How To Make Vitamin Capsule: The Complete FAQ Guide In 2025

Are you looking for producing vitamin capsules? If yes! You are at right place! The demand for vitamin capsule is increasing day by day due to the myriad of associated benefits. That's why its production is also on rise. However, most of the producers often caught in a question How To Make Vitamin Capsule?

So, we are here to give a detail answer to this question and let you simply deal with your concerns about the various ingredients used for making vitamin capsules along with the right method. Along with this, the different types of vitamin capsules and their benefits will also be covered in this FAQ guide. So, be ready to explore it well!

1.What Is Meant By Vitamin Capsule?

Vitamin E capsules- Picture Courtesy: guts.pk

Vitamin, minerals, and protein are essential for maintaining a healthy lifestyle. However, in most instances we come up with vitamin deficiency which are building block of human body. Thus, certain vitamin are gathered from different foods and enclosed into capsule shells for recovering the deficiency. These are called vitamin capsules and some of the examples include vitamin E capsules, vitamin C capsules, vitamin D capsules and so on.

These vitamin capsules play significant role in promoting good health and reviving energy which is lost due to illness and poor diet. Vitamin capsules are favored for their convenient dosage administration and easy swallowing without any bitter taste.

2.How To Make Vitamin Capsule- Ingredients Required?

There are certain ingredients required for making vitamin capsules. The detail of necessary components are given below:

Outer Shell: Capsules

Empty capsule shells- Picture Courtesy: capsulcn.com

This is the primary thing you will always need for making vitamin capsules. Capsule shell is composed of a cap and a body or base which function as a container to hold a precise volume formula inside. Depending upon the consumer preference and health concerns there are various types of capsule shells available in market today. These include gelatin capsules, HPMC Capsules or Pullulan Capsules.

Apart from this, capsules are produced in variety of sizes to aid small to large dosage. Hence, for human use, there are right sizes of capsules with different capacities for holding ingredients. These include 000, 00, 0, 1, 2, 3, 4, and 5.

Inside Mixture: Active Ingredients And Excipients

Vitamin capsules with plants and oils- Picture Courtesy: ceibarootwellness.com

Active ingredients refer to the substances which have a therapeutic effect on body and they release the intended effects. These ingredients play essential role in making vitamin capsules and are extracted from natural sources such as plants or animals. Some of the examples include elderberries, bee pollen, wheatgrass, and celery seed powder.

On the other hand, excipients are those compounds which perform secondary function whilst the production of vitamin capsules for their preservation and stability. Although, vitamin capsules The common examples include binders, disintegrants, and fillers etc.

The mixture of API's and excipients makes a formula of vitamin capsules which can be in one of the following forms:

Vitamin powder & granules capsules- Picture Courtesy: syntegon.com

Dry Solids:These include granules, pellets, powders, or small tablets which are filled in hard gelatin capsules.

Semi Solids:Semi solids mixture consists of suspension or pastes.

Liquids:These are free flowing non-aqueous liquids which are often filled in soft gelatin capsules. The common examples include fish oil.

3.How To Make Vitamin Capsule- The Process?

In this section, we will be covering how the procedure of making vitamin capsule take place both on industrial level and home level. So, let's explore it through simple steps!

Home Way

If you want to make vitamin capsules at home then it is quite easy as you will need to follow simple steps which are enumerated below:

Mixture Preparation

Mixture preparation for vitamin capsule- Picture Courtesy: mountainherbs.com

The initial step involves collecting all the necessary ingredients including capsule shells, active ingredients, and excipients. It is necessary to take care of the amount of each ingredient. Similarly, they should be properly weighed and mixed to produce a uniform formula.

Empty Capsules Opening

Empty capsules in spoon- Picture Courtesy: mountainherbs.com

Once filling mixture for vitamin capsule is prepared, the next step is to open the empty capsules. As empty capsules are available in form that they are closed for manual process you need to open each capsule while taking care of hygiene by wearing gloves.

Empty Capsules Placement

Capsule base placement into capsule maker- Picture Courtesy: mountainherbs.com

After separating the caps from capsules body now you need to place the base or body of capsules into the frame plate of capsule maker. One by one, fix the longer half of capsules into the equipment until all the places are filled.

Empty Capsules Filling

Capsule filling- Picture Courtesy: mountainherbs.com

Moving forward, it is time for pouring down your prepared vitamin capsule mixture over the capsule maker and use spreader card back and forth to fill all the capsules. For even distribution of ingredients taken the tamper and press down on the top of filled capsules to completely settle down the powder.

Capsules Closing

Capsule closing- Picture Courtesy: mountainherbs.com

It is the final step where filled vitamin capsules are closed using a capping plate. Press down on the equipment's top center until caps are rightly compressed against the capsule body. Take the capping plate off and you capsules are now ready for consumption.

Industrial Way

Producing vitamin capsules on industrial level is one of the responsible tasks which is carried out using automated and advanced equipment. However, they too follow a synchronized mechanism for making vitamin capsules. This method will be explained below:

Mixture Preparation

This step of mixture preparation goes hand in hand with both home way and industrial way of making vitamin capsule. Similarly, the required ingredients are gathered and processed to get the desired formula.

Material Loading

Empty capsules loading in hopper- Picture Courtesy: Syntegon

Another phase include the loading of capsule mixture into a hopper of the capsule making machine and stock the empty capsules in another hopper. This step of loading can be carried out manually or automatically depending upon the technology being used such as integrating a feeding unit.

Capsule Rectification and Separation

Capsule rectification & separation- Picture Courtesy: Syntegon

The machine start working by first rectifying the capsules through which individual capsules are aligned and moved from the hopper towards narrow hose. Similarly, the empty capsules enter into the lower mold after which through vacuum suction the cap is separated and holded by upper mold.

Mixture Filling

Mixture filling- Picture Courtesy: Syntegon

Now, the machine accurately weigh the precise volume of mixture and dispense it into the opened body of capsule. The same process goes for other empty capsules.

Capsule Locking

Capsule locking- Picture Courtesy: Syntegon

Once the vitamin capsules are filled, their locking step is carried out. It is done when the lower and upper mold rotates to the locking position together. The axes of both molds result into locking of filled capsules by meeting the cap with body which is a critical step in vitamin capsule production.

Capsule Ejection

At last, as the vitamin capsules are filled and locked, the push rod discharge the finished capsules which are collected in a container.

4.What Machines Are Used To Make Vitamin Capsule?

There are certain equipment which are used for making vitamin capsule. These machines are highlighted below:

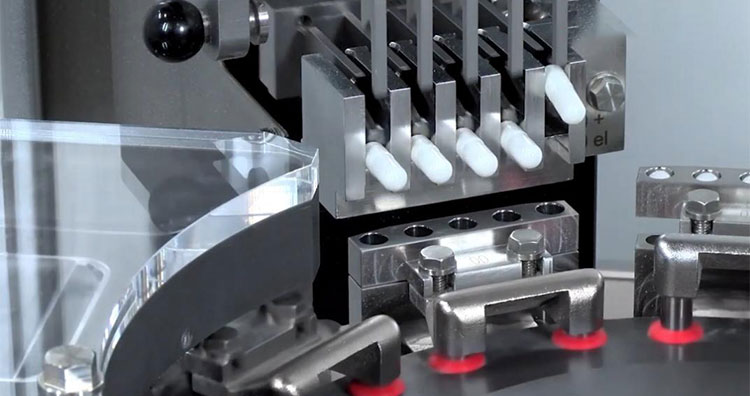

Capsule Filling Machine

AIPAK NJP-400C Automatic Capsule Filling Machine

Capsule filling machine is new design sophisticated machine designed to fill hard gel capsules with powder or granules mixture. The machine is made from stainless steel which consists of several components including a new powder hopper, capsule hopper, capsule separation unit, filling unit, and control system etc. It follows automatic system to carry out the entire process of vitamin capsule production from capsule separation till filling, locking, and ejection.

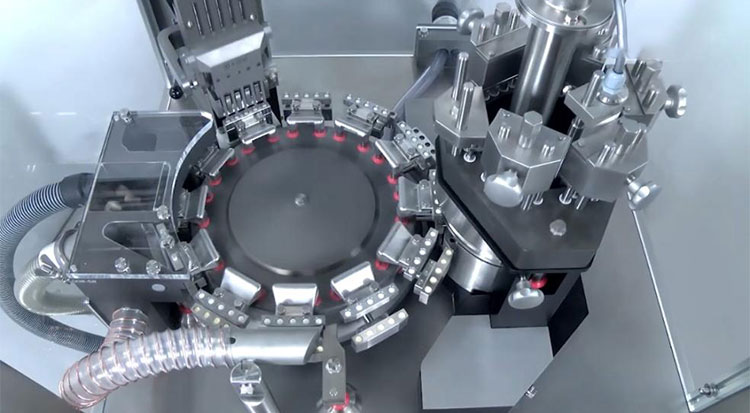

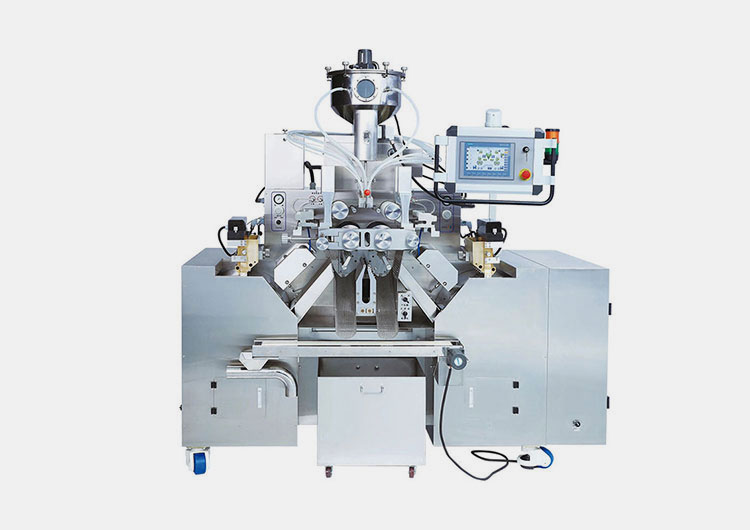

Softgel Encapsulation Machine

AIPAK SEM-100 Softgel Encapsulation Machine

Softgel encapsulation machine is another such equipment which is needed for making vitamin capsule in softgel form such as Omega-3 softgel capsules and vitamin E capsule etc. This machine is highly robust with heavy-duty machinery mainly composed of a cooling system, softgel former, hopper, wedge, spreader box, and tumble dryer etc. With the help of these parts, the machine pump the molten gelatin for softgel formation. Similarly, precise liquid vitamin essence is enclosed in the shell which is then sealed to make softgel capsules.

Handheld Capsule Filling Machine

Capsule Filling Machine Size 000- Picture Courtesy: allincapsule.com

Handheld capsule filling machine is a compact apparatus best suitable for home level production of vitamin capsule. It does not require any electricity or proper maintenance rather simply used by operator. It consists of certain parts including powder spreader, powder tamper, frame plate, capping plate, middle plate, spill guard, and body plate. By using these components, one can easily make vitamin capsules at home.

Weigh Scale

RS PRO Bench Weighing Scale, 300g Weight Capacity- Picture Courtesy:

Weigh scale is also an important tool to be used for precise weighing of the ingredients used in making vitamin capsules. Although, its size and design may vary from one type to another, however, the structure remains the same. The main parts include a weighing scale, electrical unit, and digital screen. It is often used in laboratories and research centers.

Mixer Machine

AIPAK DLH Series Cone Mixer

Mixer machine is another notable equipment used for making vitamin capsules. Its primary function is to mix various free flowing and adhesive powders or granules uniformly which is one of the significant steps whilst vitamin capsule production. It also break down the lumps formed in powders. This cone mixer machine has simple design with cone shape body inside which agitator is fixed. The movement of agitator let the powder mix and move freely.

Capsule Polishing Machine

AIPAK NFJ-150 Automatic Capsule Polishing Machine

Capsule polishing machine is an innovative apparatus well known for its function of polishing produced vitamin capsules. It also undertake the task of sorting capsules making it more comprehensive in application. The machine has hygienic body which facilitate the safe handling of capsules without any distortion. The capsules are entered from one end via hopper and thoroughly processed for polishing and sorting after which they are released from the chute located on the other end.

5.What Are The Types Of Vitamin Capsule?

There are different types of vitamin capsule available in market today. Each carry unique benefits and is used for specific outcome. Some of the commonly used vitamin capsules are enumerated as under:

Vitamin A Capsule

Vitamin A Capsules 10,000iu

Vitamin A capsule is one of the popular vitamin capsules used to treat immunity and eye health. It can help in recovering the weak eyesight and making your skin and immune system healthy.

Vitamin B Capsule

Vitamin B-50 complex capsules bottle- Picture Courtesy: herbafit.com

Vitamin B capsules are used for maintaining the health of cells, brain, heart, and metabolism. It is a good source to boost energy. There are different types of vitamin B capsules. The common examples include vitamin B1, B2, B12, and B-complex.

Vitamin C Capsule

Vitamin C capsules- Picture Courtesy: passionpulse.pk

Vitamin C capsule is another type which is frequently used for its diverse health benefits for heart health, skin, immunity, and controlling common cold. It is extracted from citrus food such as oranges and lemons. Thus, vitamin C capsules are purely natural.

Vitamin D Capsule

Vitamin D capsules

Bone health is one of the major concerns of people which is now growing due to the deficiency of vitamin D. For this reason, vitamin D capsules are made to facilitate the calcium absorption in body, so that, the bones and joints could be strengthen.

Vitamin E Capsule

Vitamin E softgel capsules- Picture Courtesy: chaldal.com

Another type of vitamin capsule include vitamin E capsule which is famous for its antioxidant properties. It is obtained from many foods such as vegetable oils, cereals, and fruits etc. It is good for skin health, improving vision, and protecting cells from free radicals.

6.Explain The Benefits Of Vitamin Capsule?

Vitamin capsules are beneficial for various reasons. Let's explore few of them!

Prevent Deficiency

Vitamin deficiency causing skin problem- Picture Courtesy: savarnasmantra.com

The foremost advantage of vitamin capsules is that they are useful in preventing the deficiency of vitamins in our bodies which need essential vitamins for survival and healthy functions of organs. In essence, vitamin A capsule is useful to treat night blindness, while as, vitamin D can help get the necessary constituents required for maintaining healthy bones and joints.

Easy to Swallow

Whether hard gel or softgel vitamin capsules, they are easily swallowable without leaving any bitter taste as is the case with tablets. For this reason, people of all ages can easily take vitamin capsules.

Convenient Administration

A person taking out vitamin capsules from bottle- Picture Courtesy: istockphoto.com

Vitamin capsules are extremely handy that you can take them alongside you wherever you go. Moreover, there is simple routine of taking vitamin capsule with no hard restrictions. Together with precise formula, vitamin capsules are convenient to consume.

7.Enumerate The Possible Side Effects Of Vitamin Capsule?

Although, vitamin capsules are known for their long lasting benefits still there are potential side effects which must be kept in mind during consumption. These are highlighted below:

Upset Stomach

Man with stomach problem- Picture Courtesy: balancenutrition.in

Overdosing vitamin capsule or continuing them for months may affect your stomach which result in bloating and heart burn. It may also leads to diarrhea and constipation.

Allergic Problem

Food allergy icon- Picture Courtesy: thesafetymag.com

As vitamin capsules are made by using the extraction of fish, poultry, vegetables, and fruits etc., some people do have allergic problem. In that case, vitamin capsule can have negative effects on the consumer health.

8.What Is The Best Storage Condition For Vitamin Capsule?

Vitamin capsule bottles on shelves- Picture Courtesy: iStock

As far as the best storage condition for vitamin capsule is concerned, so, it is similar to other forms of medications like pharmaceutical tablets, pills, and syrups etc. Keep vitamin capsules in airtight containers most preferably glass bottles or jars as they are hygienic. Apart from this, ALU ALU or blister packaging may also be used for more safe storage where each vitamin capsule is separate from the rest.

Similarly, it is necessary to store vitamin capsule in a cool and dry place away from kitchen or bathrooms which are often warmer and humid. Try to avoid direct sunlight as it can ultimately decrease the quality of vitamin capsule.

9.Is It Okay To Fill Your Own Vitamin Capsule?

Person discharging vitamin capsules over tray- Picture Courtesy: mountainherbs.com

Absolutely yes! It is perfectly fine to fill your own vitamin capsule. In fact, most of the people having reservations about the quality and hygiene of products made in factors tend to make their own vitamin capsule. It is also very easy as you are only required to have the knowledge about ingredients and equipment used along with right method which is all explained in the questions above.

10.Factors To Consider When Making Vitamin Capsule?

There are certain factors which you should keep in mind when making vitamin capsule. These are enlisted below:

Environment

Temperature icon- Picture Courtesy: stock.adobe.com

The environment in which you are making vitamin capsule is crucial to pay heed for. It must be clean, free from moisture, and possibly cold. The reason is because vitamin capsules are delicate that they can easily get contaminated if exposed to environmental factors. Thus, it should be considered for safe manufacturing.

Quality Control

Quality control icon- Picture Courtesy: mybusinesswisdom.wordpress.com

Quality control is essential for the stability and quality of vitamin capsule. These include adhering to practices under national and international quality standards such as ISO and FDA. In addition to it, certain tests should be conducted to know the disintegration, weight, and thickness of produced vitamin capsules.

Ratio and Compatibility

While making vitamin capsules, it is significant to get right information about the ratio of various ingredients used in manufacturing process. In the same manner, compatibility of different substances must be checked to avoid deterioration.

Conclusion

To sum up this FAQ guide, we hope you have got the answer to How To Make Vitamin Capsule. Well, it is pretty easy to produce vitamin capsule both on industrial level and home level the thing important is to pay attention to several factors. You should have the idea about necessary ingredients and the equipment used. Similarly, the right method is pivotal for successful manufacturing which must not be neglected. So, it was all on part of us. If you have enjoyed this post and you are eager to know more about vitamin capsule and associated machinery then AIPAK welcome you. For further information please contact us through our website! Thank you for reading!

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine