How Pharmaceutical Packaging Upgrade To Be Green Or Any Requirement?

With the development of the pharmaceutical industry, the pharmaceutical flexible packaging industry has been significantly developed, showing a strong momentum of development.

At present, the greening of plastic flexible packaging film has also become one of the important development trends, flexible packaging enterprises should follow the changes in market demand, timely adjustment of product structure, to achieve the greening of products, while paying more attention to energy saving, consumption reduction, emission reduction, safety and other new business concepts to promote more flexible packaging enterprises to upgrade.

Flexible packaging

Currently, the market of flexible packaging are mainly paper, aluminum foil, fiber, plastic film and a variety of bags, boxes, sets, wrapping, etc. made of its compound., flexible packaging with brilliant colours, rich functionality, a variety of forms of expression, become one of the main packaging forms of shelf sales .

However ,the progress in the flexible packaging industry continues, which has greatly contributed to the development of pharmaceutical, food, daily chemical and other industries.

And the development of pharmaceutical and other industries in turn further boosted the demand for flexible packaging market, so that the flexible packaging industry has gained a huge market momentum.

Industry experts point out that flexible packaging, like other packaging, to consider the three elements of packaging, namely safety, convenience and aesthetics (display promotion).

After years of development, China's flexible packaging industry has made great progress, especially in the aesthetic aspects of flexible packaging is to reach level.

However, there are still certain problems with the safety of flexible packaging.

Experts say that every medicine needs a novel packaging when it is listed, and many companies tend to choose flexible packaging.

At this time,you should understand the three elements of pharmaceutical flexible packaging, the product will be better upgraded to meet the market demand, so as to attract the attention of drug agents and bring more business opportunities for you.

It is understood that, with the continuous improvement of China's plastic flexible packaging industry supply capacity, will provide more opportunities for product export growth.

Among them, green packaging has become a trend in the development of the packaging industry today.

Although green packaging is not yet a fully unified definition, but generally speaking, can be recycled, reuse or degradation of decay, and in the entire life cycle of the product does not cause harm to the human body and the environment of moderate packaging, known as green packaging.

Its important meaning is to protect the environment, but also has the significance of resource recycling. Green packaging in its entire life cycle process, follow the circular economy, "reduce, reuse, resource" the principles of economic activities, so that the impact of packaging on the environment to a lower limit.

In general, flexible packaging industry is in a good time for development, in recent years in the plastic waste resource and the has been made reuse of progress , flexible packaging industry has gradually solved the problem of secondary pollution, is expected to be more promising future development prospects.

Plastic flexible packaging to make great progress, it is necessary to upgrade the process, focus on energy saving, consumption reduction, emission reduction, keep up with market demand, so as to promote the continuous progress of China's flexible packaging industry, medicine, food and other industries to bring greater surprise.

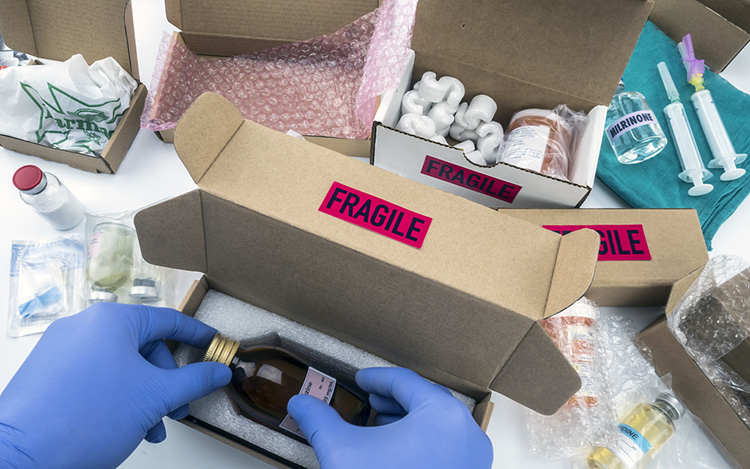

So pharmaceutical packaging or drug packaging is the packages and the packaging process for pharmaceutical preparations,it involves all the operations from production through drug distribution channels to the end consumer.Then what should be meet with ,does the pharmaceutical packaging have any requirement?

Below you will get the three basic requirements pharmaceutical packaging should meet :

It should be adapted to the needs of different circulation conditions

Drugs in circulation can be affected by transport and handling conditions, storage time, climate change and other circumstances, so the packaging of drugs should be adapted to these conditions. Such as fear of freezing drugs sent to cold areas, to add cold packaging; drug packaging measures should be considered according to the relative humidity of the largest areas, etc..

Similarly, when packaging medicines for exporting, the specific conditions of the exporting country should be fully considered to reduce the possibility of affecting the quality of medicines due to packaging to a minimum.

It should be adapted to the contents

Packaging should be combined with the physical and chemical properties and dosage form characteristics of the drugs contained, respectively, to take different measures. If the light is easy to deteriorate, exposed to the air easy to oxidation of drugs, should be used to shade the container; bottle of liquid drugs should be taken to prevent shock, anti-pressure measures.

To meet the standardisation requirements

Standardized requirements of the packaging is conducive to ensuring the quality of drugs; facilitate drug transportation, handling and storage; easy to identify and measure, conducive to the mechanization of modern ports loading and unloading; conducive to packaging, transportation, storage costs reduced.

In addition, there are some specific requirements for drug packaging, such as drug packaging (including transport packaging) must be sealed, seals, seals or or the use of anti-theft cover, cap sets, etc.; labels must be firmly posted, post right, not with the drug into the bottle; where the seals, labels, packaging containers, etc. have broken, not factory and sales.

Specially managed drugs, over-the-counter drugs and drugs for external use must have the required symbols printed on their labels.

According to data, as early as 2003, the global drug packaging market reached US $11.2 billion, with an average annual growth of nearly 5%. In 2006, it was estimated that it had exceeded US $13 billion. The United States, Japan, Britain, Germany, France and Italy occupy the largest market share in the world pharmaceutical packaging industry.

While the increasing demand of global drug packaging requirement ,the requirement for pharmaceutical packaging equipment has also increased.Aipak Pharma,one of the largest online pharmaceutical packaging equipment supplier could offer various pharmaceutical packaging equipment like the blister packaging machine ,cartoning machine,strip packaing machine,effervescent tube packing machine,etc,which assist you with your various pharmaceutical packaging requirements.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine