High Speed Tube Filling Machine: The Complete Buying Guide In 2025

Have you ever wondered how many products you use daily are packaged by high speed tube filling machine? A high speed tube filling machine marks a key role in pharmaceuticals, cosmetics, food and chemical industries. This machine proves to be a wise investment as it maximizes the productivity and attain great outcome.

When you are getting so many benefits from one machine either its precise filling and sealing of product or producing a product that meets mandatory standards with low waste production, then you must think to consider it as your prime investment.

This guide contains all the knowledge which you necessitate for buying a high speed tube filling machine and it proves to be valuable for you in future as well.

1.How do you introduce high speed tube filling machine?

AIPAK High Speed Tube Filling Machine

A high speed tube filling machine is specially designed equipment to fill and seal tubes of certain material with different products. It works automatically which make whole operation efficient and reliable.

This machine holds so much importance in current society. The reason is the property of this machine to provide established, safe and vast production of vital goods and to improve daily life along with worldwide supply chain.

2.What are the privileges of using high speed tube filling machine in industry?

The demand for high speed tube filling machine is increasing day by day in industrial sector. This machine secures precise and firm product, which aids in re-shaping the manufacturing of significant daily products.

Rapid speed production:

Flawless Filling Of Huge Number Of Tubes-Picture Courtesy: eBay

Ultra-modern structure of tube filling machine helps to ensure fast and flawless filling of huge number of tubes, without overheating. This makes it a perfect choice for large production of necessary products as speed counts a lot in manufacturing.

Precise and accurate production:

Precise Filling Of Tube-Picture Courtesy: Mckups

This tube filling machine has profound ability to fill and seal tube with high precision and accuracy. The reason could be the resourceful technology, which guarantees constant product division. Correct filling leads to low wastage and high productivity.

Reliable sealing methods:

Well-Sealed Airless Tubes-Picture Courtesy: Somewang

Originality of product is safeguarded by performing genuine sealing methods. This high speed tube filling machine assures airtight sealing by utilizing heat or ultrasonic waves. Air gaps and weak spots are removed by automatic filling machine. There are different sealing methods for different packaging materials.

Versatility:

Different Sizes Of Tube-Picture Courtesy: Lisson Packaging

This machine provides flexible packaging of important daily products. It can hold tubes made of plastic, aluminum or laminates. Different sizes of tube can be filled by it. Various products can be dispensed by the help of this machine.

Easy-to-use:

Easy To Operate Machine-Picture Courtesy: Vacuum Mixer Homogenizer

High speed tube filling machine’s system is easy to use.Touch screen controls provide smooth digital display. Operators can adjust settings straightaway. It is designed for uncomplicated learning, requires minimal training.

High durability:

Remarkable Quality Product-Picture Courtesy: Burhani Packaging

This tube filling machine is made up of stainless steel which prevents corrosion and wear. It holds powerful components like motors, pumps and sensors which last longer. Due to mentioned characteristics, it requires less maintenance with remarkable quality product.

Low energy consumption:

Nature-Friendly Operations-Picture Courtesy: The Whole Package

This machine has brilliant power management system, utilizes energy as per need. It offers nature-friendly operations.

Cost effectiveness:

Cost Effectiveness-Picture Courtesy: Monday.Com

Automaticity benefits in lowering the cost of operations carried by machine. Labor cost is decreased. All process continues to function with great precision and without misuse of material.

3.What kinds of material can be used for packaging in high speed tube filling machine?

High speed tube filling machine offers different materials for tube packaging. The selection of material completely depends upon the product type choose to be packaged in it. Recurrent packaging material for this machine is listed below:

| Packaging material | Appearance | Information |

| Laminates(a multi-layered material comprised of different substances, that are combined by using heat, pressure, welding or adhesives) |

Picture Courtesy- Letap International |

Aluminum laminate is suitable to package toothpaste, pharmaceutical and cosmetic materials, as it protects from reaction of oxygen, light and moisture.

Plastic laminate is commonly used to package cosmetic and food products. |

| Plastic |

Picture Courtesy: Visionpack.Org |

Different forms of plastics are used for different products

Polyethylene (PE)-used for creams, lotion and ointments. Polypropylene (PP)-used for specialized practice due to sturdy nature. Polyethylene terephthalate (PET): appropriate for expensive cosmetic packaging due to its transparency and durability. |

| Aluminum |

Picture Courtesy: Lisson Packaging |

It is recommended for photosensitive and air-sensitive products like pharmaceutical and chemical products. |

| Metal |

Picture Courtesy: Precision Concepts |

In metals, tin or lead can be used by this machine in industrial sector but it is not a preferable choice due to not being eco-friendly. |

4.What nature of products can be packaged by high speed tube filling machine?

High speed tube filling machines are intended to package different products, depending on their physical nature with great efficacy and correctness. Products can be divided according to their nature:

| Nature of product | Image | Examples |

| Semi-solid products |

Picture Courtesy: Instacart |

Creams: medicinal creams

Gels: hair gel Ointments: antibiotic ointment Lotions: body lotion Toothpaste |

| Liquid or semi-liquid products |

Picture courtesy: Flickr |

Sauces: ketchup, mayonnaise

Oils: lubricants Cleaning gels: hand sanitizer |

| Paste-like products |

Picture Courtesy: Weldtite |

Adhesives: glue

Greases Chemical pastes |

5.What is principle behind the functioning of high speed tube filling machine?

In order to purchase high speed tube filling machine, you really have to know how it works. It functions by filling and sealing tubes of various materials with products of different nature like semi-solid, liquid, semi-liquid etc. The major principle behind its functioning is explained below:

| Steps involved in functioning | Image |

| Tube loading: Unfilled tubes are supplied into tube feeder manually or by automatic loading system. |

Picture Courtesy: Burhani Packaging |

| Tube positioning: The machine collects each tube automatically, position it by the help of sensors or mechanical jaws and then put it in assigned holders. |

Picture Courtesy: Packaging Journal |

| Filling of tube:

Product is introduced in hopper, from where it ascends to filling nozzles. Filling of tube is carried out by the aid of pistons, which dispenses precise amount of product in to tube. |

Picture Courtesy: IWK |

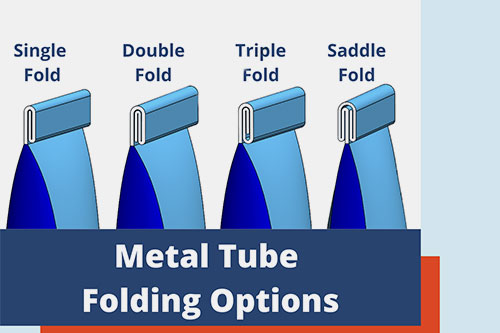

| Sealing process: After sealing, tube moves to sealing station. Sealing method relies upon the type of product.

Heat sealing method is carried out to seal plastic or laminated tubes by utilizing ultrasonic waves or hot air to close the ends. Folding and crimping method is carried out to seal aluminum tubes, by applying pressure and perform rolling to close the ends |

Picture Courtesy: The Tube Council |

| Batch coding: Expiry dates or batch numbers are imprinted by using inkjet or embossing system. |

Picture Courtesy: The Whole Package |

| Discharging of tubes: Extra matter present at the end of tube is trimmed if needed, and the finalized tubes are shifted onto a conveyor for remaining packaging. |

Picture Courtesy: RIGAO |

6.What is the classification of high speed tube filling machine?

As being a purchaser, you must be aware of classification of high speed tube filling machine. The reason behind this statement is that each type is useful according to its place of application. Production is small, medium or large scale, so you will choose the machine accordingly.

This machine is classified on the basis of level of automation and level of design.

On the level of automation:

On the basis of automation, high speed tube filling machine is divided in to:

Manual high speed tube filling machine

Semi-automatic high speed tube filling machine

Fully-automatic high speed tube filling machine

| Manual high speed tube filling machine:

In this tube filling machine, all the operations are carried out manually. It is truly designed for small-scale practices. Unlike fully automatic machine, this tube filling machine demands human interferences to continue its processing. Either it is loading of tube or filling, sealing and discharging of tube, everything is operated by humans. This tube filling machine can work on high speed, depends upon the efficiency of operator that how he makes this tube filling machine work. This tube filling machine is applicable for smalls startups, R&D laboratories etc. It can fill different ointments, gels, creams etc. in aluminum and plastic tubes and seal these tubes by heat sealing or folding method. It is considered as cost effective and holds less space for carrying out operations. |

ppp

Picture Courtesy: RIGAO |

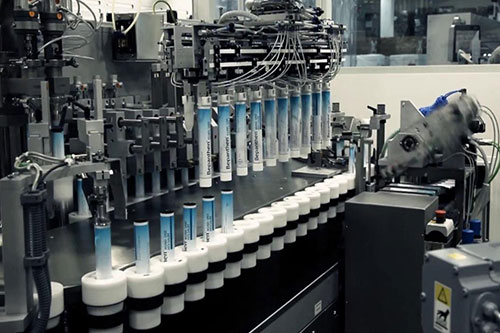

| Fully-automatic high speed tube filling machine:

This is the ultra-modern machine, employed to fill and seal various important products in to tube of different materials like laminates, aluminum, plastic, with high-level precision and accuracy. All operations performed by this machine are automatic, so you will get low labor cost, less wastage with high productivity. It is considered ideal for medium to large scale production due to harmonious filling and sealing processes. It is widely used in different industries to package their desirable products in to tubes. For example: Pharmaceutical: ointments, gels Cosmetics: skincare products, lotion Food industry: sauces, honey Chemical industry: lubricants, paints |

AIPAK N-60 fully automatic high speed tube filling machine |

| Semi-automatic high speed tube filling machine:

This machine proposes a blend of automated and manual operations. Some processes are performed manually and some needs automation, like tube loading is done manually while filling of tube is conducted automatically. This machine fills product in to tube by utilizing different packaging material like aluminum, plastic, laminates and then apply sealing method which suits the packaging material. It is considered as an appropriate option for small to medium production as it can perform functions efficiently without holding more space as compared to fully automatic machine. It is broadly used by industries like pharmaceutical, food, cosmetic or chemical that require low to moderate production capacities. For example: Pharmaceutical: medicated creams Cosmetics: beauty products Food: pastes, honey Chemical: adhesives |

AIPAK N-30 semi-automatic tube filling machine |

Level of design:

| Linear high-speed tube filling machine:

As name indicates, it is specially designed machine, capable of filling and sealing huge quantity of tubes in a continuous straight manner, which robusts the speed of operation. It has various advantages like; It can accommodate huge capacity of products and different packaging materials. It offers easy incorporation to production line. It requires low maintenance with rapid speed. It is applicable in sectors having medium to large scalability like pharmaceutical, food, cosmetic, chemical. It has dual heads, which offers tremendous advantage of using two different materials for packaging collectively. This results in increase output and precision. |

AIPAK NF-120 Linear High Speed Tube Filling Machine |

| Rotary high speed tube filling machine:

This machine operates whole process in a circular motion unlike of linear high speed tube filling machine. For each operation tube moves to its respective station i.e. filling, sealing, coding, discharging on a round table. It fills and seals tubes in various material packaging along with efficiency and precision. It has great benefits: You get a quality product due to fast speed and well defined operational structure. It holds less space due to compact design. It is easy to maintain. Due to its profound features, it is applicable in small and large both types of production. It is integral part of different industries like food, chemical, pharmaceutical, cosmetic to dispense gels, pastes, ointments, creams etc. It is available as both semi-automatic and automatic machine, depends upon the demands of manufacturer. |

AIPAK NF-80 Rotary High Speed Tube Filling Machine |

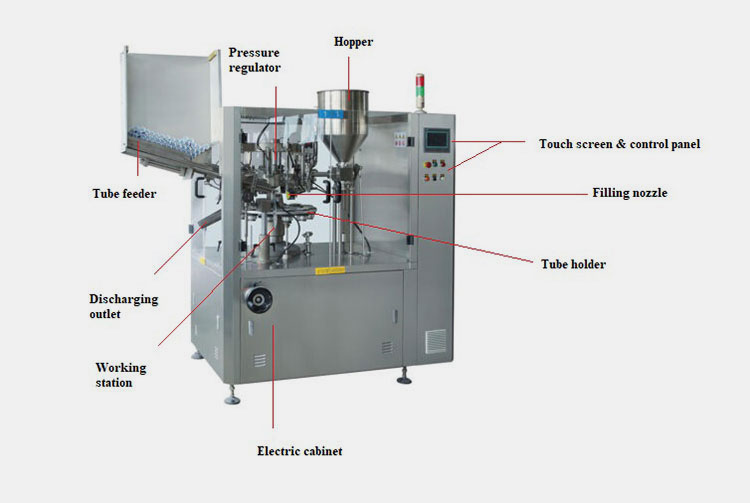

7.How you illustrate about the major components of high speed tube filling machine?

You are a buyer and looking forward to make an investment in high-speed tube filling machine, then it’s necessary for you to know about fundamental components of this machine to avoid any trouble in future.

This topic holds wholesome information about it, which is described below:

Major Components Of AIPAK High Speed Tube Filling Machine

| Major components | Function |

| Hopper | It is located at the top of this tube filling machine, to store product in huge amount, for the purpose of continuous supply of matter. |

| Pressure regulator | It contains piston which regulates pressure and by this mechanism allows the movement of correct amount of product first from hopper to filling nozzle, and then from filling nozzle to tube. |

| Filling nozzle | It performs important function of filling tube with precise amount of product. |

| Electric cabinet | It supplies electrical energy to machine for working so basically it is powerhouse of it. This part contains different wires, switches and breaker to keep operations smooth. |

| Tube feeder | It contains vast quantity of tubes to ensure un-interrupted supply and feeds them to machine during whole operation. |

| Tube holder | It holds tubes throughout the operation. |

| Working station | It is round in shape and serves like a working table to perform all the steps of filling, sealing, coding, and discharging tube. |

| Discharging outlet | Furnished tube is subjected to this tray like structure known as discharging outlet. From here tubes are collected and send forward for further packaging. |

| Touch screen and control panel | This component is responsible to control operations of machine. |

8.What are the industrial sectors in which high speed tube filling machine is applicable?

As being a buyer of high speed tube filling machine, you must be well understood about the applications of it. It provides you an edge in utilizing this machine perfectly.

This machine holds high demand in numerous industrial sectors due to fast, precise and reliable filling and sealing of daily goods. Knowledge regarding best applications of this machine is provided below:

Pharmaceutical industry:

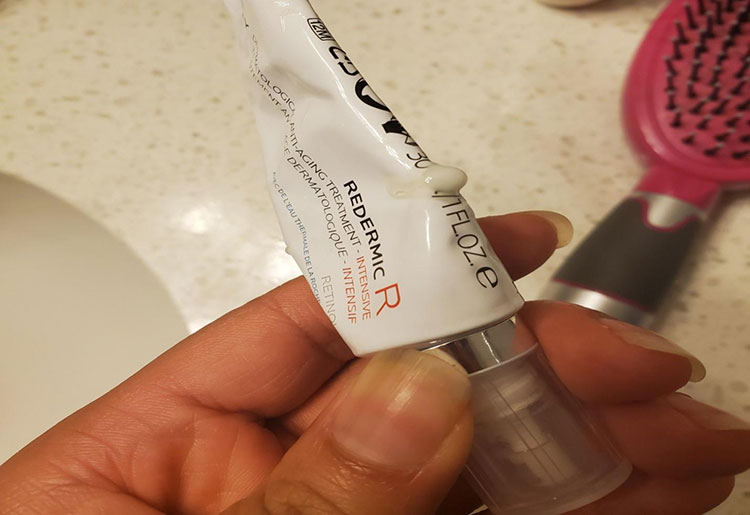

Pain-Relief Cream

You got a muscular pain and found an analgesic tube in your medical box, have you ever wondered who is behind this well-sealed and accurately filled tube? Yes, it is high speed tube filling machine. This machine secures a crucial role in filling and sealing of ointments, gels, creams and lotions in desirable tube material. It ensures accuracy & sterility of medicinal products and competency with mandatory standards. These features help to attain a high quality product.

Example:

- Ointments: antibiotic, pain relief ointments.

- Creams & lotions: Pain-relief creams, medicated lotions.

- Gels: analgesic, anti-bacterial gels.

- Toothpastes & oral gels

Food industry:

Tomato Puree-Picture Courtesy: Eat This Much

Food industry covers a huge part of our grocery. On daily basis so many products we use to make our desirable recipes. These products available in different reliable tube packaging are because of application of high speed tube filling machine in food industry.

It assures accurate, contamination-free and durable product which matches the food safety standards and costs you minimum.

Example:

- Sauces & purees such as ketchup, mayonnaise, fruit purees.

- Honey and fruit jams.

- Chocolate spreads, peanut butter & flavored syrups.

- Baby food formulations.

Chemical industry:

Tube Containing Different Paints-Picture Courtesy: Sceneries’1 Blog

Do you have any idea that these eye catching paint tubes, which are used to craft beautiful paintings, are filled and sealed by high speed tube filling machine. The products of chemical industry demand sturdy, durable and water-resistant packaging. This machine ensures to provide efficient filling and sealing of mildly and highly viscous chemical products, which enable them to save their originality.

Example:

- Adhesives like glue, epoxy resins.

- Lubricants.

- Paints.

- Cleaning and polishing agents.

Cosmetic and personal care products:

Facewash Packaged In Tube-Picture Courtesy: Spa Seylon

Face wash you use on daily basis is packaged by the help of high-speed tube filling machine. This machine employs to fill and seal cosmetic and personal use goods with accuracy in to tube of suitable material. These product needs to be packaged in contamination-free environment, which is achieved by using this machine.

Example:

- Facial creams and moisturizers.

- Beauty products like mascara, foundation.

- Hair care products.

- Lip balm, lip gloss.

- Face wash, body wash.

- Hand and body lotions.

9.What are the sizes and shapes of tubes handled by high speed tube filling machine?

High speed tube filling machine is versatile equipment, which can handles tubes of various sizes and shapes. This feature depends upon manufacturer demand and product characteristics. The information about sizes and shapes of tube is discussed below:

Tube sizes:

50 ml tubes

This machine can accommodate different sizes, which depends on type of product and machine features.

| Diameter | Usually ranges from 16mm to 60mm |

| Tube length | Adaptable between 50mm to 250mm |

| Filling volume | Lies between 3ml to 500ml |

Tube shapes:

Different tube shapes are selected on the basis of product type and packaging material.

| Round:

Commonly used for pharmaceutical, food, cosmetic goods. |

Picture Courtesy: Cosmetic Packaging |

| Oval:

Used for premium cosmetic products. |

Picture Courtesy: Custom Plastic Packaging |

| Flat:

Used for lotions, tooth paste. |

Picture Courtesy: Surbiton Dental |

| Super-ellipse (a blend of oval and round shapes):

Used for cosmetic and personal care products. This shape provides ease in handling. |

Picture Courtesy: Global Sources |

| Custom-shaped:

Some manufacturers customize distinctive tubes for making them look attractive to consumers. This is seen in skincare, beauty or personal care products |

Picture Courtesy: Design And Packaging |

10.What are the core factors you need to consider for high speed tube filling machine?

Choosing the right machine for your production is the most important thing. You cannot select it without having knowledge about its core features, which are listed below

Capacity and speed:

Increase Speed And Capacity Results In High Productivity-Picture Courtesy: Bubblelime

You must be aware of the capacity of machine either it matches your production needs or not. Secondly high speed tube filling machine can fill up to 60-300 plus tubes / min. So keep in mind to invest in such machine, which will be fruitful for you.

Versatility:

Versatility-Picture Courtesy: Good Houskeeping

High speed tube filling machine must be versatile, can package tubes of different materials, sizes and shapes in order to meet manufacturer and product requirements.

Precise filling:

Precise Filling Of Tube Results In Quality Product-Picture Courtesy: BeautyGirl.pk

You must look for a precise filling system in machine, which is achieved by the presence of pistons. These pistons build pressure and causes accurate filling of matter. This results in quality product. To avoid spillage, anti-drip nozzle system must be present in it.

Sealing mechanisms:

Aluminum Tube Sealed By Folding Method-Picture Courtesy: Naheed.pk

High speed tube filling machine must be capable of carrying out different sealing methods as different packaging materials are sealed in different ways.

As for plastic tubes, we use heat sealing method and for aluminum, it is suitable to use folding method.

Automation:

Large Scale Production Requires Automation-Picture Courtesy: Plastic Tube Packaging

For large scale production, it’s ideal to select fully automated machine. It gives you high productivity with low expenditure and decrease waste production.

For small to medium production, it’s better to choose semi-automatic machine. It has some operations which are performed manually but it provides efficient filling of product, which is your ultimate goal. It has compact design which holds less space.

Easy to maintain:

High Speed Tube Filling Machine Constructed With Stainless Steel

Machine must be constructed with stainless steel to avoid contamination as stainless steel is less corrosive.

It must be assembled easily.

It must have touch screen with PLC controls so that it would be easy to operate.

Sensor system must be updated.

It must be easy to clean, acquires uncomplicated design.

Incorporation to other production line:

Caps Are Placed On Tubes By The Help Of Capping Machines-Picture Courtesy: Ameena.pk

Machine must be capable of integrated with other systems need to be attached with it for flawless operations. For example, this incorporation could be with labelling and capping machine.

Compliance with safety regulations:

A Well-Furnished Product-Picture Courtesy: LBB

Machine must meet mandatory standards proposed by GMP, FDA in order to get well furnished product.

Operations must be carried out in contamination free and eco-friendly environment.

Manufacturer’s guide must be followed by operators.

11.What are the strategies to maintain high speed tube filling machine?

Supreme Quality Product-Picture Courtesy: Everyday Beauty

Maintenance is essential for every machine in order to get a supreme quality product. Ignorance in maintaining a machine leads to malfunctioning of it. This affects the product originality and it gets contaminated easily. Strategies to maintain high speed tube filling machine is listed below:

| Strategies | How to follow? |

| Deep cleaning and lubrication: | Parts of machine that are in continuous contact with product, must be deep cleaned after single shift

Lubrication of moving parts must be carried out. Lubricating agents must be approved by food safety regulatory. |

| Inspection of machine: | Must inspect for worn out parts of machine and replace them with good quality parts

Check for leakage to avoid inaccuracy and contamination in furnished product. |

| Calibration of machine: | Calibrate the different processes of machine i.e. tube loading, filling, sealing, coding, discharging etc. to avoid any trouble in middle of operation. |

| Monitoring of different systems: | Check electrical system for correct wiring, placement of switches etc.

Check pneumatic and sensor system. |

| Staff training: | Educate your staff about correct ways of handling machine and what measures to be taken in case of trouble.

Make sure to follow guidelines given by manufacturer. |

12.What can be the issues of high speed tube filling machine and how would you resolve them?

Inaccurate filling of product:

Improper Filling Of Product-Picture Courtesy: Bayview Pharmacy

Reasons behind improper filling of product could be many like wrong calibration of filling system, air captured in filling system, deformation of parts involved in filling process, and change in viscosity of product.

All these issues are resolved by performing proper calibration of filling system, removing air from system, replacing deformed parts with good quality parts and maintaining uniform viscosity.

Tube dislocation:

High Quality Tube Material-Picture Courtesy: CHAL Aluminium Company

This issue is caused by wrong adjustment of tube holder, poor functioning of sensors, presence of dust in tube loading system and low-grade quality of tube.

These problems have some solutions that includes; right alignment of tube loading system, deep cleaning of parts involved in tube loading, calibrate sensor system, and use high-grade quality of tubes.

Poor sealing:

Poor Sealing Of Tube-Picture Courtesy: Reddit

The main reasons of this fault are sealing method is not performed accurately i.e. incorrect application of heat and pressure, contaminated sealing jaws, presence of moisture or dirt and less quality tube and sealing material.

Solution of this trouble is to apply heat and pressure in right way to get reliable sealing of tube, clean or replace sealing jaws and other parts involved in sealing, use appropriate quality of tube and sealing material.

Machine stopped functioning:

Calibrate Electrical And Other Systems-Picture Courtesy: Information System

This happens when there is faulty electrical, pneumatic or sensor systems.

Calibrate electrical and other systems. First look for filling station either filling lines are choked or not. Then move to sealing station to check sealing rings are working properly or not.

Check electricals components for damage. Inspect pneumatic system either working efficiently or not. Update software if needed.

Conclusion:

Buying a high speed tube filling machine is an important investment that has its prolong effects on efficiency and stability of your product. It also offers eco-friendly operational processes which makes it a perfect choice for your production.

Selection of right machine is first step to get a high quality product, for this purpose you must be careful about having trustful knowledge of its features, which is mentioned in this guide. For any query, you can contact AIPAK anytime.

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine