How To Deal With Demoulding Difficulties In Tablet Manufacturing Process?

Have you ever get trouble while making tablets? What are the common trouble in tablet manufacturing? The small problem in tablet making process may lead the big trouble for you tablet manufacturing and sale. The solving of these problems can make you great benefits for your tablet products.

How to deal with demoulding difficulties in tablet manufacturing process? What are the standard of high qualified tablet products? What are the basic problem of tablet manufacturing? How to deal with the common problem in tablet manufacturing? Here the answer for the whole question. Come on and have a reading!

1.What Is Tablet Manufacturing?

Tablet Manufacturing-Sourced:pharmaceuticalmanufacturer

Tablet is made by pressing various medicine powder. And tablet manufacturing refers to the process of pressing medical powder or excipients into tablet shape. The process is long and complicated and you may find the material preparing, blending, pressing, coating and packaging all as the important tablet manufacturing process.

In tablet manufacturing process, there may exist the problem like particle fracture, deformation, breaking, rearranging and so on. And for the nice effect, great look and long lifespan, there are many things you should pay attention to in tablet manufacturing process.

2.What Is The Process Of Tablet Manufacturing?

Tablet manufacturing covers the long process. And here are the essential process of tablet manufacturing.

Material preparing

Material Preparing-Sourced:deltaformulations

The first step of tablet manufacturing is to prepare the material for your products. Sometimes it is essential for the grinding of your material to the even and uniform particles. The great preparing of your products is the base for your later tablet manufacturing process.

Granulating

Granulating-Sourced:fabtechnologies

Granulating can make the better flow, stick and pressing of your powder for your better later tablet manufacturing. There are wet granulation and dry granulation which make the different powder and particles.

Material blending

After the preparing of all medical powder and excipients, it is now time for the blending of the material. It can make sure the even and uniformity of later tablet products. And here are various blender for you to choose.

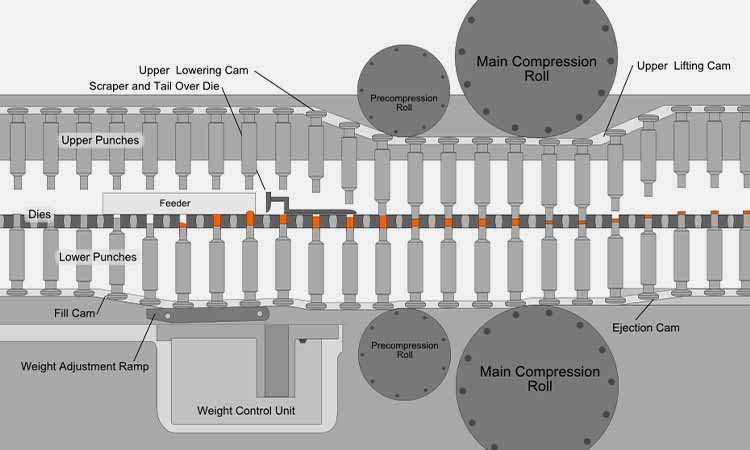

Tablet pressing

Tablet Pressing-Sourced:huadapharma

Here are tablet pressing machines for you to make the tablet pressing work. With different die and mold, you may make the tablets with various size and shape. Tablet pressing machine can make the flexible and elegant work.

Tablet coating

Tablet Coating-Sourced:globalmachinery

Tablet coating is also important for many of your tablet products. Coating makes the important work of defending bad smell, protecting tablets and making color for your tablet products. There are tablet coating machine for you to make the uniform and even tablets products.

Tablet packaging

Tablet Packaging-Sourced:packaging-gateway

Tablet packaging is the last and most important step for your tablet manufacturing process. Here you may find various packaging type including bottle packaging, sachet packaging, blister packaging and so on.

3.How To Deal With Demoulding Difficulties In Tablet Manufacturing Process?

Demoulding difficulty is one of the most common problem in tablet manufacturing process. So how to deal with it?

Adjusting process parameters

Adjusting Process Parameters-Sourced:wikipedia

Reduce pressure

Excessive pressure may cause the binding force between the tablet and the mold to be strong, making it difficult to eject the tablet. The pressure of the tablet press can be appropriately reduced to make the tablet easier to release from the mold, while ensuring tablet hardness and quality.

Increase holding time

During the tablet pressing process, appropriately extending the holding time can help the tablet form better within the mold, reducing ejection difficulties due to incomplete formation. Generally, the holding time can be extended by 1-3 seconds from the original setting for testing and adjustment.

Adjust speed

If the press speed is too fast, the tablet may stay in the mold for too short a time, leading to insufficient formation and ejection difficulties. The speed of the tablet press can be appropriately reduced to allow enough time for the tablet to compact and form properly in the mold.

Optimize material properties

Optimize Material Properties-Sourced:syntegon

Improve granule flow

Poor granule flow can cause uneven filling of the mold, affecting tablet ejection. The flow can be improved by adding appropriate lubricants, such as magnesium stearate or talcum powder, which helps the material fill the mold evenly and facilitates ejection.

Adjust granule moisture content

Too high or too low moisture content in granules can affect tablet ejection. High moisture content can cause granules to stick to the mold, while low moisture content results in poor plasticity, causing fragile tablets and difficult ejection. Generally, the moisture content should be controlled at 3%-5%, with adjustments based on specific materials and processes.

Choose suitable excipients

Certain excipients can affect tablet ejection. For example, excipients with good lubricating and demolding properties, such as fumed silica and hydrogenated vegetable oil, can improve tablet ejection.

Mold maintenance and treatment

Mold Maintenance And Treatment-Sourced:saintytec

Clean the mold

Dirt and residual material on the mold surface can increase friction between the tablet and the mold, making ejection difficult. Regularly clean the mold thoroughly using specialized mold cleaners and tools to ensure the mold surface is smooth and clean.

Lubricate the mold

Apply an appropriate amount of release agent to the mold surface, such as silicone oil or liquid paraffin, which forms a lubricating film between the tablet and the mold, reducing friction and making the tablet easier to eject. However, be cautious of excessive release agent, as it may affect tablet quality.

Check mold wear

Long usage or improper handling of molds can cause wear or deformation, affecting tablet ejection. Regularly check the mold for wear and replace severely worn or deformed molds in a timely manner.

Environmental control

Environmental Control-Sourced:controlsohio

Control temperature and humidity

Environmental temperature and humidity also affect tablet ejection. Generally, the temperature should be controlled between 18-26°c, and relative humidity should be between 45%-65%. In high-temperature and high-humidity environments, granules tend to absorb moisture, leading to sticking and difficult ejection. In low temperature and low humidity environments, granules may become too dry, affecting tablet formation and ejection.

4.What Are The Disadvantages Of Tablet Products?

Tablets products benefit us in a comprehensive way. But there are still some disadvantages of tablets products.

Low bioavailability

Low bioavailability refers to the poor absorption rate of medicine. And for some kind of medicine tablets, it is essential to make a large dose of the drug concentration for the effect.

Stomach harming

Stomach Harming-Sourced:healthline

Tablets may lead the harm for your gastrointestinal tract. The irritant effects may harm your stomach and reduce the medicine effect. The invention of suitable formulation may reduce the bad effect of stomach harming.

Hard swallowing

Hard Swallowing-Sourced:harvard

Tablets are square and hard. And for elders and children, it is hard for people to swallow it. And the chock may lead the problem for patients’ safety. The fear in taking tablet products may also lead the negative effect for disease healing.

Limited medicine type

Here are some tablets which are forbidden to be made as tablet feature. The medicine with slow dissolution and large dosage are hard to make tablets. And insulin can also not be made as tablets as it can only take by injection.

5.What Are The Standard Of High Qualified Tablet Products?

What are the standard of high qualified and even tablet products? Here are the standard you should know.

Hygienic and efficient tablets

Hygienic And Efficient Tablets-Sourced:uclahealth

The tablet products with high standard should be hygienic and effect. Only without contamination, your tablets can be safe and reliable. And the great effect is also the important consideration for your tablets products high quality.

No bad taste or odor

No Bad Taste Or Odor-Sourced:science

The standard tablets should have no bad taste or odor. The high qualified tablets apply coating as the important part for the defending of bad taste and odor. The tablets without bad taste and odor is the great tablets.

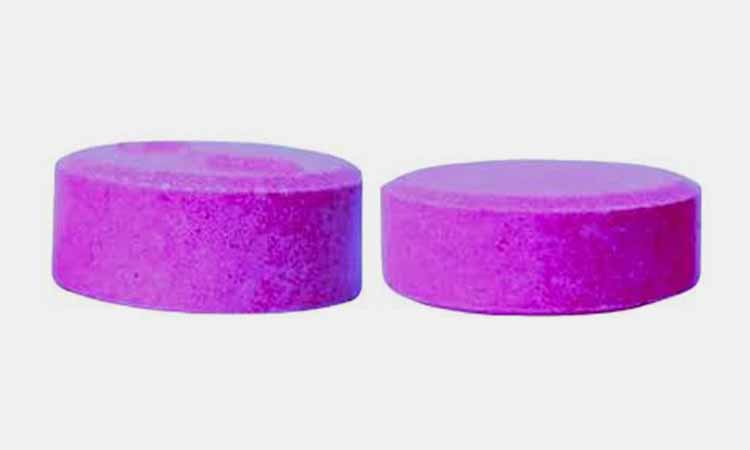

Great appearance

Great Appearance-Sourced:aidsmap

Your tablets products should have great appearance. The tablets products should be complete and even. The nice appearance of tablets products can also show the great protection your coating give to your tablets.

Gastrointestinal protection

The qualified tablet products should have the outstanding work in delaying tablets release. This delayed releasing can make gastrointestinal protection for patient. And this is good for your medicine effect and patient care.

6.What Are The Basic Problem Of Tablet Manufacturing?

In tablet manufacturing, here are common problems. And here are the basic problem you should know about tablet manufacturing.

Weight variation

The even and uniform table content is the base for your high qualified tablet products. Weight variation makes the dosage and effect change of your tablets products. You should make sure the even weight of your tablets products.

Mechanical strength related

Hardness and friability of your tablets products refers to mechanical strength related problems. Your tablets products should not be that hard or fragile. There is a balance in tablet hardness which makes the great protect for your products and easy dissolving of your tablets products.

Content uniformity

Content Uniformity-Sourced:agilent

Content uniformity makes the direct linking with your medicine effect. The uneven medicine powder may lead the trouble for your medicine effect. You should apply the reliable blender for the even mixing for your tablets products material making and tablets pressing.

Visual defects

Visual Defects-Sourced:pharmaguddu

Visual defects refers to the problem in tablets appearance. You may find tablet breaking, mottling, melting and so on as the common visual defects. It is clear that visual defects are the first step of the tablets products feature change.

7.How To Deal With The Common Problem In Tablet Manufacturing?

For the many problem happened for your tablets products, how to deal with them. Here are your solution about the dealing of the common problem in tablet manufacturing.

Problem And Solution-Sourced:skipprichard

| Tablet defects | Reason | Solution |

| Cracking

Cracking-Sourced:huadapharma |

The large, dry and unqualified granules may lead the cracking problem easily. You should also pay attention to the temperature and air entrapment which may also lead cracking problem. | The adjusting of granules size and stick can make the great solving of cracking problem. Besides, you should also adjust temperature environment and apply conical die for the cracking problem. |

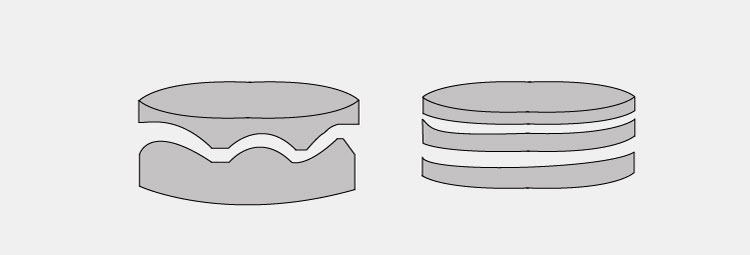

| Capping

Capping-Sourced:freemantech |

Capping comes from the fine granules and unsuitable lubricants and binder. The high pressing strength and high pressing speed can also make capping. | You should make the balance of granules in medicine powder and adopt the efficient binder or lubricants. And you should also get the most suitable pressure and equipment for your machine. |

| Chipping

Chipping-Sourced:ipharmachine |

Dry and stick punch face may make chipping of your tablets products. | For the solving, you should make sure the suitable punch face. Your formulation should also be suitable for the tablets products. |

| Sticking and picking

Picking-Sourced:huadapharma |

Sticking or picking tablets products come from the wrong formulation. | You should check your material condition first. The dry, hot, oily, soft material can all make the sticking or picking of your material. You should also adjust the punch or equipment for the solving. |

| Flaking

Flaking-Sourced:pharmapproach |

Tablet flaking occurs for coating problem. | You should adjust the coating formulation for the solving of flaking problem and you should also adjust spraying rate and drying temperature. |

| Binding

Binding-Sourced:lfatabletpresses |

Binding comes for the dry medicine powder. | The adding of moisture and lubricants of your medicine powder can help the solving of binding problem. Besides, you should also apply the suitable punch. |

| Weight variation

Weight Variation-Sourced:pharmabossbd |

Weight variation comes from the wrong formulation, unsuitable mold and high press speed. | You may solve the weight variation problem by reducing granulation and compressing. The adding of flow enhancer can also avoid the work. |

| Hardness

Hardness-Sourced:istockphoto |

The unified of bulk density and particle size can avoid the hardness of tablet products. | The achieving of homogeneous bulk density and efficient binder can make the great compacting property. |

| Mottling

Mottling-Sourced:biogrund |

Die migrates may lead mottling problem. | You should make the deep mixing of die migrates and adopt the proper mixing color binder solution. |

| Lamination

Lamination-Sourced:lfatabletpresses

|

Lamination comes from the poor flow and uneven compression. You should also pay attention to binder and moisture content for the lamination solving. | It is clear that you should improve powder flow and control moisture content for your lamination work. Besides, you should also adjust the compression force. |

8.How To Make The Reliable Tablet Formulation?

In the manufacturing of tablet formulation, here are the tips you should pay attention to while making the reliable tablet formulation.

Reliable Tablet Formulation-Sourced:acg-world

Formulation with suitable feature

Your formulation should have suitable feature. The medicine powder should not be sticky or has poor flow. Besides, the formulation which isn’t soluble should also be avoided. Your formulation should have suitable feature which can make the easy pressing for your tablet pressing machine and also great flow and uniformity.

Formulation with no abrasive

For natural medicine powder, there may be abrasive part with no fine grinding. And the abrasive formulation may lead the uneven medicine products and also lead the degradation and damage with time goes on. It may also lead the defects of tablets. The careful and precise grinding and blending can make the great prevention of it.

Formulation with stable feature

Stability is the important feature you should consider in your life. For the ingredients like magnesium chloride, L-arginine, chondroitin, mushroom powders and so on, you should make great handling of them. The stable formulation can make the best effect of your medicine products.

9.What Test You Should Make For Your Tablet Quality Control?

How to make sure the great quality of your tablets products. Here are the test you may adopt for the tablet quality control work.

Content of active ingredient

Content Of Active Ingredient-Sourced:tasconusa

You should make the test about the content of active ingredients. This test can tell you the absolute drug content which is so helpful for the testing of your medicine tablet quality. Content of your active ingredient is the show of your products effect.

Weight variation test

Weight variation test makes the careful test about the weight uniformity of your medicine products. It makes the clear show of uniformity of medicine tablet products. Weight variation test is thus important factor you should consider for your tablet products testing.

Content uniformity test

Content uniformity test makes sure the even and uniform distribution of your medicine powder in your pills. The uneven distribution may lead the bad effect for your disease. And for some disease with the high request on medicine dosage, the little change may lead big difference.

Disintegration time and dissolution test

Disintegration Time And Dissolution Test-Sourced:istockphoto

Disintegration time and dissolution of your tablets make great influence on your medicine effect. The different affecting manner of your tablets on your body affects your stomach and intestines. The suitable disintegration time and dissolution can make great benefit for you.

Hardness and friability test

Hardness And Friability Test-Sourced:merlin-pc

The hard tablet or fragile tablet can’t make the best effect of medicine for you. There is the according hardness and friability of your certain type of medicines. You should make the hardness and friability test for your certain type of tablets for your great tablets feature.

Conclusion

How to deal with tablet demoulding difficulties? How to deal with the other common problems in tablet manufacturing process. Here you may have your answers. Congratulation for the solution you get from this post! For any question or problem, you should have no hesitate and contact AIPAK now.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine