AIPAK Automatic Capsule Filler Machines

NJP-400C Automatic Capsule Filler Machine

NJP-400C automatic capsule filler machine is suitable for automatically completing capsule feeding,separating,filling,(waste capsule rejecting),closing,finished product ejecting for powder or tiny pill medicine in capsule。It is designed sophisticatedly by our factory according to the practice on domestic,It is fully accord with the GMP standard.

Reliable quality

Reasonable price

GMP standard

NJP-800C Laboratory Pharmaceutical Automatic Capsule Filler Machine

Type NJP-800C Automatic capsule filler machine is designed opposite to the normal models(With open style in dosing station and turret) in Chinese market, and it has been developed to fully enclose stations to ensure their flawless performance. And adopts the advanced technology at home and international similar products, The whole machine appeared as Humanity, Automation, Stability, Beautiful. And in accordance with to CE, ISO and GMP international standard.

Easy dismantling installation

Fast mould change

Convenient operating

NJP-1200C Automatic Capsule Filler Machine

NJP-1200C automatic capsule filler machine is designed and further improved on the base of the original full automatic capsule filling machine from both home and aboard. With high technology and exclusive performance, it has reached international leading level.Thsi automatic capsule filling machine is an ideal equipment for capsule and medicine in pharmaceutical industry which is in full compliance with GMP requirements.

Easy operation

Capsule qualified rate is higher than 99%

Low power consumption

NJP-1200D Automatic Capsule Filler Machine

NJP-1200D automatic capsule filler machine is designed and further improved on the base of original full automatic capsule filling machine from both home and aboard. With high technology and exclusive performance, it has reached international leading level.Thsi automatic capsule filling machine is an ideal equipment for capsule and medicine in pharmaceutical industry which is in full compliance with GMP requirements.

Easy operation

Capsule qualified rate is higher than 99%

Low power consumption

How To Choose The Best Capsule Filler As Your Requirement: The Complete Guide in 2025

Have you ever wondered how to fill your medicine capsules?

In fact,the capsule filling process refers to the encapsulation and lots of various techniques that are used to enclose the medicines into a stable shell,normally called an empty capsule,that can be taken orally or as a suppository.

A capsule filler is to fill powder into empty capsules and then lock the capsules.

Capsule filler machines are available in different types,like the automatic,semi-automatic,manual capsule filler .

And automatic capsule filler machines can also automatically reject the failed filling capsules.

How to choose the best capsule filler to meet your requirement,today I am going to give you more knowledge about that.

Spend a few minutes reading through,you will find the best answer to suit your needs.

Let’s start with some questions.

1.What is Capsule Filler?

Various filled capsules by capsule fillers

Capsule filler also known as encapsulation,that is a mechanical device to encapsulation products like powder,pallets or tablet kinds of materials or nutrients into empty capsules.

2.What Kind of Capsule Can be Filled by the Capsule Filler?

All kinds of can be filled capsules

There are totally two kinds of capsules:gelatin capsules and vegetarian capsules in the world.

Among which the gelatin capsules can be divided into hard gelatin capsules and soft gelatin capsules.

And hard gelatin capsules are mainly filled by the capsule filler ,while the soft gelatin capsules are commonly filled with liquid by another device called capsule liquid filling and sealing machine.

Vegetarian capsules can be separated as HPMC capsules and Pullulan capsules.

Both of them can be filled by capsule filler.

Vegetarian capsules

With low moisture content and good toughness,HPMC capsules are not easy to be affected by the damp.

Therefore,HPMC capsules are more suitable for filling hygroscopic materials and moisture sensitive material.They will not react or mix with any of the contents,that is ,HPMC capsules will not cause any disintegration delay.

So if you have medication with strong hygroscopicity,HPMC capsules may be your best choice to be filled by the capsule filler,as it solves the problem that some material easily mix or react with gelatin.

While Pullulan capsules are very stable and can be good barrier to oxygen,isolate odor,so if you have oxygen-sensitive material,Pullulan capsules may be your best choice to be filled by capsule filler.

3.What Materials Can be Filled by Capsule Filler?

Materials filled by the capsule filler can be granules, powder, or pellets individually or in different types of combination of pallets and powder .

Various powders

Now with the increasing of requirements,tablets are used to filled into capsules for special purpose or nutrient supplement.

However,before the filling of tablets,you must make sure that the tablets must be film-coated,that is to prevent dust generation and the size must fit for the capsule body so that it can freely fall into it but no need to turn on their sides.

Apart from that,you can also fill multiparticulates and mini-tablets into hard gelatin capsules through capsule filler.

4.Can Capsule Filler Fill Liquid ?

Most of you would ask if you can use the capsule filler to fill liquid materials into the soft gels.

In fact,the answer is yes,you can use capsule filler to fill liquid.but that need special rotating die with special process.

Filled with liquid capsules

Now,with advanced technology,you would get capsule liquid filling and sealing machine to fill your liquid substance as the liquid filled capsules need special band sealing that not only protects from leaking but also provides a visible sign to warn someone who have tampering attempts.

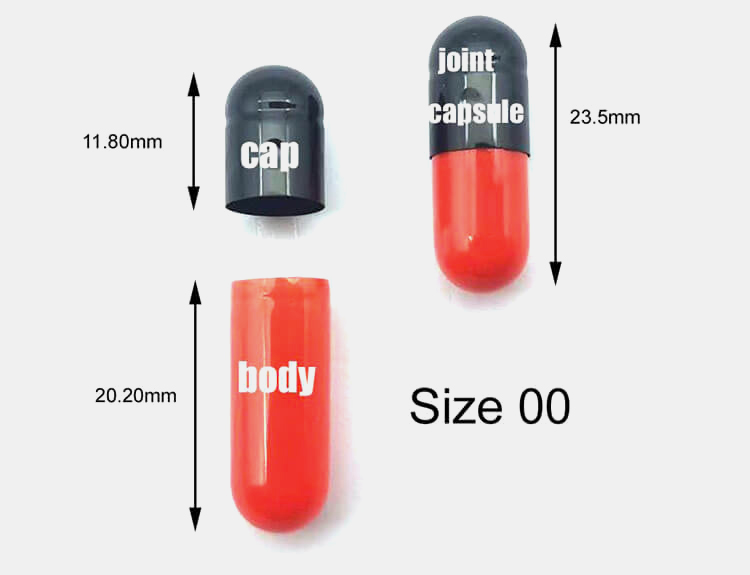

5.What Size of Capsules can be Filled by Capsule Filler?

You can produce varying sizes of capsules ranging from #00,#1,#2,#3,#4,#5 and all kinds of safety capsules through the capsule filler.

Various sizes of capsules

Besides,your capsule length and width can be in the range of 400mm and 300mm respectively.

6.What Capsule Size is Right For You?

You may find it hard to figure out which size of capsule is right for your needs as there are so many different capsule sizes.

In fact,for most applications,a size #00 and #0 that are normally classed as standard capsule sizes will be enough fit your requirements.

| Mode | Outer Diameter (mm) | Length (mm)土0.4 | Locked Length (mm) 土0.5 | Weight Difference (mg) | |

| 000# | Cap | 9.80-9.90 | 13.10 | 25.7 | 土10 |

| Body | 9.44-9.54 | 22.00 | |||

| 00# | Cap | 8.50-8.60 | 11 .80 | 23.4 | 土8 |

| Body | 8.15-8.25 | 20.20 | |||

| 0# | Cap | 7.61-7.71 | 10.90 | 21.7 | 土6 |

| Body | 7.30-7.40 | 18.60 | |||

| 1# | Cap | 6.90-7.00 | 9.80 | 19.3 | 士5 |

| Body | 6.61-6. 69 | 16.50 | |||

| 2# | Cap | 6.32-6.40 | 9.00 | 17.8 | 士4 |

| Body | 6.05-6.13 | 15.30 | |||

| 3# | Cap | 5.79-5.87 | 8.10 | 15.7 | 土3 |

| Body | 5.53-5.61 | 13.60 | |||

| 4# | Cap | 5.28-5.36 | 7.20 | 14.2 | 土3 |

| Body | 5.00-5. .08 | 12.20 | |||

| 5# | Cap | 4.87-4.95 | 6. 40 | 11.2 | 土3 |

| Body | 4.56-4.64 | 9.20 | |||

A size #00 holds about 735mg or 0.735 grams powder while a size #0 holds about 500mg or 0.5 grams,which will be enough for your normal needs.

For other kind of capsule ,you may find your answer below:

Large Size Capsule

Capsule size #000 is the largest size for human use ,and it normally holds about 1000mg powder on the average.

So because of this ,to choose the most suitable capsule,it is best for you to check the powder density and mesh size before your filling.

Average Size Capsule

Average size capsule normally refers to #00 capsule that holds about 750mg powder,it is one of the most commonly used capsule sizes used in the pharmaceutical industry.,and whose volume is 0.93ml and dimension is 23.6mm.

Small Size Capsules

Small size capsules often include size #1 and #2.

Among which, size #1 holds about 400mg powder and 0.50ml volume filling density.So if you have trouble with swallowing,that will be your great choice but not will be your great choice if you have high dosage.

Size #2 capsule has lower filling density than that of size #1,that is 300mg,which is also good choice if you have trouble swallowing and like such kind of small volume capsules.

In conclusion,small size capsules are one of the cheapest capsules as its low materials cost but because of small size ,they are hard to fill by capsule fillers,and not very popular among consumers.

7.What is the Filling Weight by Capsule Filler?

Get that most sizes of capsules can be filled by the capsule filler,you must want to know how much mg can be filled by each capsule.

In fact,different sizes of capsules may have variant filling weights that not only depend on the capsule size but also depend on the powder density ,fineness and particle size.

Some powders may be denser than other powders.

Therefore,it is best for you to know your material powder mesh size and respectively capsule size chart before filling.

| Capsule Size Chart | #000 | #00 | #0 | #1 | #2 |

| Volume (ml) | 1.37 | 0.93 | 0.68 | 0.50 | 0.37 |

| Lock Length +/- 0.7mm | 26.14 | 23.6 | 21.3 | 19.2 | 17.5 |

| Capsule Capacity (mg) | |||||

| 0.6g/ml | 822 | 558 | 408 | 300 | 222 |

| 0.8g/ml | 1096 | 744 | 544 | 400 | 296 |

| 1.0g/ml | 1370 | 930 | 680 | 500 | 370 |

| 1.2g/ml | 1644 | 1116 | 816 | 600 | 444 |

8.Which Industries Are Capsule Filler Widely Used?

Every day,more than 1600 types of capsule filler are installed worldwide,that is ,capsule filling machines are widely used in various industries for various industrial and pharmaceutical purposes.

You can find industries that include:

Pharmaceutical Industry

Pharmaceutical capsules

This industry is the biggest one that capsule fillers are used.

Here capsule fillers are widely used to fill empty capsules of various sizes with powders,granules,tablets or any kinds of their mixture that include active pharmaceutical ingredients or drug substances or excipients.

Capsules that you daily take may be produced by pharmaceutical plants through various capsule fillers.

And all these capsules are either used for treating your disease or a supplement to some kind of nutrition for you.

Healthcare Industry

Nowadays,with more attention to health,more and more people prefer to take capsules to give their body an extra supplement.

So that has made capsule fillers more and more popular in the healthcare industry.

Food Industry

In food industry,some active food are crushed into powder or granules ,then filled into capsule for easy and convenient taken.

In fact,other industries,like cosmetic industries,chemical industries also use capsule filler to fill capsules that are widely used in their respective industries.

Capsules used in cosmetic industry

9.Why Invest in Capsule Filler?

There are several benefits from investing on capsule filler:

Quantity

Quantity means you can fill a lot of capsules at once.

For example, our NJP1200 capsule filling machine can fill a maximum of 72,000 capsules every hour .

High Efficient

If you choose the right capsule filler,like the full automatic capsule filling machine,you will have your time and cost saved and maximize your productivity.

So think about what this means for your business?

Hands-off

You will have your hands-off as you no need to operate a machine manually.

And you don’t have to add capsules or filling medication to the machine manually,either.

What you only have to do is follow the instructions and learn about the machine to avoid unnecessary issues and in this way you may also won’t have too much waste capsules.

Capsule Variety

Various capsules

There are a variety of capsules you can fill with automatic capsule machines.

Size 00-4 are standards for capsule fillers.

All of these features make the automatic capsule filling machine a great choice.

10.How Many Types of Capsule Filler Are There?

You can get three types of capsule fillers,namely:

.Full automatic capsule filling machine

.Semi automatic capsule filling machine

.Manual capsule filling machine

.Full automatic capsule filling machine

AIPAK full automatic capsule filling machine

Both automatic capsule filling machines are mechanical devices,full automatic capsule filling machine can work totally automatically,that means,you will no need extra operationer to run the machine.

If you are in large of capsules,this kind of full capsule filling machine will be your perfect choice.

.Semi automatic capsule filling machine

AIPAK CGN-208D2 semi-automatic capsule filling machine

Semi automatic capsule filling machine work between automatic and manual.It is very simple in design and very easy to operation for newcomers.

Besides,semi automatic capsule filling machine is also very hygiene in use.

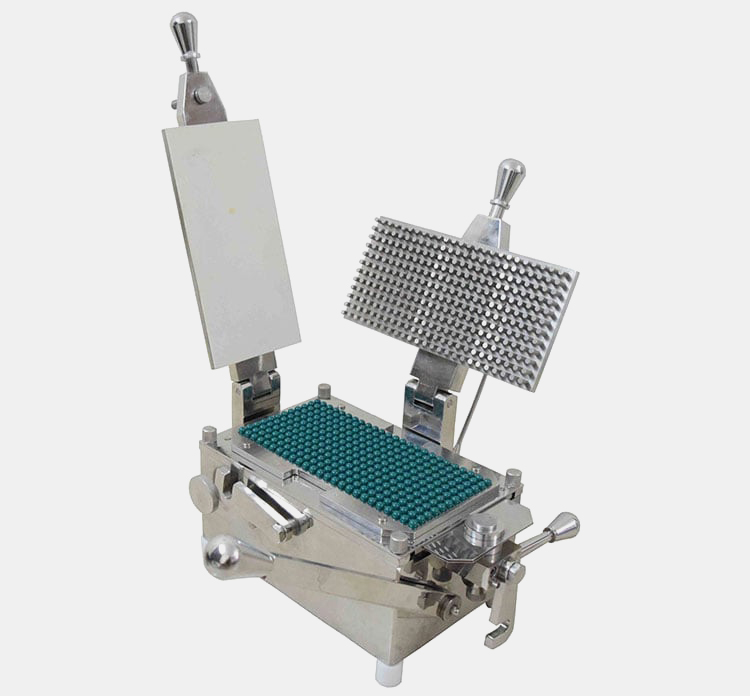

.Manual capsule filling machine

Manual capsule filling machine-Kanhan International

Manual capsule machines are normally widely used by small scale pharmaceutical companies since they may have less quantity of capsules and it is done manually.

The manual capsule fillers need no power and can be operated by hand.

Of course,manual capsule fillers are very popular among those who want to make their individual nutrient supplement at home as they are easy and small to operate.

11.What are the Advantages of Full Automatic Capsule Filler Machine?

Full automatic capsule filling machine is some kind of fully automatic,that is outstanding than all other capsule fillers to some extent.

To be specific,they are:

1.Filling all sizes of capsule

You can use full automatic capsule filling machine to fill all sizes of capsules.That is a full automatic capsule filling machine will meet your various size of capsule filling needs,you will just need to take less than 10 minutes for the changing size operation.

2.High speed filling machine

Full automatic capsule filling machine are scalable and high-speed filling machine and are compliant with GMP requirements.

If you have large scale of capsules needs to be filled,the full automatic capsule filling machine may be your good choice.

And some full automatic capsule filling machines also allow aseptic filling that is suitable for powders that have special requirements.

3.Lower power consumption machine

You will find that fully automatic capsule filling machines are capsule filling equipment that integrating machine,electricity and gas.

It has high degree of automation,and adopts micromputer programmable controller, touch panel operation, frequency conversion speed control, and electronic automatic counting device,that all these have made it a lower power consumption machine.

4.Accurate Filling Dose

The dosing tools in the fully automatic capsule filling machine are very precise and you can have it adjust the filling weight for your capsules.

Apart from,it also ensures your capsules are precisely filled with correct dosage materials for you to get an accurate filled dosage capsule.

5.Aseptic Filling

During the working process of fully automatic capsule filling machine,you will find the turnable in that helps intercept the dust particles from contact with the parts of the machine.

While fully automatic capsule filling machine also uses vacuum operation for the capsule separation that will have less amount of dust produced during the operation.

Besides,you will find the presence of the enclosed dosing system in the fully automatic capsule filler also ensures the dust suction that you will no need frequently clean the inside of the machine.

12.Are There Any Drawbacks of Full Automatic Capsule Filler Machine?

Like all other machines,full automatic capsule filler machine also has some kind of disadvantages,namely:

You need to spend higher cost for a full automatic capsule filler machine than other capsule fillers as it is the result of high technology,some of its parts are designed through meticulous and elaborately research and development.

Apart from that you will find full automatic capsule filler machine is bigger than other capsule fillers,that is ,full automatic capsule fillers are heavier than the semi-automatic or manual capsule fillers.

It will be hard for you to move the full automatic capsule filler machine from one place to other place.

13.Why You Should Use Semi-automatic Capsule Filler Machine?

Semi-automatic capsule filler machine is also kind of automatic capsule filling machine,the reason why should choose semi-automatic capsule is that it not only owns the advantages that automatic capsule filling machine has,but also you will other benefits from :

You will no need to spend too much cost purchasing the semi-automatic capsule filler machine as it is semi- automatic equipment,its technical requirements are not too much.

You will no need to vacate large space to hold the semi-automatic capsule filler as it occupies small area.

Through the semi-automatic capsule filler,you will no need to choose the filling materials too seriously as the semi-automatic capsule filler machine has not very high requirements to the materials ,that is whatever fine powder or sticky powder,both can be filled effectively by the semi-automatic capsule filler machines.

Last but not the least ,you will find semi-automatic capsule filler machine has low noise,low energy consumption and needs simple maintenance.

14.Are There Any Disadvantages of Semi-automatic Capsule Filler Machine?

The drawbacks of semi-automatic capsule filler machine are:

1.You will get limited production capacity by the semi-automatic capsule filling machine as some of its operations need a worker and it is only suitable for medium scale pharmaceutical companies that do not need large scale of capsule supply.

2.As the first,you will need to hire an operator to operate the semi-automatic capsule filler machine,and the operator may have the same workload as the machine when it is in process.

15.How Will You Benefit From Manual Capsule Filler?

Different from the automatic capsule filler machines,a manual capsule filler means you will fill your capsules through your hands.

So the biggest advantage of a manual capsule filler is it is simplicity,easy for your operation.

Now manual capsule filler machines are very popular among some individuals who want to make their own nutrient supplement.

They can purchase the manual capsule filler machine to use it at home to fill the nutrient they want,the hard capsule shell not only cover bad taste of the materials,but also make the active material easy taken for your body.

Part of manual capsule filler process

Besides,you will be easy to assemble or disassemble the manual capsule filler machine as it has simple design and structure,that in other words,you will also be easy to troubleshoot some problems.

16.Are there Any Drawbacks of Manual Capsule Filler?

Compared with automatic automatic capsule filling machines,the manual capsule fillers has some drawbacks,like it may only suitable for home individual use or pharmaceutical company laboratory use or small scale of capsule needs.

As manual capsule filler not only increases the labor costs but also increases the risk of physical injury as most of the operations are operated by hand.

17.What are the Differences Between Different Types of Capsule Fillers?

The production rate of different types of capsule fillers varies with different models,so it is better for you to choose the most suitable machine as your desired application.

But there are other differences you should know,they are:

Automatic capsule filling machine

You will have the automatic capsule filling machine to fill a wide range of gelatin capsule sizes with powder,pallets and granules with high accuracy.

And you will have all these materials filled separately or in all possible combinations.

And you will find automatic capsule filling machine has its frame built by stainless steel 316/304 that makes it a sturdy appearance.

Semi-automatic capsule filling machine

Semi-automatic capsule filler machines nowadays are popular in modern pharmaceutical practises for its precise manufacturing requirements.

The machine is also precise in filling all sizes of capsule with powder,granules or pellets.

Besides that,semi-automatic capsule filling machine also provides higher degree of automation with an elevated level of filling weight accuracy.

Semi-automatic capsule filling machine is compliant with all GMP requirements that has good durability and reliability.

Same with automatic capsule filling machine,semi-automatic capsule filling machine has stainless steel covering and has the capacity of 25000 to 45000 pcs capsule per hour.

Manual capsule filler

The biggest difference that manual capsule filler differs from automatic capsule filling machine is that it is suitable for small scale application or individual use.

Manual capsule filler also can fill various different sizes of capsule,you can only change the parts.

One of the happy things is that you can use manual capsule filler to fill difficult powders and materials that may be hard to fill.

And manual capsule filler also has the advantage that it can be easily disassembled to be cleaned and maintained.

Same with automatic capsule filling machine,manual capsule filler is made of 304 that makes it durable for long time operation,so as a result,you will have at least 8000 pcs capsule produced per hour,though it is operated manually at a low output.

At present ,the manual capsule filler machines are widely used in small scale capsule filling not only because of its simple operation but also its ability to perform highly precise filling.

So,to be conclude,if you have medium scale production,you may choose automatic capsule loader or manual capsule loader in combination with manual capsule filler to load capsule automatically on the loading tray of capsule filling machine .As in such way,it will your production output but also saves the time to load the capsules.

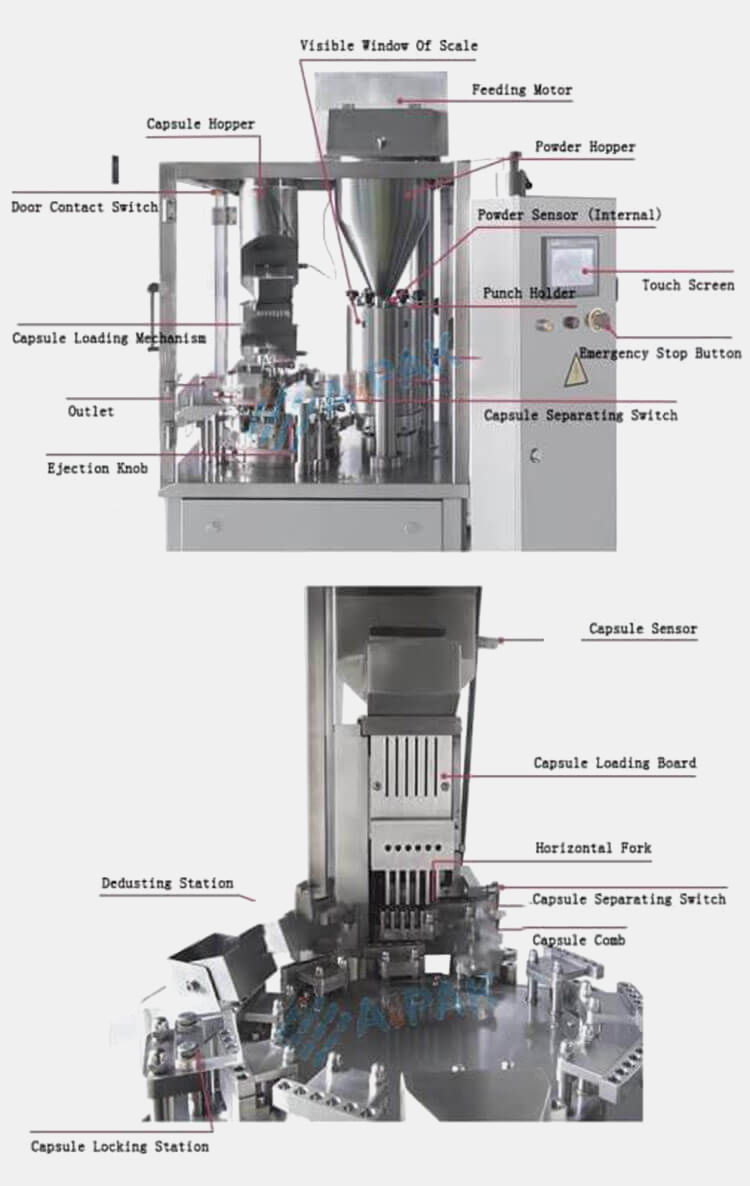

18.What are the Main Components of Full Automatic Capsule Filler Machine?

There are several parts that comprise the full automatic capsule filler machine,among which the most important components you should know include:

1.Powder Hopper

This part is place where you can put various powder or filling materials you want to fill into the capsules.

It is made of stainless steel that will be easy for your maintenance.

And normally,the powder hopper locates at the same height with the capsule holder or some different design may higher than the capsule hopper and inside there is the powder sensor that regulates the amount of powder to be filled.

Powders inside the hopper are driving by the compact feeding mechanism to move forward to the filling station.

In fact,the powder hopper not only holds the materials but also will make homogeneous mixture of all the powders to be filled to make it move into the next filling station.

2.Capsule Hopper

Capsule hopper as its name is a place where all the to be filled empty capsules are stored.

It not only holds all the empty capsules,but also controls the quantity supply of the empty capsules with the help of the sensors.

The capsule hopper is made by stainless steel that you will find there are 3 kinds shape of capsule hopper in the market now ,they are cubic shapes of capsule hopper,cylindrical shapes of capsule hopper and conical shapes of capsule hopper.

3.Capsule Feeding Unit

Capsule feeding unit stands on the top of the automatic capsule filling machine that its main function is to control the number of empty capsules running into the filling parts.

You can adjust the capsule feeding unit as per your actual production requirements.

Besides,capsules that have defects are not allowed to go through this area to the next feeding unit,it will be blocked here,so you will no worry about the empty capsule defects go into the filling parts.

4.Capsule Separation Station

The capsule separation station is as its name to separate the caps and body of the to be filled empty capsules.

Actually,apart from that it also connect the powder feeding with the powder hopper and the capsule loading with the capsule hopper.

5.Closed Dosage Device

The closed dosage device is a place where the precise amount of powder dosage goes into the filling hopper to be filled into the empty capsules.

But also here there is the powder sensor that controls the flowing of the powder,drive the powder to be filled or cut down the excessive amount of powder.

And during the capsule filling process,you will find powders on the closed dosage device will be derived to move into the filling hopper by the compressed air jet.

6.Closed Rotary Turret

This is the main part of the automatic capsule filling machine as it controls the whole capsule filling process.

The closed rotary turret is a closed design that will get rid of dust,you will no need to worry that dust or particles in the air sticks to the powder due to long time operation.And frequent clean or assembling of the mold may also increase the cost for you.

Of course,the closed rotary turret also compliant with the GMP requirements.

7.Mechanical Drive System

The mechanical drive system is the critical part of the automatic capsule filling machine as it starts all the process and determines all the motions that include the main drive,motor ,hopper drive and the vacuum drive of the machine.

It consists of the motor,gear and conveyor which unites to movitates the machine.And also completely closed to get free from dust and avoid other issues led by frequent cleanings.

In fact,there is the PLC control system who displays the technological elements of the automatic capsule filling machine that regulate the mechanical drive system.

8.Lubrication System

The lubrication system of the automatic capsule filling machine is to lubricate the moving parts and the mechanical parts for long-time running then reduce the worn-out.

At the same time,guarantees the smooth filling process.

You will no need to use lubrication oil to lubricate the conveyor and the moving parts to decrease the friction between each components,the lubrication system will work automatically to lubricate the filling and powder dosage discs to ensure sufficient ejection.

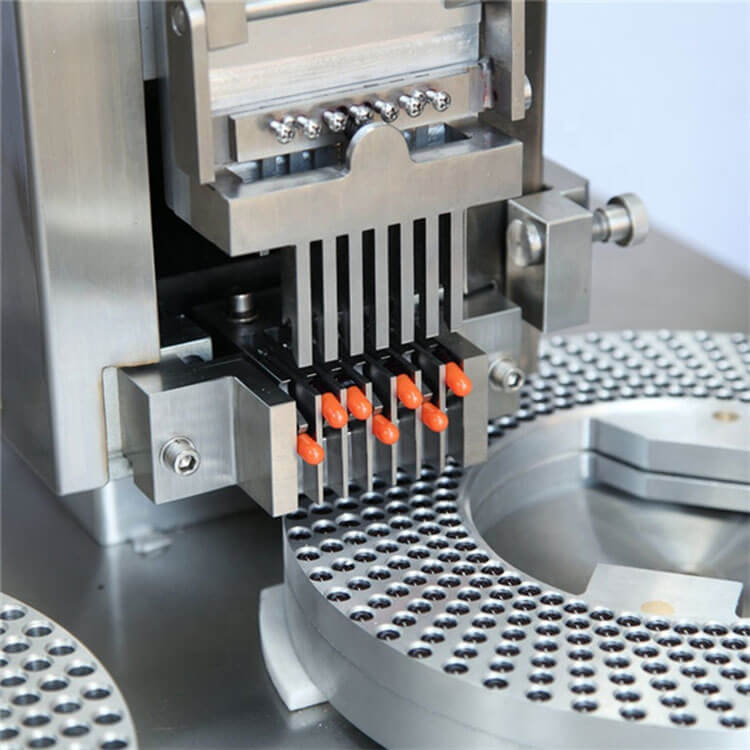

19.How Does Automatic Capsule Filler Machine Work?

Working principle of automatic capsule filler can be divided into :

.Capsule rectification

You know that most empty capsules are joined capsules whose caps and bodies are joined together,that is,they need to be rectified before the filling process.

Capsules are randomly poured into the capsule feeding unit then go through the capsule hopper.

You will find at the lower part of the capsule hopper there is the spring pieces,when the automatic capsule filling machine starting to work,the capsule delivery plate will reciprocate up and down to make the capsule either enter the holes or stuck by the spring piece.

After that the capsule delivery plate will move downwards to make the spring piece release the capsules,and the capsules will fall.

In fact,at this step,the capsules need further rectification as it may be body end downward or cap end downwards when falling.

Then when the capsules are allowed to fall on a horizontal fork that locates on the center of the capsule,a vertical fork will adjust the direction of these capsules.

Now the capsule rectification is completed.

.Separating capsule caps and bodies

When the capsules are rectified,the capsule tray will move to the capsule filling station,here the vacuum divider will raise to make its upper surface near to the lower surface of the lower segment .

Then the capsules are separated by the vacuum because of the different diameter of the capsule caps and bodies.

After that,the capsule caps will be stuck to the upper part of the capsule tray and the capsule bodies will go downwards.

That is when the separation is done ,the caps and bodies will be transferred to their respective stations.

.Medications Filling

Here you will find the capsule body will be conveyed to the filling station for filling medication.

Automatic capsule filling machines use vacuum filling to fill the active ingredients into the capsule.

Vacuum filling is applicable to all kinds of medication,as there is no mechanical moving and it has little damage to the medication.

.Waste Capsule Rejection

During the capsule filling process,you may find some of the capsule bodies may not be separated ,they are wasted products.

In fact,there are pins inside the automatic capsule filling machine that will pull such capsules out of the mold and blow them into a collection station.

While the filled capsule bodies and caps are transferred to the next station for locking.

.Capsule Locking

The upper and lower capsule tray will rotate together to the locking station at the same time,and simultaneously,the axis line of the upper and lower capsule tray will overlap.

Then the baffle plate above the capsule tray and the pin below the tray start to move to make the capsule be locked.

.Capsule Ejection

Once the filled capsule is locked in place,an ejection device,that is very similar to the capsule rejection device,will eject the locked capsules out of the capsule tray and send them to the outlet.

.Clean

When all the capsules are ejected ,the capsule tray will move back to the first station,the capsule rectification station.

Then tray will automatically cleaned for any powder remains by the compressed air and waste capsule debris are collected at the dust collecting system.

The above is the whole automatic capsule filler machine working process,though it seems cumbersome,each step may take very short time.

In fact,with reasonable design of circular structure,automatic capsule filling machine can make these steps proceed simultaneously.

That is automatic capsule filling machine can fill up to 12k-450k capsules per hour,which will be your best choice if you need large scale capsule production.

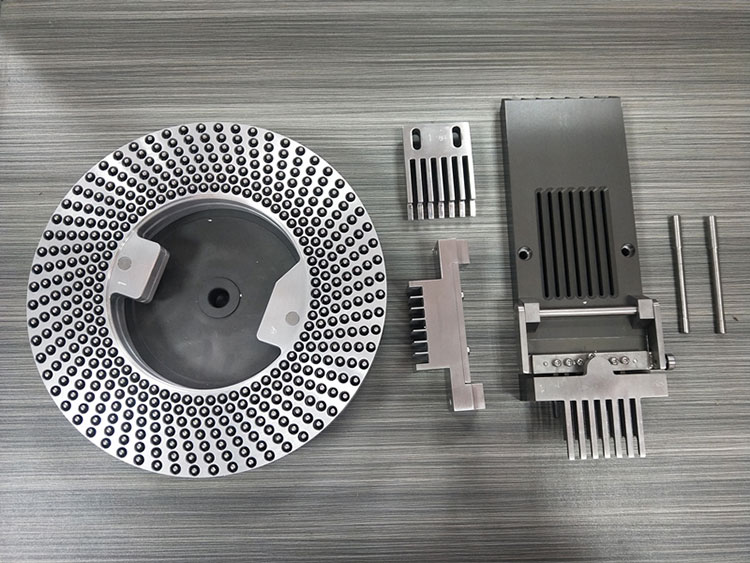

20.What are the Main Parts of Semi-automatic Capsule Filler Machine?

Main parts of semi-automatic capsule filler machine include:

1.Powder Hopper

Same with the full automatic capsule filling machine,semi-automatic capsule filling also has powder hopper to hold the powder you want to fill into the empty capsules.

It is also made by stainless steel that makes it has good appearance.

Besides,different model of semi-automatic capsule filling machine may have different size of powder hopper depends on the productivity of the machine.

2.Machine Body

Machine body is the most important part of the semi-automatic capsule filling machine.

It holds all the other parts of the machine on and is very strong and can bear the heavy forces during the filling process of the semi-automatic capsule filler machine.

3.Touchscreen Panel

Touchscreen panel

You can key the parameter according to your production requirement through the touchscreen panel which is also called PLC /HMI interface.

4.Powder Filling Auger System

Powder Filling Auger System

The powder filling auger system is the place that the powders or granules filled into the empty capsules.

Here it also controls the capsule filling capability of the machine.

5.Loading System

Loading System

Loading system of the semi-automatic capsule filling machine is the part that load the empty capsules.

Here it makes all the capsules are placed well to be filled.

6.Mechanical System

Here in the mechanical system,compressed air is applied as the mechanical system to push the powder or granules filled to the empty capsules.

7.Electrical Unit

Electrical Box

This is the power supply to the machine to give the electricity force to the capsule filling process.

8.Capsule Filling Table

The powder hopper,the touchscreen ,the filling auger system,the loading system ,that all the dosing are on the capsule filling table.

9.Capsules Body Tray

This part is mainly to make the separation of the capsule caps and bodies more easier.

10.Capsule Rectifier

It is the part to separate the capsule caps and body for the later filling process.

11.Capsule Opening and Closing System

Locking System

It is a section that forms the peg ring and joiner chute.

21.How Does Semi-automatic Capsule Filler Machine Work?

Semi-automatic capsule filler machine is a combination of both automatic and manual capsule filler machine,you will find its working process can be described as below:

Loading of Capsules:

When the machine is in good condition,it will start to load the empty capsules and the filling medication into their respective hoppers.

Then your operator will have to press the start button to make the machine start to work and key the operation parameters at the touchscreen panel to guide the operation of the semi-automatic capsule filler machine.

Capsule Separating

All the empty capsules in the capsule hopper will go through the delivery system of the machine to the round capsule tray.

Then the upper capsule tray will hold the caps while the bottom tray hold the lower body .

Your operator will need to manually remove the upper tray while the bottom tray will keep hold the lower body of the empty capsule.

Then the body will stay intact and moves around the conveyor belt waiting to be filled.

Filling Capsules

Then the semi-automatic capsule filler machine will start to fill the medication into the empty capsule body.

You will find the filling table will place the filling nozzles above the empty capsules and the tray will keep in continuous motion when the filling medication goes into the empty capsule body.

And through the dosing disk,the filling quantity and speed can be controlled accurately.

Finally,when all the capsules are filled with medication,the filling nozzle will be retrieved automatically .

Caps And Bodies Locking

Your operator will need to place the caps tray directly above the body tray to push the caps locked with the capsule bodies.

Here your operator may need to apply a little pressure at the compression zone so that the capsule caps can fit onto the body perfectly.

Then,all the semi-automatic capsule filler machine capsule filling processed completed,you can take the filled capsules out from the machine for further inspection or packaging.

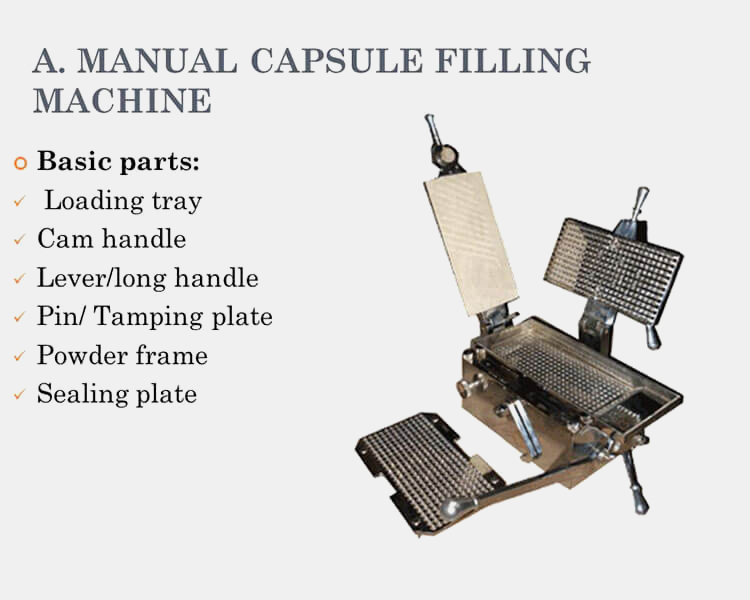

22.What are the Main Parts of Manual Capsule Filler Machine?

Basic parts of the manual capsule filler machine are :

.Loading tray

.Cam handle

.Lever/long handle

.Pin/tamping plate

.Powder frame

.Sealing plate

In fact,the main parts may vary for different model,you may have to review your technical manual instruction or user specification to get more familiar with the main parts of the machine ,so as to know more about its function.

23.How are Capsules Filled by Manual Capsule Filler Machine?

The main difference that capsules filled by manual capsule filler machine from automatic capsule filling machine is that the capsule caps and bodies are separated manually first and then inserted into the loading tray .

Capsules filled by manual capsule filling machine

Then you can fill the medication into the capsule bodies and make them seal off,and forwardly pull the the locking level.

At this stage,the capsule bodies are at the same level with the filling surface.

You will have to measure the powder first to make it up to your desired filling weight.

Of course,the machine can help compress the powder if you need to make the powder more compact.

Then once the capsules are filled with the filling medications,it will move to the next stage to be locked.

The part handling the bodies will be pushed back into caps all at one time thus make the capsule locked.

Then you finished the capsule filling manually and the capsules are arranged over the tray to exit the manual capsule filler to be packed.

24.Which Equipment Are Needed in Aiding in the Entire Capsule Making More Efficiently?

A complete capsule filling line is not alone,along with the capsule filler,combined with other equipment that as well play an important role in aiding in the entire capsule making more efficiently.

Capsule Polishing Machine

AIPAK capsule polishing machine

An automatic capsule polishing machine helps in making the outside surface of the capsule more shiny and appealing so that the capsules can be in a more attracting and enjoyable form.

Capsule Ejector

A capsule ejector will assist in removing the capsules from the batch that are not filled with contents.

In that way,the faulty capsules will be detected and will not go the next step to be packaged or shipped.

Capsule Sorter

This machine will help in guaranteeing the quality of the capsule,it will sort out the defective capsules and only allow the good shaped and sizes of capsules enter into the capsule hopper this easy for the later steps.

Capsule Packaging Machine

AIPAK Blister packaging machine

Capsule packaging machine commonly used is also called blister packaging machine that assists in packaging the capsule under blisters for easy and dosage taking.

Besides,capsules packed by the blister packaging machine are more hygienic and convenient for taking.

Cartoning Machine

AIPAK cartoning machine

After packing by the blister packaging machine,you may need to put that blister of capsules into box,then there need the cartoning machine.

A cartoning machine will fully automatically put the capsules in blister into pre-prepared boxes and the instruction manual into the boxes.

25.What Quality Standards Should the Capsule Filler Comply With?

To regulate all behaviors, there must be some quality standards or certification documents that capsule filler must meet with.

GMP

GMP or cGMP are two one of the most important standards that all pharmaceutical manufacturers must comply with.

They both regulate and guarantee the safety and reliability of the capsule filling process.

That is,they are documents in detail that remark all possible happening behaviors and its respective measurements.

And prevents and possible contamination.

ISO

ISO stands for International Organization for Standardization, which is an international standard for capsule filling machine.

Comply with which means not only ensures the machine safety and quality but alos encouraging innovation in the global market.

CE

CE represents the capsule filler manufacturer or service provider's assurance that the capsule filler complies with the corresponding European Union directive and has completed the corresponding assessment procedure.

FDA

FDA stands for the U.S.Food And Drug Administration that means the sales of capsule filler belong to a kind of medical device must comply with the U.S. drug administration.

26.What Should You Consider When Choosing Capsule Filler?

There are factors you should consider when choosing capsule filler to meet your actual production requirements.

1.Identify the right technology

That is ,you should not only focus on price or make that your initial consideration when purchasing capsule filler machine .

In fact,firstly,you should consider what on earth is the best technology for your actual production.

As in capsule filling,there are lots of technologies on the market now,and each may have various unique advantages,the reason these unique technologies exist may due to these advantages.

So you have to consider the characteristics of the medication you are going to fill,them compare them with the equipment capabilities.

Then before making your final purchasing determination,negotiate with your machine suppliers to do some factory tests,see which equipment run most naturally with your medications.

2.Identify the right vendor

The most often overlooked you need to consider is the equipment reliability and after sales support.

For example,when your some parts of your new capsule filling machine crashes for the first time,where can you find the replacement?Or if the OEM parts can be found elsewhere near your area.

Does the vendor have site support or other kinds of support if you have problems that is difficult for your technician to troubleshoot.

Does the vendor have an English guide for you to solve the problem more fluently?

If your problems can’t be solved immediately,how long will it take ?

In fact,a good vendor should offer wonderous supports through training,after sales service and maintenance assistance.

A good vendor should be its industry support can be easy accessible and common through the industry.

3.Identify the right size of equipment

Optimizing equipment uptime in manufacturing nowadays can be said to be one of the greatest challenges faced by most production leaders.

While you may spend large efforts to optimize your uptime if the machine size is not correct at first time.

The size of the equipment determines the production capacity,projected uptime or the changeover time,or you may have to project the appropriate space to hold the machine .

4.Designed Downtime

Some companies may not consider the downtime for maintenance that lead to production stagnation because of breakdown.

In fact,neglecting the downtime may result in more cost than a machine which is regularly maintained.

27.How to Troubleshoot Common Problems of Automatic Capsule Filler Machines?

Capsules are easy to fill,but sometimes,things may still go wrong.

Below you will find some tips on how to troubleshoot these problems:

First,before filling a capsule hopper with empty capsules,you have to check if the capsules meet your dimensional specifications through checking one representative sample first.Since capsules offered by different manufacturers may vary .

Secondly,make some adjustments first to your tooling as the tooling may also differ by different vendors.verify your setting and check that if the routine maintenance has been done before the capsule filler start to run.

Thirdly,get some knowledge that you understand or familiar with the medication or active ingredient to see if they affect the filling.

Fourthly,you have to check if the environmental condition in the capsule filler room is suitable for filling.The ideal temperature is 22°C ± 2° and the relative humidity is at 40 to 50 percent.

If the temperature or humidity are beyond that range,you await for some time for the room or filling medication to self acclimate before starting your production.

Next,you may follow below steps troubleshooting common problems that may happen during the capsule filling process:

Lumpy or misshapen capsules

Before loading the empty capsules on the capsule hopper,if you find the capsules are lumps or misshapen,you may check the condition your capsules are transported or stored.Then next time please remain the empty capsules at a temperature between 15° and 30°C and relative humidity between 40 and 65 percent.

And you also need to not expose the empty capsules directly to light or heat.And not move the capsules from a high-temperature to a low one suddenly.

Improper rectification

If your capsules are not oriented properly with cap up and body down,first,you have to verify the stroke of the pushers or fingers are set properly according to the joint length of the shells.

Pay attention you should not use a plastic container to transport the capsules as plastic can cause an electrostatic charge to develop, hindering rectification.Use stainless steel containers and scoops instead.

Failure to separate

You may check the vacuum if the caps and bodies fail to separate.

Then you may adjust the gap between the machine’s cap segments and body segments.

Then you may also check the timing of the solenoid valve and if the segments’ hole align with the raceway fingers.

Another way is checking the filter bag and cleaning it regularly.

Dented capsules

Dents of capsules may be found on the cap,body as many reasons.

One reason may be improper setup that results in the machine applying too much pressure.

So,to see if the setting is correct,you can do some tests by manually lock 20 capsules together to measure the capsule length.

Then you may check out the correct parameter and adjust the machine to that parameters through the tie rod.

In fact,another reason for the dented capsules is overfilling.

So ,to correct this,you have to weigh 20 filled capsules,whose average weight should not exceed the specific volume of the capsules you are using.If over that ,you may consider use large capsules.

Telescoping

This kind of problem happens when the cap and body misalign and the capsule split and part of the capsule covers its cap.

To solve this problem,you have to make sure all the capsules are round.

Or you can also use a gauge to check if the alignment of the cap and body bushing and segment.

Besides,the environment condition may also have effect on this problem.Then you may have to stop the machine at least half an hour but protect the capsule shells from direct exposure to the environment.

Popping

If you find your capsules open or elongate after filling,it may be excessive locking pressure or overfilling.

It may be the locking mechanism is too weak.

Brittleness

This problem,you have to check your storage conditions.Since when the capsule gets rid of moisture,due to poor storage conditions,they will become brittle.

Apart from that,the filled capsules that have hygroscopic active or excipient may also lead to brittleness.

However,capsules that made from HPMC will not likely become brittle easily.

28.How to Maintain Automatic Capsule Filler Machine?

Steps for you to maintain the automatic capsule filler machine are as follows:

(1)When the capsule filler works for a long time,some parts that contact directly with the drug should be cleaned regularly.

(2)You will have to add appropriate amount of lubricating oil to the transmission mechanism under the working table of the capsule filler to reduce the worn out of the moving parts.

(3)Add lubricating oil in the main drive drop box when the capsule filler runs for 250-300 hours and check the powder feeding mechanism and replenish lubricating oil.

(4)The vacuum separator of the vacuum system is to inhale the capsule into the upper and lower modules and separate the cap and body in the capsule filling.

So if the capsule cap and body can’t be separated,the later filling may be not possible.

When you find the capsule cap and body separation is not smooth,you should check the gap between the upper plane of the vacuum separator and lower plane od the lower module.

Then you may need to adjust the position of the vacuum separator, turn the main motor shaft by the handle, make the vacuum separator to rise to the highest position, loosen the adjustment of the machine mesa falls at the ends of the rod lock nut (a left-handed nut, a right-handed nut), and then turn adjusting screw to adjust the height of the vacuum separator, then lock nut and turn the main motor shaft test by the handle until it is right.

For the vacuum system, you may have to change the circulating water in the circulating bucket once a week to ensure the cleaning of vacuum pump.

Last,you have to regularly turn on the filter to remove clogged dirt.

(5)You have to check the tightness of the transmission chain once a week,adjust and remove the grease.

(6)Regularly check if the axial fan is well-ventilated.

Make sure the inverter heat dissipation is good.

If the main engine is stopped due to abnormal conditions in the working process of the frequency converter, the reason for the abnormal conditions should be found according to the display code on the frequency converter, troubleshooting, cutting off the power supply of the frequency converter. After triggering the display to go out, switch on the power supply again and restart the machine.

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine