AIPAK Horizontal Liquid Filling And Sealing Machine

AIPAK Horizontal liquid filling and sealing machine is a kind of plastic bottle thermoforming filling & sealing equipment,it’s suitable for bigger batch filling in pharmacy,pesticide,cosmetic ,food & beverage and nutrition etc.Field for liquid & Cream material,it’s widely used for filling oral liquid ,liquid pesticide & fertilizer,E-liquid ,liquid & Cream cosmetic,edible oil,beverage and liquid health care product etc.

The Buyer's Guide

How to Choose The Right Liquid Filling And Sealing Machine For Your Project:the Ultimate Buying Guide in 2025

If you are new to the world of liquid filling and sealing, trying to decide the best liquid machine for your product can sometimes feel confusing and overwhelming with the various options and machines available.

It is important for you to make the right decision and to choose the best liquid filling and sealing machine for your project, and here I am going to assist you.

To get started, there are many factors to take into consideration when choosing a liquid filling and sealing machine, such as overflow, gravity, pistons, and pumps, and choosing the right machine also depends on what you want to achieve.

Today ,I have put together some helpful questions to act as a starting place, and the answers to these questions will help to guide you towards choosing the best machine.

Let’s get started now.

1.What is Liquid Filling And Sealing Machine?

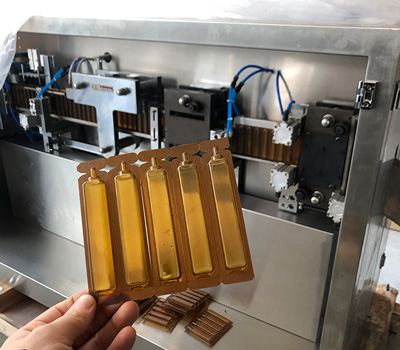

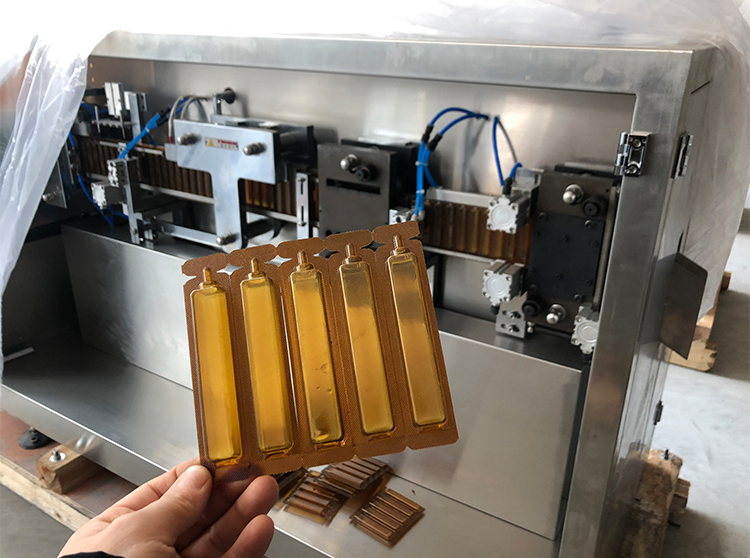

Products by Liquid Filling and Sealing Machine

The liquid filling and sealing machine is a specialised type of machine that has revolutionised many industries in the world. You can say it is the modified form of the liquid filling machine with an added feature of sealing the containers.

The liquid filling and sealing machine performs both the functions i.e. filling of different types of liquids into the suitable containers and then properly sealing the container.

This is a special type of machine that is very fast and very accurate at the same time. It comes in different types and each type works on different principles.

2.What is AIPAK Horizontal Liquid Filling And Sealing Machine?

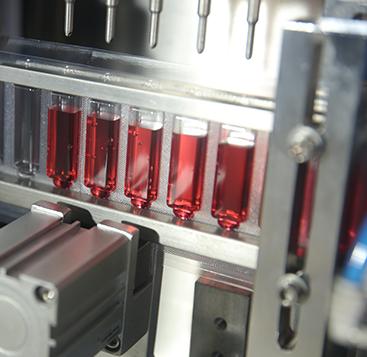

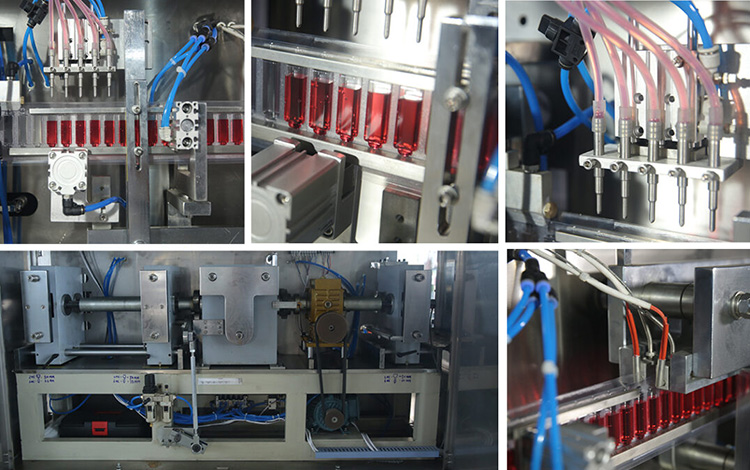

AIPAK Liquid Filling and Sealing Machine

AIPAK Horizontal Liquid Filling And Sealing Machine is an equipment that is used to fill and seal different types of containers. It has varied applications in different fields including pharmaceutical, food, cosmetics, and beverage industries. It is called a horizontal liquid filling and sealing machine because different parts and components of the machine are placed in a horizontal manner.

An AIPAK horizontal liquid filling and sealing machine is an efficient and accurate machine that performs all the basic operations for you that are needed during filling a liquid in a bottle or a container and then sealing it.

It is an automatic machine that completes almost all of its tasks without requiring any human interference. Therefore the chances of error drop to almost zero.

The AIPAK horizontal liquid filling and sealing machine conforms to all the quality standards of GMP and safety standards too.

3.Which Industry is Liquid Filling And Sealing Machine Widely Used?

The liquid filling and sealing machine is used in different industries and are very useful when it comes to increased production and greater accuracy. Following are the industries in which liquid filling and sealing machines are used widely.

1.Pharmaceutical Industry

Pharma bottles Sealed and Packed-Photo Credit: weenier

The liquid filling and sealing machine have vast applications in the pharmaceutical industry. They are used to fill the liquid pharmaceutical products that maybe syrups or injections into different types of containers like bottles and ampoules.

In the recent times, the demand of the pharmaceutical products has increased many folds and thus in order to meet the requirements, the liquid filling and sealing machine is used for a greater production rate.

High quality sealing prevents any contaminant from entering the container and thus the pharmaceutical efficacy of the medicine is retained throughout its shelf life.

2.Chemical Industry

Chemcical Bottles Packed- Photo Credit: Shopee

Different types of chemicals are filled in different containers by using liquid filling and sealing machine. Prime requirement in the chemicals packaging is accurate packing and absence of any contaminant during packing.

This makes liquid filling and sealing machine an important equipment of the chemical industry.

3.Cosmetic Industry

The cosmetic industry also depends on the liquid filling and sealing machine for its proper operation. These industries use this machine to fill different products like lotions and different serums and make up products into different containers.

Perfect filling and sealing make this machine very useful to preserve the quality of cosmetic products.

Photo Credit-SY Cosmetics

4.Food and Beverage Industry

Food and beverage industry has the most important and vast applications of liquid filling and sealing machine. Most of the liquid products such as beverages are packed in their bottles by using this machine. Perfect sealing ability and accurate filling makes it vital for use in the food and beverage industry.

Perfect sealing retains the quality of the food and beverages and keep them fresh and healthy for a greater time.

Packing without the presence of any contaminants is the quality of liquid filling and sealing machine that makes it perfect for use in pharmaceutical industry.

Photo Credit-Pinterest

5.Pesticide Industry

Pesticides Bottle Sealed and Filled- Photo Credit : Unitedcaps

The liquid filling and sealing machine also find its application in the pesticide industry. The filling of pesticides inside different kinds of containers is done accurately and effectively by using this machine.

4.How does Liquid Filling And Sealing Machine Affect the Liquor Industry?

The liquid filling and sealing machine is widely used in different industries for filling their respective liquid products into the suitable containers and then properly sealing it to avoid any spillage or contamination.

In the liquor industry, the liquid filling and sealing machine is used to fill different liquid products like beer, wine, liquor or cocktail and other related products.

In case of the liquor industry, the containers maybe bottles (can be small or large depending on the volume of liquid to be filled) or barrels.

Some of the above-mentioned products have gas and others do not have any gas in them. So, filling of the liquids having gas in them requires special techniques for proper filling into the containers and then the sealing must be perfect to avoid leakage of gas form the container.

Before the invention of liquid filling and sealing machine, the products of the liquor industry were filled in then containers manually. This method of filling had many drawbacks like

incorrect filling or faulty sealing that ultimately brings bad name to the company.

Another interesting feature that the liquid filling and sealing machine gives to the liquor industry is that it prevents loss of beer or wine during the filling process. Lesser the wastage, greater the production and greater the profit.

Photo Credit-Mockup World

The liquid filling and sealing machine also reduces the requirement of labour and thus saves a lot of money for the company.

5.What Product can be Filled and Sealed by the Liquid Filling And Sealing Machine?

AIPAK Filled Material

The liquid filling and sealing machine is used to fill different kinds of liquid products into the suitable containers. Different products filled in different industries are described below.

In the pharmaceutical industry it is used for filling different liquid medications in the vials, injections etc and then sealing these containers.

In the food and beverage industry, it is used for filling liquid food products such as juices, colas and sodas etc and the containers are then sealed.

In the cosmetics industry, it is the used for filling different cosmetic products such as creams, pastes and serums into suitable containers and then the containers are sealed.

In the pesticide industry, the liquid filling and sealing machine is used for filling and sealing of poisonous pesticides and herbicides etc.

In the liquor industry, it is used for filling and sealing of beer, wines and liquor etc.

The liquid filling and sealing machine is used for filling and sealing of hazardous and dangerous chemicals in the chemical.

Different types of gas-containing liquids and the liquids without gas are filled into the suitable containers by the application of liquid filling and sealing machine.

Photo Credit-BBC

6.Why Invest in a Liquid Filling And Sealing Machine?

The liquid filling and sealing machine is a great invention that has revolutionised many industries. Because of its efficient and effective filling and sealing operations, this has become the central need of many industries including pharmaceutical industry, food industry, cosmetics industry, liquor industry etc.

There are many advantages of the liquid filling and sealing machine that will convince you to invest in the machine.

Some of the advantages of the liquid filling and sealing machine are listed below.

1.Steady Filling and Sealing

While working with the liquid filling and sealing machine, you do nit have to worry about inconstistent filling and sealing.

AIPAK Liquid Filling and Sealing Machine

You can set the machine to a point according to your needs and the machine will continue following the instructions until you change the settings.

This consistency of filling and sealing cannot be achieved by manual filling of the liquid into the containers.

2. High-Speed Liquid Filling and Container Sealing

High Speed Filling and Sealing

The liquid filling and sealing machine provides a very high speed of filling the liquids into the container and then sealing the container.

It can fill greater number of bottles as compared to manual filling and thus they provide efficient filling and sealing of the container. By filling the bottles at a swift speed, it helps you meet your production requirement.

The speed of the liquid filling and sealing machine can be further increased according to the needs of your production. Increasing the number of filling heads increases the filling speed.

3.Versatility

The liquid filling and sealing machine provides a greater versatility. It can be used for filling and sealing a variety of products and even greater varieties of bottles.

This feature makes it useful for the filling and sealing purposes in the industries in which greater number of products are manufactured.

4.Easy to Operate

The liquid filling and sealing machine is very easy to operate. It has a very simple interface that provides an easy access to many functions of the liquid filling and sealing machine.

The operator interface has touch screens that makes it very easy to operate. The interface reduces the efforts required for the operation.

5.Offers Growth Potential

Because of greater production, the liquid filling and sealing machine it provides greater potential for the growth of your company in future.

6.Faster Filling and Sealing

The liquid filling and sealing machine provides a faster filling and sealing of the liquid into the container. This helps you increase the productivity and thus increases the overall production of your company ultimately increasing the revenue of your company.

7.Accuracy

One of the most important feature of the liquid filling and sealing machine that makes it a vital component of many industries is its accuracy.

It performs both of its works i.e. filling and sealing accurately. Accurate filling of the liquid is very important especially in the pharmaceutical industry. Errors in the filling can lead to incorrect dosage that can cause severe complications to the patients.

Perfect and accurate sealing is also the prime requirement in the pharmaceutical industry. Incorrect sealing can also cause the contamination of the product and so the product of medication may get expired before its actual date of expiry. Consumption of expired medicine can again cause health complications.

8.Provides Good Hygiene

The liquid filling and sealing machine often provides a good hygienic condition. It stops the entrance of any contaminants into the liquid or into the container during its operation.

Good hygienic conditions are of prime importance especially in the food and the pharmaceutical industries.

9.Minimizes the Wastage

The liquid filling and sealing machine helps prevent the wastage of your liquid product during the filling and sealing operations.

It ensures the accurate sealing so that there is no or very less spillage of the liquid product.

7.Are there Any Drawbacks of Liquid Filling And Sealing Machines?

Besides many advantages of the liquid filling and sealing machine that are already discussed, there are some drawbacks you should know before buying a liquid filling and sealing machine.

Some of the drawbacks of liquid filling and sealing machine are discussed below.

1.Specific for Filling Liquids Only

The liquid filling and sealing machine is only specific for filling liquid into the container and can not be used to fill solids.

This makes it useless for the industries whose products are non-liquids. It also causes trouble for the industries which produce both solid and liquid products. Such industries have to buy two different types of filling machines as the liquid filling and sealing machine can only help them fill the liquid products.

2.Needs Some Expertise for Proper Operation

Although the operator interface of the machine is not very complicated and it is very easy to operate, handling and operating the machine still requires some level of expertise as any mistake in the interface controlling can cause major malfunctioning of the liquid filling and sealing machine leading to inaccurate result and during the extreme conditions, this can lead to severe technical problems to the machine.

3.Requires Proper Maintenance

The liquid filling and sealing machine requires a proper and regular maintenance for continuing its normal functioning. If the machine is not maintained properly, it gets damaged over the period of time, thus reducing the accuracy of filling and sealing.

8.How many Types of Liquid Filling And Sealing Machine are there?

The liquid filling and sealing machine comes in many different types. Depending on the nature of the product to be filled and the process to be used during filling, the type of the liquid filling and sealing machine varies.

Each type of liquid filling and sealing machine has its own process and thus the working principle varies from one type to the other.

Different types of the liquid filling and sealing machine along with their mechanism of action are described below.

1.Negative Pressure Filling Machine

It is a type of liquid filling and sealing machine that uses the negatively induced pressure for the filling process.

The working principle of negative pressure filling machine is that it creates a negative pressure pumping the packaging container. Because of this negative pressure, the product (liquid) gets filled into the desired container.

AIPAK Liquid Filling and Sealing Machine

Types of Negative Pressure Filling Machine

There are two types of negative pressure filling machine depending upon the container on which the negative pressure is created.

a) Pressure Differential Negative Pressure Filling Machine

This type of negative pressure filling machine creates a positive pressure on the storage tank and negative pressure on the packaging container. This is a type of negative pressure filling machine relies on the differential pressure for the process of accurate filling.

b) Gravity Type Negative Pressure Filling Machine

This type of negative pressure filling machine creates a negative pressure on the storage tank and the packaging container. This relies on the process of Self-Loading filling.

Best Suited For:

This machine is best suited for filling of the fruit juices, artificial drinks, different hazardous chemical reagents and toxic pesticides, insecticides and herbicides etc.

Details About The Negative Pressure Filling Machine

On the lower turntable 13, the tray is installed. The lifting of the tray is driven by the tray lifting guide wheel 16. The liquid level control device 14 controls the liquid level in the tank.

On the upper turntable 9, the filling valve 5 is fixed. the height of the upper turntable can be controlled by the tank height control device 15. You can adjust the height to meet the requirements of different bottle heights. For stepless adjustment of the spindle speed, the speed control hand wheel 19 is used. This is done to meet the productivity requirements of the main engine.

Prominent Features of this machine:

- No leakage of the the filling liquid

- Low bottle breakage rate,

- Very small loss of the liquid fragrance, and

- This machine is suitable for filling various liquids.

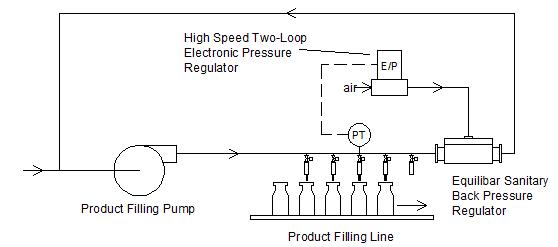

2.Pressure Filling Machine

Process of Pressure Filling-Photo Credit: Equilibar

This is a type of liquid filling and sealing machine that fills the liquid product into the packaging container by the application of external negative pressure.

Best Suited For:

Filling the more viscous products like pastes, ketchup, toothpaste, balsam, bean paste, etc.

Details About The Pressure Filling Machine

Stainless steel is used for making the seasoning box 1. The bottom of the box is rigidly connected with the shaft, and the bottom of the box is welded into a box-shaped seat. The box has 12 pistons at the bottom. The lower end of the piston rod is equipped with a roller in order to control the reciprocating movement of the piston. This roller runs along a circular track. At one end of the rail, a lifting mechanism is installed. The function of this lifting mechanism is adjusting the stroke of the piston. on the outside of the sauce box, twelve filling valves are installed. All of these twelve filling valves are connected to the sauce box.

3.Atmospheric Filling Machine

Atmospheric Filling Machine

This is probably the simplest type of liquid filling and sealing machine that fills the liquid product into the packaging container under normal pressure.

Best Suited For:

This machine is best suited for filling and sealing of the liquids that are gas-free and have a very low viscosity. These include wine, soy sauce, vinegar etc.

Details About The Atmosphere Filling Machine

The atmospheric filling machine mainly comprises of bottle inlet conveyor, liquid tank inlet wheel, bottle outlet wheel, main shaft, filling valve, and transmission system. On the same level, there are bottle inlet and outlet wheels. On the lifting rod, the tray is installed. On the bearing seat, the main shaft is installed vertically. On the top of the main shaft, the tank 1 is installed. 24 filling valves are present under the tank. 24 pallets are corresponded by the middle part and the lower rail realizes the lifting movement. The transmission system and the motor are installed within the frame.

4.Isobaric Irrigation Machine

The isobaric irrigation machine is a type of liquid filling and sealing machine that fills the liquid product into the packaging container by a special method.

First of all, it inflates the container until it equalizes the gas pressure to the gas pressure in the container. After the pressure is equalized, the isobaric irrigation machine fills the container.

Best Suited For:

The isobaric irrigation machine is best suitable for filling the gas-containing wines such as beers and gas-containing soft drinks such as cola and other gas-containing sodas.

Details About The Isobaric Irrigation Machine

The isobaric irrigation machine mainly comprises of the star wheel, the annular liquid chamber, the central feed pipe, the separation feed screw, the feed pipe, and the feed valve. The gas chamber and the liquid storage chamber of this type of liquid filling and sealing machine are present in the same tank. The isobaric irrigation machine is a single-chamber liquid supply system and is very useful when it comes to the filling and sealing of the gas-containing liquids in the containers.

9.What is the Working Principle of Liquid Filling And Sealing Machine?

The liquid filling and sealing machine is divided into three different types depending on their working principle. Different types of the liquid filling and sealing machine work on different principles. These include;

1.Ordinary Filling Machine

This is the type of the liquid filling and sealing machine in which the working principle includes filling of the liquids according to their weights.

It works on the principle of gravity. However, maintenance of special requirements in order to conserve the viscosity or the gas of the liquid product is very important.

Grape wines and milk bottles are filled by this principle.

2.Vaccuum Filling Machine

The working principle of this type of liquid filling and sealing machine is that the liquid is filled into the bottles that have a lower pressure as compared to the atmospheric pressure.

Liquids with high viscosity such as syrups and oils are filled by this method.

3.Pressure Filling Machine

This type of liquid filling and sealing machine has the working principle that the liquids are filled at a pressure greater than the atmospheric pressure.

The pressure induced in the liquid containing container can either be higher than or equal to the pressure of the container being filled.

10.How to Install the Liquid Filling And Sealing Machine?

The installation of the liquid filling and sealing machine is a complicated process and requires a certain level of expertise so that there are minimum chances of errors in the installation process.

The liquid filling and sealing machine has the screw-type leak-proof device of liquid dispensing machine, which includes the lower part of the packaging hopper and the sub-packing screw is placed within it.

The material tube is provided with a damping ring under the material tube, and in the material tube, the material nozzle is fixed in the material tube with the help of a nut.

Nowadays, the device of the new liquid filling and sealing is simple, which solves the problems caused by the incosistent filling of liquid products and the liquid leakage from the container.

It ensures the loading accuracy and the packaging quality of liquid products, and promotes industrial production.

The liquid filling and sealing machine has the production efficiency of anti-caking function. This includes the base and the main body of the dispensing machine is tightly installed on the upper end of this base.

The upper end of the the liquid filling and sealing machine body is equipped with a hopper. The body side is equipped with a mounting frame and a battery box. The side of the battery box is provided with a storage box.

The upper end of the suction pump is provided with a feeding pipe, while the lower end is provided with a suction pipe. On one side of the feeding hopper, the discharge pipe is placed. A pressure roller is present inside the machine.

The advantage of the new type of liquid filling and sealing machine is that they have a pressure roller and thus the agglomerates in the loose liquid carried by the suction pump can be flattened.

After which the liquid enters the main body of the liquid filling and sealing machine. This tiny equipment makes sure that the quality and the quantity of filling and sealing of the product is perfect.

The lower end of the storage cylinder is equipped with an intermittent discharge port, while the lower end of the discharge port is equipped with a rotating table for the purpose of receiving the products.

11.Where Should be Inspected Before the Working Process of Liquid Filling And Sealing Machine?

Before the working process of the liquid filling and sealing machine, you should inspect different things so that the machine gives an optimised performance. Some of the factors that should be inspected carefully before operating the liquid filling and sealing machine.

1.Check for Air Leakage

Before working with the liquid filling and sealing machine, you should make sure that there is no air leakage at the connection. Most of the times, air leaks are caused by cracks in the pipes, and thus these pipes need careful checking and monitoring.

2.Check the Wiring

The includes careful checking and making sure that the connected power cord is correct and there is no short circuit. Then, make sure that the three-phase four-wire is correct, this is very critical. You should also make sure that the neutral line is connected correctly.

3.Check Normal Computer Display

You should check and make sure that all the monitors are displaying normally. Also make sure that all the switches are closed.

4.Check for Normally Working Gland

You need to make sure that the gland is working properly, so that the measurement can be correct.

12.Which Factors will Affect the Efficiency of the Liquid Filling And Sealing Machine Filling Process?

There are some factors that can reduce the efficiency of your liquid filling and sealing machine. Some of these factors are listed below;

1.Inaccurate filling level and time

2.Power supply problem

3.Foaming and dripping

The details of these problems and their possible solutions are discussed later in this section.

13.What are the Operation Precautions of Liquid Filling And Sealing Machine?

For a successful and efficient operation of any machine, there are some instructions and precautions that need to be followed very strictly. Some of the precautions for the liquid filling and sealing machine are described below.

The loose screw should be tightened Whenever the machine is adjusted, and the machine should be turned with the handle to see if there is any abnormality.

For the purpose of adjusting the liquid filling and sealing machine, you should be careful enough to use the tools appropriately. usage of excessive tools or excessive force to remove parts of the machine is strictly forbidden to avoid any damage to the parts.

You should make sure that the machine is always kept clean. oil stains, liquid chemicals or glass fragments on the machine are strictly prohibited so that the damage to the machine can be avoided

14.What Other Equipment are Needed to Form A Complete Liquid Production Line?

A complete liquid production line requires the following equipment.

1.Bottle Washing Machine

It used for thorough cleaning of the bottle from inside and outside.

2.Bottle Inspection Machine (Visual Inspection)

It is used to inspect the bottles after they have been washed.

3.Turn Table

It receives containers (bottles, vials, ampoules, etc) and then passes them to the conveyer present next to it.

4.Inspection Table

This is used for manual and visual inspection of the sealed container. It is made sure that the liquid is accurately filled and the container is sealed tightly so that no spillage occurs.

5.Label Applicator

This machine automatically applies a label on the container.

6.Packing Conveyer

It helps in handling the container and then passing it from one point to the other.

7.Bundle Packing Machine

It is used to pack the containers into a bundle form.

15.How to Disinfect the Liquid Filling And Sealing Machine before Working?

Disinfection refers to the process in which killing of all kinds of life takes place. This is a type of cleaning process and is very important phenomenon when it comes to maintenance purposes of a machine.

The liquid filling and sealing machine also requires timely disinfection for its proper functioning. The method of disinfection is as follows.

Photo Credit-E &I Cooperate Services

You should loosen the upper and lower set screws and then remove the liquid injection system for overall disinfection of the liquid filling and sealing machine.

Then you should insert the liquid inlet pipe in the cleaning liquid and start the process of cleaning.

You should make sure that the measuring cylinder is accurate before the formal filling because the 500ml model may have errors in actual filling.

16.How to Solve the Unstable Loading of Liquid Filling And Sealing Machine?

The unstable loading of the liquid filling and sealing machine can occur because of different reasons. Different types of problems have different solutions. Some of the problems along with their solutions are described below.

1.For the sterilization equipment, non-metallic materials are not selected. During sterilization, the pump rod comes in contact with the metallic materials, and the metallic materials get stuck on the pump rod.

This causes many problems like wearing of the pump rod, formation of bubbles during the filling process, and poor air tightness.

This problem is easy to solve. You must try using the equipment dedicated for sterilization.

2.The pump body and the pump rod are mixed during the installation of the pump, and the gap of the pump is not matched. This causes many problems like wearing of the pump rod, formation of bubbles during the filling process, and poor air tightness.

For solving this problem, the pump body and the pump rod are marked and not mixed.

3.Bubbles or dripping will occur if the connections between the silicone tube, the dispenser and the ceramic pump are not tightened.

Replacing the connector or silicone tube can help solving this problem.

4.The connection between the rotary valve and the ceramic pump shook too much or the dripping is caused by the verticality of the pump.

This problem can be solved by replacing the slip knots if the connection slip knot shakes too much.

5.Slight shaking of the ceramic pump in the later stage of filling is caused by the lack of rigidity of the filling servo motor itself. This leads to dripping.

17.What Should you Consider when Buying Liquid Filling And Sealing Machine?

Before buying a liquid filling and sealing machine, you should make sure that the features of the machine are compatible with your factory and the machine is good enough to meet your requirements.

Following features must be considered.

1.Viscosity of the Product

You should choose a liquid filling and sealing machine according to the viscosity of your products. You should look for the type of the machine that best suits your product viscosity.

2.Evaluate the Quality and Performance of the Machine

You should make sure that the a liquid filling and sealing machine is efficient enough to fulfil the demands of your production unit. You must prefer buying that machine which is flexible enough to fill different kinds of liquids and seal the containers of different types and different sizes.

3.Check for the Availability of Spare Parts

You should make sure that the spare parts of the a liquid filling and sealing machine you are going to buy are easily available so you do not have to face any problem in finding them when you need them.

18.How to Maintain Liquid Filling And Sealing Machine?

The liquid filling and sealing machine requires regular cleaning for its proper functioning. If the machine is not given proper care and maintenance, it starts giving error and its efficiency starts declining. Regular cleaning of the machine is required after every eight days.

The liquid medicine or glass fragments should be removed in time during the production process of the machine.

Water at 0-1℃ must be used to reduce the temperature of the liquid filling and sealing machine tank and conveying pipeline before each operation of the liquid filling and sealing machine. This avoids unstable functioning of the liquid filling and sealing machine due to temperature changes.

19.How to Clean Liquid Filling And Sealing Machine?

Cleaning of the liquid filling and sealing machine is a crucial step in maintaining it. The cleaning saves it from rust and other technical problems. Method of cleaning the liquid filling and sealing machine is described below.

You should strictly inspect and clean the filling container so that the medicament after filling does not get contaminated. Otherwise, this will cause serious hidden dangers to product quality.

The pipes of the liquid filling and sealing machine must be kept clean. All pipelines must be kept clean (especially those in direct or direct contact with materials).

You must scrub them every week and the water must be drained every day. It must be sterilized each time to ensure that there are no dirt and bacteria in the parts that come into contact with the material.

Before the shift, all parts of the machine surface should be cleaned once. Clean lubricating oil should be added to each activity department to avoid corrosion and friction.

20.What is the Common Problems of Liquid Filling And Sealing Machine?How to Solve?

During the operation of the liquid filling and sealing machine, some problems may arise and cause a decrease in overall efficiency of the production.

Some of these problems, along with their solutions and methods of avoiding them, are described below.

1.Foaming and dripping

insufficient sealing is the possible problem if your liquid filling machine encounters foam or dripping problems.

Dripping and foaming of the liquid will waste a lot of liquid and this will cause the product to lose a lot of cost over time.

This problem can be effectively solved by tightening the sealing ring and ensuring that after the filling process is completed the valve does not leak.

The entire filling machine may need to be replaced, if the seal cannot be repaired. The use of submersible nozzles may be require for solving the foaming issues.

2.Inaccurate filling level and time

This is Another major problem that may cause product waste and overall insufficient liquid filling. The product overflow and waste, or insufficient filling of the container may result if the filling amount is not correct.

Poor sealing is a common cause of inaccurate filling levels. You must check and tighten the seals and the seals may need to be replaced if the tightening of seals does not work.

Routine maintenance checks on the parts that may be loose or can allow air to enter the product channel will help you avoid this problem. Inaccurate time is a simple problem that is easily solved by changing operating settings instead of adjusting device hardware.

You should keep in mind the viscosity of your product, as this also affects the volume filling process.

3.Power supply problem

The lack of power is a problem that has nothing to do with the device itself. In order to solve this power related problem, you have to take certain steps to make sure that you can avoid power surges and you can provide enough voltage for even circulation among your machines. Power surges can have a huge impact on your production line.

It can lead to a complete breakdown, causing a complete loss of productivity, and if it lasts long enough, it can lead to product damage.

To avoid this problem, you have to make sure that your industry has enough backup generators and can provide enough power for proper handling of every piece of equipment you introduce in the liquid filling line.

This will ensure that your equipment keeps operating at high speed with greater efficiency.

Horizontal Liquid Filling And Sealing Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586