How Is Spray Drying Applied In The Pharmaceutical Industry?

Do you know that spray drying is one of the most prominent technologies used in the pharmaceutical industries? Or, how much do you know about spray drying?

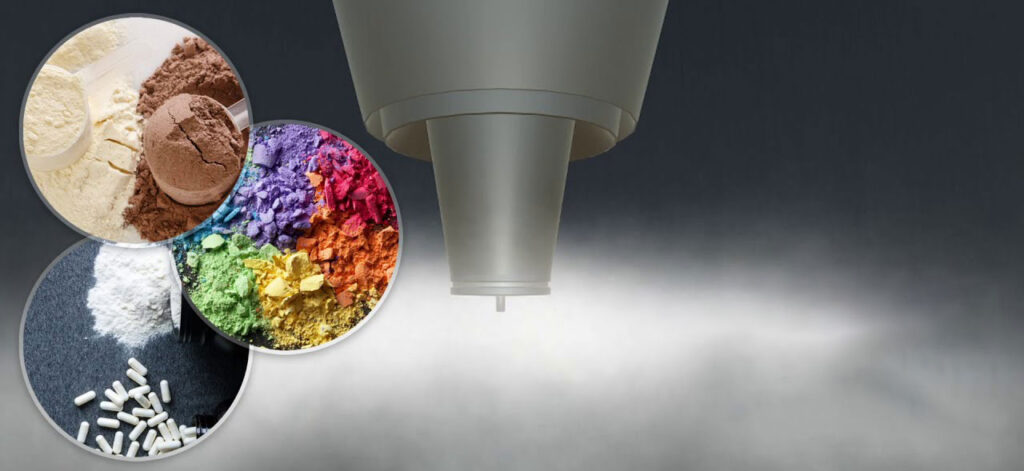

The first thing you should know is that it is a consecutive process. And it can transform the liquid feed into powder just in one step. What’s more, when you have some special requirements in the particle size, form, stability and accuracy, it is also an ideal process for production.

So, from this essay, it describes the spray drying technology, the present and future applications of spray drying and how to let the stage of process development become unhindered and risk-free.

Basic information of spray drying

Spray drying is one of the most widely used drying methods, which was firstly regarded and used in drying and modifying the concentrated liquid more than 140 years ago. But it was until the 20th century, its sophisticated process and some relevant knowledge were permitted to industrial application.

Like powdered milk we are familiar with in daily life, its production was the first commercial application during that period. At present, sparing drying is still used in powdered milk production.

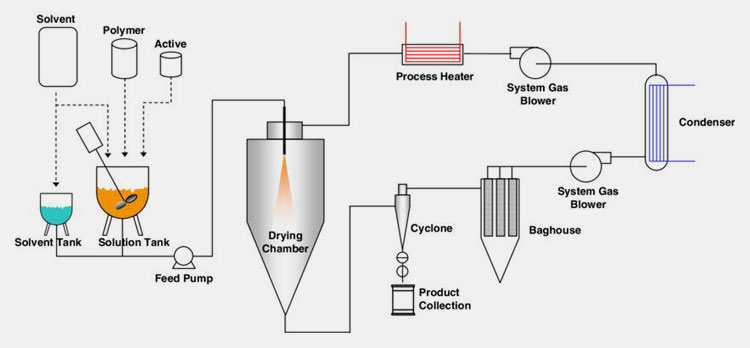

Spray drying, just as its name implies, is the process by which atoms in a liquid feed become very small droplets under the function of thermal air drying, and then the droplets rapidly dry into solid particles.

And then, using the cyclone separator and pocket filter to isolate particles and drying gas as an eventual spray drying product. During this process, the feeding part can be a liquor, a suspension and an emulsion. The product can be classified into powder, particles and agglomerates.

Spray drying in medicine application

Spray drying in medicine application

The spray drying technology is beneficial to the subsequent processing of dried products(e.g. direct compression). For example, spray drying lactose, which was introduced as an excipient in the 1960’s can be directly compressed to preparation in a simple fabrication process.

Lactose can be suspended in a saturated aqueous solution before the spray drying process. The drying process converts them into free flowing particles with a mixed solid state of crystalline and amorphous forms. The resulting unique internal structure can allow the dry powder to exhibit good plasticity and bonding during direct tabletting.

Spray drying in preparations application: solid dispersions

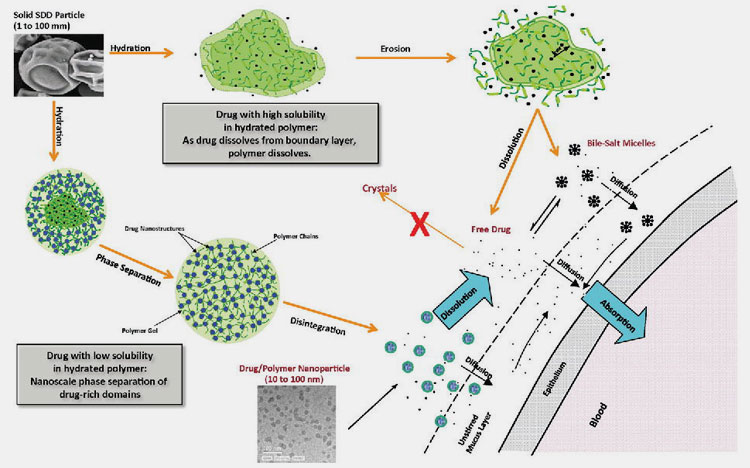

Typically, API is spray dried with some excipients in order to better perform the functions of pharmaceutical formulations. One of the main applications of this technology in the pharmaceutical industry is the production of solid dispersions by spray drying.

When we are using spray drying techniques for the preparation of solid dispersions, such as ethanol, chloroform or a mixture of ethanol and dichloromethane, it is generally necessary that we dissolve the drug and polymer carrier in an organic solvent and spray it into a heated stream of nitrogen in order to remove the organic solvent.

But this process will also have certain deficiencies, such as the use of organic solvents, high preparation costs, and so on. Furthermore, among the developments of solid dispersions, the physical stability of molecularly dispersed drugs remains a major challenge.

Microencapsulation

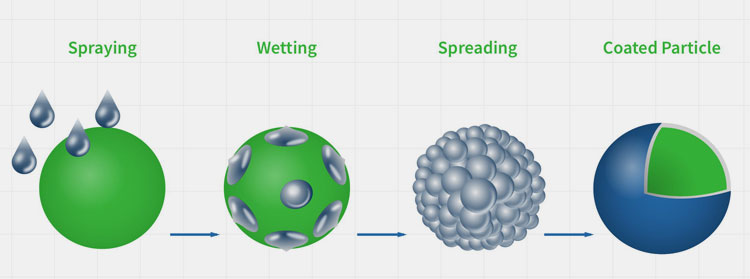

The targets of microencapsulation in the pharmaceutical industry are to stabilize the active compound, cover the bitter taste of drugs or design sustained-release drug preparations.

By selecting suitable excipients and feed solvents, you can encapsulate the active drug substance in a polymer shell or coating. Microencapsulation can also be achieved by spray coagulation, in which the material is melted and sprayed into cold air to condense the particles, rather than dissolved in the solvent medium before atomization.

Dry powder for inhalation

Different from other preparations, one clear advantage of spray drying in the production of inhaled dry powders lies in their unique particle engineering characteristics. As for the dry aerosol preparations, the particle characteristics are extremely important, because it determines the lung deposition efficiency of the dry aerosol, as well as the therapeutic efficacy.

The advent and application of a range of technologies, such as supercritical fluid technology and spray freeze drying can affect the application of spray drying, but spray drying is still considered the most common method used in the pharmaceutical industry to produce dry aerosol formulations in addition to grinding processes.

However, spray drying is more competent than grinding processes in terms of pulmonary delivery of pharmaceuticals.

Spry drying in sterile production

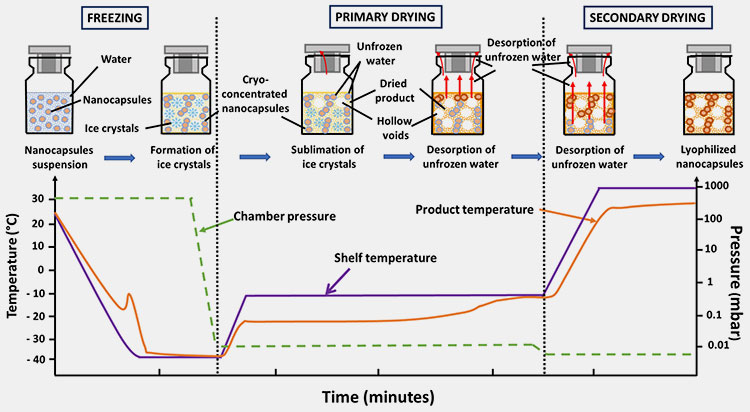

There is no doubt that the productions of dry aerosol preparations, injectable long- acting preparations and biological pharmaceutical preparations need sterile spray dying production. Just like protein and peptide drugs, biological pharmaceuticals have become a type of more and more important therapeutic agent in the pharmaceutical industry.

They always keep in a solid form because of stability problems. Currently, legalization is still the most common method to produce dried protein products. So, compared to lyophilization, aseptic spray drying production may be an alternative to producing dried protein products due to its more economical features on installation and operation.

Spray drying in other medicine research application

In addition to the above pharmaceutical applications, spray drying has also been attempted for the design of many other pharmaceutical formulations.

For example, liposomal formulations, lipid-based self-emulsifying drug delivery systems, porous and nonporous silica dispersions, solid in oil dispersions, prepared nanoparticle suspensions, etc.

The foreground of spray drying

Drugs’ spray drying is not merely a method to obtain the drying product. In the past few decades,

We moved from our empirical formulation work to a pellet design approach based on a better understanding of pellet formation during spray drying.

To design complex drug delivery systems, particle engineering by spray drying has been one of the most studied areas in pharmaceutical research.

From an industrial point of view, there is no doubt that spray drying will gradually become part of the standard in the pharmaceutical industry. Further advances in spray drying can be achieved by combining the spray drying process with additional processing steps and the application of computational fluid dynamics (CFD).

However, one of the obstacles of spray drying in pharmaceutical applications lies in the fact that many pharmaceutical companies do not have a detailed perception of the technology.

Fortunately, an increasing number of pharmaceutical organizations are now aware of the critical role of processes and formulations. Pharmaceutical technologists are also beginning to be involved in early drug development, which may be able to take full advantage of this powerful technology in the near future.

Don't forget to share this post!

Drier Machine Related Posts

Drier Machine Related Products

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine