How To Make Tablet Content Uniform?

You may always have your tablets in the same size and shape of a tablet type. But can you prove the content uniformity of your tablet? In pharmaceutical industry, the little wavering of your medicine content may affect the medicine effect and also lead the change for your recovering.

So how to make tablet content uniformity? What are the tablet manufacturing method? Why should you make the uniform tablet content? How to solve tablet content uniformity? What machines can help you make the uniform tablet content? You may find the answers here! Come on and have a check!

1.What Is Tablet And Tablet Content?

Tablet-Sourced:verywellhealth

Tablet is a medicine type which is widely used in pharmaceutical industry. It has the various type and you may find round, square, oval and so on. It has also different size and you may take it in oral. Tablets makes the outstanding transferring job of your needed nutrition and medicines.

Tablet content refers to the active ingredients and excipients which make the relative curing or caring job in human body. You may find the difference tablet content for different types of tablets.

2.What Are The Tablet Manufacturing Method?

Have you ever wondered the tablet manufacturing method? Here is the common tablet manufacturing methods.

Wet granulation

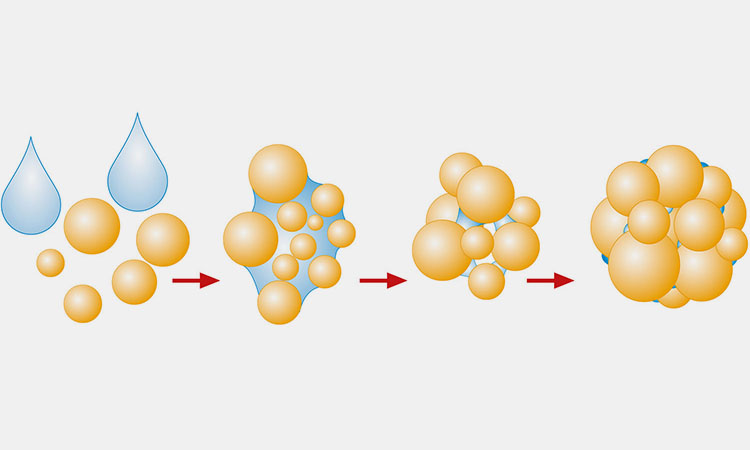

Wet Granulation-Sourced:foodfeedfinechemicals

Wet granulation refers to the tablet manufacturing process which apply the adding of solution in powder mass. For wet granulation, you should apply API, excipients and binder solution as the important material. The wet screening and granule drying makes the great tablet.

Dry granulation

Dry Granulation-Sourced:idiva

Dry granulation has the general process of pressed the mixed powder into bulk and then separate them as the even granules. Dry granulation saved the manufacturing process of wet granulation and saved the risk of heat exposing of medicine.

Direct compression

Direct Compression-Sourced:huadapharma

Direct compression makes the direct tablet manufacturing by pressing the powder. This granulation manner is economic and efficient. You may have your tablets formed with physical properties saved and potential risk avoided.

3.Why Should You Make The Uniform Tablet Content?

Why there is the request on making the uniform tablet content? Here you may check the reasons.

Potency prove

Potency Prove-Sourced:skginternationals

Why you should make the uniform tablet content? Potency is also the important factor for uniform tablet content. The uneven tablet content may lead the potency short or potency excess. You should make sure the potency for the great medicine quality.

Safety prove

Safety Prove-Sourced:ctvnews

The different tablet content makes different effect to your human body. And the excess may affect the shelf life of your medicine and also affect your body. The uniform and suitable tablet can prove your medicine safety.

4.What Are The Factors Affect Tablet Content Uniformity?

In tablet manufacturing, you may find the problem in making the uniformity of tablet content. And here are the factors which affect tablet content uniformity.

Blending or mixing equipment

Blending Or Mixing-Sourced:bulkinside

The high qualified blender and mixer can make the particles with same size which help make the even distributing of content on tablet. You should get the machine with high quality and great accuracy. Properly, you can get the great results here

Excipients

Excipients-Sourced:access-pharma

You should choose the excipients with great flow and even granules which may help you a lot in making the tablet with uniform tablet content. The unqualified excipients may lead the terrible tablet content uniformity.

Manufacturing manner

Manufacturing Manner-Sourced:theonpharma

In tablet manufacturing, you should take methods to avoid the agglomerates of the various material and you should also make the reasonable adding of the medical materials for the great uniformity of tablet content.

5.How To Make Tablet Content Uniform?

Raw Materials and Excipients

Active Pharmaceutical Ingredient (API) Processing

Particle Size Control

Particle Size Control-Sourced:nature

Ensure the particle size distribution of the API is uniform. For APIs with significant particle size differences, You may adopt methods such as grinding and sieving. This can help achieve more uniform particle size which makes the blending process more consistent and improves the content uniformity of tablets.

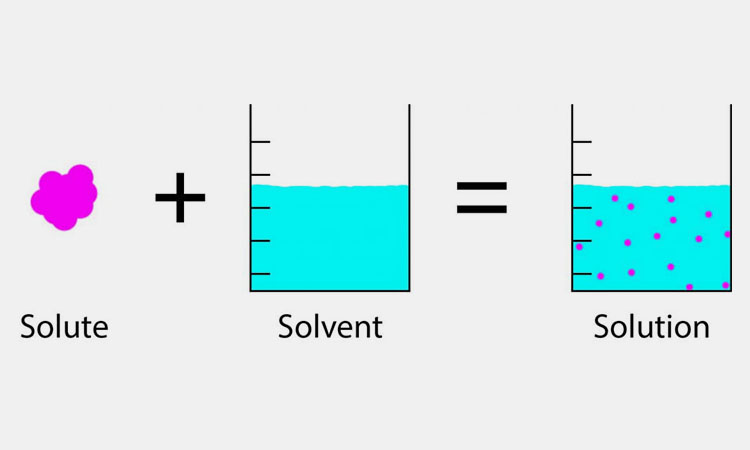

Solubility Enhancement

Solubility-Sourced:chemistrytalk

For poorly soluble APIs, you should apply appropriate techniques to improve solubility to help improve content uniformity. For example, converting the API into a solid dispersion, where the API is dispersed in molecular, microcrystalline or amorphous form within a water-soluble carrier material.

During tablet manufacturing, this form of the API can be more evenly distributed, which avoids content variability due to uneven dissolution.

Excipients Selection and Pre-treatment

Filler Selection

You should choose fillers with good flow properties and uniform particle size. For example, microcrystalline cellulose has good flowability and compressibility, which helps the API and excipients mix better during the blending process. Also, pre-treat the fillers, such as drying them to control their moisture content. This helps to avoid uneven blending caused by variations in the moisture content of the filler.

Binder Selection and Optimization

Binder Selection and Optimization-Sourced:jrspharma

Select an appropriate binder, such as hydroxypropyl methylcellulose (HPMC) which effectively binds the API and excipients together. Optimize the binder's usage through experiments to ensure the right binding strength between particles, avoiding issues caused by overly strong or weak bonding, which could lead to uneven drug distribution.

Disintegrant Selection and Addition Method

Choose an appropriate disintegrant, such as crosslinked sodium carboxymethyl cellulose, which can rapidly disintegrate the tablet when exposed to water, facilitating drug release and uniform distribution. The disintegrant can be added both internally (during granulation) and externally (after granules are dried), improving tablet disintegration and content uniformity.

Lubricant Selection and Dosage Control

Lubricant Selection-Sourced:machinerylubrication

Select lubricants that have minimal impact on content uniformity, such as calcium stearate. Control the lubricant dosage carefully, as excessive lubricant can cause stratification of the API and excipients during mixing which affects content uniformity.

Mixing Process

Equipment Selection and Parameter Optimization

Mixer Selection

You should choose the appropriate mixing equipment based on the properties of the API and excipients. For materials prone to static electricity, a double-cone mixer may be more suitable than a standard V-shaped mixer because its mixing method reduces static electricity generation.

Meanwhile, optimize mixing parameters, such as mixing time and speed, through experiments to determine the ideal settings for uniform blending of the API and excipients.

Preventing Segregation and Clumping

Preventing Segregation and Clumping-Sourced:atlasbars

During mixing, measures should be taken to prevent segregation and clumping of materials. For materials prone to segregation, you may consider adding excipients in layers—mixing some excipients, adding the API and other excipients, and continuing the mixing process. For materials that tend to clump, an anti-static agent or dispersing agent, such as silica, can be added to improve dispersion.

Optimization of Mixing Sequence

Reasonable Addition Sequence

Determine an optimal sequence for adding the API and excipients. Typically, most of the filler is added first for pre-mixing, followed by the API, and finally the binder, disintegrant, and lubricant. This helps the API better disperse within the filler and prevents the API from coming into direct contact with lubricants, which may affect its distribution.

Liquid Excipient Addition Method

Liquid Excipient Addition Method-Sourced:excipientworld

For liquid excipients, such as binder solutions, you may use an appropriate method for addition. One effective approach is to spray the liquid excipients evenly onto the solid materials while mixing, ensuring that the liquid excipients are uniformly distributed on the surface of the solid particles, improving mixing uniformity.

Granulation Process

Wet Granulation

Binder Addition Control

During wet granulation, you should accurately control the amount and rate of binder addition. Equipment such as peristaltic pumps allows precise control over binder addition should be applied. The binder should be added slowly and evenly to ensure uniform particle formation, preventing the accumulation of excessive binder in certain areas, which could lead to uneven content distribution.

Control of Wet Granule Drying

You should ensure uniform drying of wet granules. You should use appropriate drying equipment, such as a fluidized bed dryer, and control the drying temperature and time to ensure uniform dryness both inside and outside the granules. Uneven drying may result in variations in granule hardness and API distribution.

Dry Granulation

Pressure Control

Pressure Control-Sourced:fluidhandlingpro

In dry granulation, you should control the granulation pressure. Experimentally determine the appropriate pressure range to achieve uniform particle density and hardness. Improper pressure levels may cause uneven distribution of the API within the granules.

Material Pre-treatment

Before dry granulation, you should pre-treat the materials by controlling their moisture content and particle size. You should ensure that the materials are in the optimal condition which will facilitate more even distribution of the API during the granulation process.

Quality Control and Feedback

Selection and Optimization of Content Detection Methods

Content Detection Methods-Sourced:fleksy

Choose appropriate content detection methods, such as High-Performance Liquid Chromatography (HPLC) or UV-Visible Spectrophotometry. For different APIs and tablet types, you should optimize detection conditions, such as chromatographic column type, mobile phase composition, and detection wavelength, to ensure the accuracy and reliability of the results.

Process Quality Control and Feedback Adjustment

Quality Control-Sourced:getprodio

You should conduct process quality control during tablet manufacturing. Periodically take samples for content testing and adjust process parameters promptly based on the results. For example, if content uniformity does not meet the required standards, analyze potential causes (such as insufficient mixing time or incorrect binder amount) and adjust the corresponding process parameters accordingly.

6.What Machines Can Help You Make The Uniform Tablet Content?

In tablet manufacturing, you may adopt the various kind of machines. And there are the machines which can help make the uniform tablet content.

Air jet mill

Air Jet Mill-Sourced:shriramassociate

Mill like air jet mill, colloid mill and so on are applied in various place for the even and efficient crushing of medicine material. It can make the particles in the adequate and suitable size which make the even and uniform tablet content for the further work.

Mixer

AIPAK Mixer

There are various kinds of mixer. And you should choose the one according to your medicine material and excipients feature. You should also make the deep research for the great mixing parameter for the high qualified blending of your material.

Fluid bed dryer

AIPAK Fluid Bed Dryer

Fluid bed dryer is the essential manufacturing equipment which is applied in wet granulation. This equipment helps make the even drying for granulation and makes the uniform distributing of medical particles.

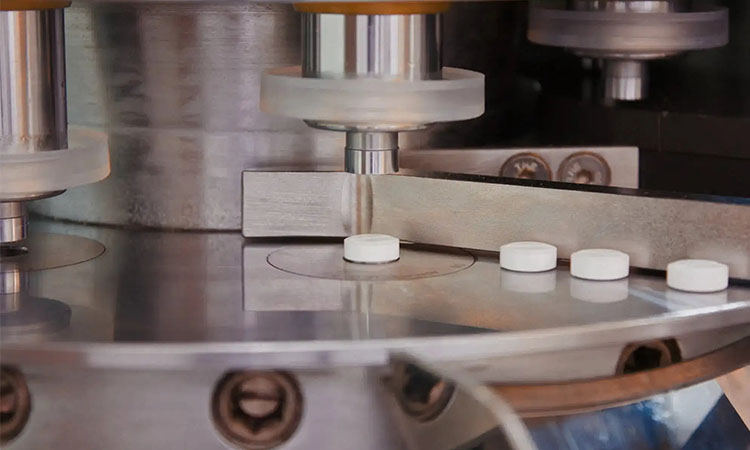

Tablet press machine

AIPAK Tablet Press Machine

Tablet press machine should also be efficient and makes the even and suitable pressing for your tablet medicines. The high press and low press can neither make the tablet with uniform tablet content.

7.What Industry Can Your Tablet Content Uniform Solution Be Applied?

The solution for tablet content uniform is versatile and can be applied to many industries.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:sedpharma

In pharmaceutical industry, there is the wide use of the solution for tablet content uniformity to make the even powder for the medicine manufacturing. It can be applied to many different types of medical products.

Cosmetic industry

Cosmetic Industry-Sourced:womenshealthmag

There is also the requirements for the cosmetic products manufacturing in cosmetic industry. You can apply it in manufacturing the uniform powder for making up, body caring and so on.

Food industry

Food Industry-Sourced:globalsources

In food industry, to make the high qualified and standard food, you may apply tablet content uniformity solution. There is the special need of even and uniform powder in seasoning.

Agricultural industry

Agricultural industry-Sourced:dimolanka

You may find the various types of fertilizer, pesticide and insecticides and so much agricultural products which applied the tablet content uniformity for the agricultural products manufacturing.

8.How To Check Tablet Content Uniformity?

Tablet content uniformity is so important in medicine manufacturing. So how to check tablet content uniformity? Here is some advice.

Quality control

Quality control is the most frequently used tablet content uniformity checking methods. You may get the sample and make the special test about the content of tablet content.

High-Performance Liquid Chromatography (HPLC)

HPLC-Sourced:labx

High performance liquid chromatograghy has the abbreviation of HPLC. It is the technique which is applied to separate the chemical mixture. And you can then get the mobile phase composition for the uniformity settling and so on.

UV-Visible Spectrophotometry

UV-Visible Spectrophotometry-Sourced:denovix

UV-Visible Spectrophotometry is the welcomed control manner which apply the light source for the tablet content testing. From the electromagnetic spectrum, you may get the tablet content distribution easily.

Conclusion

How to make tablet content uniform? You have your own answers. And you may apply it for your later tablet manufacturing. For the tablet content uniformity, you may have your own plan. And if you have any great advice or problem in tablet content uniformity, you may contact us right now.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine