqueous film coating is the tablet coating technique which makes the advance and powerful protection for API. It makes less pollution for environment and saves more energy in coating manufacturing.

6.What Are The Machines Used For Tablet Coating?

For the manufacturing of the qualified and great coated tablets. Here are the machines you should apply.

Standard coating pan

AIPAK Standard Coating Pan

Standard coating pan is the machine which is flexible and versatile for the coating of various kinds of tablets products. It can be applied in pharmaceutical industry and food industry. The efficient coating work of coating pan can help you make the coated tablets effectively.

Tablet coating machine

AIPAK Tablet Coating Machine

Tablet coating machine can make the consistent coating work for your various types pf tablets, pills, candies and so on. Perforated coating system is efficient in producing the various types of coated products. This coating system can make the stable, smooth and firm coating film in a second.

7.How Does Tablet Coating Made?

Tablet coating process isn’t hard process. And here is the comprehensive process of your coated tablets products.

Coating formulation preparing

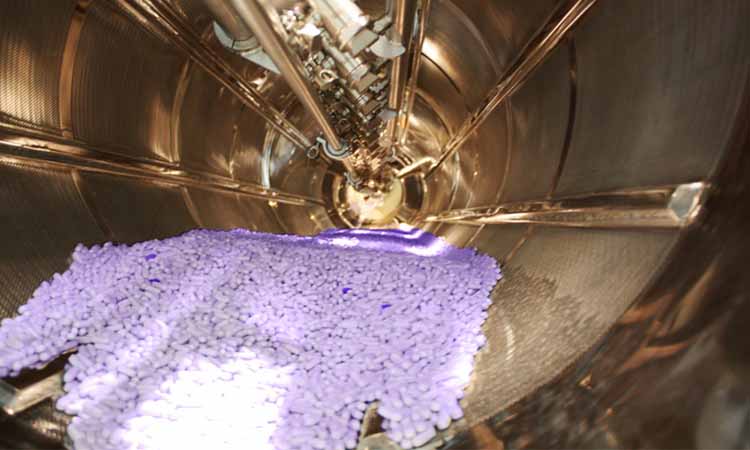

Coating Formulation Preparing-Sourced:malvernpanalytical

There are different coating type and also the different coating solution for you to choose. You should make the formulation according to your products type and medicine feature. The color, thickness and many things should all be considered in your coating formulation preparing.

Material loading

Material Loading-Sourced:syntegon

You should then load tablets and solution in the tablet coating machine. The cleaning and disinfecting of your machine is essential for your tablet coating work. Besides, you should also make the setting of relative parameter according to your tablets products type.

Solution spraying

Spraying is the process which decides the coating quality. In solution spraying, the coating solution can be sprayed evenly on the coated tablets. The problem or mistake in this process may lead the coated tablets appearance change.

Coat drying

Coat Drying-Sourced:redvector

The solution won’t dry in a second. And there is a few minutes for tablet coat drying. For the professional and reliable tablet coating machine, you can have your coated tablets dried in a second.

Products inspecting

Products Inspecting-Sourced:capsulcn

For the well coated tablets, it is time for the products inspecting. The inspecting process will inspect the quality of your coated tablets and pick out the unqualified one. Products inspecting can prove the quality of your products.

8.What Is The Main Features Of Qualified Tablet Coating Products?

There are various coated tablets products in market. How to find the real qualified tablets coating products. Here are the main features of the real qualified one.

Qualified coating film

Qualified Coating Film-Sourced:pharmamachinery

The real qualified tablet coating products should have the qualified coating film. The qualified coating film is smooth, elegant and shiny. The qualified coating film should be pretty and complete for its appearance. The qualified coating film shows great protection and attractive appearance of tablets.

Stable feature

Stable Feature-Sourced:colorcon

The coating of coated tablets should have stable feature. It should be stable in light, heat and moisture. Without the protective property, coated tablets lose its main feature. Your tablets then lose the stability.

Nice taste and odor

The other use of coated tablets lie in the the covering of the bad taste or odor of tablets. The failure in defecting the smell or taste from previous tablets make the coating no use. Thus, the qualified tablet coating should have nice taste and odor.

Compatible

Compatibility-Sourced:silverson

Compatibility and solubility are also the factors you should consider seriously in tablet coating. Your tablets coating should be compatible for the tablets components. The great compatibility is the factor for the real qualified tablets products rating.

9.What You Should Do To Make The Great Tablet Coating Work?

In tablet coating manufacturing process, here are the things you should conform to make the great tablets coating work.

Coating formulation

Formulation makes much in affecting the coated tablets quality. Different formulation makes different coated tablets type and feature. You should explore the most suitable coating formulation for the great tablet coating work.

Manufacturing temperature and moisture

Manufacturing Temperature And Moisture-Sourced:ruknews

Manufacturing temperature and moisture can make great impact for coated tablets work. The inlet temperature should be high enough for the coat drying and the moisture should also be suitable for the preventing of coating cracking or peeling.

Drying time

Drying time is the important factor which refers to the time coating formed in tablet coating process. Different formulation, tablet size and manufacturing condition make different affect for drying time. And the suitable drying time promotes the great work of qualified coated tablets.

Spraying condition

Spraying Condition-Sourced:coatingsystems

Spraying condition refers to the spraying speed and spraying distance applied for tablets coating process. The spraying condition affect the coating solution distribution and coating completeness. You should make sure the right spraying condition to make the qualified products.

Conclusion

How to prevent cracks in tablet coating process? How to make the great and qualified coated products? The many question and problem of tablet coating have answered here. You may know the secrets! Come on and make it! If you have any question or problem, you should have no hesitate to contact us now!

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine