How Much Do you Know About Flow Wrap Machine?

In the past, most flow wrap machines in food and medicine packaging production equipment were backward products with low speed and high energy consumption.

With the expansion of market demand, packaging companies actively develop and upgrade flow wrap machines.

According to the survey of relevant data, the current production speed of flow wrap machine production line can be stabilized at 40-230 packets per minute, basically meeting the needs of various industries.

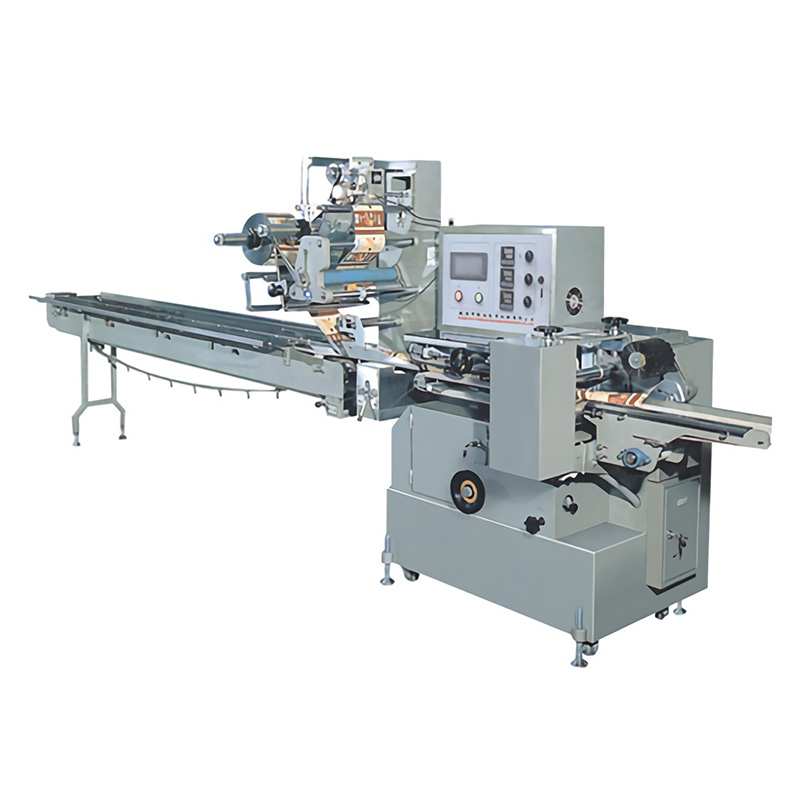

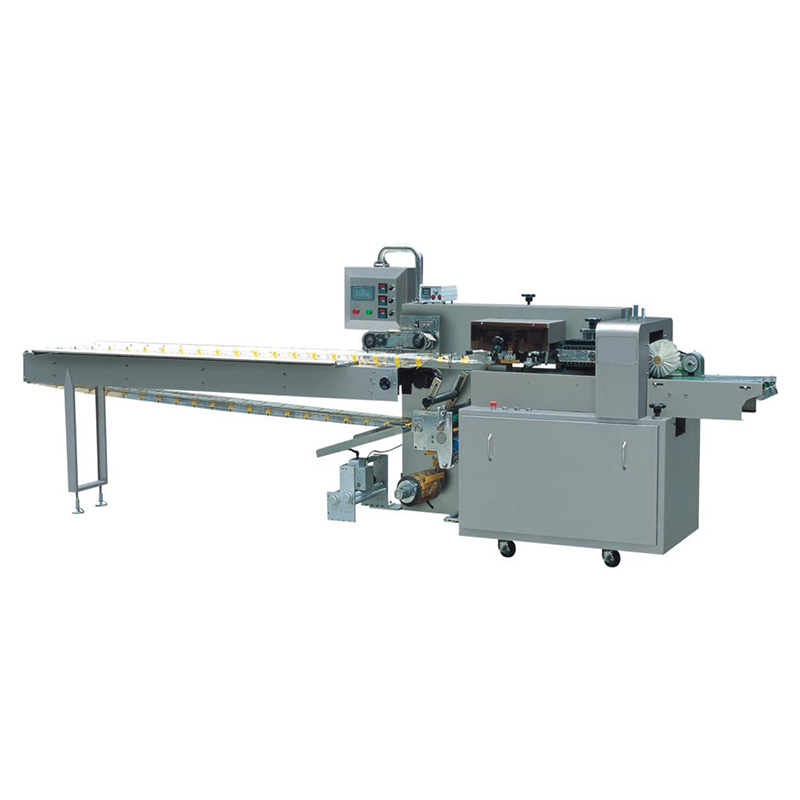

At present, the flow wrap machine is a kind of continuous packaging machine with very strong packaging capacity and can be used for food and non-food packaging in various specifications.

It can be used not only for packaging of non trademark packaging materials, but also for high-speed packaging with drum materials pre printed with trademark patterns.

So, do you know the characteristics of the flow wrap machine? If you want to study or buy a flow wrap machine, then understanding its characteristics is also something we must grasp.

First, the flow wrap machine adopts a dual frequency conversion controller.

The bag length setting and sealing can be carried out synchronously, and you do not need to adjust the empty bag, which greatly saves time and mold consumption.

Second, the flow wrap machine uses a human-machine interface, so when you set parameters, it will be more convenient and fast.

Third, the flow wrap machine itself has a fault self diagnosis function. Where the problem occurs, there will be a display, which greatly saves you a lot of time to check the machine’s problems.

Fourth, the flow wrap machine has a high sensitivity photoelectric eye color mark tracking system and digitally input sealing and cutting position, which can make the sealing and cutting position more accurate, without requiring you to calibrate manually.

Fifth, the flow wrap machine adopts independent PID control, which is better suitable for various packaging materials.

Sixthly, the flow wrap machine has positioning and shutdown functions, so when you operate it, you will not stick the knife and avoid waste of packaging materials.

Seventh, the transmission system of the flow wrap machine is simple and clear, which makes it easy to work, more reliable, and more convenient for you to maintain.

Eighth, all controls are implemented by software, which is convenient for you to adjust the flow wrap machine functions and upgrade the technology.

After knowing the flow wrap machine’s characteristics.

If you plan to buy a flow wrap machine, what do you think you should pay attention to when purchasing this machine?

Do you have any ideas of your own? If you do not have an idea, here are suggestions for you.

First, you need to determine which products will be packaged by the flow wrap machine you want to buy in the future.

Because some flow wrap machine manufacturers have many kinds of products, when purchasing flow wrap machines, try to consider a machine that can cover as many of your products as possible.

However, in most cases, the packaging effect of the special flow wrap machine is better than that of the compatible flow wrap machine.

You should remember that it is better not to pack more than 3-5 varieties with one packaging machine.

In addition, products with large difference in overall dimensions shall be packaged by machines as far as possible. Otherwise, the overall packaging efficiency is affected.

Second, when you buy a flow wrap machine, you must remember that high cost performance is the first principle for you to choose the machine.

At this stage, the quality of the flow wrap machine produced in China has been greatly improved compared with that in the past, and the proportion of exports has gradually exceeded the proportion of imports.

Sometimes, the price of flow wrap machines in China can completely purchase the quality of imported machines.

Only buy the right ones, not the expensive ones.

Third, you should understand that selecting a flow wrap machine is not only a simple choice of this machine, but also a qualified and reliable flow wrap machine supplier.

Therefore, you need to choose a flow wrap machine company with a long history as far as possible, so that the quality of the machines can be guaranteed.

The selection of models with mature technology and stable quality is conducive to faster and more stable packaging, and the whole packaging process is characterized by low energy consumption, low manual work and low scrap rate.

If you purchase a low-quality flow wrap machine, the waste of packaging film will become a serious problem in future daily production.

Fourth, if you have the time or energy to make a field, visit the flow warp machine manufacture.

You should bring the relevant samples to the machine for a test run, so that you can have a more intuitive sense of the strength of the manufacturer and the specific operation of the machine.

Fifth, you must pay attention to the after-sales service of a flow wrap machine company.

Because as long as the machine is in operation, some problems will inevitably occur, but if the after-sales service is timely and can quickly solve the problems.

It is essential for the normal operation of the machine, especially in the food packaging field.

Just think about the food that will sell well only at certain festivals, such as moon cake.

If the packaging machine has problems in production and cannot be solved immediately, the loss caused to the company is obviously incalculable.

Sixth, try to purchase flow wrap machines with simple operation and maintenance, complete accessories, and automatic continuous feeding mechanism, which can not only improve packaging efficiency and reduce labor costs, but also adapt to the long-term development of companies.

Through this article, I hope you can learn more about flow wrap machines. You should understand that it is not easy to choose a suitable flow wrap machine,

It is important to choose a flow wrap machine that is suitable for the company's production needs, but more importantly, you should actively learn and master more knowledge about the machine in this process.

Don't forget to share this post!

Flow Wrap Machine Related Posts

Flow Wrap Machine Related Products

Flow Wrap Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine