How Much Do You Know About Mesh-Belt Dryer Machine?

Mesh-belt dryer machine is a continuous drying equipment used in mass production.

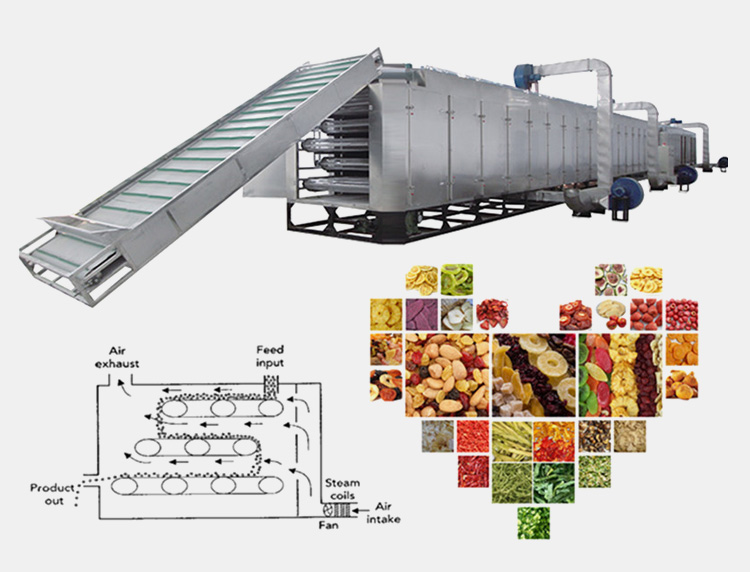

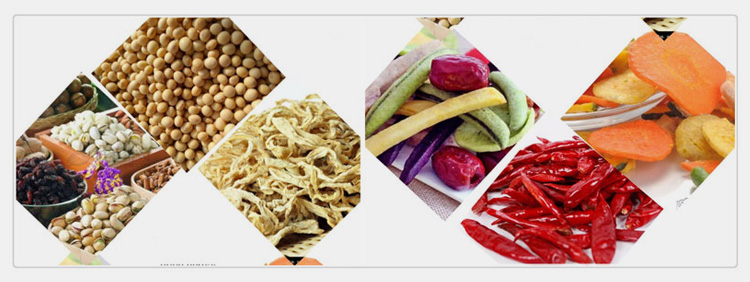

It is used for the drying of sheet, strip, granule and some paste materials with good air permeability. It is especially suitable for dehydrated vegetables, Chinese herbal decoction pieces and other materials with high moisture content and heat sensitivity.

It has the advantages of high drying rate, high evaporation intensity and good product quality.

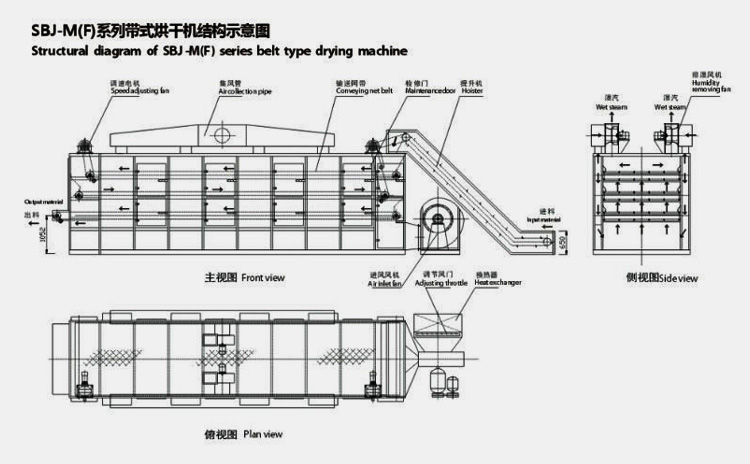

The mesh-belt dryer is composed of several independent unit segments. The operating meters of drying medium quantity, temperature, humidity and tail gas circulation volume can be controlled independently, so as to ensure the reliability of operation and the optimization of operating conditions.

The dryer machine with flexible operation, wet material feeding, drying process in a completely sealed box, working conditions are better, avoid dust leakage.

The Working Principle of the mesh-belt dryer machine

The material is evenly spread on the mesh belt by the feeder, and the mesh belt is made of 12-60 mesh stainless steel mesh. It is driven by the transmission device to move in the dryer machine.

The dryer machine is composed of a number of units, each unit hot air circulates independently, part of the tail gas is discharged by the special humidifier, the exhaust gas is controlled by the regulating valve, the hot gas passes through the material spread on the mesh belt from bottom to top or from top to bottom, heating and drying and takes away the moisture.

The mesh-belt moves slowly, the running speed can be adjusted freely according to the temperature of the material, and the finished product after continuously drying falls into the receiver. The up and down circulation unit can be flexibly equipped according to the needs of users, and the number of units can be selected according to the needs.

Four basic parameters in the drying process

Some basics of the drying process itself may help you. The drying process has four basic parameters that help produce dry, warm particles. The first and most important is temperature.

Temperature controls the rate at which the resin particles reach equilibrium with the surrounding air. It is generally accepted that the higher the temperature, the faster the polymer dries. Of course, there will be limitations, as some materials may over-dry, damage the resin or cause premature melting.

The second is the dew point, a measure of humidity in dry air, which tells you how much water the dryer absorbs from the air and determines how easily the polymer and surrounding water vapor evaporates into the surrounding air.

The third parameter is the drying time, sometimes called dwell time, which is the time the polymer is exposed to dry air at a specified temperature and dew point.

Because plastic particles do not conduct heat well, there must be enough time for each particle to reach temperature; Once properly heated, moisture is released onto the particle surface and warm, dry air moves it out of the hopper.

The fourth parameter is air flow. Although most molders are generally familiar with temperature, dew point, and drying time, the function of air flow is often misunderstood.

Briefly, airflow is the speed at which a certain volume of air passes through the hopper, bringing hot air from the dryer into the hopper and absorbing moisture from the hopper. This number is expressed in cubic feet per minute and is known as "CFM". Airflow is usually calculated relative to the resin flow rate in pounds per hour, but airflow is not dependent on the resin flow rate.

Methods of accurately replacing mesh-belt in dryer machine

Generally, the mesh-belt is a frequent problem accessory in the dryer machine, and if you notice that the belt is cracked or missing grooves before work, the belt will need to be replaced.

So how is the mesh-belt broken and how to accurately replace it after it is broken? By understanding the following points, you can correctly replace the belt in the mesh-belt dryer.

Belt friction does not occur when the belt dryer is held stationary, and breakage and lack of grooves do not occur. However, the main cause of drum blockage is overload.

First, we need to check the load of the machine; Secondly, we also need to check the weight of the material and make a suitable solution, so that the belt will not be burned because the pulley cannot slide on the fixed belt due to the high load weight.

Second, you need to check that the drum in the mesh-belt dryer machine whether it is twisted. If the drum is twisted, the belt is likely to jump off the drum when you turn on the dryer. At this situation you just need to change around the drum.

Another way to check is through the access panel on the back of the mesh-belt dryer dryer. Generally, there is a maintenance panel on the back of it. You can clearly see the motor and idler wheel through the maintenance panel. You can find problems in the machine at startup by looking at the service panel and replacing damaged parts.

Mesh-belt dryer machine is a popular equipment in recent years. All customers who have used it have a special preference for it because of its large processing capacity, large production capacity and low vacuum temperature throughout the process.

The features, colors and smells are well preserved, which greatly reduces the cost of enterprise users and ensures safety. In addition, the device is particularly sought after by some customers.

The emergence of mesh-belt dryer machine has largely solved the problems of the destruction of heat sensitive elements, material sticking to the wall, material easy to be polluted, high energy consumption, and unable to achieve continuous production.

The mesh-belt dryer machine can help customers solve the above problems to a certain extent. The use of this machine can effectively reduce the loss of heat-sensitive components, accelerate the drying speed, safety and health, low energy consumption, can help users to achieve continuous production operation.

In addition, the full automation of mesh-belt dryer machine, not only can effectively ensure the quality of products, and only need 1-2 people to operate, for the user to save labor costs, at the same time the production capacity of ordinary dryer is incomparable.

At the same time, from the perspective of application scope, belt dryer can be used in traditional Chinese medicine extract, biopharmaceutical, polysaccharide drugs, food and food additives, fine chemicals, lithium battery energy, etc., a wide range of application, considerable prospect.

Don't forget to share this post!

Drier Machine Related Posts

Drier Machine Related Products

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine