High Shear Mixer Granulator For Candy Chips: The Complete Buying Guide In 2025

Have you ever wondered how your favorite candy chips get that perfect crunch, shimmer and melt-in-your-mouth magic? It is not just a sugar and flavor, it is a hard working machinery doing their exceptional work. Do you know the hero behind your favorite candy chips manufacturing?

It’s a high shear mixer granulator. The silent hero that work hard in candy chip industry.

In 2025, as the consumers expectation are rising and with the candy chips industry booming, it is not just essential to make high quality candy chips but it is also necessary to invest on the right high shear mixer granulator.

High shear mixer granulator not only make your favorite sweet candies, but also making sure to add vibrant and uniform in size candies.

Let’s explore the machine used, its components and how to use it so that your investment worth it. Keep reading!

1.What is high shear mixer granulator for candy chips?

High shear mixer granulator for candy chips

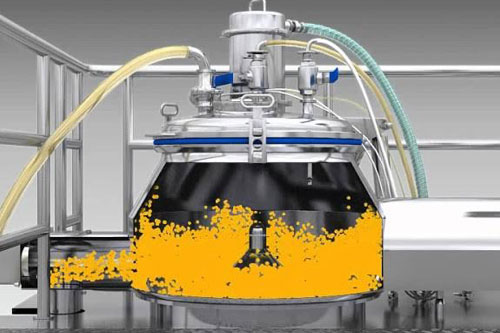

A high shear mixer granulator for candy chips is a specialized machine used to mix, knead, and granulated ingredients at high speed to produce a uniform dough. This dough is combined with syrups and other ingredients and embark on the process of mechanical forces and high shear and shape the mass into candy chips.

This machine is used for the uniform, homogenous and enhanced product quality in the confectionary industry.

2.What are the benefits of using high shear mixer granulator for candy chips?

While investment on high shear mixer granulator, you must know about the benefits you can get from this machine. Here is a detail overlook.

Microstructural uniformity

Microstructural uniformity-Picture courtesy: pixabay.com

High shear mixer granulator ensures the uniform mixing and granulation formation. It ensures mixing of fine particles, binder distribution, flavor mixing and distribution of sugar crystal at microscopic level. By this homogenous mixing, you can obtain even sweetness, smooth texture and vibrant colors candy chips.

Enhanced flavor release

Enhanced flavor color

As this equipment ensures the evenly distribution of flavor at micro-level so, you will be noticed the uniformity in whole chips. With each bite, your sensory nerves experience a delicious, balanced and consistent profile.

By consumption of these flavored candy chips, you may not need other flavoring agents for assistance.

Improved shelf life

Improved shelf life

The high shear mixer granulator ensures the precise control over moisture and quick drying procedure. The reduced moisture content in your candy chips ensured the safety against microbial growth, and prevent the granules from spoilage.

Moreover, this equipment mixes well all the sugar crystals with other ingredients so, the candy formed in this machine are stable and do not deteriorate its quality for a long time. In this way, these candy chips have long shelf life.

Reduced air entrapment

Reduced air entrapment-Picture courtesy: pexels.com

This equipment is expert in forming high quality granulation and minimize the entrapment of air into the candy mass. If there is less air entrapment, then it is difficult to suffer from oxidation and hence, less spoilage.

Due to this quality, it ensures the structural integrity of the candy chips and improved the quality and shelf life of candies.

Repeatability and predictive quality control

Repeatability and predictive quality control

The high shear mixer granulator has programmed temperature, speed, time and granulation size so it produced a uniform batches. This consistency is necessary for your quality assurance.

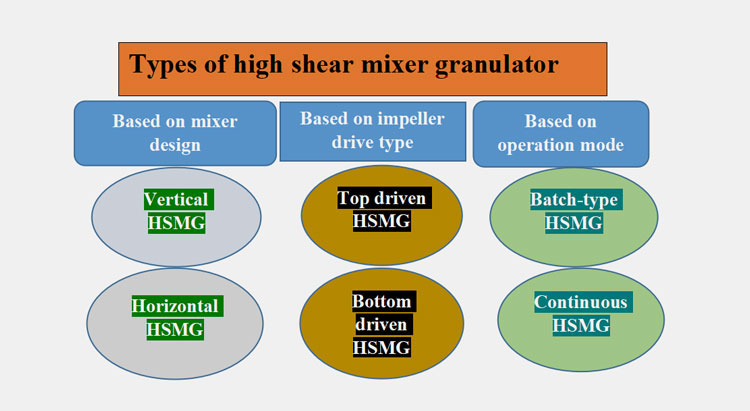

3.What are the types of high shear mixer granulator for candy chips?

Types of high shear mixer granulator

There are various types of high shear mixer granulator is used for making candy chips in confectionary factories. They are categorized into various types depending on the design, mixing orientation and the production mode.

Based on mixer design

Based on the mixer bowl design, it is divided into two types.

Vertical high shear mixer granulator

Vertical high shear mixer granulator-Picture courtesy: loedige.de

The vertical high shear mixer granulator is designed in such a way that the bowl is vertical and holds the ingredients. The impeller is fitted at the center or at the bottom of the mixing bowl.

This machine is best for general purpose granulation in both research and development and batch production.

The benefit you can get by using this equipment is it can easily be cleaned and sanitize, also good for batch processing and you can get consistent quality batches.

Horizontal high shear mixer granulator

Horizontal high shear mixer granulator-Picture courtesy: AIPAK

The horizontal high shear mixer granulator is designed in such a manner that it has horizontal chamber with rotating impellers.

It is best suitable for the sensitive ingredients. If you are making dense, sticky and heat sensitive candy then you can go for this machine.

The advantage of using this tool is easier discharge for sensitive candies as it has horizontal layout.

Based on impeller drive type

Based on the impeller attachment to the bowl, it is divide into two types.

Top-driven high shear mixer granulator

Top-driven high shear mixer granulator-Picture courtesy: freundglobal.com

The top driven high shear mixer granulator is crafted as impeller is powered from the top.

It is best suitable for good manufacturing practice (GMP), having cleanliness and controlled environment system. It can also be installed if the floor space is limited.

The main advantage you can get by using it to prevent the chance of motor contamination.

Bottom driven high shear mixer granulator

Bottom driven high shear mixer granulator-Picture courtesy: pharmacy-machines.com

As the name indicated, the impeller in bottom driven granulator is attached at the base of the mixing bowl.

This equipment is suitable for handling high efficiency handling and fast processing.

The merits of using this machine are high shear forces that make your dough consistent. It ensures uniform mixing of dense or thick candy mass production.

Based on operation mode

Based on the production of candy chips, it is divided into two types.

Batch-type high shear mixer granulator

Batch-type high shear mixer granulator

This granulator is suitable for processing one batch at a time. This machine is suitable for flexible and precise batch production. The advantages you can get by using it to reset between the flavors and great for testing new candy chips formulas.

Continuous high shear mixer granulator

Continuous high shear mixer granulator

Continuous high shear granulator has constant input and output operation. It is suitable for high volume candy chips production. It can reduce the batch to batch variability and ideal for continuous production batches.

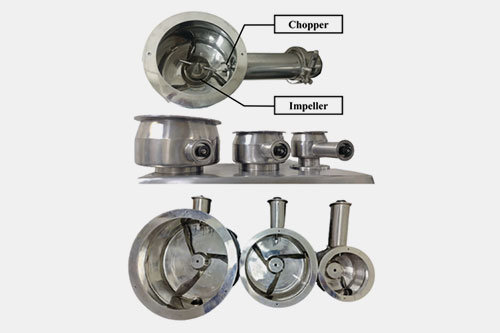

4.What are the main components of high shear mixer granulator for candy chips?

High shear mixer granulator is carefully designed to form the delicate candy chips with high quality. The main components are as follows:

| Mixing bowl

Mixing bowl |

The mixing bowl is a central chamber where all the ingredients used in making the candy chips are loaded and processed.

Mixing bowl is made up of stainless steel which is very essential for food processing items. It may be jacketed for temperature control. The size of mixing bowl vary depending on the batch production. |

| Impeller

Impeller |

It is the backbone of the machine because it is used for primary mixing and agitating of the ingredients. It mixes powder, sweet syrup and preservative at moderate to high speed and ensure even blending to begin candy granulation. |

| Chopper blade

Chopper-Picture courtesy: Springerlink.com |

The chopper blade functions in breaking down the lumps into fine particles. It rotates at very high speed to ensure the prevention of the agglomeration and controls granule size. It also helps in improving the texture uniformity of the candy chips. |

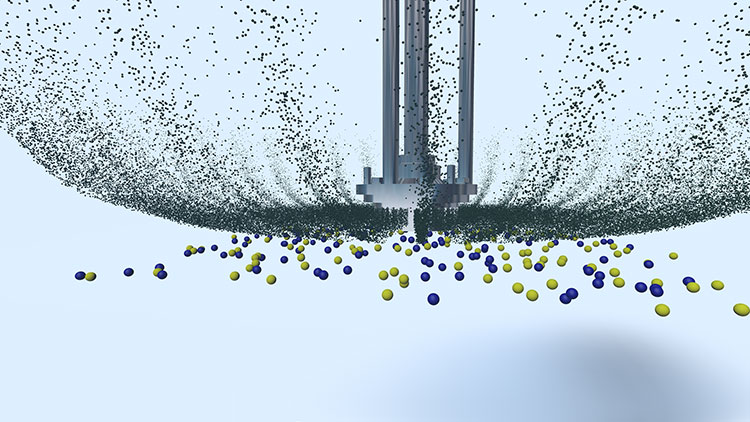

| Binder liquid spray system

Binder liquid spray system-Picture courtesy: pharmec |

The binder spray nozzle is mounted at the top of the mixing bowl. The control system in the nozzle adjust the viscosity of the binder and pressure at which the binder solution is dispersed into the powder. It helps in binding the particles by preserving the flavor. |

| Motor and drive system | Usually two motors are implemented in this machine. One powers the impeller while the other powers the chopper.

It is sealed and food safe design. |

| Control panel | The control panel act as a brain of the machine. It manage all the operational setting used in making the candy chips. By this, you can adjust the speed, mixing time, spray nozzle setting and temperature for the consistent batch production. |

| Discharge unit

Discharge unit |

It is the outlet valve which can be automatic or manual depending upon the brand. It allows the finished candy chip mass to release from the bowl and you can now store a high quality candy chips. |

| Lid with safety lock

Lid with safety lock |

It is the cover which provide a sealed and close atmosphere to the bowl and prevent it from cross contamination. It has also viewing window through which you can view the process occurring during the candy chip production.

It has also ports which is specialized for binder input into the ingredients. |

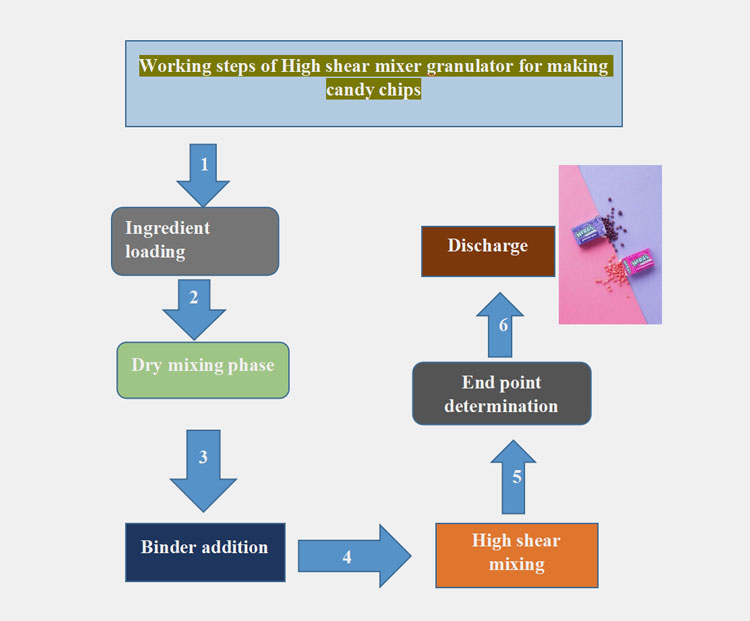

5.What are the working steps of high shear mixer granulator for making candy chips?

Working steps of high shear mixer granulator for candy chips

Imagine transforming the ingredients into crunchy and mouthwatering candy chips with high tech granulator. Here are the steps how it works, to do this fantastic job.

Ingredient loading

Ingredient loading

In the first step, add the raw materials in to the mixing bowl. You have to add powders like milk solids, sugar, citric acid and cocoa (if flavored) and additives i.e. food colors, flavors, emulsifier and stabilizers.

Ingredient loading should be done in clean and sealed environment to ensure preventing cross contamination.

It also ensures accurate weight based dosing for its consistency. The ingredients can be done through automated hoppers or through manual feeding.

Dry mixing phase

Dry mixing-Picture courtesy: saintytec.com

In this phase, all the ingredients are distributed homogenously. The clumps or segregations are eliminated in the final granule. By this, it prepares an even base that is free of clumps for the addition of binding solution in the next step.

Do you know which part of the machine does this job? You need to know the interior of the machine and its job. This job is done by impeller and chopper blade. The impeller rotates at moderate speed to mix the ingredients while the chopper blade de-agglomerate fine particles at low speed.

Binder addition

Binder addition-Picture courtesy: grandpackmachine.com

In this phase, binder is added to form granules. The binder solution usually you can use in candy chips are corn syrup, sugar solution, glucose syrup and water.

Are you curious to know how can this binder be added? Well, the granulator has spray nozzle through which the binder is distributed into the powder under pressure. If viscous or thick binders are used, then some systems also have heated nozzles that produce heat and by this, you can get less viscous binder which can easily be distributed in the powder homogenously.

The controlled system monitored the binder volume and its flow. You must be ensured that the binder solution should be added gradually to prevent over wetting and get a candies that has flowability.

High shear mixing

High shear mixing-Picture courtesy: mixingtanksusa.com

In this phase, the combine effect of shear force and mixing, granulate the mass. The impeller speed is increases in this phase and moves the mass in the radial and tangential direction. The chopper speed is very high and it breaks down forming clumps, helps in refine granule size.

By the mutual effort of impeller and chopper, you get dense, cohesive and moist granules. The formation of sticky mass make it flow for further processes.

End point determination

End point determination-Picture courtesy: mixquip.com

You can inspect the non-sticky and properly formed granules through the bowl lid. If you find them nice and consistent granules then you can shaped into the different shaped candy chips.

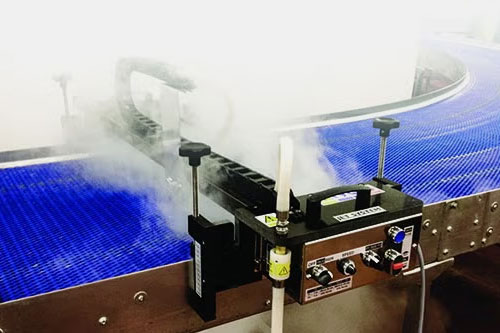

Discharge

Discharging of candy chips-Picture courtesy: hywellco.com

In this phase, the prepared candy mass or granules are removed from the bowl. You can discharge the candy chips either manually or through automated discharge on to the conveyor or you can also collect them into the collection trays.

The discharge part is designed like a slope that ensures full discharge of candy chips. You can collect the final candies.

6.Is high shear mixer granulator suitable for small scale candy chips production or only for large factories?

High shear mixer granulator for small and large scale production-Picture courtesy: nupharmamachine.com

Absolutely! You can use high shear mixer granulator for both small scale as well as large scale production of candy chips. Let’s dive into the more detail:

Suitable for small scale candy chips production:

Are you really want to produce candy chips on small scale? Or wants to test new flavors of candy chips? You have the hero in the market that can reduce your headache. The small-capacity models (10 liter) of granulator is suitable for startups and you can test multiple formulas quickly in it with reduced cost and ingredient waste.

It has a system that controls impeller and chopper speed, time setting and nozzle spray adjustment which results in uniform, high quality and controlled shape and texture candy chips.

Suitable for large scale production:

If you want large scale production of candy chips then invest on the large sized (ranging from 25 liter to several hundred liters) granulator. It produces continuous and large scale candy chips meeting the demands of wholesale order and supermarkets.

This machine reduces the mixing and granulation time and you can get full batch within 10 minutes.

You can test different formulas for candy chips with a small scale model, once you get perfect candy then you will able to know the perfect recipe and technique. This technique is then implement on large scale model without needing to change your process.

7.What role do chopper blades and binder liquid distribution play in candy chip texture and granule uniformity?

Have you ever wondered how every bite of candy chip has a uniform texture and flavor? The secret lies in the game changing hero known as impeller and binder. Let’s dive into the magic bringing in the candy chips production.

Role of chopper blades

Role of chopper blade in candy chips texture

If you look at the anatomy of high shear mixer granulator, the chopper is implement on the side of the mixing bowl. It is a high speed blade that prevent the agglomeration and de-agglomerated the particles.

Impact on structure and uniformity:

The effect of chopper blade on the candy chip texture and granule uniformity is as follows:

The chopper speed ensures the final candy chips are consistent in size and shape by breaking the large sized and wet masses into fine particles and granules.

It also prevent the sticky mass formation due to which you can get poor texture and uneven shapes of the candy chips.

Due to high speed blades, you can get homogenous mixing of sugar and other fat based substances.

It also produces uniform surface of the granules which is very crucial for the flowability and compressibility of the granules.

Role of binder liquid distribution:

Role of binder liquid distribution in candy chips

The binder liquid is sprayed through the nozzle in to the dry mixture to form wet granules. The possible binder solution used in candy chips making are glucose syrup or sugar solution.

Effect on texture and uniformity:

The possible effect of the texture and on uniformity are as follows:

By proper spraying the binder solution on the particles ensures equal receiving the binder and forming the even granulation.

The uniform binder distribution bind the particles properly without excessive compression which gives strength to candy chips.

The uniform binder liquid distribution creates candy mass with consistent density which is essential for mouth feel.

8.Can you use the high shear mixer granulator with new candy chip formulas and flavors?

Think of high shear mixer granulator as a high technology kitchen for making candy chips. If you want to bring changes in candy chip formulas and flavors then absolutely, it can brings innovation in confectionary production.

The high shear mixer granulator brings creative ideas to your life with consistency and precision. Here is a close look for why you can use it for new candy chip formulas and flavors.

Flexibility with ingredients

Flexibility with ingredients-Picture courtesy: crazyforcrust.com

The HSMG is capable of try out natural and artificial flavors, sweeteners and colorants. It can even try out to handle functional additives like caffeine and probiotics as well.

So, this machine can handle all kind of flavors and candy chip formulas by evenly distribute everything and your new flavor profile will also be consistent in every bite.

Rapid prototyping

Rapid prototyping

Do you want to test a spicy orange chip one day and a fizzy cola one the next day? And you also want economically small batches.

Well, this equipment is smart in handling and mixing. You can test small experimental batches through which you can initiate craft candy setups and large production developing seasonal and limited edition flavors. This equipment is also expert in reset between the trials. You can set all the process parameter for the consistent batch production.

Texture with mouthfeel control

Texture of candy chips

Do you know different formulas affect the texture of your desired candy? Some ingredients you used in this process may make it too sticky, grainier or chewier. But in this pioneering tool, you can adjust the mixing time, binder volume and impeller speed to how you can make your candies that melts and affect your customer’s sensory experience.

Scalable success

Scalable success-Picture courtesy: inkme.bio

Once you have accomplishes the perfect formula then you can adjust high shear mixer granulator for large- scale production as well. You can get perfect large batches with the same formula without effecting the quality and consistency of the batch.

9.How to maintain high shear mixer granulator for candy chips?

The maintenance of high shear mixer granulator used for candy chips or other confectionary product is very important. The maintenance of tis machine involve cleanliness, lubrication, and inspection and part replacement. This will ensure that your equipment will produce high quality, germ free products and longevity of the machine. Let’s explain them:

Daily maintenance

Daily cleanliness-Picture courtesy: espcleaning.sg

You must clean the machine after each batch. The syrup and sugar used in candy chip production may stick to the machine parts, you must wash them with warm water.

You must check the sealing to prevent leakage or contamination.

Also inspect the mixing tool like chopper and the impeller.

Weekly maintenance

Lubrication of machine-Picture courtesy: gulfoilltd.com

Once a week, you must lubricate the machine parts by using food-grade lubricants.

Also inspect the sensors and ensure that there is no moisture content in the machine. You must also check for the loose fittings and make sure to tighten them.

Monthly maintenance

Monthly maintenance-Picture courtesy: envirofluid.com

In a month, you have to calibrate the sensors for accurate operation. If there is abnormal vibration or noise then check the gearbox and drive systems.

You can also replace the parts if you find them wear down.

Once in a month, dis-assemble the parts and wash, clean and sanitize them with food grade sanitizer.

10.What hygiene factors are to be considered while operating high shear mixer granulator for candy chips?

When you are operating high shear mixer granulator for candy chips or other confectionary products, you must focus on the hygiene because it is very necessary. Here are some of the hygienic measures that you must to be consider while candy chips making.

| Features | Detail |

| Material of construction

|

The machine must be made up of stainless steel which can be considered as a food-grade. Stainless steel have less chances of corrosion. That’s why it is considered as good for carrying food ingredients. |

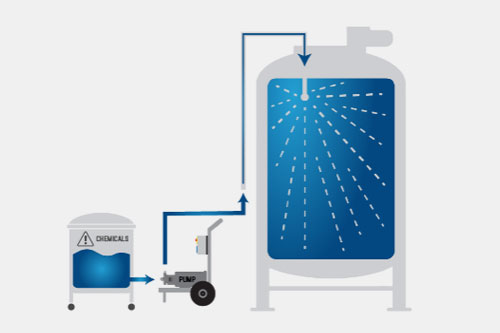

| Easy-to-clean design | The machine parts also be able to disassemble or you can say, you can deconstruct and reconstruct them. Due to this blessing, you can easily clean the syrup and other sticky materials used in candy chips making and can also sanitize the machine. Due to this feature, it may have no chance of the residue retention and microbial growth. |

| CIP system for cleaning

|

If your machine have clean_in_place and steam-in-place system then you can get benefit from it without dissemblance of the machine parts. This will allow to clean and scrub the residue in your machine without requiring disassembly of machine parts. |

| Routine sanitation

Picture courtesy: Goodway technologies |

You are dealing with sugar and other fat-based material so, if you will not clean it then there is high risk of microbial growth. You must have clean and sanitize the machine parts in order to prevent any cross-contamination. |

| Proper sealing | You must have to seal the machine to prevent any entry of foreign agent or contamination. Otherwise, they will enter into the confectionary items and the consumers may suffer from food poisoning. |

11.What safety features should you look for when buying high shear mixer granulator?

When you are buying a high shear mixer granulator, especially for food application like candy chips, you must look for the safety features that protect the product quality and the operator. Here are the essential safety features that must be considered while buying it.

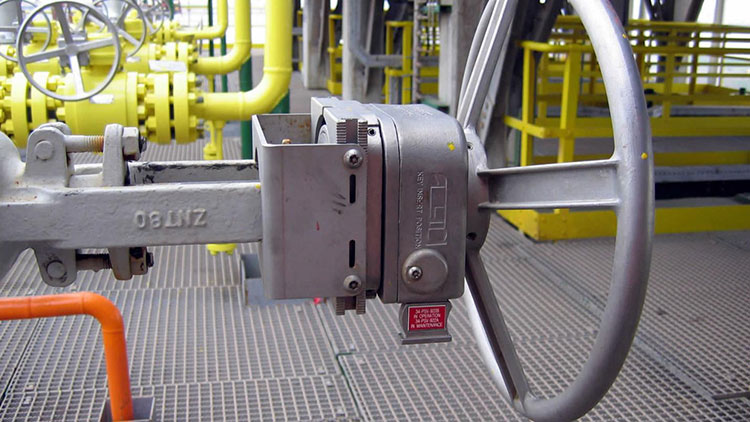

Interlocking system

Interlocking system-Picture courtesy: sofisglobal.com

You must be look for the interlock system which is used for the safety of ingredients inside the bowl. Make sure not to run the machine if the valve is open.

Emergency button

Emergency button

You must be noticed that the emergency button is easily accessible for the operator from all the sides. If there is a need to stop the operation immediately, then operator can easily turn off the machine and stop the process.

Safety guards and shields

Safety guards and shields

If there will safety shields like transparent cover or stainless steel covers over the moving parts, then you can easily inspect the process as well as to handle the accidental contact with any parts.

Hygienic design features

The machine must be buildup of stainless steel which is food-grade and prevent any bacterial growth.

PLC control with alarm system

PLC control with alarm system-Picture courtesy: control.com

It must have control system in which you can easily adjust the process timing and ingredients amount.it must also have alarm system, If pressure or overheating occur, then it must alert the operator for smooth batch production of candy chips.

Conclusion

High shear mixer granulator is used for the production of candy chips or other confectionary products. HSMG from AIPAK is an excellent investment because it ensures the mixing and granulating the uniform and efficient candy chips production.

This machine is made from stainless steel material which is best for user friendly operation. It is suitable for both small-scale batch production and industrial production. Choosing us guarantees your enhanced quality production!

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine