How To Make The Capsule Filling Machine Have More Stable Performance?

The traditional Chinese herbal medicine pharmaceutical method has a long cycle and relatively high cost, and the medicine cannot be stored for a long time, which is difficult to meet the modern fast-paced life. However, the production of capsules, a form of drug outsourcing, solves the above dilemma.

The traditional capsule manufacturing process is complicated. In recent years, with the continuous development of science and technology, capsule equipment has been widely used. Its short production cycle, high efficiency and low cost play a pivotal role in the capsule production process.

At present, with the development of automation technology, equipment with a higher degree of automation has emerged to meet the needs of efficient production of capsule companies.

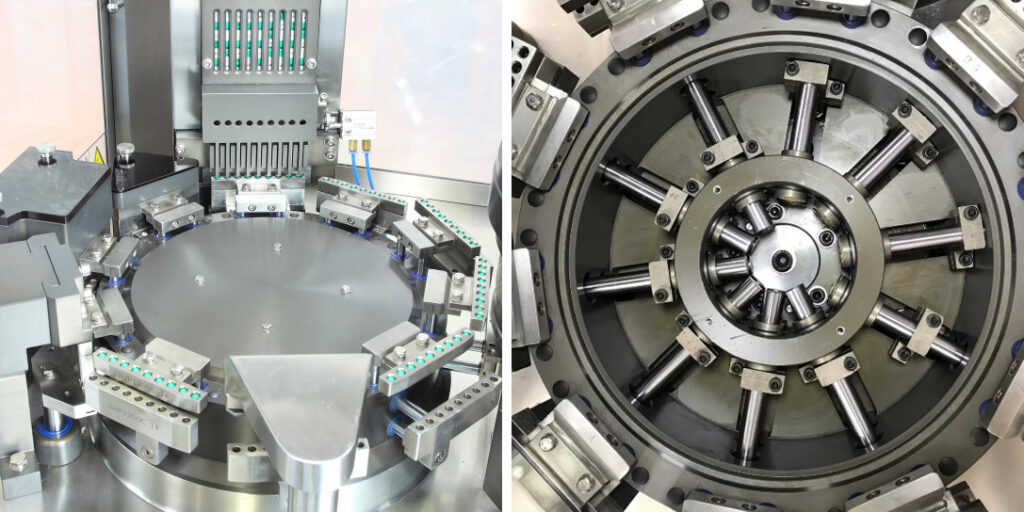

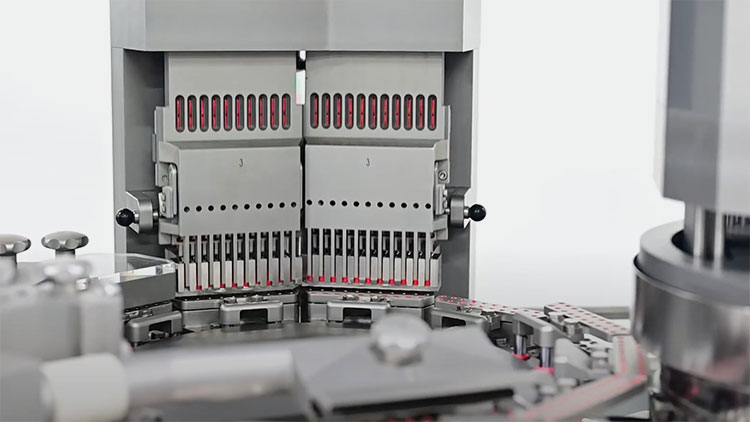

The automatic capsule filling machine is a device integrating machine, electricity and gas. It improves the frequency and amplitude of the vibrator and the radian of the arrangement guide plate on the basis of the traditional capsule filling machine, so that the arrangement speed is faster.

The automatic arrangement has a higher success rate, and has the characteristics of small size, low energy consumption, fast mold replacement, convenient operation and easy cleaning.

It is understood that the automatic capsule filling machine has become economical practical equipment for filling capsule medicines in the pharmaceutical industry. According to the movement state, the automatic capsule filling machine is mainly divided into two types: intermittent movement and continuous movement.

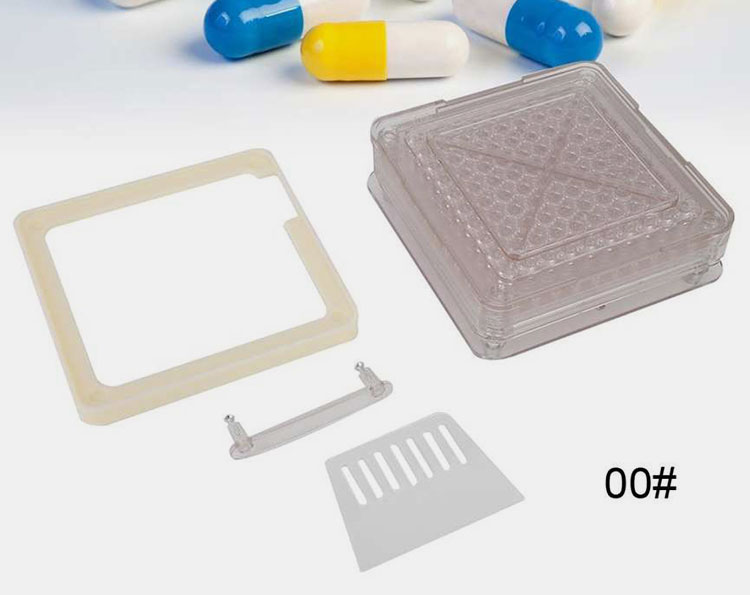

According to the structure, it can be divided into metering disk and needle tube type. At present, the metering disk is mainly used in large-scale production.

According to a manufacturer's introduction, the bottom of the metering plate of its automatic capsule filling machine is embedded with an imported sealing device, which improves the powder leakage situation.

The powder scraper makes the head and tail loading of each station of the metering plate consistent with other holes, which is beneficial to improve the loading accuracy of the powder.

In addition, the man-machine interface of the machine is equipped with intelligent modules, and the monitoring functions are complete. It realizes automatic diagnosis and monitoring, automatic alarm and stop for operation failures such as material shortage, lack of capsule, material channel blockage and mechanical failure.

Statistical preparation of production date, production time, real-time per-grain measurement and cumulative output can be guaranteed.

In recent years, with the stricter supervision of the pharmaceutical industry, capsule companies have become more stringent in the selection of equipment.

In order to meet the needs of users, some manufacturers continue to improve the equipment so that the automatic capsule filling machine avoids cross-contamination and energy saving.

Some manufacturers redesign the discharging mechanism of finished capsules, eliminating the need for air compressors, thereby reducing the overall size and noise of the whole machine to avoid cross-contamination and movement failure caused by pneumatic discharge, and achieve significant energy-saving effect.

In addition, in view of the different characteristics of Chinese and Western medicines, some manufacturers require larger operating pressure for filling, increase the size of the cam, and use nitrogen flower treatment on the surface of the cam to increase the surface hardness and ensure the service life and operational reliability of the equipment.

According to experts, with the development of the capsule industry and the improvement of national GMP standards, there are new requirements for the structure and equipment design of capsule filling machines. So there are many filling machine manufacturers who have invested in the goal of improving equipment. For example:

The inner surface of the equipment contacting the material is mirror polished, and the outer surface is matt.

All concave and convex parts on the inner and outer surfaces of the equipment adopt arc transitions or chamfer transitions of not less than 135 degrees.

It is equipped with all relevant material conveying pipes and quick joints between the outlet of customers’ capsule filling machine's feeding barrel and the receiving barrel of capsule finished product, and the whole process is in a sealed conveying state.

All parts are connected in the form of quick installation and easy cleaning.

The design of the connection structure between the equipment and the relevant plant floor must ensure that the plant facilities are not damaged, there is no dead angle, it is easy to clean, and it is easy to maintain.

Every aspect of part design has a certain impact on the overall performance of the equipment. In this regard, great patience and sufficient technical experience are required to ensure the successful upgrade of the equipment.

With the development of automation technology and the efforts of the capsule filling machine industry, the automatic capsule filling machine is currently the most popular capsule filling equipment in the pharmaceutical industry.

It is based on the traditional capsule filling machine and has been repeatedly improved. The frequency and amplitude of vibrator and the radian of the arrangement guide plate are improved so that the arrangement speed is faster and the success rate of automatic arrangement is higher.

The automatic design is conducive to saving manpower and material resources, and is more in line with GMP requirements. In addition, it is carried out in a closed environment, which also reduces the pollution of drugs by human factors.

In the past, Chinese capsule manufacturers used expensive imported equipment. In recent years, with the continuous development of domestic capsule filling technology, Chinese capsule filling machines have their own advantages compared with imported products.

According to the industry, the advantages of China’s capsule filling machines are very obvious, such as low price, low maintenance cost and convenient after-sales service. As long as the advantages of the equipment are fully utilized scientifically and rationally, the performance of these equipment can be brought into play, so that the equipment can better serve production.

In fact, in recent years, there are many buyers who have the intention of purchasing a Chinese capsule filing machine, but the premise is to ensure stable performance. Therefore, for every capsule filling machine manufacturer, stable performance is also one of the directions that needs continuous improvement.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine