How to Make Capsule?

Do you know that capsules are the easiest way of taking medication? For convenience and ease different home-based users are preparing their own capsule supplement and herbal formulations. At first, it seems that capsule making is a complicated task; however, it is not as difficult as it seems.

Nowadays, consumers prefer to make their supplements and sports capsules as the ingredient lists on the back of commercially prepared capsules are often filled with inaccuracies and substandard materials. This is because supplement products are not rigorously checked by drug authorities in contrast with pharmaceutical products.

In this guide, we will explain in detail the raw materials required and the process for making supplement capsules at home.

1.What are Capsules?

Capsules

Capsules are the type of pill orally taken or delivered via other routes such as the rectum, vagina, etc. It is a one- or two-piece pill enclosing drug substances inside its shell. These contain different forms of medications such as oils, powders, pellets, tablets, granules, and semi-solids.

Capsule components are broken down as they enter the gastrointestinal tract. They are made with gelatin or cellulose or HPMC or pullulan ion case of vegetarian capsules.

Based on the composition of the shell, the capsules are either hard shells encapsulating all types of medications or soft shells encapsulating mostly liquid medications. Softshell capsules are known as soft gel while hard shell capsules are called hard gel capsules.

Numerous patients favour capsules over tablets because they have no taste, have a quicker onset of action, and have better bioavailability.

2.What are the Necessary Materials Required to Make Capsules?

Before jumping right into capsule making, first prepare the following materials as it will be convenient and save you time.

Empty Capsule

Empty Capsules

First and foremost, you will need empty capsules that are easily available in online stores. However, these capsules come in a variety of sizes, so it is important to choose the right size depending on your dosage requirement.

| Capsules | 000 | 00 | 0 | 1 | 2 | 3 | 4 | 5 |

| Locked Length

(mm) |

26.14 | 23.30 | 21.70 | 19.40 | 18.00 | 15.90 | 14.30 | 11.10 |

| Cap Length

(mm) |

21.95 | 11.8 | 10.85 | 9.85 | 8.8 | 8 | 7.2 | 6.2 |

| Body Length (mm) | 22.2 | 20.22 | 18.35 | 16.4 | 15.15 | 13.45 | 12.1 | 9.3 |

Size 000 is the largest capsule while size 5 is the smallest capsule. For filling nutraceutical supplements, mostly size 00 capsules are used, owing to their higher capacity to accommodate more fill materials.

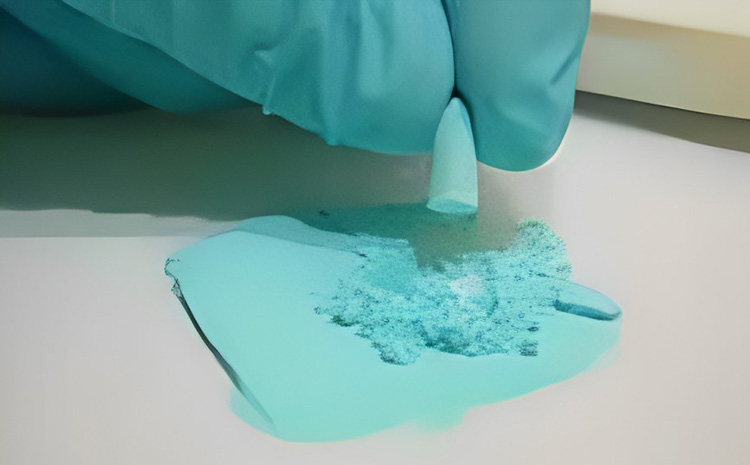

Fill Materials

Fill Materials

These are the ingredients such as vitamin powders, mineral powders, biotin powders and many more that are to be filled in the capsule. It is important to buy in bulk as it will save money.

Weighing Scale

Weighing Scale- Picture Courtesy: quadrant360.com

These come in handy when you are manually filling the capsule. This helps in measuring the precise amount of fill material powders that will be loaded in the empty capsule. Select a scale that offers measurement in milligrams.

Scooping Tools

Scooping Tools

These devices help you to fill an accurate quantity of powders inside the capsules, especially smaller-sized capsules. Scooping tools like micro-spoons, scapulas, funnels, and mini scoops provide convenience over filling with bare hands and prevent wastage and spillage of fill materials.

Capsule Filling Machine

Capsule Filling Machine

For small-scale industries and home-based and lab-based settings, a manual capsule-filling machine is a cost-effective option. It offers several advantages over typical hand filling, for instance, higher processivity, convenience, effectivity, accuracy, and clean hygienic filling of capsules.

Storage Bottles or Bags

Storage Bottles or Bags

Last but not least, you must have at hand different storage containers like plastic bottles or zip-lock bags depending upon your preference. The filled capsules are packed inside these containers for protection against elements and spoilage by microbial agents.

3.How to Make Capsule?

Before making a capsule, first, it is essential to select the size of a capsule which is done by estimating the formulation density and mass of the fill material.

The formula for calculating formulation density is

Density=Mass (g)/Volume (ml)

The mass or weight of fill materials is determined by measuring their weight on a weighing scale. For example, if your required volume is 0.90 ml and the weight of formulation is about 540 mg then the density according to the above-mentioned formula is 0.6 g/ml.

The next step is to look at the chart

| Empty Capsule Sizes | ||||||||||

| Capsule Size | 000 | 00E | 00 | 0E | 0 | 1 | 2 | 3 | 4 | 5 |

| Empty Capsule Volume | 1.37 | 1.00 | 0.90 | 0.78 | 0.68 | 0.48 | 0.36 | 0.27 | 0.20 | 0.13

|

| Formulation Density (g/ml) | ||||||||||

| 0.6g/ml | 822 | 600 | 540 | 468 | 408 | 288 | 216 | 162 | 120 | 78 |

| 0.8g/ml | 1096 | 800 | 720 | 624 | 544 | 384 | 288 | 216 | 160 | 104 |

| 1.0g/ml | 1370 | 1000 | 900 | 780 | 680 | 480 | 360 | 270 | 200 | 130 |

| 1.2g/ml | 1644 | 1200 | 1080 | 936 | 816 | 576 | 432 | 324 | 240 | 156 |

Look in the row of 0.6g ml and find the value closest to 540 mg, this will tell you about the size of the capsule which is 00.

4.How to Make Capsules by Hand

For simple home-based making of capsules, there are two widely methods- dip and twist and scoop and push. The details of these methods are explained below:

Dip and Twist Method

Dip and Twist Method- Picture Courtesy: Blate Papes

This method requires careful handling and dexterity but achieves improved powder dissemination. There are no tools needed for this filling by hand and it works for all kinds of powder whether heavy or light. These are the steps:

| Step 1 | First place bulk fill material in the large bowl or other container. |

| Step 2 | Next, separate the cap and body parts of the capsules. |

| Step 3 | Hold the cap and body of capsules in both hands and then dip them into the fill material bowl. |

| Step 4 | Rotate and tap the halves of capsules to fill the powders inside them. Do not overfill the cap portion. |

| Step 5 | Once the capsule halves are filled to the required level, carefully place the two halves together and use a slight pressure to fuse them. |

Scoop and Push Method

Scoop and Push Method- Picture Courtesy: Blate Papes

If you are dealing with fluffy or lightweight fill materials then this method works best. The scoop-and-push method uses small instruments such as spoons, funnels, etc. This technique of capsule filling ensures higher precision in dosage than the dip and twist method. These are the steps for scoop and push:

| Step 1 | Place some quantity of fill material in an empty bowl. |

| Step 2 | Twist the capsule to separate the cap and body parts. |

| Step 3 | Put the funnel on the capsule body. Scoop a small quantity of powders through a spatula and mini spoon and gradually pour this amount via funnel inside the capsule body. The small paper strip is also used instead of small devices to pour powders inside the capsule. |

| Step 4 | Tamp the fill materials inside the body of the capsule with the paper card and ascertain it is firmly loaded inside the capsule half. |

| Step 5 | Finally, push two halves together and firmly press them against each other to join. |

5.How To Make Capsules With A Manual Capsule Filling Machine

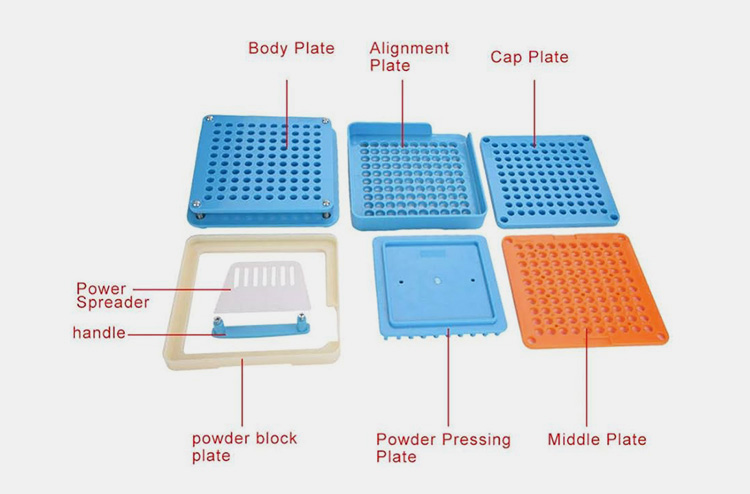

Parts of Manual Capsule Filling Machine

Besides hand fill, a manual capsule-filling machine is also employed for making capsules at home or in laboratories. This increases fill capacity and precision.

There are different types of manual capsule-filling machines but they all have similar modes of working. These simple and easy steps for making capsules with a machine are:

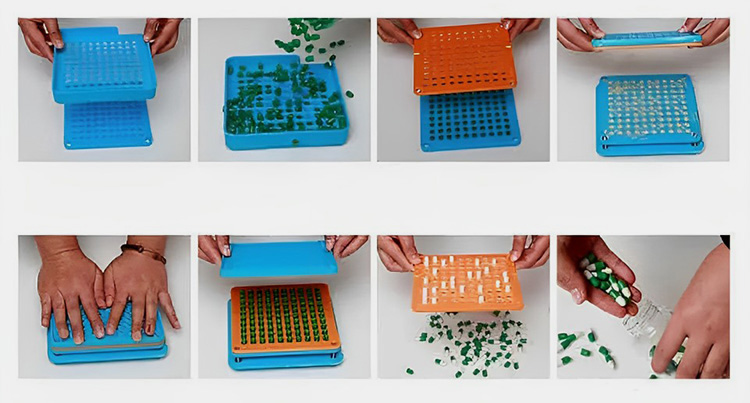

Steps of Capsule Making in Manual Capsule Filling Machine- Picture Courtesy: vitamondo.net

| Step 1 | First, place the alignment board on the top of the cap plate and then dispense the empty capsule caps over the latter. Gently shake them so that empty capsules drop into slots. |

| Step 2 | Tilt the alignment board to unload excess capsule caps. |

| Step 3 | Position the middle board over the cap plate and push them together. |

| Step 4 | Now put the alignment board over the body plate and place empty capsule bodies over them. Gently shake the arrangement so that these halves will drop into empty pockets of the body plate. |

| Step 5 | Tilt the alignment board to unload the excess capsule body. |

| Step 6 | Now place the powder block plate over the body plate and pour the pre-measured amount of fill material into the powder block plate. Use the powder spreader to scrape excess fill material into the capsule bodies. |

| Step 7 | Then remove the excess fill materials with the powder spreader from the powder block plate. |

| Step 8 | Place the powder pressing plate over the powder block plate with the protruding ends of the former pointing down towards the powder block plate. Next press the arrangement gently together to compact the fill powder inside the capsule bodies. |

| Step 9 | Upon filling, remove the powder block plate and powder pressing plate from the body plate. |

| Step 10 | Invert the arrangement of the middle and cap plates and place them onto the body plate. |

| Step 11 | Lightly push the cap plate to lock capsule halves together. Then invert the plates with the body plate now on the top. Again, gently push the plate for the complete locking of capsules. |

| Step 12 | Afterwards, remove the plates from each other and gently shake the middle plate to remove the locked capsules. |

6.How To Make Capsules With A Semi-automatic Capsule Filling Machine

This machine is employed in small and medium-scale industries for making capsules at a relatively larger scale than at home. The steps for making capsules in a semi-automatic machine are:

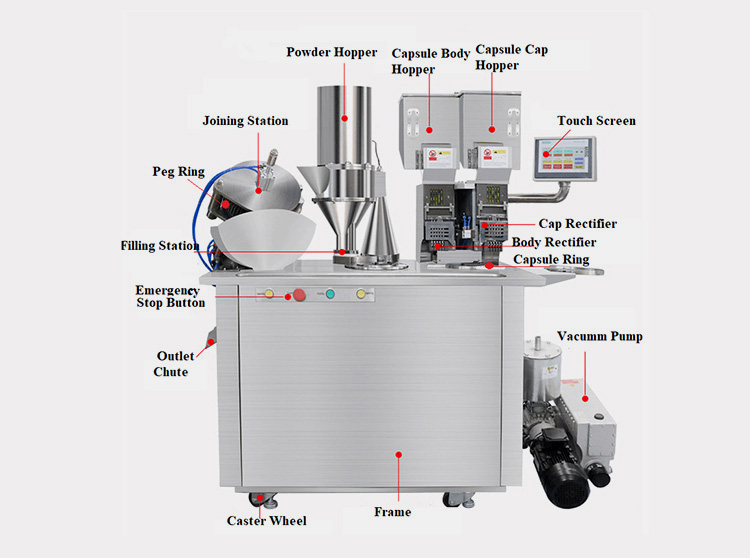

Parts of Semi-automatic Machine

| Step 1 | The first step is accompanied by separation of empty capsules into two halves (caps and body). |

| Step 2 | Then load the capsule cap and body in the separate hoppers. Then feed the powder material inside the powder hopper. |

| Step 3 | Place the right-sized loading ring as per the required capsule size onto the loading station. |

| Step 4 | Start the machine and move the caps and bodies of capsules from their respective hopper into their rectifier section. This station positions caps and body in the right position. |

| Step 5 | Pull the lever so that capsule bodies go to the lower holding ring and caps from their rectifier will go to the upper holding ring. |

| Step 6 | Carry the lower loading ring and place it into the turntable that is fixed in the filling station. |

| Step 7 | Press the powder filling option so that powder fill materials from the hopper flow to filling nozzles, from where they are dispensed inside the capsule body. The auger filler regulates the amount of fill material. |

| Step 8 | Upon successful filling, put the upper loading ring containing capsule caps over the lower loading ring containing filled capsules. |

| Step 9 | Afterwards, place the whole arrangement of loading rings onto the peg ring of the joining station. Make sure that the capsule ejection pins are inserted into the slots of the capsule loading rings. |

| Step 10 | The pneumatic system present in the joining station locks the capsule halves together and forces the powder filling into complete capsules. |

| Step 11 | At the last step, manufactured capsules are forced out of the joining station into the outlet chute via ejector pins. |

7.How To Make Capsules With An Automatic Capsule Filling Machine

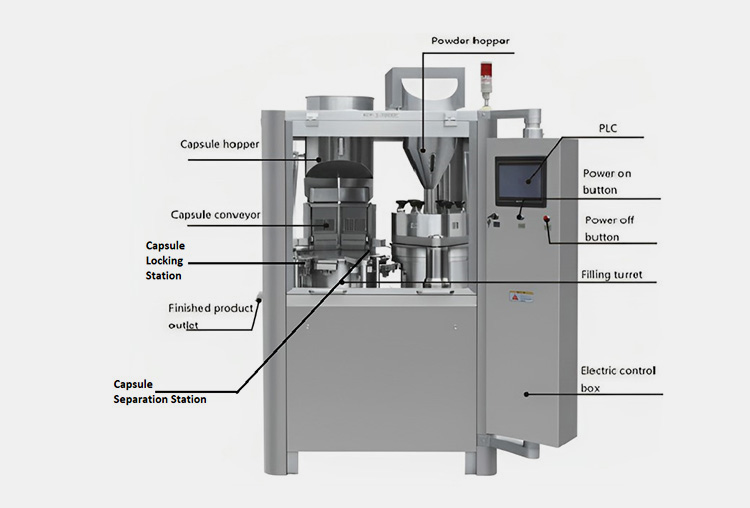

The automatic capsule filling machine is a great fixture in large-scale industries and it is routinely employed to make capsules at a massive scale because of its high productivity and automation.

The step-by-step detail for making capsules with an automatic capsule filling machine is penned below for your information.

Parts of Automatic Capsule-Making Machine

| Step 1 | Prepare the fill materials that should be well-blended and free of lumps and then load the powder into a powder hopper. |

| Step 2 | Load the empty capsules in the capsule hopper. |

| Step 3 | Start the machine, the capsules from the hopper are moved to the alignment and rectifying section present below the capsule hopper. In the rectifying section, capsules are positioned in an upright position so that capsule bodies are facing the downward direction. |

| Step 4 | Then the capsule tray is carried to the capsule separation station where a vacuum system is used to separate caps from capsule bodies. The caps remain in the upper capsule tray while the lower capsule tray is transported to the dosing or filling station. |

| Step 5 | Upon detection of the capsule tray, the powder from the hopper is moved to the auger filler from where it is dispensed in the capsule bodies. |

| Step 6 | When capsule filling is completed, the filled capsule bodies are transported to the rejection centre. |

| Step 7 | At the rejection centre, faulty, intact, damaged, underfilled or overfilled capsules are rejected from the machine. rejection pins force these capsules out of the tray into the collection bin. |

| Step 8 | The high-quality capsule bodies are carried to a locking station where the upper capsule tray containing caps and lower capsule tray containing capsule bodies are rotated. The baffle plate and locking pin aid in the locking of capsule halves. |

| Step 9 | Then locked capsules are transported to the ejection station from where ejection pins push the capsules out of the machine into the outlet chute. |

8.FDA Rules and Regulations for Making Capsules

Making capsules for commercial purposes is not for everyone as it falls under strict rules set by the FDA. Numerous legal concerns must be considered when introducing medicinal products in the market such as their safety, contamination-free manufacturing, thorough labelling, trial proof etc.

However, for personal and home-based use, there are no stringent guidelines and regulations imposed by the FDA. Here are some regulations and instructions for making your own supplement and sports capsules.

Always Use Quality Fill Materials

Quality Fill Materials

When making capsules at home, always make sure that the ingredients or fill materials you are using are of high quality. These herbal, vitamins, minerals, or other supplements should not harm your health in any way and are safe for ingestion.

Implement Good Manufacturing Practices

Clean Practics During Making Capsule- Picture Courtesy: Pharmacy Skills Laboratory

Even if you are making capsules, it is advised to follow good manufacturing practices such as keeping the benchtop clean to avoid contamination. Use sterile equipment and hygienic protocols as otherwise it will compromise the safety of your capsules.

Consistency in Filling

Consistency in Filling

When making personal capsules, it is recommended to implement basic quality measures. It is important to measure the accuracy of your filling process to attain maximum health benefits. Moreover, check for contamination in fill materials and capsules.

Labelling

Labeled Capsule Bottles

It is imperative to label your capsule containers to avoid confusion with any products. Label bottles or plastic bags with details of the ingredient list, its intended use, and benefits of filled capsules and precautions, etc.

9.How to Make Capsules- Frequent Issues?

Many issues arise while making capsules and this is a source of frustration and worry for people. However, every problem comes with a solution and it is also true for making capsules. Here is a list of some frequent issues and their solutions:

Sticking of Capsules

Sticking of Capsules

Sometimes capsules stick to each other and there is difficulty in separating them.

Causes

- The benchtop or machine is not properly cleaned.

- High ambient humidity during capsule making process.

- High room temperature

- Improper lubrication of the machine

Solutions

- Clean the machine and bench top properly and dry them.

- Control the ambient humidity during capsule making process.

- Decrease the room temperature

- Lubricate the capsule-filling machine

Over or Under Filling of Capsules

Over or Under Filling of Capsules

There are times when capsules are not filled properly leading to poor dosage of supplements.

Causes

- Use of inaccurate measuring scales.

- Poor calibration of capsule filling machine

- Incompatibility in capsule size and amount of fill ingredients

- The presence of air pockets in fill materials

- Improper blending of fill ingredients

- A high filling rate by the operator could cause overfilling.

- Non-use of tampering instruments.

Solutions

- Use a precise measuring scale to achieve accuracy in measuring fill ingredients.

- Recalibrate the machine to avoid fill inconsistency

- Use accurate capsule size as per fill weight

- Tap the capsule with filling devices gently to eliminate air pockets

- Properly blend the fill ingredients to attain uniformity in the filling

- Slowly and gradually fill capsules to avoid overfilling

- Gently tamp the capsule with a packing card to compact the powders inside the capsules

Breaking of Capsules

Breaking of Capsules

During handling, empty or filled capsules break apart.

Causes

- Use of substandard empty capsules

- Forceful handling during capsule filling.

Solutions

- Use high-quality empty capsules

- Fill and handle capsules gently.

Brittle Capsules

Brittle Capsules

With time, stored capsules may develop inelasticity.

Causes

- Storing of capsules at high temperatures and in sunlight.

- Not enough plasticizer in the capsule shell

Solutions

- Keep the manufactured capsules low temperature and away from direct sunlight exposure.

- Use capsule with more plasticizer content

Improper Locking of Filled Capsules

Improper Locking of Filled Capsules

Capsule body and cap do not lock properly which results in leakage and spilling of ingredients.

Causes

- Low-quality capsule shell

- Distortions or abnormalities on the capsule

Solutions

- Consider using high-quality empty capsules

- Look for physical imperfections on the capsule shell

10.What are Storage Tips for Manufactured Capsules?

Storage of Manufactured Capsules

Now that you have made capsules are you wondering about how to store them? Manufactured capsules must be stored properly, as otherwise, it will risk the health of consumers.

The storage tips for your information are penned below:

Store the manufactured capsules at a cool and dry place with a steady temperature in the range of 15-25°C. Avoid storing them at places that have high temperatures or continuous fluctuations of temperature because it will severely impact the ingredient quality and could result in capsule disintegration.

Do not store home-based capsule supplements in a highly humid setting. It is best to store capsules below 50% humidity and with a dehumidifier because high moisture in the air could lead to the sticking of capsules, dissolve specific fill materials, and boost the microbial population.

Keep capsules away from sunlight because UV radiations in sunlight degrade fill materials and decrease their effectivity. It is recommended to store the capsule in a dark and opaque container to reduce light contact.

Always store your capsules in airtight bottles or bags to prevent air and contaminants entry as they deteriorate the capsule's integrity. Use desiccants in storage bottles, especially with hygroscopic ingredients for humidity control.

11.Success Tips For How to Make Capsules

Making capsules at home is a fun activity that also brings fruitful results. However, you must implement safe and clean procedures for making capsules and always check the quality of manufactured capsules.

Here are some success tips just for you.

Research and Consult Experts

Research and Consult Experts

Before making capsules, first conduct thorough research on your desired fill materials. Always buy high-quality powders as your health is dependent on them. Also, consult with the expert regarding the correct process for making capsules at home.

Invest in Basic Instruments

Invest in Basic Instruments

Invest in small tools like spatulas, mini spoons, weighing scales, and small funnels to ensure accuracy and convenience in the capsule-making procedure. If your budget allows, then buy the manual capsule filling machine as it will speed up your filling process.

Right Capsule Size

Right Capsule Size- Picture Courtesy: Aipak

It is recommended to select the right capsule size after making formulation density calculations and looking at the capsule chart. It is important because there are different capsule sizes and the fill dosage is specific for every capsule size. Going randomly for capsule size could result in a loss of investment.

Start With Smaller Batches

Start With Smaller Batches- Picture Courtesy: Empty Capsules

As a beginner, you should start with smaller batches to get a know-how of capsule making. It will minimize potential wastage and increase your confidence for larger batches of capsule making.

Select the Right Filling Method

Select the Right Filling Method- Picture Courtesy: woodlands.adventist.org

As already mentioned, there are various methods of capsule making, for instance, scoop and push, tamper filling or dip and twist. Select a filling method depending on your ease and the availability of instruments. Carefully follow every step of that method to acquire optimal quality capsules.

Quality Control

Quality Control- Picture Courtesy: Sensum

Last but not least, after successful filling, carefully determine the seal and lock of the capsule as it will prevent material leakage and contamination. Moreover, visually look for defects in capsules, such as dented, scratched, broken, and, cracked capsules and discard them.

Conclusion

Making your capsules is quite a simple and easy feat that does not require specialized tools and devices. This feat saves money and capsules at home are manufactured with significantly less price than the cost of store-bought capsules. Moreover, there are no stringent regulations for home-based capsule supplements and anyone can make them at home. All you require empty capsules, fill powders, some kitchen equipment and capsule making machine. Making capsules at home allows you to consume natural herbal powders and also provides you with quality capsules. Have more questions about how to make capsules then contact our customer care.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours