How To Achieve Rapid And Reliable Mixing Of Ingredients In Vacuum Emulsifying Mixer?

The vacuum emulsifying mixer is a multi-functional integrated emulsification system. The efficiency of the vacuum emulsifying mixer is relatively high when dealing with materials with complex processes, especially when dealing with materials with high batch yields.

Vacuum emulsifying mixer system is generally used in the process of uniform dispersion, homogenization, emulsification, stirring, shear particle size, defoaming and other processes of multiphase materials in cosmetic, daily chemical, food, pharmaceutical and chemical industries.

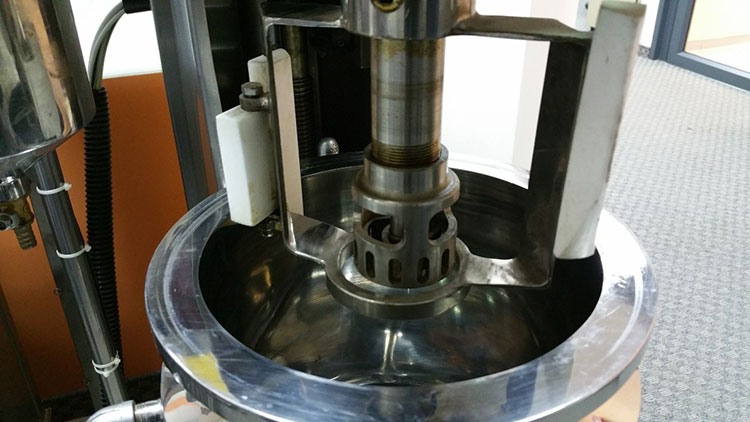

The general working principle of the vacuum emulsifying mixer machinery is to perform high-speed shearing, dispersion, homogenization, emulsification and mixing for the liquid materials that need to be mixed and stirred through the mechanical kinetic energy provided by the stator and rotor homogenizer and the agitator.

In the cosmetic, food, pharmaceutical, and chemical industries, the quality of the product mainly depends on the production effect of the emulsification equipment, so what are the parts of the vacuum emulsifying mixer, what are the characteristics of the machine, and how does it achieve fast and reliable mixing of ingredients, which is worth learning and understanding.

Components of a typical vacuum emulsifying mixer

First, pretreatment water and oil pan: This is the part of the emulsifier for material pretreatment, which contains a water pot and an oil pot that can be heated, dissolved, dispersed and stirred.

Emulsifying pot: The emulsifying pot consists of a lid that can be lifted and lowered, an emulsifying pot body that can be turned over, and a homogenizing stirring system. The lid is provided with multiple feed ports, small feed ports, observation windows, vacuum ports, vacuum pressure gauges and other devices.

Third, vacuum device: The vacuum device can choose different types of vacuum pumps according to different specifications and materials, such as rotary vane type or water ring type.

Fourth, heating, cooling and temperature control system: The vacuum emulsifying mixer adopts electric heating or steam heating. Generally, there are many customers who use the electric heating method, which can greatly reduce the heating cost. The cooling of the vacuum emulsifying mixer generally uses tap water as the cooling water source (the user can use chilled water for a better cooling effect).

Fifth, Electrical control system: The control system of the emulsifier can realize the speed control of the oil phase, water phase, main stirring and homogenizing stirring motors; realize the intelligent control of the temperature of the oil phase pot, the water phase pot and the emulsification pot; realize the emulsification vacuum pressure control and hydraulic lift control.

The advantages of vacuum emulsifying mixer

First, the operation is simple, the startup of the equipment, the adjustment and setting of functions such as temperature, speed, and the lifting and lowering of the lid can all be operated on the control panel.

Second, small footprint can better plan and layout the workshop.

Third, the transfer of materials can be carried out through pipelines, and material loss and environmental pollution are kept to a minimum.

Fourth, maintenance work is simple.

Fifth, high level of safety production. The device operates in a closed system at high speed, and operators do not come into contact with the mechanical transmission system, so industrial accidents can be minimized.

How to achieve rapid and reliable mixing of ingredients in vacuum emulsifying mixer?

First, automatic closed system to provide guarantee for hygienic and clean production of products.

Because the machine is completely sealed, there is no risk of contaminants entering the system, thus ensuring the safety and hygiene of the product. In fact, the entire mixer is designed for hygienic performance and can be configured to meet EHEDG and 3A regulations.

And the shelf life of the final product is also extended due to degassing, as the sealed environment is not suitable for the growth of microorganisms.

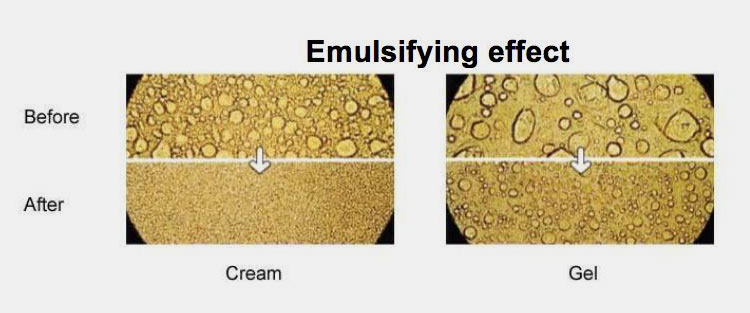

Second, high shear homogenizer for efficient, fast and repeatable emulsification mixing

The vacuum emulsifying mixer is the heart of the high shear mixer unit. The shear and energy dissipation rates of this machine are significantly higher than those of conventional mixing vessels.

Therefore, the mixer is suitable for solid-liquid dispersion, dissolution and emulsification, as well as liquid-liquid homogenization and emulsification. The mixing process is so intense that it can even dissolve some of the more difficult-to-dissolve ingredients like pectin in seconds.

Third, Frequency conversion speed regulation; vacuum water saving economical and environmental protection.

The speed of the high shear homogenizer and the speed of the stirring paddle of the vacuum emulsifying mixer are all adjusted by frequency conversion. According to the process requirements, the motor can be adjusted to the necessary speed through the frequency converter to achieve the effect of energy saving and environmental protection.

Fourth, vacuum suction to achieve no pollution feeding of liquid and powder materials

Vacuum suction is a very practical function of vacuum emulsifying machine, and uniform speed can be achieved by vacuuming. If the vacuum is lost for any reason, it shuts off immediately and is equipped with a vacuum buffer tank. This eliminates the risk of backflow and prevents blockages, enabling the machine to stop production in time.

Fifth, automatic level control to achieve smooth, uninterrupted production

The vacuum emulsifying mixer can be equipped with a liquid level control system and weighing system. Level control is used in conjunction with product inlet/outlet to maintain the proper amount of fluid circulating in the system.

If the liquid level is too high or too low, the load cell and frequency controlled outlet pump will return it to the desired liquid level. The amount of powder in the mixture also fluctuates during production (e.g sugar, lactose, stabilizers).

No matter how much powder enters the mixer, the emulsification stirring system of the vacuum emulsifying mixer can maintain stable production.

In the future production and life, with the improvement of people's living standards, the vacuum emulsifying mixer market also has considerable development prospects.

In the process of continuously obtaining business opportunities, enterprises also need to constantly accept the challenges given by the market, and continue to innovate and upgrade to meet the needs of the market and consumers, so as to help the entire vacuum emulsifying mixer industry. Towards a better future.

Don't forget to share this post!

Vacuum Emulsifying Mixer Related Posts

Vacuum Emulsifying Mixer Related Products

Vacuum Emulsifying Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine