How To Fill Capsules With Liquid?

Most capsule filling materials on the market are mainly powdered. But with the increasing number of liquid supplements and intake of essential nutrients, liquid capsules are becoming increasingly popular. Get your daily dose of vitamins, minerals and nutrients by filling empty capsules with liquid supplements and nutrients.

How To Fill Capsules With Liquid-sourced: pharma-trends

The production of liquid capsules is difficult. Compared to regular powder capsules, how to fill capsules with liquid? To fill capsules with liquid gives you the opportunity to fill the capsules with the liquid herbs or vitamins of your choice and know exactly what's in your dose.

1.What Is Filling Capsules With Liquid?

Capsules With Liquid-sourced: lefancaps

Filling capsules with liquid is different from filling powders or granules into the hard capsules, which is a type of new way to manufacture the liquid capsules.

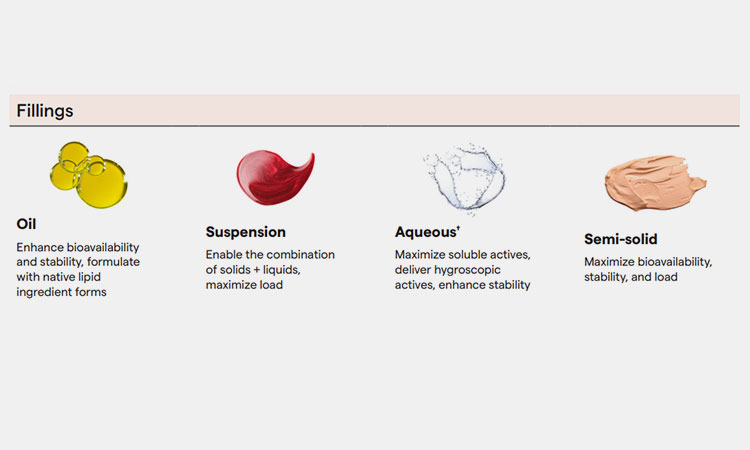

Liquid capsules consist of two pieces of hard capsules that are designed to filled with liquid or semi-solid preparations. It can be used in a variety of liquid formulations, including oils, suspensions, solutions, semi-solids, pastes, and waxy substances. They are ideal for dietary supplements, nutraceuticals and pharmaceuticals.

Liquid Capsules-sourced: ingredientsnetwork

It can solve the challenges of complex active pharmaceutical ingredient formulation and improving bioavailability. Liquid capsules can improve the bioavailability of active pharmaceutical ingredients by processing and encapsulating active substances that have low water solubility or poor permeability.

2.What Are The Benefits To Fill Capsules With Liquid?

As it gradually becomes a favorable alternative to soft capsules, to fill capsules with liquid has many advantages:

Easy to Absorb

Easy to Absorb-sourced: europeanpharmaceuticalreview

The pharmaceutical ingredients in liquid capsules are absorbed gently and act quickly. Especially for substances that are poorly soluble in water, liquid capsules can improve their bioavailability.

Not Easily Oxidized

Liquid capsules have lower oxygen permeability than soft capsules, making them less susceptible to oxidation and masking their odor.

No Plasticizers

Because it contains no plasticizers, the liquid capsules disintegrate quickly and do not stick.

Good Oxygen Barrier Properties

Good Oxygen Barrier Properties-sourced: ingredientsnetwork

Liquid capsules have good oxygen barrier properties and can reliably protect highly active drugs, prevent deterioration, and maintain drug efficacy.

Even Content

Even Content-sourced: expopharm

Compared with powder capsules, liquid capsules have better content uniformity and are more suitable for human body absorption.

Simple Process

The production process of liquid capsules is simple and flexible, and can achieve mass production.

Beautiful Appearance

Beautiful Appearance-sourced: cphi

Liquid capsule formulations are beautiful to look at and you can offer both gelatin capsules and vegetable capsules in a variety of sizes and colors.

3.How To Fill Capsules With Liquid?

Fill Capsules With Liquid-sourced: manufacturingchemist

Hard capsules can be used to fill powders, as well as non-aqueous liquids, suspensions, semi-solids, thixotropic gels, self-emulsifying drugs, etc.

To fill capsules with liquid, you can choose the manual method and machine method:

Manual Method

Step 1: Prepare the Ingredients

Prepare the Ingredients-sourced: expopharm

You can choose your own liquid formation that are needed to filled in the capsules like oils, suspensions, solutions, semi-solids, pastes, and waxy substances, etc. Put the ingredients thoroughly mixed and evenly distributed in a bowl.

Step 2: Separate the Empty Capsules

Separate the Empty Capsules-sourced: healthbloomsupplements

Gently separate the empty capsules into their cap and body halves. Place them on a clean surface or in a small dish for easy access.

Step 3: Fill the Capsules With Liquid

Fill the Capsules With Liquid-sourced: ingredientsnetwork

Use a syringe to suck in the liquid formation material you need. Fill the capsules with injection until it feels pretty over. Slowly inject the liquids into the capsule through the scale on the syringe.

Step 4: Cap the Capsules

After the capsules are filled with liquid formation, take the cap half(shorter part) of the capsule and place it over the filled body, aligning the edges and snapping them together. Lock and secure them.

Step 5: Store the Capsules

Place the filled capsules in a dark glass container or a pill organizer. Store them in a cool, dry place away from direct sunlight and moisture.

Machine Method

To use the liquid capsule filling machine, you can automatically complete the liquid capsule filling and sealing with high efficiency and production:

Step 1: Capsule Arrangement

Load the hard empty capsule shells into a hopper and then conveyed horizontally into multiple pipes.

Step 2: Calibration Direction

Calibration Direction-sourced: ruidapacking

The capsule shell is conjoined and consists of body and cap. When the hard empty capsule shells are fed into the track, they are randomly poured onto a capsule conveying plate with multiple inward circular channels. Through these capsule transport plates, the capsule shells are oriented.

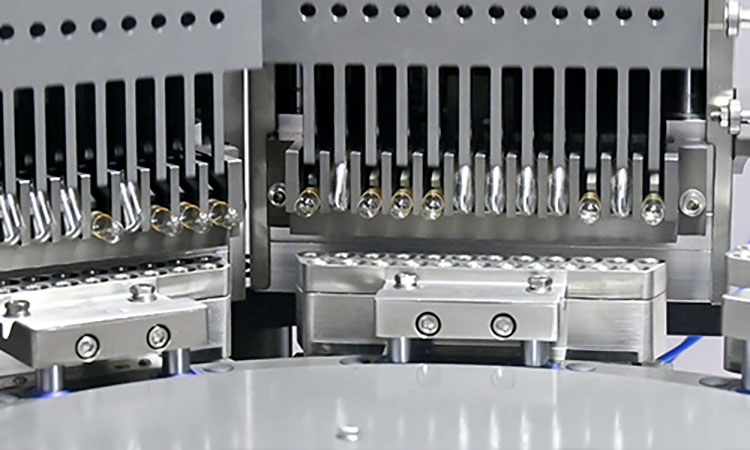

Step 3: Capsule Separation

Capsule Separation-sourced: ruidapacking

When the corrected capsule shell is transferred to the capsule tray, the upper surface of the tray is in close contact with the lower surface. As the lower and upper parts of the vacuum and capsule tray are separated, the body and cap parts of the capsule shell are also separated.

Step 4: Waste Capsule Rejection

Waste Capsule Rejection-sourced: ruidapacking

For various reasons, parts of the capsule shells were not completely separated. These un-separated capsule shells are pulled out of the mold by pins and the capsules are blown into the capsule bag.

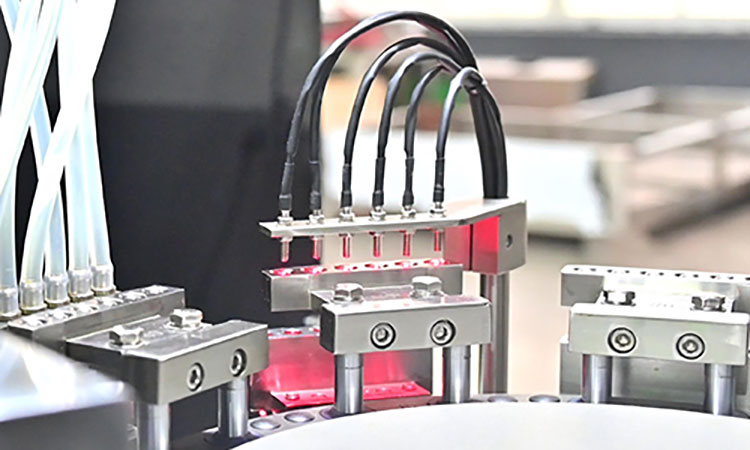

Step 5: Liquid Dosing and Filling

Liquid Dosing and Filling-sourced: ruidapacking

When the completely separated capsule shells are transferred to the filling station, liquids are pumped into the filling station that enables precise liquid dosing without leaking, dripping or air bubbles. Various liquids and liquid-formulated pharmaceuticals are filled into empty capsules in the shell.

Step 6: Capsule Closing

When the filled capsules rotate simultaneously on the upper and lower capsule trays, the capsule body and cap will be locked with each other and then overlap. A row of pins push the body up from the bottom of the lower section to close the capsule.

Step 7: Capsule Transferring

Any capsules that cannot be closed will be removed by vacuum. The closed capsules will enter a transfer system consisting of a turntable, guide chutes, transfer rollers and plate conveyors. This transfer system is responsible for transporting the liquid-filled capsules to the sealing and drying station.

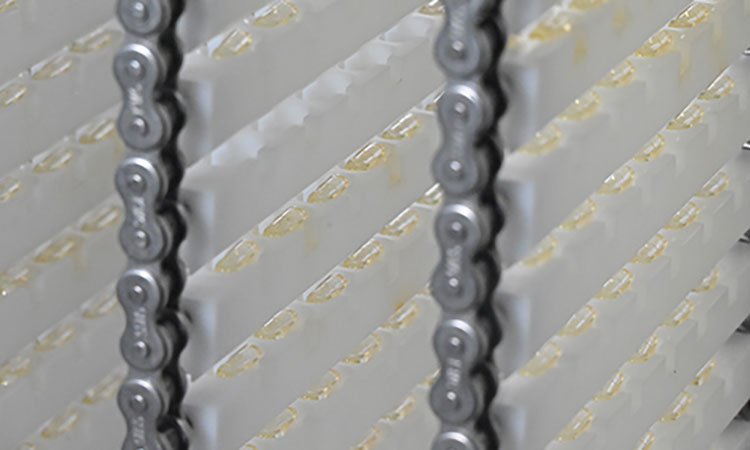

Step 8: Capsule Sealing

Capsule Sealing-sourced: ruidapacking

When the capsule transfer system reaches the sealing station, the sealing rollers are heated and then rotate and heat-seal around the seams of the liquid capsule shells. To improve the sealing effect of liquid capsules.

Step 9: Capsule Drying

Capsule Drying-sourced: ruidapacking

The heated and sealed capsules will be sent to the drying area for drying to improve the preservation effect of the capsules. The sealing fluid is solidified by the air blown in so that the solution does not stick to the drum.

Step 10: Capsule Discharge

The processed liquid capsule will be rejected and discharged.

4.What Is The Hard Capsule Filling Machine?

Hard capsule liquid filling machine is specially designed for filling and sealing liquids and mixed liquid solutions into hard gelatin capsules. It provides pharmaceutical companies and health care product manufacturers with professional pharmaceutical solutions for packaging highly active, insoluble liquid materials.

Distinguished according to the automation, hard capsule liquid filling machines are divided into three types:

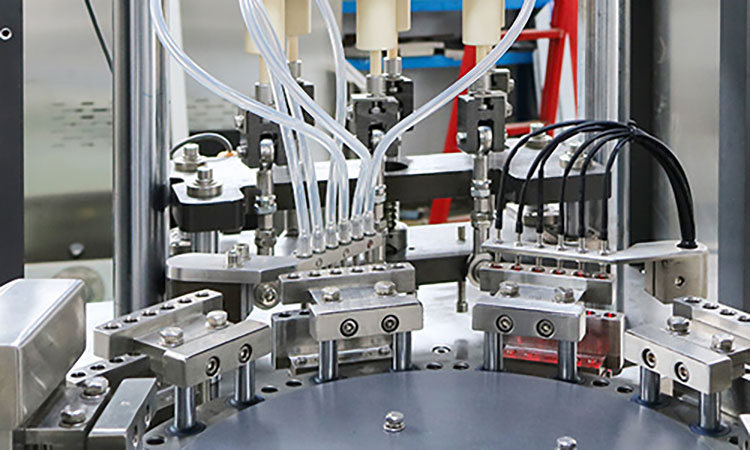

Automatic Hard Capsule Liquid Filling Machine

Automatic Hard Capsule Liquid Filling Machine-sourced: allpack

To fill capsules with liquid in a large volume and production, you can apply the hard capsule filling machine which is specially designed for manufacturing liquid capsules. The automatic hard capsule liquid filling machine can be applied for automatically filling hard capsule with solution, suspension, micro-emulsion in the pharmaceutical, health care, and other industries.

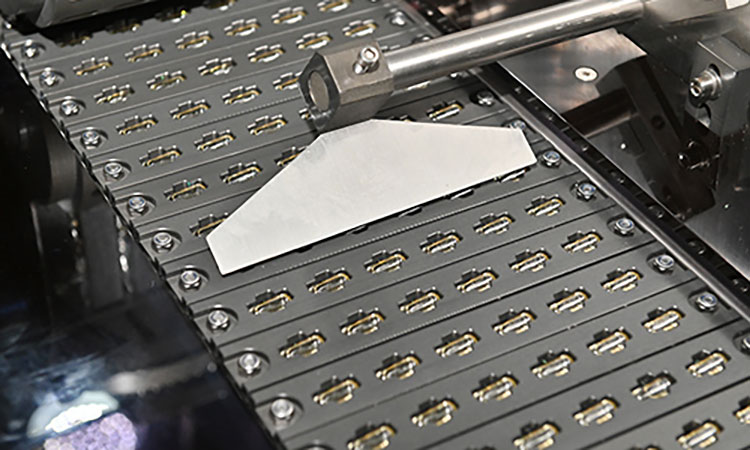

Automatic Hard Capsule Liquid Filling Machine Production Line

Hard Capsule Liquid Filling Machine-sourced: allpack

Automatic hard capsule liquid filling machine production line can automatically realize the processes of continuous capsule dispensing, capsule dividing, filling, locking, waste discharge, online detection, product output and other processes.

It can achieve a filling accuracy of about 1-2%, and has the advantages of stable operation and no noise. The hard capsule liquid filling production line has accurate filling and good sealing performance, which improves product safety during storage, transportation and clinical application.

5.What Are The Basic Rules To Fill Capsules With Liquid?

There are some ground rules you need to consider before you fill capsules with liquid. Following the rules below, you might get a perfect liquid capsules with good effects.

Only Hard Capsules Applied

Only Apply Hard Capsules-sourced: symbio

In order to fill capsules with liquid, you only can select the hard capsules. The hard capsules are made of collagen from beef bone, cowhide and pigskin. Or replace animal materials with vegetarian ones such as potato starch and polymers of carrageenan from seaweed.

Excipient Needed

When you are filling capsules with liquid, liquid pharmaceutical formulations require excipients. For example, lipophilic liquid or semi-solid carriers, solubilizers, surfactants and emulsifiers, etc.

Filling Materials Features

Filling Materials Features-sourced: farmacapsulas

The filling material should have certain properties that make it suitable for filling in hard capsules. The liquids should be chemically inert and compatible with the gelatin shell. Shells with moisture content between 13-16% should not have more than 2% moisture exchange to maintain flexibility.

Suitable Temperature

To fill capsules with liquid shall be controlled in the right temperature to keep the material reactivity.

Conclusion

To fill capsules with liquid can help you make your own liquid filled capsule supplements. Through this "how to fill capsules with liquid", you have learned how to make supplements and take capsules of essential nutrients. If there are more you want to know, please contact us now for more information!

Don't forget to share this post!

Hard Capsule Liquid Filling Machine Related Posts

Hard Capsule Liquid Filling Machine Related Products

Hard Capsule Liquid Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine