How To Make Tablets

In today's life, tablets are used more and more widely. Many functional medicines and household & industrial detergents are often made into tablets for people to use. For example, cold tablets and effervescent tablets that people often take, detergents and toilet cleaning effervescent tablets that housewives often use, etc., have brought great convenience to people's lives.

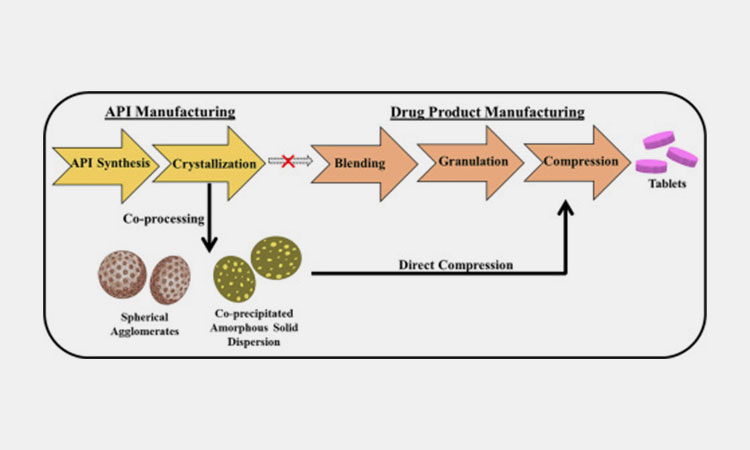

Tablet Manufacturing-sourced: brandnutra

The benefits of tablets are many. Including, simple production method, easy to use, easy to swallow, small side effects, easy to package and transport, able to control the dosage well, able to delay the effect of the drug, etc.

So. How are tablets made? Although most tablets look similar, their manufacturing processes and formulations are different. Through this article, you can have a thorough understanding of tablets and the production process of tablets, so that you can have an in-depth understanding of the characteristics of tablets. Let's start exploring together!

1.What Are Tablets?

Tablets-sourced: brandnutra

A tablet, also known as a pill, is a pharmaceutical oral dosage form or solid unit dosage form. Tablets refer to a mixture of pharmacological substances pressed into a small cake or bar with a specific dose of medicine.

There are many types of tablets. Different tablets have different formulations and manufacturing processes. Making tablets mainly involves formula and production process. A good formula and fine manufacturing process can result in good tablets.

Types of Tablets:

Oral Tablets

Oral Tablets-sourced: usnews

Oral tablets are ordinary tablets that can be swallowed directly with warm water. This tablet is one of the most popular tablets available today. It includes coated tablets, multilayer tablets, etc.

Chewable Tablets

Chewable tablets are pills that can be chewed orally and then swallowed. Chewable tablets are generally the same size as regular tablets and can be made into different shapes as needed. The more common chewable tablets on the market include calcium carbonate chewable tablets, vitamin chewable tablets, etc.

Effervescent Tablets

Effervescent tablets refer to tablets containing effervescent disintegrants. Effervescent tablets can produce gas when exposed to water, causing the tablets to rapidly disintegrate. Such as effervescent vitamin C tablets, etc.

Dispersible Tablets

Dispersible tablets refer to tablets that can quickly disintegrate when placed in warm water and then disperse in water to form a suspension. This tablet is suitable for infants, young children, the elderly, etc. who have imperfect swallowing functions.

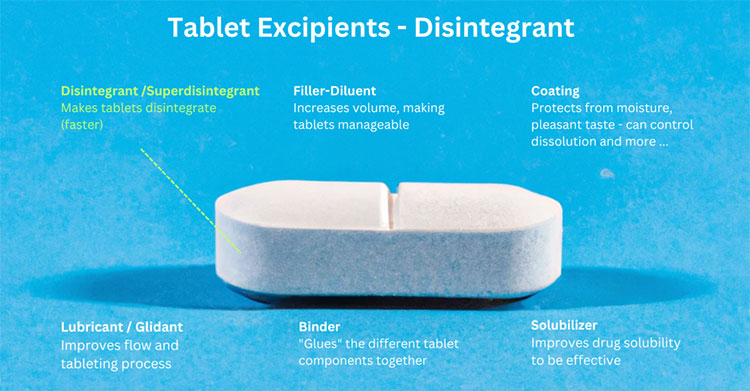

2.What Are The Excipients That Needed For Making Tablets?

Excipients are additions to the main drug. They are stable in nature which have no incompatibility with the main drug without any side effects, and do not affect the efficacy. In the production process of tablets, excipients play an important role, including binding, lubrication, disintegration, emulsification, coloring, flavoring, preservatives, etc.

Types of Excipients:

Diluents

Diluents-sourced: thermofisher

Diluents are inert substances that facilitate dilution of the powder during tablet processing. Typical diluents include calcium phosphate, cellulose, starch, sorbitol, lactose, dextrin, and so on.

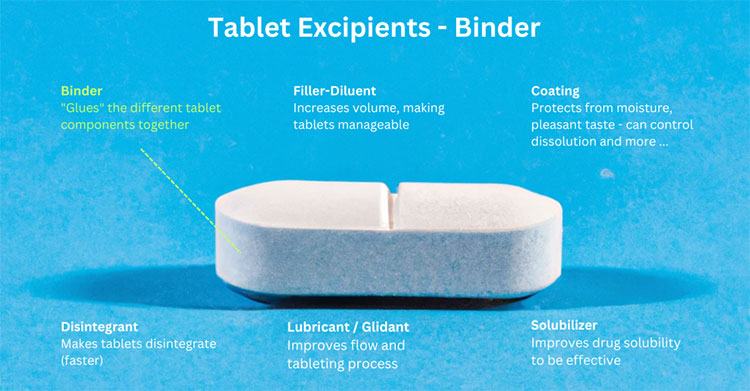

Binders

Binders-sourced: pharmaexcipients

Binders are one of the most important auxiliary materials for tablet making. It allows different materials in the tablet formula to be well combined, thus facilitating later compression. There are different binders including liquid glucose, gelatin, povidone, zein, starch, and so on.

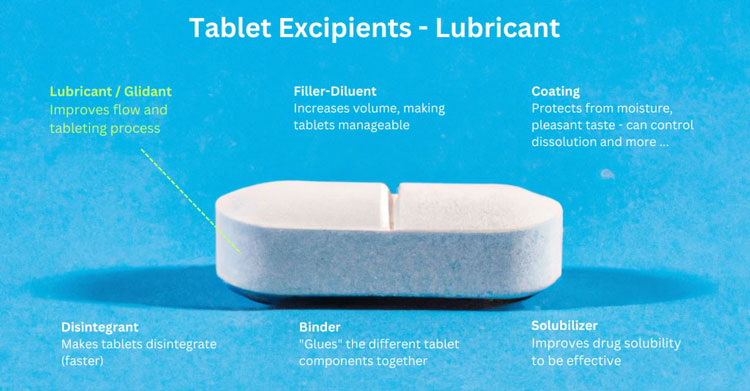

Lubricants

Lubricants-sourced: pharmaexcipients

A certain amount of lubricant must be added to the tablet particles before tableting to increase the fluidity of the particles. This can reduce the friction between the particles and the die, which facilitates subsequent tablet pressing and the appearance and neatness of the tablets. Common lubricants include calcium stearate, magnesium oxide, polyvinyl alcohol, stearic acid, talc, etc.

Glidants

A glidant is a substance used to improve the flow of powders to ensure uniform mixing and correct dosing of drugs during production. Common glidants include cellulose, starch, talc, magnesium trisilicate, etc.

Disintegrants

Disintegrants-sourced: pharmaexcipients

Disintegrants refer to substances that can quickly break tablets into small particles in gastrointestinal fluid, so that functional ingredients can be quickly dissolved and absorbed to play their role. Most of these substances have good water absorption and swelling properties, which can achieve tablet disintegration. Common disintegrants include alginic acid, cellulose, colloidal silicon dioxide, croscarmellose sodium, etc.

Coloring Agents

Coloring Agents-sourced: pharmaeducation

Coloring agents can dye the tablet very well, thus changing the color of the tablet. Common coloring agents include lake pigments, etc.

Flavoring Agents

Flavoring Agents-sourced: pharmaeducation

Flavoring agents can mask bad odor in tablets, thereby aiding swallowing and taking of the tablets. Common flavoring agents include ethyl maltol, ethyl vanillin, menthol, vanillin, etc.

3.How To Make Tablets?

Tablet making is mainly the process of pressing and making granular and powdered drugs. This process can be divided into manual DIY production and machine production. The manual production process requires you to use molds to make it. The process of using the machine is relatively simple and safe. Next, we will explain to you making tablets with hand press and the machine press.

(1)Making Tablets With Hands:

Hand Tablet Making-sourced: farmalabor

Hand tablet press is the simplest and most portable way to make tablets. Its production tool is very light and requires no power supply, making it easy to carry. The advantage of this method is that it can be suitable for laboratory and small batch production of formula tablets and granulation, making it an ideal choice for families and laboratories.

Tools Needed For Hand Tablet Press

There are several tools that needed for you to use when you are making tablets with your hands:

a.Tablet Triturate Molds

Tablet Triturate Molds -sourced: totalpharmacysupply

Tablet triturate molds are suitable for the production of various vitamin and pharmaceutical tablets. It's made from durable, corrosion-resistant anodized aluminum. Each mold consists of a bottom plate and a top plate with corresponding holes. Tablet preparation is possible with just your hand. Depending on how fast you press, you can get any number of tablets.

b.Pharmaceutical Scale

Pharmaceutical Scale-sourced: precisa

Pharmaceutical scale provides you with the most accurate weighing of mixed medications. The pharmaceutical ingredients in tablets need to be precisely dosed to ensure maximum safety and efficacy.

c.Steel Micro Lab Scoop

Steel Micro Lab Scoop-sourced: imedscientific

Steel Micro Lab Scoop is used for extracting powder during tablet making. It's perfect for taking small amounts of powder. The scoop's handle is very finely crafted and easy to hold.

d.Pharmaceutical Spatula

Pharmaceutical Spatula-sourced: htss

Pharmaceutical spatula is a tool that is specially used to fill a mixture of drug granules or powders into the holes of the mold. It is mainly made of stainless steel, very safe and clean.

B.Steps of Hand Tablet Making

Steps of Hand Tablet Making-sourced: Farmalabor

STEP 1: Insert

Insert the first plate on the base, followed by the other two plates.

STEP 2: Install Slider

Use the slider if the quantity needed is less than 100 pieces.

STEP 3: Mix

Mix the functional substances with the base tablet, then add the biding solution to the mixture. Work it with the mortar until you obtain a smooth paste

STEP 4: Spread

Spread the paste with the spatula, in order to fill the holes completely. Before use the tablets, let them dry on the plate for 12/24 hours.

STEP 5: Push

Push with your fingers the lower plate until tablets come out from holes.

There are three different ways to make tablets with machine: manual tablet press with machine, semi-automatic tablet press with machine and automatic tablet press with machine. The advantages of making tablets with machines are efficient, safe, high quality, high capacity and so on.

(2)Making Tablets With Machines:

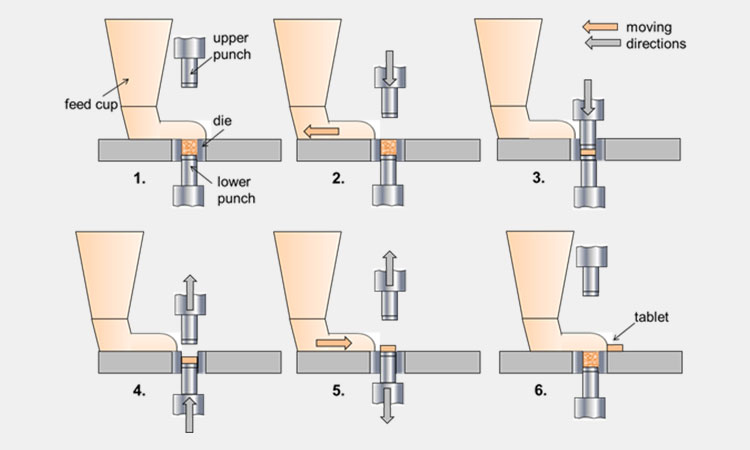

A.Manual Tablet Press With Machine

Manual Tablet Press-sourced: besttabletpress

Manual tablet press is a method of using a manual tablet press to compress drug powder or granules into tablets. This method is very simple and direct. A lot of human support is required. The equipment required for this method is: manual tablet press machine, weight scale, and mold.

Manual tablet press machine is also called as hand pill tablet press machine or single punch tablet press machine. Manual tablet press machine has compact structure and light weight. It can be placed on the ground or on the table. And it supports mold customization, which can facilitate your mold customization, etc.

a.Step of Manual Tablet Press

Step of Manual Tablet Press-sourced: besttabletpress

STEP 1: Filling.

Powder or granules are manually filled into the hopper.

STEP 2: Weight Adjustment.

After controlling the amount of tablets you need, operate the hand lever to compress the powder or granular material. The powder in the grinding tool will be compressed by the upper and lower punches.

STEP 3: Compression.

When the powders are compressed, they are converted into tablet form. Tablet compression is accomplished by adjusting the tablet's hardness and thickness. The greater the pressure, the harder the tablet.

STEP 4: Ejection.

Ejection is the final stage of the tableting process. After the tablets are compressed, they can be de-molded from the mold and packaged.

B.Semi-automatic Tablet Press With Machine

Semi-automatic tablet press refers to the use the semi-automatic tablet press machine to complete the tablet compression. This method is a combination of manual loading and automatic tableting. It can press the tablets evenly up and down at the same time, so that the air in the drug particles can be fully discharged. The advantages of this method are small machine vibration, low noise, low energy consumption, high efficiency, and accurate tablet weight.

a.Steps of Semi-automatic Tablet Press

Steps of Semi-automatic Tablet Press-sourced: sedpharma

STEP 1: Adjustment.

Adjust the mold to make the punch position of the lower punch of the mold from the lower end of the middle die hole to the position inside the middle die hole.

STEP 2: Filling.

Load the drug powder or granules into the hopper. After starting the machine, the drug powder or granules in the hopper will automatically be filled into the hole in the middle of the mold.

STEP 3: Compression.

The upper punch will fall into the die hole from the upper end of the die hole and suppress the drug powder or granules.

STEP 4: Ejection.

When the drug powder or granules are pressed and formed, the lower punch will automatically rise to push the tablet out of the die hole.

STEP 5: Refilling.

After the previous round of tablets is pressed, new drug powder will be added into the hopper and mold again to start a new round of tablet pressing.

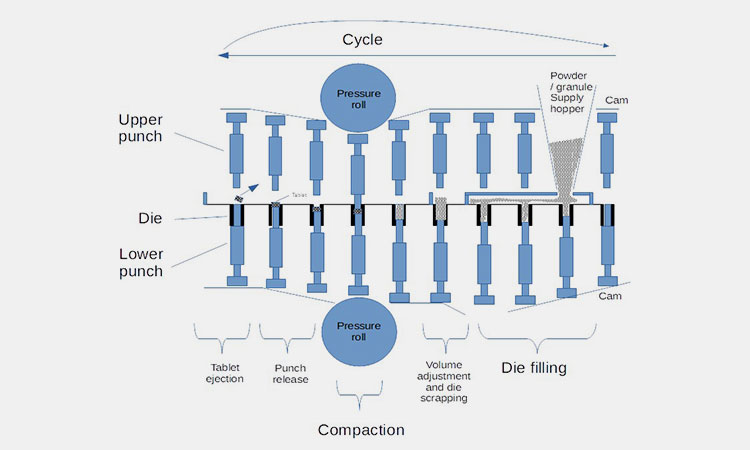

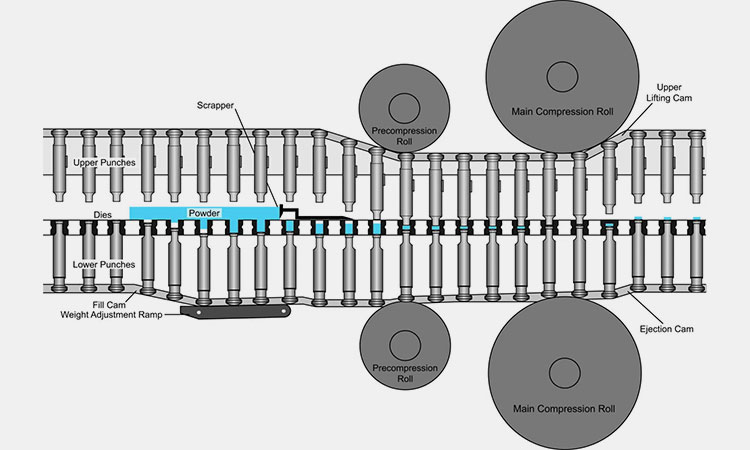

C.Automatic Tablet Press With Machine

The automatic direct compression refers to use the automatic tablet press to complete the tablet compression. The automatic tablet press is the rotary tablet press machine. The whole process of automatic direct compression includes powder or granule filling, pre-compression, main compression, tablet ejection, rejection.

a.Steps of Automatic Tablet Press

Steps of Automatic Tablet Press-sourced: natoli

STEP 1: Filling.

Powder or granules are filled into the hopper. Sensors in the hopper continuously monitor the powder level. After filling, control the tablet weight you need according to different molds.

STEP 2: Pre-compression.

The material will be partially formed under the action of the pre-compression roller. During the pre-compression stage, the air in the material will be pressed out, and the tablets will be compressed more evenly. If air remains inside the gap, it will affect subsequent capping problems.

STEP 3: Main Compression.

The main pressure roller can exert greater pressure and compress the powder more tightly and evenly.

STEP 4: Tablet Ejection.

After the tablet is compressed, it will be polished to make the surface of the tablet smoother and brighter.

STEP 5: Rejection.

After the tablets are ejected, the machine will monitor and screen, collect and reject all unqualified products.

4.What Are The Important Aspects Of Making Tablets?

The most common methods of making tablets are direct compression, dry granulation and wet granulation. The active pharmaceutical ingredients (API) contained in different drugs are different, and different preparation methods may affect the active ingredients in the drugs. Even if the correct equipment is selected, various defects may occur that affect tablet quality and create defects.

The important aspects of making tablets:

Compression Properties of the API

Compression Properties of the API-sourced: sciencedirect

The solubility, stability, in vitro dissolution and bioavailability of API are crucial to the formulation. It affects not only formulation selection and design, but also powder flow and performance.

Physical and Chemical Stability of API During Making Tablets

Some tablets have active ingredients that are highly sensitive to moisture, or cannot withstand high temperatures, etc. These are their physical properties. These physical properties are not suitable for wet granulation methods. The active ingredients of some tablets can chemically react with some binders and disintegrants, so such tablets can only use the most direct direct compression method.

Particle Size of Formula Ingredients

Particle Size of Formula Ingredients-sourced: capsulcn

Different particle sizes will affect subsequent grinding, screening, pressing, granulation, etc.

Manufacturing Cost

Considering the cost requirements, the production process of direct compression is complex but low cost. The production process of dry granulation and wet granulation is simple but the cost is higher.

5.What Other Equipment Are Used In Tablets Making Process?

There are a lot equipment are used in the tablets making process for different needs:

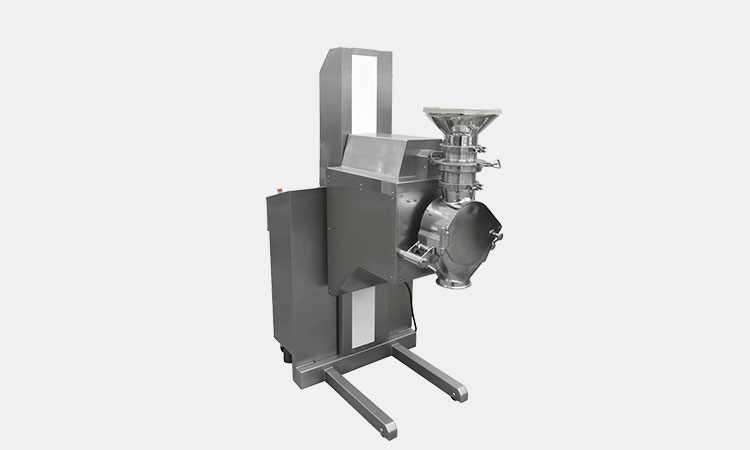

Grinding Equipment

Hammer Mill-sourced: lbbohle

The first step in the tablet making process is grinding and crushing. Commonly used grinding equipment in the tablet manufacturing process include various grinding equipment, such as hammer mills, vibration mills, pin mills, end-runner mills, edge-runner mills, cutter mills, and ball mills, etc.

Weighing Scale

The success of tablet making depends on accurate weighing of the materials. Some automatic machines have matching precision scales. Manual tablet presses require you to use a matching scale.

Granulator

High Shear Granulator

The granulator is suitable for dry granulation and wet granulation except direct compression. Currently commonly used granulators include mechanical agitator granulators, high-shear granulators, fluidized-bed granulators, and dry granulators.

Mixing Equipment

The most common powder and granule mixing equipment include diffusion mixers, convective mixers, ribbon blenders, etc.

Drying Equipment

Drying Equipment-sourced: neocorp

Drying equipment is mainly used to reduce moisture in tablets. Commonly used tablet drying equipment include spray dryers, rotary dryers, and fluidized-bed dryers, etc.

Tablet Press Machine

The dried powders and granules are finally pressed into tablets of uniform shape, size and weight by a tablet press. There are high-speed rotary tablet machines and multi-layer rotary tablet presses for your choice.

Coating and Polishing Machines

Coating and polishing are the final steps in tablet production. The coating can mask the odor of the drug. Polishing can make it easier for users to take.

6.What Are The Quality Control When Making Tablets?

In the pharmaceutical manufacturing process, quality control is very important. The manufacturing process for each tablet follows strict quality standards. The entire process must be strictly monitored and controlled. In order to make the production of tablets meet the specified quality standards, it is necessary to conduct quality test on the production of tablets.

There are two important tests that need to carry out on tablets.

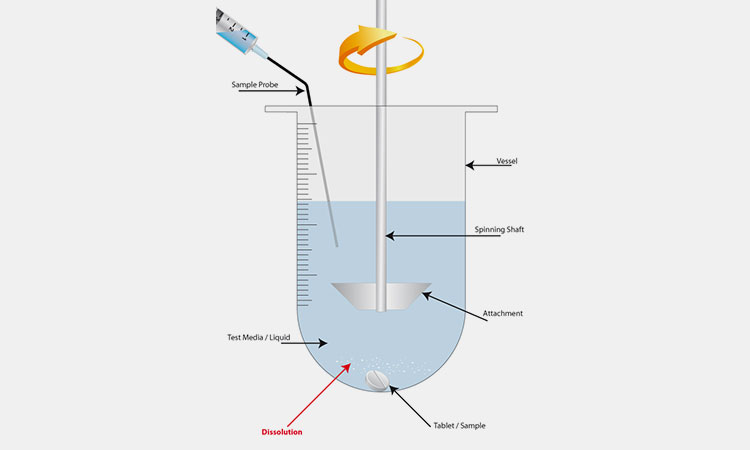

Dissolution Test

Dissolution Test-sourced: totallaboratoryservices

Dissolution test is a method to correctly test and evaluate the dissolution of tablets. Dissolution can be a good predictor of tablets and a quality standard for production. Because the dissolution rate of tablets is very important for testing the efficacy of tablets.

In order to test the dissolution of tablets, general manufacturers can use equipment with specific test conditions and combine it with acceptance criteria to evaluate tablet performance. There are four standardized apparatus for you to conduct the test including basket, paddle, reciprocating cylinder, and flow-through cell.

Content Uniformity Test

Content Uniformity Test-sourced: pharmapproach

Content uniformity test is one of the tests used to evaluate the quality of tablet batches. This test can help ensure that the strength of a tablet remains within specified acceptable limits. After the tablets are made, each batch of tablets needs to undergo this kind of test to ensure the safety and quality of the tablets.

If the individual drug content in your formula is about 85% to 115% of the average content, the tablets you make meet the test requirements. If the individual drug product in your formulation exceeds these limits, or if one of the drug ingredients alone exceeds 75% to 125% of the average content, your formulation does not meet the testing requirements.

7.What Are The Common Defects During the Tablet Making?

Good quality tablets should be free of any visual and functional defects. Serious tablet defects can have serious consequences for patients. The common defects during the tablets making are:

Visual Defects:

Visual defects after tablet production include rough and uneven surfaces, large color differences, insufficient dryness, cracks, agglomerations, wrinkles, too soft, unshaped, and insufficient tablet coating.

Causes

Use of inferior raw materials, insufficient mixing of raw materials, equipment failure, wrong temperature settings, inaccurate ingredient control of formula ingredients, insufficient pressing time, etc.

Functional Defects:

Functional Defects-sourced: aaps

Tablet weight variation. Tablets do not disperse or release easily. Tablets do not dissolve properly in water. Reduced tablet stability, pigment changes and oxidation, etc.

Causes

Uneven distribution of excipients and raw materials. The binders and coating materials in the formulation are not suitable. Improper temperature, humidity or lighting conditions during preparation. The amount of active ingredient in the formula is too high or too low. Improper filling selection. Improper pressure during preparation, etc.

8.What Are The Goals To Aim For Making Tablets?

The tablet making is complex. The goals that need to be achieved during the manufacturing process of tablets are:

No Surface Defects

Making Tablets-sourced: pharmtech

Tablets with smooth and clean surfaces are not only convenient for patients to take, but also provide patients with a good taking experience and reduce patients’ anxiety and pain.

Chemically and Physically Stable

Chemically and physically stable tablets facilitate long-term administration and storage. Long-term storage will not affect the efficacy and appearance of the tablets.

Hard Exterior

Hard Exterior-sourced: wtop

Tablets that are strong and hard enough to facilitate subsequent packaging, transportation and distribution, and can withstand mechanical physical impact.

Conclusion

Making tablets is a rigorous and complex process, which not only requires precise material dosage and formula matching, but also requires strict operation and monitoring of tablets. From this how to make tablets post, you can know well about the ways and methods to make your ideal tablets. If there are more you want to know, never hesitate to come to us for help!

Don't forget to share this post!

Drier Machine Related Products

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine