How To Determine Excipient Quantity In Tablet Weight Calculation?

With the continuous development of pharmaceutical technology and equipment, patients' treatment and medication needs are constantly being met. In addition, various drug formulations and ingredient developments are becoming more mature. Among them, the use and addition of excipients are becoming more standardized.

In order to avoid the ingredients and dosages of excipients used in tablet manufacturing from harming the drug itself, this post focuses on the selection of excipient types and quantities. You may get why excipients to be added is important to tablet manufacturing and how to control the quantities. Get started now!

1.What Is Excipients For Tablet Manufacturing?

Excipients For Tablet Manufacturing-sourced: pacuthbert

Excipients are important for tablet manufacturing. In the process of tablets production, its main components are active ingredients and excipients. The main function of excipients are to protect, support or stabilize the stability of the drug during the production process and improve the utilization of the active ingredients in the drug. Although it cannot play a direct role, it can help patients identify drugs and drug ingredients and improve the safety of drugs.

2.Is It Important To Strictly Control Excipient Quantities In Tablet Weight Calculation?

Sure, it is important to strictly control excipient dosage when calculating tablet weight. It lies on:

Excipients account for the majority of total dosage form

Excipients account for the majority of total dosage form-sourced: jrspharma

Although excipients do not directly produce effects, their auxiliary effects are very important. Moreover, in the dosage form of half of the tablets, excipients account for the majority of the dosage. Therefore, it is particularly important to control the dosage of excipients. It plays a decisive role in the stability of the tablet.

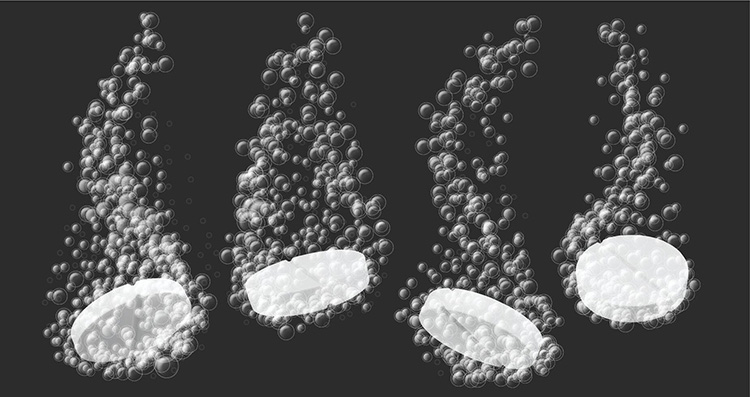

Promote drug decomposition

Promote drug decomposition-sourced: vecteezy

On the one hand, excipients will prevent the drug from being released too early in the body, thereby preventing the drug from causing stomach discomfort or irritation. On the other hand, it helps the drug to be decomposed into small enough particles in the intestine, so that the active substance of the drug can enter the blood circulation earlier and play a role. The role of excipients is inseparable from the dosage.

Improve product appearance

Improve product appearance-sourced: pharmaexcipients

Excipients can also improve the appearance of the drug, thereby improving patient compliance, especially for children and the elderly. However, too much excipient dosage can easily lead to poor appearance or excessive weight of the drug, so it is very important to control the dosage.

3.How To Determine Excipient Quantity In Tablet Weight Calculation?

When calculating the dosage of excipients, you need to consider the following factors. It includes:

Calculate and adjust the prescription ratio

Calculate and adjust the prescription ratio-sourced: buildapill

The dosage of excipients is determined by the dosage of the total substance in the prescription. The formula is adjusted and tested through experiments, and the ratio of the main ingredients and excipients is comprehensively considered. In conventional formulas, the ratio of drug content to excipient content is generally about 1:1.5. That is, if the drug content in the formula is 1g, the dosage of the excipient is 1.5g.

Add the corresponding dosage according to the function of the excipient

Different excipients may have different effects. You need to distinguish the dosage according to the specific function of the excipient:

Fillers

Fillers-sourced: freund

Fillers are mainly used to increase the tablet weight of the drug. If the content of the drug ingredient is low, the dosage of the excipient should be increased. If the content of the drug ingredient is high, the dosage of the excipient should be reduced.

Binders

Binders-sourced: alicdn

The addition of drug binders is mainly for tablet molding and corresponding hardness. If the drug powder has poor viscosity or poor hydrophobicity, a higher concentration of binder is required. On the contrary, if the drug powder has good viscosity and hydrophobicity, a lower concentration of binder is required.

Disintegrant

Disintegrant-sourced: quadragroup

Disintegrants can help the disintegration and absorption of drugs in the body. If the drug is difficult to dissolve, more disintegrants need to be added. On the contrary, less disintegrants need to be added.

Lubricant

Lubricant-sourced: tschopp

By adding an appropriate amount of lubricant, the friction between the drug powder and the equipment mold can be reduced.

Determined according to the production process

Determined according to the production process-sourced: sigmaaldrich

Different production processes have different dosage requirements for excipients. In the tableting process, the compressibility of the powder is required to be high, so the demand for excipients is large. In the wet granulation process, the demand for solution concentration and binder solution is high.

Optimize through experiments

Optimize through experiments-sourced: cphi

Any proportion formula of excipients needs to be optimized step by step through experiments. You can use the experimental control group to add the corresponding excipient dosage in sequence to test the hardness, disintegration, dissolution rate, etc. of the tablets to achieve the most ideal state.

4.Why Tablets Need Excipients?

The role of excipients is diverse. But its core role is to maintain drug stability so that the drug can achieve the best effect during decomposition and absorption.

Protect product stability

Protect product stability-sourced: hubspot

In addition to active pharmaceutical ingredients, other excipients in pharmaceutical products include fillers, binders, disintegrants, lubricants, colorants and preservatives. These excipients can maintain product stability to a certain extent and improve the utilization of active pharmaceutical ingredients.

Improve product appearance

Improve product appearance-sourced: thomasprocessing

In order to improve patient compliance, especially for children and the elderly, pharmaceutical products will add certain excipients to improve the swallowing and appearance of the product. This will make patients more willing to take such products.

Improve bioavailability

Improve bioavailability-sourced: drug-dev

Some active pharmaceutical ingredients are easily affected by the external environment, such as humidity, temperature or pressure, which can easily affect biological activity. Therefore, by adding excipients, the biological activity of the drug can be well protected, thereby improving bioavailability.

Improve tablet hardness

Improve tablet hardness-sourced: ipharmachine

The adhesion and hydrophobicity of some pharmaceutical powder materials are too low. By adding excipients such as adhesives, the hardness of the material can be enhanced when compressed later, making the product more durable during later storage and storage.

5.What Are The Types And Benefits Of Excipients Used In Tablet Manufacturing?

In the tablet production process, there are various types of excipients that can be selected, including:

Diluents

Diluents-sourced: static

Some powder materials are too sticky and may stick to the mold during the later compression process, thus affecting the product molding. You can dilute the drug ingredients by adding diluents such as lactose to reduce its viscosity, thereby increasing the hardness of tablet compression.

Binders

Binders-sourced: lemelange

For powder materials with low viscosity or hydrophobicity, adding excipients such as binders can help the product maintain its integrity, stability, and a certain hardness during the later production process. Its representative excipients include microcrystalline cellulose.

Disintegrants

Disintegrants-sourced: pharmaexcipients

The addition of disintegrants is conducive to the good release and absorption of drugs during the later patient use process. Its representative materials include starch, etc.

Lubricants

Lubricants-sourced: colorcon

In order to prevent the material from sticking to the equipment during the production process, such as tableting, due to excessive viscosity, resulting in incomplete products. You can improve its hardness by adding lubricants. Its representative materials include magnesium stearate.

Colorants

Colorants-sourced: commercev3

In addition to white tablet products, there are also red, yellow, blue, etc. on the market. This is achieved by adding various colorants. The main purpose of doing this is to improve the appearance and attractiveness of the product, so that patients can accept it more easily.

Sweeteners

Sweeteners-sourced: clevelandclinic

Sweeteners can well cover up the bitterness, astringency, and other flavors in drug ingredients that are not easily accepted by patients. Most sweeteners are suitable for various children's chewing products.

Preservatives

Preservatives-sourced: bentleyinstruments

For drug ingredients with a short shelf life or high sensitivity, you can add preservatives to prevent the growth of microbial components in the drug and delay its freshness and shelf life. Representative materials include sodium benzoate and sorbic acid.

The benefits they can bring include:

Maintain drug stability

Maintain drug stability-sourced: geminipharm

Excipients can improve drug stability and protect tablets from external factors after forming, including humidity, temperature, light and oxygen.

Improve bioavailability

Improve bioavailability-sourced: googleusercontent

Some drug ingredients have poor solubility and are easily affected by environmental factors, such as light, oxygen, humidity, etc. By adding corresponding excipients, the utilization of bioactive ingredients in drugs can be improved, so that the product has better quality.

Improve product appearance and taste

Improve product appearance and taste-sourced: promoboz

By improving the appearance and taste of drugs, patient compliance can be improved, making patients more willing to try during use.

Control drug release

Control drug release-sourced: geminipharm

In order to prevent certain drugs from causing damage to the stomach, excipients can control drug release so that the drug can dissolve in the intestine and be well absorbed by the intestine.

6.What Are The Other Excipients Risks And Challenges For Tablet Manufacturing?

Excipients not only bring benefits, but also potential risks and challenges. These include:

Safety issues

Safety issues-sourced: fette-compacting

Most excipients are considered safe, but they have not been thoroughly evaluated and their effects tracked. The world is constantly updating the composition and dosage requirements of excipients every year, but it is difficult to ensure its safety in terms of dosage.

Variability issues

Variability issues-sourced: nitrocdn

Although excipients are stable in a single environment, it is not ruled out that they can remain stable after mixing and interacting with other excipients and other drug ingredients. This combination is very necessary for timely effect tracking and variability strategy control in the future.

Interaction

Interaction-sourced: pharmaceutical

Different excipients may interact with each other or other drug ingredients under different circumstances, and change the stability, release or bioavailability of the drug, resulting in uncontrollable effects.

Legal compliance

Legal compliance-sourced: ekalab

The amount and type of excipients used in different countries may be different, and additional review is required to achieve legal compliance.

7.What Are The Most Important Considerations When Selecting Excipients?

When choosing excipients suitable for your powder materials, you need to consider the following factors:

Functionality

Functionality-sourced: pharma

Different excipients have different functionalities. When choosing, you must carefully examine whether the functionality of the excipients you need matches your own formula to maintain the safety and stability of the drug.

Compatibility

Compatibility-sourced: scene7

When choosing excipients according to your own drug formula, you must consider whether it is compatible with other active ingredients or excipients in your formula. This is related to whether there will be reactions between them, resulting in mutations.

Safety

Safety-sourced: cphi

The excipients themselves also need to have safety and quality audit requirements and standards. You need to choose the excipients that suit you according to the standards and requirements of the Drug Administration in your area.

Manufacturing feasibility

Manufacturing feasibility-sourced: bruker

When manufacturing or producing tablets, even if the excipients you need are compatible with your own formula, you must also consider the cost and economic benefits of this excipient in the production process, and whether it is compatible with the pharmaceutical process you adopt.

Sustainability

Sustainability-sourced: talentlms

Drug production is a long-term and sustainable project. The excipients you choose need to meet the requirements of sustainable production. This can well meet the needs of patients while not making the product environmentally unfriendly or unable to be continuously supplied in the future.

Conclusion:

Being able to select and calculate the type and dosage of excipients for your tablet manufacturing is crucial to the stability, safety and high quality of the final product. In order to obtain the best quality tablets, following the above requirements and standards can solve your own problems. If there are more you want to know, contact AIPAK now!

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine