How To Improve the Irrational Design Of Boiling dryer machine?

The production equipment of solid preparations can be divided into granulator machine, boiling dryer machine, bin mixer machine, tablet press machine, capsule filling machine and so on according to the functions.

Among them, the boiling dryer machine is a kind of dryer machine, which has developed rapidly and widely used in the field of oral solid preparation drying. It is mainly suitable for the rapid removal of moisture in wet soft materials and wet materials (particles), so as to make dry powder, dry materials (particles) and other solid products.

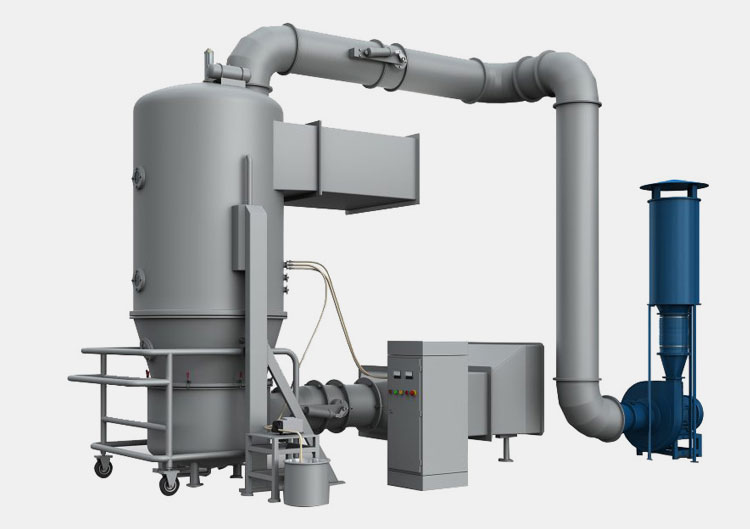

Generally speaking, the boiling dryer machine is mainly composed of air inlet filter system (primary effect, medium effect, air filter), steam heater, main engine (material room, expansion room), induced draft fan, dust collector, electrical control system, operation table and other components.

Due to the large contact area between the material and the drying medium, and the continuous vigorous stirring of the material in the bed, the heat transfer effect is good and the heat capacity coefficient is large.

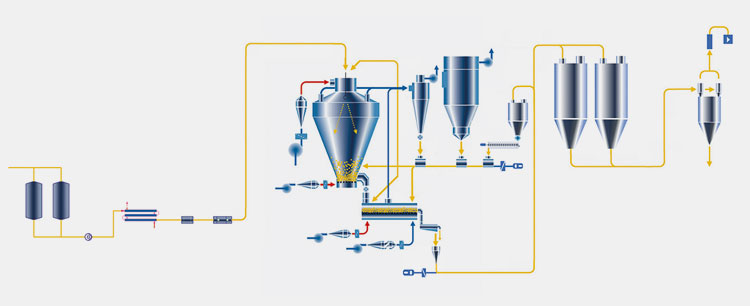

You should know that the boiling dryer machine mainly uses the function of the end induced draft fan, the air in the front end is introduced into the air supply pipe through the filter and the heater, and then the hot air is evenly distributed into the material room and the expansion room through the air distribution plate at the bottom of the material room.

Due to the action of wind pressure, the wet material forms a boiling state in the dryer, and the contact surface area with the hot air increases, it continuously proceeds extensive contact, the moisture is quickly evaporated, so as to complete the drying of the material in a short time.

After the drying process is finished, the exhaust gas is filtered out by the fan through the filter chamber and the dust collector.

There are some obvious characteristics when using a boiling dryer machine to do drying work:

First, the wet particles are constantly in a boiling state under the agitation of hot air, which has the characteristics of intense movement, rapid heat exchange, fluidized drying, fast drying speed and short time.

Second, the operation process is simple. As long as the inlet air temperature is set, the process of the material from wet to dry is operated in a closed container under negative pressure conditions.

In addition, the sealing of boiling dryer machine is also good, the drying process does not need to turn over the material, no dust flying, tipping and unloading, convenient and rapid.

Third, after drying with a boiling dryer, the moisture content of the material is uniform, and the material can be dried to the expected moisture by controlling the length of time the material stays in the container.

Fourth, because the material is in a boiling state, the temperature in the container is controllable, and the distribution is uniform. There is no local overheating of the material, so it is also suitable for the drying of some heat-sensitive materials.

Fifth, when making a placebo, if you use an oven to dry, the color difference migration problem of the material is not easy to solve, and the boiling dryer machine can just solve the problem that the pigment contained in the material may migrate with moisture.

Sixth, the boiling dryer machine has good adaptability to different materials, and the equipment is small in size, strong in production capacity, high in thermal efficiency, convenient in operation and control, and small in particle breakage rate.

Although the boiling dryer machine has many characteristics and benefits, it also has many unreasonable problems.

For example, the tuyere of some boiling dryer machines are "big and small" horn mouth, which is not conducive to fresh air entering the auxiliary engine section and spreading the radiator fully contact. In addition, this will also lead to poor heating effect, and heat is easy to lose, not energy saving.

The steam radiator structure of some equipment is superimposed layer by layer, which is not only not conducive to maintenance, but also leads to more than ten air leakage points. The welding torch cannot reach the leakage point for welding repair, the heat exchange effect is poor, and the radiator can only be eliminated and scrapped.

There are also some steam radiators that are directly welded on the outer frame of the auxiliary machine. It is very difficult to remove the radiator from the outer frame after welding, which is not conducive to maintenance.

In addition, the fresh air treatment section without any fresh air insect control net and fresh air filter device, completely relying on the filter for processing, will increase the burden of the filter, shorten its service life.

However, the air duct between the auxiliary machine and the boiling dryer is long, and there is a dead angle of sanitation and cleaning, which is not conducive to the daily production and cleaning, and the risk of cross contamination is relatively large.

In response to the above unreasonable places, some companies have made corresponding improvements, such as adding functional accessories for top spray granulation, changing the installation position of the thermometer, controlling the steam pressure, adding a thermometer in the material room, etc.

The improved boiling dryer machine can control the frequent opening and closing of the steam solenoid valve, which reduces the influence of the residual steam heating temperature on the system control temperature and avoids the huge fluctuation of the heating chamber temperature.

Although boiling dryer technology is relatively mature, there are still some shortcomings in the aspect of equipment design, compound rules in order to ensure that equipment and production technology requirements.

Some related equipment companies need to modify the original equipment, including technology, design, equipment, technology, etc., so that the boiling drier and solid preparation equipment to better service for pharmaceutical production.

The industry professionals express that if the boiling dryer manufacturing industry and the product itself can realize the upgrading and full application of intelligent equipment, it can significantly improve the intelligent level of the production process and the product itself.

And greatly improve production efficiency, product technology level and product quality, reduce waste of resources and energy, reduce production costs, and improve after-sales service.

Don't forget to share this post!

Drier Machine Related Posts

Drier Machine Related Products

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine