High Speed Dispersers VS Homogenizers

Have you ever learned about the applications of high speed dispersers and homogenizers in different industries, especially the cosmetics industry? Have you ever explored the inner working principles, functions, advantages, and applications of these two devices? Why are more and more people demanding higher and higher requirements for high speed dispersers and homogenizers as technology develops?

If you are not clear about the differences or applications of uncommon dispersers, homogenizers, emulsifiers, etc. on the market, this post about high speed dispersers and homogenizers would do you a great favor. Let's take a look now!

1.What Is A High Speed Disperser And Homogenizer, Emulsifier?

High speed disperser and homogenizer are both devices used to process liquids or viscous materials.

High speed disperser

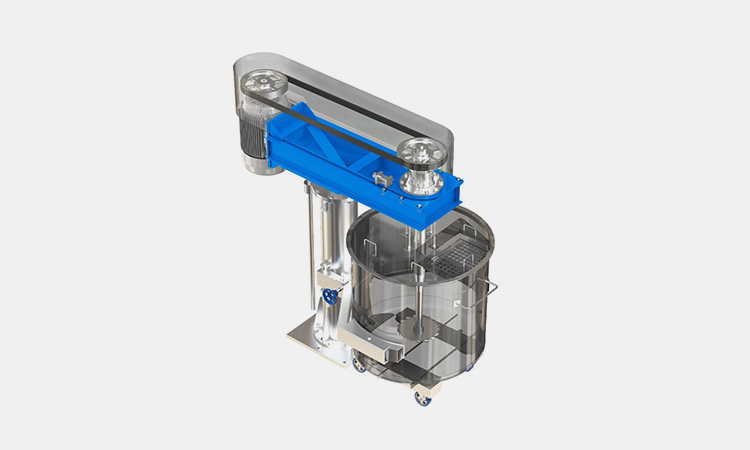

High speed disperser-sourced: gmmpfaudler

High speed disperser is used to process various polymers, composite materials, inks, coatings, adhesives and various food liquids or viscous materials. This equipment can provide you with stable particle agglomeration and dispersion functions. It can mechanically disperse solid raw materials in the solution to provide you with good results.

Homogenizer

Homogenizer-sourced: ele-mix

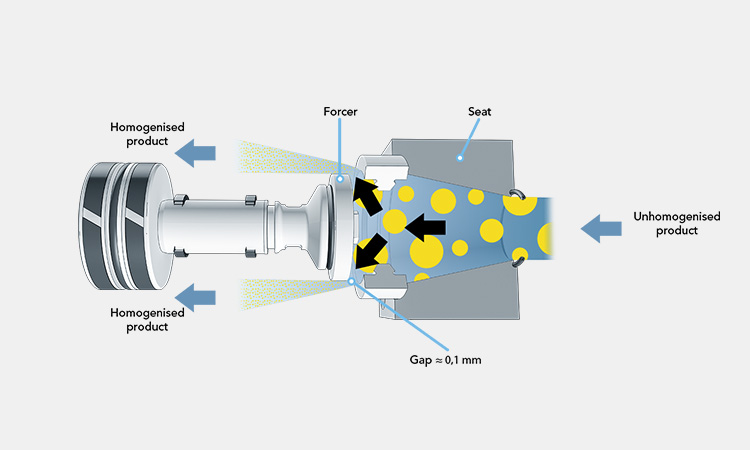

Homogenizer is a device that can generate strong shear force, impact force and crushing function under high pressure. It can disperse and emulsify various powders, particles and solutions into stable emulsions for you. This device can balance the concentration and temperature differences in the solution.

Emulsifier

AIPAK Emulsifier

Emulsifier, also called as vacuum emulsifier or vacuum emulsifier homogenizer, is a professional equipment specially suitable for the production of emulsions, dispersions and suspensions in small or large cosmetics, pharmaceutical, food and chemical industries. Compared with high-speed dispersers and homogenizers, it has a stronger mixing effect and ability to handle different materials. This equipment can emulsify, stir and mix different materials using a vacuum tank.

2.High Speed Disperser VS Homogenizer And Emulsifier: What Are Their Key Differences?

Although both high speed dispersers and homogenizers are used to achieve mixing, stirring, shearing and emulsification of various materials, their methods and effects are significantly different. These include:

| High speed dispersers | Homogenizers | Emulsifier | |

| Images |

High speed disperser-sourced: ginhong |

Homogenizer-sourced: jutaomachinery |

AIPAK Vacuum Emulsifier |

| Working principle | High-speed dispersers mainly use high-speed rotation of impellers and blades to produce stirring and shearing effects, so that different materials can be sheared and particle size can be reduced; | Homogenizers mainly reduce particles and emulsify by increasing mechanical shear force; | Put the materials to be processed into the vacuum tank;

The mixing tank in the vacuum tank has a fixed impeller; When the equipment is started, the impeller will rotate in both positive and negative directions to mix and emulsify the materials at high speed; |

| Application | High-speed dispersers are more widely used and are suitable for the processing of different materials;

It is widely used in the dispersion, shearing and tearing of particles, or the preparation of suspensions, the mixing of solutions, etc.; |

Homogenizers are mainly suitable for the application of various liquid and viscous materials;

It is mainly used to emulsify liquids or It is used to prepare suspensions, etc.

|

It is mainly used to prepare various suspensions, emulsions, etc. in the cosmetics, pharmaceutical and food industries; |

| Effects | High-speed dispersers can achieve stability and uniformity of different materials; | Homogenizers can achieve ultra-fine and emulsified processing of materials; | It is mainly used to prepare various suspensions, emulsions, etc. in the cosmetics, pharmaceutical and food industries; |

| Scale and integration | High-speed dispersers can be integrated into the entire line to carry out in-line processing of materials; | Homogenizers are generally used as stand-alone machines; | Emulsifier is usually connected to the entire production line of different materials;

After processing, it is convenient for the subsequent filling and packaging; |

| Processing capacity | High-speed dispersers are mainly suitable for processing small batches or medium materials;

More suitable for laboratories or small-scale production; |

Although homogenizers are used as stand-alone machines, they are usually suitable for processing large volumes of materials; | It is able to handle different materials;

Empty tanks are very suitable for handling very sensitive and highly reactive materials; |

3.What Are The Applications of High Speed Disperser And Homogenizer, Emulsifier?

Both of them have a wide range of applications, including chemical industry, pharmaceutical food processing, coatings, cosmetics and other industries.

Chemical industry

Chemical industry-sourced: camachem

In the chemical industry, they can be used for the processing and mixing of various chemicals, coatings and pigments. Such as coatings, paints, and detergents.

Pharmaceutical industry

Pharmaceutical industry-sourced: capecrystalbrands

In the pharmaceutical industry, they can make various emulsions and suspensions with high precision and high active ingredient content. The equipment can ensure that various active ingredients can be evenly mixed in the solution you need.

Food industry

Food industry-sourced: simplyhomecooked

In the food industry, high-speed dispersers and homogenizers can help you process and make various creams, sauces, beverages, and soups. By homogenizing the product, you can ensure the consistency of the smoothness of your food.

Cosmetics industry

Cosmetics industry-sourced: ecology

The application in the cosmetics industry is huge, from various emulsions to face creams, lipsticks, and makeup, it can ensure that pigments and active ingredients are evenly added to different emulsions.

4.What Are The Functions of High Speed Disperser And Homogenizer, Emulsifier?

Generally speaking, their functions are similar. But in detail, their functions are different:

Main function of high-speed disperser

Main function of high-speed disperser-sourced: gmmpfaudler

The main function of a high-speed disperser is to mix various materials, such as particles, solids, liquids or powders. It can help you get a stable, high-precision and uniform mixture. And by generating shear force through high-speed rotation, it can shear, disperse and mix the raw materials.

Main function of homogenizer

Main function of homogenizer-sourced: wikipedia

The homogenizer is different. It mainly refines and homogenizes the material through high-precision and high-intensity mechanical shear force. Its processing mainly includes extrusion, cutting or shearing. It can make larger particles or viscous materials smaller, finer and more uniform.

Main function of emulsifier

Main function of AIPAK vacuum emulsifier

The main functions of the vacuum emulsifier are mixing, dispersing and emulsifying. It can simultaneously function as a high-speed disperser and a homogenizer. At the same time, it can handle emulsions of different viscosities. Whether it is cream, lotion, ointment, cream, medicinal ointment, oral syrup, etc., they can all be processed using a vacuum emulsifier.

5.What Are The Types of Dispersion Blades For Your Choice?

The blades of high-speed dispersers are mainly used for shearing and mixing materials. There are three types of blades for high-speed dispersers. These include

Cowles blades

Cowles blades-sourced: morehousecowles

It can mainly provide you with equal shearing amount and flow rate.

High flow blades

High flow blades-sourced: mixerdirect

The high flow blade mainly adopts a geometric axial flow structure, which can provide you with high flow shearing process and strength.

Ultra shear blades

Ultra shear blades-sourced: mixerdirect

Ultra shear blades are usually used in higher-level industrial fields. It can greatly improve the shearing force and strength by increasing the shearing area of the blade, and can more professionally handle large flow and large capacity material processing.

6.What Are The Types of Homogenizer For Your Choice And Their Stators?

The types of homogenizers mainly include:

Rotor stator homogenizer

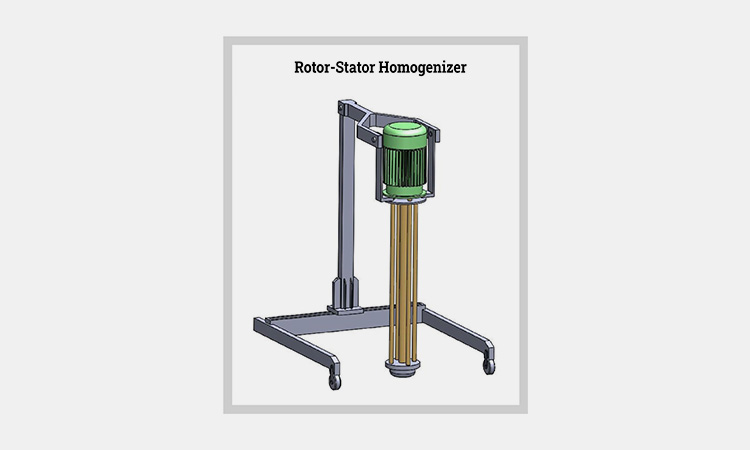

Rotor stator homogenizer-sourced: industrialmixers

Rotor stator homogenizer mainly adopts rotor and stator design. Its structure is relatively simple and its function is relatively single. It is more suitable for small-scale industrial applications and laboratory applications.

High-pressure homogenizer

High-pressure homogenizer-sourced: duoningbio

Through the special high-pressure design, it can provide high-intensity shear force to the material through the valve. It is very suitable for materials that are difficult to handle.

Ultrasonic homogenizer

Ultrasonic homogenizer-sourced: homogenizers

Through the special ultrasonic design, the ultrasonic homogenizer can facilitate the processing and mixing of your materials.

The rotor is an important component of the homogenizer for processing materials. Its main function is to provide shear and mixing for different materials. In order to meet the challenges of different materials, you can choose the following types of rotor structures:

Angle slot stator

Angle slot stator-sourced: indmixers

The angle slot stator mainly uses inclined vertical slots to guide the rotor to rotate at high speed, thereby generating high-intensity shearing. It can handle products with viscosities up to 10,000 cps.

Emulser stator

Emulser stator-sourced: mixerdirect

It is mainly suitable for processing low-viscosity mixtures, such as fine emulsions or suspensions. Emulsifier stator are often used in the pharmaceutical industry to help you process more delicate and consistent products.

General purpose stator

General purpose stator are widely used and perform well. They can help products flow at high speeds under the rotor.

7.What Are The Benefits To Choose High Speed Disperser And Homogenizer?

Whether it is a high-speed disperser or a homogenizer, they can bring you different advantages.

The advantages of a high-speed disperser are:

Flexibility

Flexibility-sourced: longxing

High-speed dispersers are suitable for materials of almost all sizes, materials and capacities. By using a disperser with matching capacity, you can choose a variety of different batches of materials to process at one time.

Scalability

Scalability-sourced: azonano

High-speed dispersers are not only suitable for small-scale laboratories, but also for medium or large-scale pharmaceutical and chemical industries.

High-speed mixing

High-speed mixing-sourced: multimix

High-speed dispersers can provide you with stable and high-intensity material mixing and shearing. For the processing of various materials, it can provide very high-quality processes and effects.

Safety

High-speed dispersers use various protection measures and safety settings to ensure that you will not be in any danger during use.

High efficiency

High-speed dispersers can quickly and stably disperse, dissolve and mix various materials. Compared with traditional methods, it can provide you with high-quality material processing in a shorter time.

High-quality processing

High-quality processing-sourced: dairyprocessinghandbook

High-speed dispersers and homogenizers can provide you with excellent and consistent mixture processing. Among other things, they help you reduce the particle size of your material to a minimum, giving you options for handling a wide range of material sizes.

8.What Are The Main Materials Made For High Speed Disperser And Homogenizer?

Main Materials Made For High Speed Disperser And Homogenizer-sourced: hongtai

High-speed dispersers and homogenizers are usually made of high-quality food-grade stainless steel. It can ensure high-intensity material handling and has good corrosion resistance. In addition to providing your equipment with a longer life, it can also reduce weight.

9.How Does High Speed Disperser And Homogenizer Work?

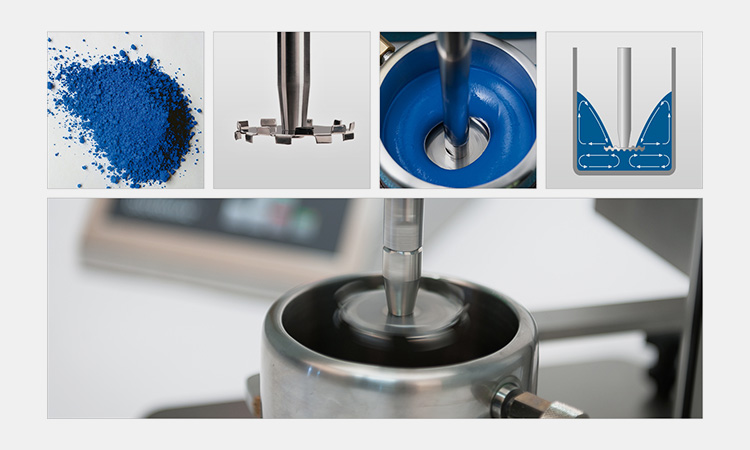

High-speed dispersers mainly use speed rotation to reduce the size and viscosity of particles in the material. Its working principle is:

Working principle of high speed dispersers-sourced: FRANLI

- High-speed dispersers use a high-speed impeller design. When the equipment is started, the blades with serrated edges will rotate at high speed;

- When the blades rotate at high speed, the strong flow will absorb and continuously mix the materials in the equipment;

- When the impeller speed of the equipment increases, huge shear force will be generated;

- This shear force will continuously shear and reduce the size of the material;

- When the equipment continues to shear and mix, a smooth and highly consistent mixture will be formed in the end;

- Both the size and viscosity of the particles will be reduced.

The working principle of the homogenizer is very simple. It is:

Working principle of homogenizers-sourced: Silverson Machines

- When the equipment is working, huge pressure will be generated through the valve inside the equipment;

- This pressure will form a shock wave, which will impact, tear and destroy the particles;

- When shear force is generated, the high pressure inside the equipment will cause cavitation effect in the center;

- This cavitation effect will further shear and tear the materials in the equipment;

- When the materials in the equipment are torn and sheared, a high-speed fluid will be formed in the equipment;

- This fluid will continuously generate heat to melt and fuse the materials.

10.What Are The Key Components of High Speed Disperser And Homogenizer?

By understanding the components of the equipment, we can further understand the operating principle of the high-speed disperser. Its main components are

Key Components of High Speed Disperser-sourced: mixerdirect |

|

| Motor | The motor of the high-speed disperser can provide huge energy and high-speed rotation for the rotation and shearing of the equipment. This rotation force can handle materials of various viscosities. |

| Shaft | The shaft is a bridge specially used to connect the motor and the impeller of the equipment. It is responsible for transmitting the rotational force generated by the motor to the impeller, so as to ensure that the equipment can smoothly and effectively output torsional force and rotational force during operation. |

| Impeller | The impeller is one of the most critical parts of the equipment. It mainly adopts a blade design with a serrated edge or a toothed edge, which can provide a strong shear force for the equipment to disperse and tear particles in the material. |

| Container | The container of the equipment is mainly used for storage or space for material processing. It is usually made of 314 stainless steel. This component can provide you with safe and stable material processing. |

| Mounting system | The equipment mounting system mainly includes various fixtures or brackets. It can effectively prevent the vibration generated by the equipment during operation. |

The equipment structure of the homogenizer is relatively simple, and it mainly includes:

Key Components of Homogenizer-sourced: scienceinfo |

|

| Homogenizer valve | The homogenizer valve is the core component of the homogenizer. It is mainly used to adjust the tension between various springs. The homogenizer valve is usually composed of a valve, a valve seat and an impact ring. |

| Homogenizer pump | It can continuously transmit the required pressure for the equipment. |

| Breaker ring | The breaker ring is the main component of the homogenizer valve. When the material you need to process enters the valve, the breaker ring can provide you with a vertical impact destructive force, which can further reduce the size of your particles. |

| Tension spring | It can provide the required tension for your access, thereby increasing reliable pressure. |

11.How To Choose Between High Speed Disperser And Homogenizer?

Both high-speed dispersers and homogenizers can handle a variety of different materials. But the choice depends on the following factors:

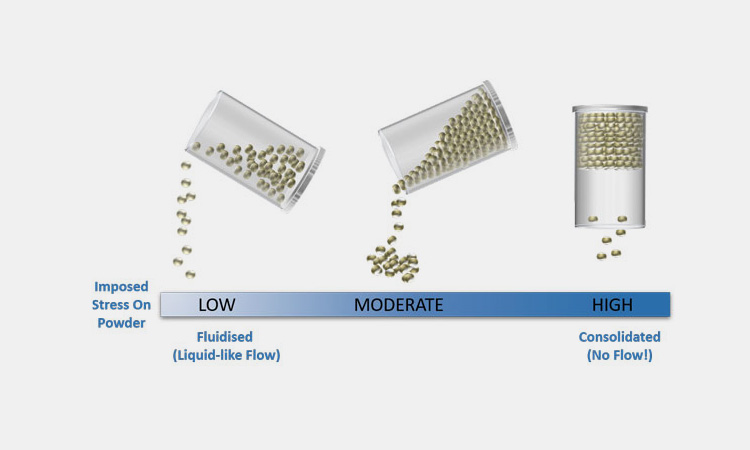

Material particle size

Material particle size-sourced: wstyler

If your needs for material processing are to reduce the particle size with more efficient mixing and dispersion, then a high-speed disperser is your best choice.

Emulsion stability

Emulsion stability-sourced: biolinscientific

If you pursue the stability of the final emulsion, then a high-speed disperser is your best choice.

Capacity and scale

If the initial material particles are coarse and the particle size difference is large, then a high-speed disperser can provide you with a perfect solution. If you need to control the stability and precision of the mixture, then a homogenizer is better.

Material properties

Material properties-sourced: freemantech

If you need to handle more sensitive materials, then you can choose a homogenizer. If you need to handle materials with higher particle size or harder materials, then a high-speed disperser can provide you with the best results.

Material viscosity

Material viscosity-sourced: anton

If the viscosity of the material is thicker, that is, the more viscous the material is, the greater the power of the equipment you need, then a high-speed disperser will work very well. If the viscosity of the material you need to process is lower and the water content of the solution is higher, then a homogenizer will be your better choice.

12.What Are The Safety Measures You Should Follow To Ensure The Good Performance of High Speed Disperser And Homogenizer?

High-speed dispersers and homogenizers are both extremely precise equipment. The following safety measures must be observed during use:

Safety Measures You Should Follow To Ensure The Good Performance of High Speed Disperser And Homogenizer-sourced: getzmann

- The protective cover of the mixing shaft must be set up;

- The switch with limit must be handled properly;

- The limit switch on the lifting device can prevent the operator from accidentally touching the machine blade, etc.;

- Before use, the equipment and the tank of the equipment must be thoroughly cleaned;

- Select the appropriate formula;

- Before use, the use status of the blade must be confirmed;

- When the equipment is started, the rotation speed of the blade must be set.

13.What Are The Precautions When You Are Using A High Speed Disperser And Homogenizer?

Following the steps below will provide you with the best results.

Precautions When You Are Using A High Speed Disperser And Homogenizer-sourced: infectioncontrolresults

Before using the equipment

- When the equipment is not in use, be sure to cut off the power supply and clean the outside and inside;

- The core part of the equipment and the blade part must be covered with a protective cover;

During the use of the equipment

- The equipment must be monitored and inspected regularly during use. Once overheating or noise is found, the operation of the equipment must be stopped immediately;

- When the equipment is running, do not add any materials to the mixer in the equipment tank;

- During the operation of the equipment, it is strictly forbidden to place various packaging bags and items in the rope into the tank to prevent entanglement accidents;

- When the equipment is running, guards and monitoring personnel must be set up to prevent safety problems;

After using the equipment

- Regularly check the wearing parts and bearings of the equipment. If the parts of the equipment are found to be severely worn, they should be replaced and adjusted immediately;

Conclusion:

High speed dispersers and homogenizers are excellent equipment in the industry. They are designed to provide you with efficient and high-quality product production and preparation. Through this high speed dispersers VS homogenizers post, you can learn that they can provide you with high-quality solutions for a variety of materials. If you want to know more about high speed dispersers and homogenizers, come and consult AIPAK now!

Don't forget to share this post!

Vacuum Emulsifying Mixer Related Posts

Vacuum Emulsifying Mixer Related Products

Vacuum Emulsifying Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide