Why do many tablets have a thin layer of sugar coating on the surface? Do you know what the role of sugar coating of tablets is? The current sugar coating technology has been developed very maturely, but it may also face some problems in details.

How to ensure the uniform thickness of tablet sugar coating is the main problem that you may occur during the sugar coating process. Explore more to this post, you may get solutions how to solve the problems. Check it out now!

1.What Is Tablet Sugar Coating In Pharma?

What Is Tablet Sugar Coating In Pharma-sourced: lfatabletpresses

Tablet sugar coating is a process specifically used in the pharmaceutical or healthcare industry. It mainly coats various tablets or tablet cores with a thin layer of sugar coating. This sugar coating tastes similar to syrup and can improve the appearance or taste of the tablet.

In addition to making the tablet look more attractive, it can also cover up some nauseating or vomiting tastes or odors inside the tablet. Sugar coating can provide a barrier for the tablet, prevent the active pharmaceutical ingredients in the tablet from being affected by the outside world, and extend the shelf life of the tablet.

2.What Are The Main Materials Applied For Tablet Sugar Coating?

Tablet sugar coating consists of a variety of ingredients, and different formulations may achieve different functions. The main materials applied for tablet sugar coating are:

Sucrose and other sugar alcohols

Sucrose and other sugar alcohols-sourced: britannica

Sucrose and sugar alcohols are used to improve the taste of tablets and to mask the bitter drug ingredients in the tablets. The use of sugar alcohols can avoid tooth decay caused by sucrose.

Binders

Binders-sourced: buildapill

Binders are added to the coating solution to enhance the strength and elasticity of the coating. Its main ingredients include dextrin, gum arabic, gelatin, agar and starch.

Fillers

Fillers-sourced: mcepharma

Fillers can increase the structure and quality of the coating, such as calcium carbonate, talc, kaolin, gum arabic powder, corn starch and calcium sulfate.

Colorants

Colorants-sourced: brambleberry

Colorants can add color to the coating and cover possible defects in the core. Its main materials include dyes, pigments, etc.

Anti-adhesives, lubricants

Anti-adhesives, lubricants-sourced: pharmaeducation

These materials can reduce the friction between the tablets after coating, thereby preventing dust from forming during the drying process. Its main ingredients include talc, colloids, silicon dioxide, etc.

Flavoring agents

Flavoring agents-sourced: sbblgroup

Flavoring agents can improve the taste of the coating, increase the acceptability of the tablets, and maximize the compliance of users, such as cinnamon, fruit, etc.

Suspension stabilizer

Suspension stabilizer-sourced: setylose

It can prevent the coating solution from separating or precipitating during spraying or application. Its main ingredients include emulsifiers, bentonite, thickeners, etc.

Polishing agent

Polishing agent-sourced: freund

Polishing agent can enhance the reflectivity and intensity of the coating color and make the tablet surface neat and beautiful. Its main ingredients are beeswax and carnauba wax, etc.

3.What Are The Benefits Of Tablet Sugar Coating?

Main benefits of tablet sugar coating:

Enhanced durability

Enhanced durability-sourced: menafn

After tablets have been sugar coating and polished, it can increase the durability of tablets during transportation and extend the shelf life. At the same time, it is convenient for patients and manufacturers to identify the type and dosage of tablet products.

Masking odor and taste

Masking odor and taste-sourced: capsulcn

Some tablets have unpleasant, bitter and disgusting tastes. Tablet sugar coating can well cover the odor and taste of tablets, making it convenient for users to use.

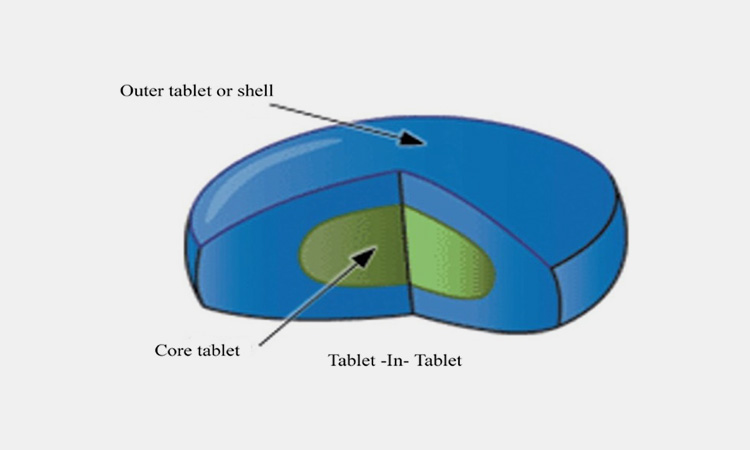

Delayed release

Delayed release-sourced: sinolead

Some sugar coatings have functional ingredients. In addition to protecting tablets from external contamination, they can also adjust the release method and time of tablets, so that tablets can be slowly released in the body and more suitable for the patient's body to absorb.

Strengthen gastric protection

Strengthen gastric protection-sourced: capsulcn

Some drug ingredients are very harmful to the stomach. Therefore, tablet sugar coating can reduce the irritation and damage of drug ingredients in tablets to the stomach.

4.What Is The Tablet Sugar CoatingProcess?

The production process of tablet sugar coating mainly includes:

Tablet Sugar Coating Process

Sealing layer

Apply a sealing coating to the bottom layer of the tablet core. This can prevent moisture or oxygen in the air from entering the tablet core.

Base coating

Applying a base coating on the sealing layer of the tablet can make the edge of the tablet core smooth and increase the weight of the tablet appropriately.

Syrup coating

Syrup coating is mainly used to cover up the defects in the appearance or function of the tablet. In this step, you can customize any required layer color, size and shape to meet your appearance requirements.

Coloring

Using coloring to improve the appearance of the tablet can not only protect the active ingredients in the tablet from being affected, but also attract users and improve user compliance rate.

Polishing

In this step, you need to polish the surface of the tablet with beeswax or carnauba wax. Finally, the tablet surface shows a beautiful luster to attract users to choose and use.

5.How To Ensure Uniform Thickness Of Tablet Sugar Coating?

To achieve uniformity in the thickness of tablet sugar coating, you need to control the following aspects:

Core quality

Core quality-sourced: springeropen

Before coating the tablets, you need to ensure that the size, shape and hardness of the tablets and cores are uniform or consistent. If the size, shape and hardness of the cores are quite different, the amount of sugar coating attached during coating will be different, which will affect the final thickness and uniformity of the tablets.

Coating material

Coating material-sourced: Epicurious

The choice of coating material is also very important. You can choose syrup or talcum powder, which has the best quality and stability. This coating material can make the coating liquid adhere more evenly and avoid the deviation of coating thickness due to the size difference of particles.

Equipment

AIPAK Equipment

The choice of coating equipment ultimately determines the quality of your tablet coating and the effect of the finished product. When choosing coating equipment, be sure to choose coating equipment suitable for tablets, and make sure whether its shape is regular and the inside is smooth. Whether the uniformity process is smooth and whether various functions are intact.

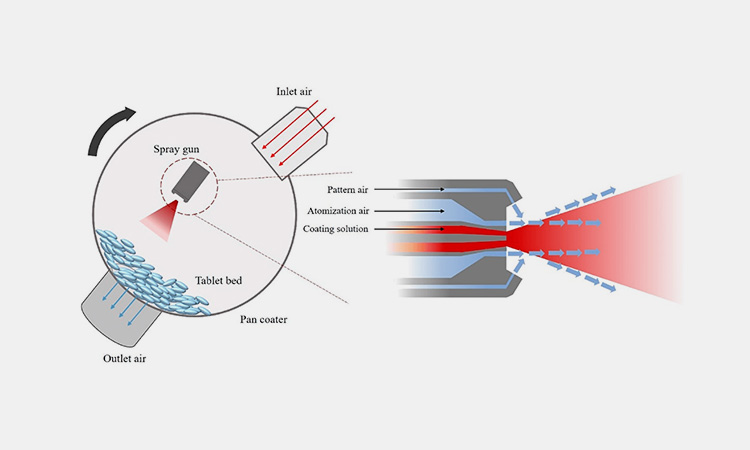

Spray device

Spray device-sourced: freundglobal

In addition to coating equipment, spray devices also need to be considered. The spray system can ensure that the coating of the sugar coating is uniform and stable. Before the spray system is used, the nozzle must be kept unobstructed and the spray pressure can be adjusted at any time so that the coating liquid can be evenly sprinkled on the surface of the tablet.

Operation skills

Operation skills-sourced: ipharmachine

Operation skills mainly include coating sequence, feeding method, and drying conditions. You should strictly follow the order of isolation layer, bottom layer, sugar coating layer, etc. for coating. Each layer of coating must be evenly distributed, and after sufficient drying, the next layer of coating can be carried out.

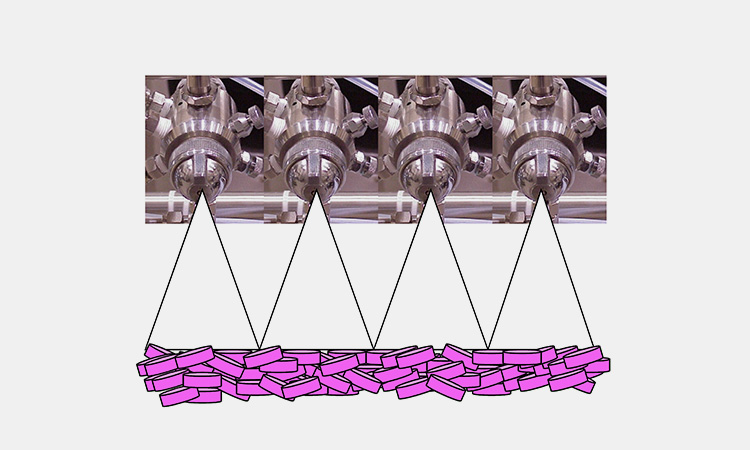

Feeding method

Feeding method-sourced: emdgroup

You can use a small amount of multiple times to add coating materials such as syrup and talcum powder to the equipment evenly. Avoid excessive addition at one time, which will cause the accumulation of sugar coating layers on the surface of the tablet, making the sugar coating uneven.

Drying conditions

Drying conditions-sourced: jinlupacking

In addition to controlling the temperature and wind speed in the drying environment, it is necessary to ensure that each layer of coating material is evenly dried on the surface of the tablet core. And after curing, the next layer of coating can be carried out, so that the uniform thickness of each layer of coating is the same.

Quality control

Quality control-sourced: ipharmachine

Whether during the coating process or after obtaining the finished product, you must take random samples and check the thickness and uniformity of the sugar coating with the naked eye and various tools. If problems are found, the relevant coating parameters can be adjusted in time.

Thickness measurement

Thickness measurement-sourced: pharmapproach

Professional tools can be used to measure the thickness of each layer of the tablet core and calculate the average thickness and thickness deviation of the sugar coating. For batches with uneven thickness, the cause can be analyzed immediately and corresponding adjustment measures can be taken. For example, adjust the speed of the coating equipment, the spray volume of the coating liquid, or the spray pressure.

6.What Is The Main Equipment Applied For Tablet Sugar Coating?

The main equipment applied for tablet sugar coating is:

Tablet coating machine

AIPAK tablet coating machine

Coating equipment is a kind of tablet coating machine widely used in pharmaceutical, health care and food industries. It can coat a thin and uniform film on different tablet cores or tablet surfaces. This can not only protect the active ingredients of the drug from the influence of the external environment, but also increase the beauty of the tablets and improve the compliance of users. It can accurately control the coating process of each tablet core.

Main parts of tablet coating machine are:

Main parts of AIPAK tablet coating machine |

|

| Coating room | It is the main place where all tablets and cores are coated. The whole process of tablet tumbling, spraying, coating and drying can be completed here. |

| Heating system | It can ensure that the tablet coating is cured and dried at the optimal temperature, so that the coating film on the core is stable and firm. |

| Control system | It is mainly used to manage the temperature, humidity, airflow, spray pressure and thickness of the tablet coating process. It can ensure the quality and uniformity of the coating. |

| Nozzle system | It is mainly used to evenly apply and spray the coating liquid onto the core. |

| Air handling unit | It is mainly used for the air circulation and filtration system of the tablet during the coating process to prevent contamination. |

Working process of tablet coating machine is:

Working process of tablet coating machine

- Load the cores or tablets you need to process into the coating chamber. If necessary, preheat the equipment in advance.

- Spray the treated coating solution on the tumbling tablets in small amounts and multiple times evenly. This process requires multiple cycles and small amounts to achieve uniform coverage.

- When the tablets are evenly coated with a sugar coating, you can use a drying system to dry and solidify the surface of the tablets to ensure the stability of the tablet sugar coating.

- When the tablet surface sugar coating is dried and solidified, in order to prevent the tablets from sticking to each other, you need to make sure that the tablets and the sugar coating are completely cooled before the tablets are taken out or the next step is carried out.

- When the tablets have completed all the steps, you can collect them and then proceed to the next step of processing or packaging.

7.What Are The Common Problems That May Occur During Tablet Sugar Coating And Their Solutions?

The common problems that may occur during tablet sugar coating with its solutions are:

Chipping

Chipping-sourced: tech-publish

| Causes: |

|

| Solutions: |

|

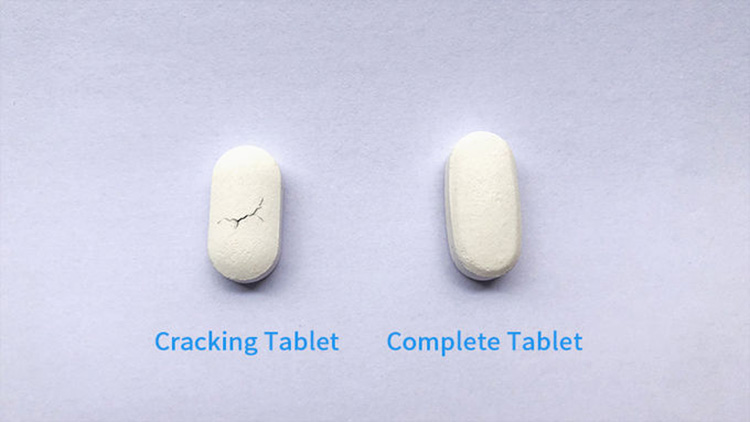

Cracking

Cracking-sourced: pharmaprocessmachines

| Causes: |

|

| Solutions: |

|

Non-drying

| Causes: |

|

| Solutions: |

|

Twinning

Twinning-sourced: licdn

| Causes: |

|

| Solutions: |

|

Uneven Coloring

Uneven coloring-sourced: capsulcn

| Causes: |

|

| Solutions: |

|

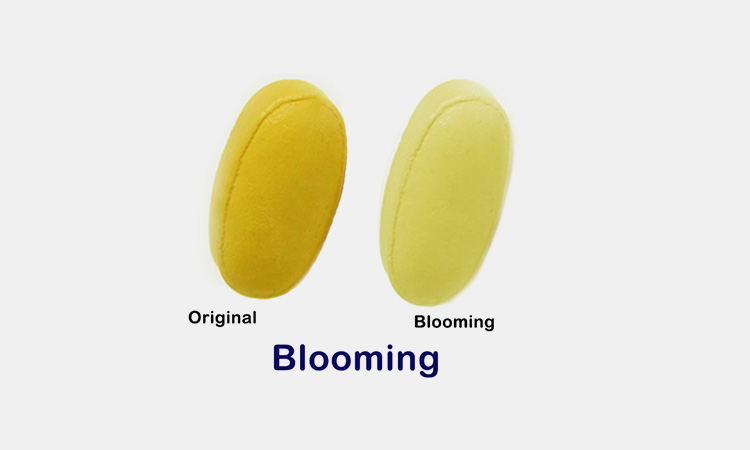

Blooming

Blooming-sourced: tech-publish

| Causes: |

|

| Solutions: |

|

8.What Are The Innovations For Tablet Sugar Coating In The Future?

Although tablet sugar coating technology has been developed very maturely, the future tablet coating technology is still a challenging and innovative process. The innovations for tablet sugar coating in the future are:

New coating materials

New coating materials-sourced: konicaminolta

The current research focus is on developing new coating materials, enhancing the controllability of the process and the stability of the coating quality, and improving the process efficiency, flexibility and environmental sustainability of the coating.

Process sustainability

Process sustainability-sourced: syntegon

For future coating processes, sustainability is a key focus. How to develop and use more environmentally friendly materials and equipment is a big challenge and innovation.

Spray system

Spray system-sourced: mdpi

How to develop a laser-guided spray system can not only improve the efficiency of coating, but also reduce waste and increase recycling.

Conclusion:

How to ensure uniform thickness of tablet sugar coating is a problem that requires continuous improvement and adjustment. In order to ensure higher quality output, improve efficiency and reduce waste, tablet sugar coating and tablet coating machine is your consideration. Explore more and contact AIPAK now for more!

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine