High Shear Granulator:The Ultimate Importing Guide in 2025

Mixing powder is an art!

High shear granulator is an important instrument for the mixing of chemicals for pharmaceutical dosage formulations. It is used to mix dry powders at the high speed. It also helps in the formulations of wet pellets. High shearing forces in these granulators easily mix aqueous solution and granules.

It is widely used in the pharmaceutical industry due to its production of high-quality granules. The use of high shear granulator results in even mixing of chemicals, less time in formations of granules, and control of granules size.

Procuring this machine is very beneficial for your business. But before purchasing this machine let's learn about some features and benefits of high shear granulator.

AIPAK High Shear Granulator

This guide is packed with lots of useful information about high shear granulators. By going through this blog, you will learn about different aspects of high shear granulator such as its characteristics, design, parts, working, maintenance, troubleshooting, and much more. This is the ultimate guide about high-shear granulators. Now get ready for learning about high shear granulators!

1.How do you define high shear granulator?

High shear granulators are used for mixing/blending various kinds of substances. It helps in the clumping and agglomeration of various residues by assimilating solutions or fluids and strong mixing.

The mixing of substances in different industries like pharmaceutical and detergent is achieved by high shear granulators. These are also called ‘rapid mix granulators.

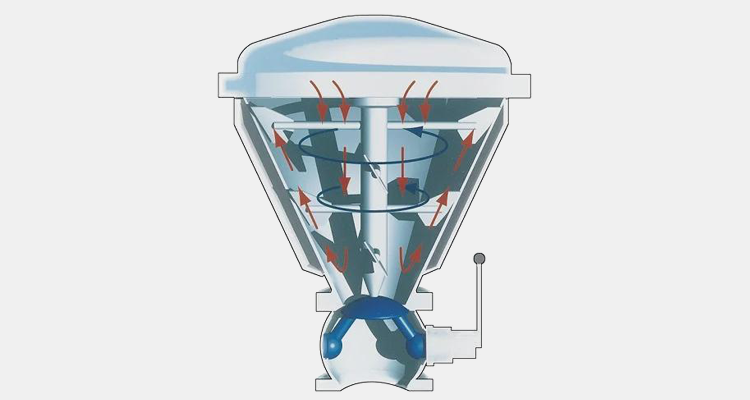

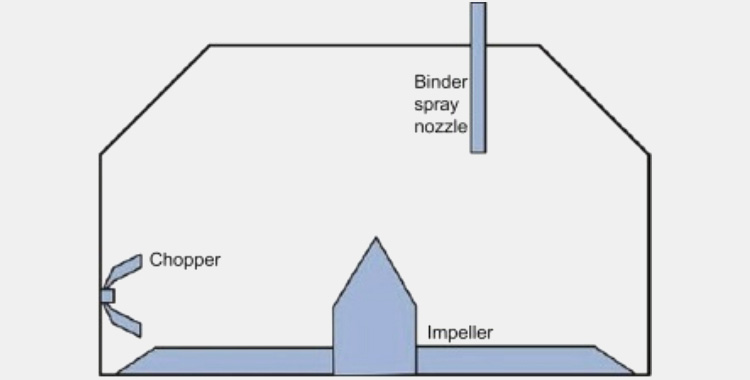

Schematic diagram of high shear mixer granulator

They are multi-processors which employed for two purposes

- They are used for mixing dry residues at high velocities

- Secondly, they are used to form pellets with a blending of organic solvents (binders).

High shearing forces in these granulators facilitate the production of pellets in a short time. These are widely used in industry because of their efficient design. They are used for their high blending properties. They produce pellets of equal sizes which are highly used for manufacturing tablets of excellent quality. Tablets produced by these mixers have low chances of being rejected.

High Shear Granulator- Video Courtesy - Glatt

2.What is high shear mixing?

When a force presses something in one direction while another part of object in other direction surrounded in same parallel plane, we call is phenomena as ‘Shear’. A high shear mixing is dispersion and transportation of ingredients from one phase into continuous phase or liquid. This technique is mostly used to mix solid or liquid substances that are ordinarily not easy to mix.

A high shear mixer is comprised of rotor that rotates at a high speed that allows material towards a stationary stator to shear the material.

You can use variable rotor speed to control shear energy required for each application.

3.What is the importance of granulation in pharma?

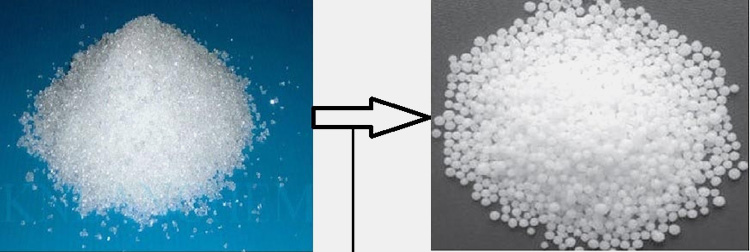

Granulation converts fine powders into dust-free and free-flowing form by agglomeration method. A granule is easy to compress, pack, etc.

In the pharmaceutical application, the average size of granules must be in the range of 0.2 to 0.4mm.

Granulation in pharma industries is very important due to following reasons:

- In pharmaceutical dosage formulations, the high shear granulation process may simplify the compression procedure during tablet formation and avoid wastage of raw materials.

- It increases the flowability of powder and mechanical strength to tablets.

- Granules enable uniformity of APIs in the finished pharmaceutical dosage form.

- Granulation process is important to control the release of the drug.

- It enables meter or volumetric dispensing of substances.

- It improves the density of the blend; therefore, it occupies lesser space in order to get suitable storage and shipment.

4.Discuss some important characteristics of high shear granulator?

High shear granulators are widely used for mixing purposes. These machines have many characteristics and purchasing this machine is highly suitable for your business.

High Speed Mixer Granulator

Now let’s take a look at a few important features of high shear granulators.

- These are provided with insulated pots that have a dual purpose of heating and cooling.

- They have efficient blades for breaking the materials.

- Their production yield is high. Granules made by these machines are robust, rounded, and even in size.

- Their cleaning is easy and modern high shear granulators have a cleaning in place system.

- Working parts are completely enclosed and personnel is not exposed to drug dust.

- Processes of blending and granulation are carried out in one step. And the end product is mechanically discharged.

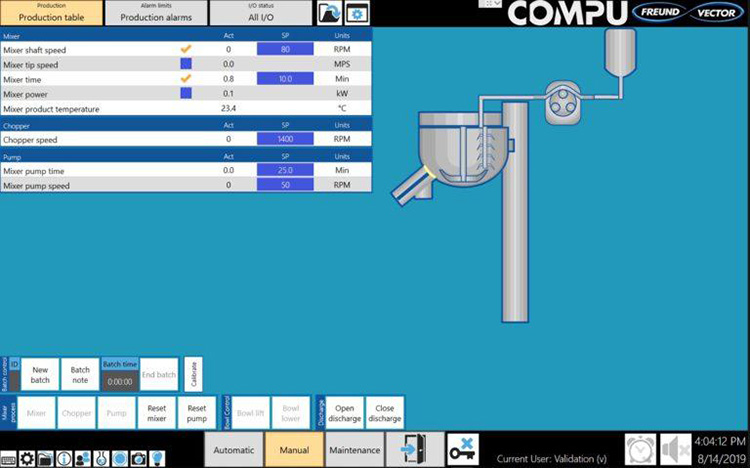

- They are provided with an automated control system and touch screen. Operational parameters like temperature, rotation speed, etc are selected both automatically and manually.

- Strong agitating forces make mixing robust and even. Also, these have grinders for efficient granulation.

- They conserve binder solutions.

- The solvent solutions can be easily recovered at low temperatures.

5.What are the pros of using high shear granulators?

Purchasing a high shear granulator is very advantageous for your business. It saves a lot of money, manual labor, and time. A few advantages of this highly recommended machine are given below;

- Simple Processing

This machine does not need a lot of binder for the process of granulation as compared to the low shear granulator and fluid bed granulator.

- Fast & Rapid Mechanism

High shearing forces used in this rapid mixer allow pellet formation in a short time.

- Compression Forces

This equipment aids in the compression and assembly of strong pellets. The pellets produced by these types of equipment can work within forces and do not break apart easily. These pellets are of high density.

- Pellets Granulation- Uniform Sizes

Pellets granulated by high shear granulators are of uniform sizes.

- Safe & Protective Production

Personnel exposure to drug residues is less while operating high shear granulators as these mixers less amount of drug residues.

- Time-Effective

It is easy to predict the ending time of the high shear granulator process.

- Suitable for Cohesive Material

Granulation of cohesive materials is done easily by these granulators. These materials are difficult to granulate by other methods.

6.What are the cons of using high shear granulator?

High shear granulators have drawbacks like many other machines.

Do not worry!

These machines only have a few limitations. These are given below:

- These machines have a limited set of working. If there are fluctuations in the operational conditions, then high shear granulators will not work properly.

- Heat-labile substances deteriorate if they are subjected to heat in the granulator.

- Large clumps are formed when the granules are exposed to over-wetting conditions.

- Due to high shear forces, fragile materials get degraded easily.

- Granules produced by high shear granulators do not have much compressibility in comparison with a low shear granulator.

7.What are the industrial applications of high shear granulators?

A high shear machine is a suitable machine that has many applications. These days it is used in many industries such as:

1.Pharmaceutical Industries

High shear machine a modern technology is widely used to make drugs in the pharmaceutical industry.

- These are used to make tablets and capsules by mixing formulated drugs in the liquid.

- These are used to make micro granules present in capsules for the slow release of drugs. These micro granules are only made by high shear granulators.

- These are used in the production of creams and salves.

- Prescription lens solutions are also made by these machines.

2.Agrochemical Industry

High shear granulators are mixing powders for fertilizers like silica and insecticides in agrochemical industries.

3.Food Industry

These machines have many uses in the food industry such as making emulsions for soft drinks, sugar syrups, confectionaries, and smoothies. High shear granulators are also used to process cheese. High shear machines are used to preserve food, enhance its shelf life, and increase the quality of the food.

4.Beauty Industry

They have also found their use in the cosmetic industry as well. These are used to mix and blend cosmetic powders

8.What do you know about various components of high shear granulators?

High shear granulators consist of the following components.

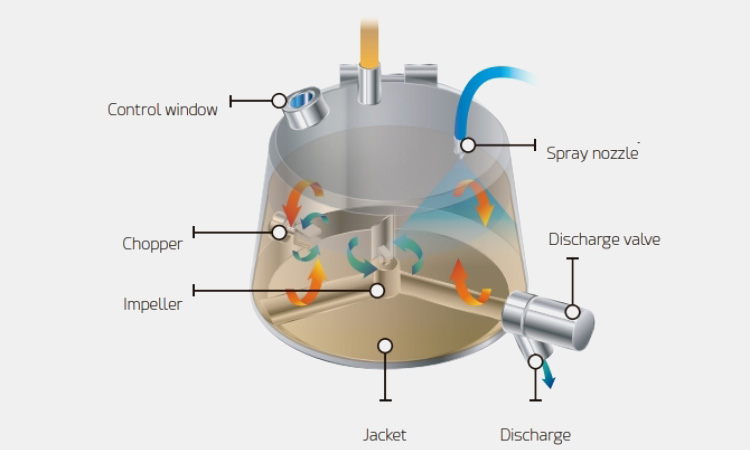

- Bowl

- Impeller

- Chopper

- Exhaust Port

- Filter

- Motor

- Control Panel

1.Bowl

This is a cylinder or dome-shaped container in which granulating process occurs. It is equipped with duplicators. These duplicators heat and cool the mixing bowl depending upon the requirement of the process.

Laboratory bowls have the holding capacity of 1 liter while the granulators used in industries are provided with large capacity mixing bowls that can hold material of about 300 liters.

There are three basic shapes of the bowls

- Dome

- Circular

- Cylindrical

All these shapes prevent dead spots and adhesion of materials to the walls of the bowl. This adhesion of material causes inefficiency in the process of granulation.

2.Impeller

These are attached at the bottom part of the dome bowl. It has four blades of varying length; one set has full length while the other set of blades are half in length.

The function of small blades is to raise the material and the purpose of full-length blades is to push material for mixing. Breaking of material into small fragments and pellets is done by impellers. The rotation of the impeller is in an anticlockwise direction. Speed of impellers cause two types of motions:

- Bumping motion

Low speed of impeller causes bumping motion of impeller and results in uneven mixing of granules with the binder. Due to these pellets are failed to form.

- Ropping motion

The high speed of the impeller causes the ropping motion. This ropping motion increases the size of granules. But if this ropping motion occurs for a long time, collisions between particles occur that result in granules of smaller size.

3.Grinder/Chopper

These are exclusively constructed blades placed at the lower part of the bowl. It has a high-speed of 1500 rpm.

The purpose of the chopper is to fracture large lumps into smaller parts. It causes also an increase in the number of small clumps. The role of the chopper depends upon the binder solution, working conditions, and the shape of the bowl. When the speed of the impeller is high then the grinder does not have any effect on the granules.

Grinder/Chopper-High Speed Mixer Granulator

4.Exhaust port

The ejection port is placed at the lower part of the bowl in the horizontal direction. The purpose of the discharge port is to pump the final product/granules into the container. A pneumatic cylinder having packed with compressed air regulates the discharge through an exhaust port. This cylinder has about 3-5 kg/cm2 of compressed air.

5.Filter

These granulators have filters placed in the vent that filters the system of dust and drug residues.

6.Motors

There are two motors in the high shear granulators. One is used to rotate the impeller and the other is used to rotate the chopper.

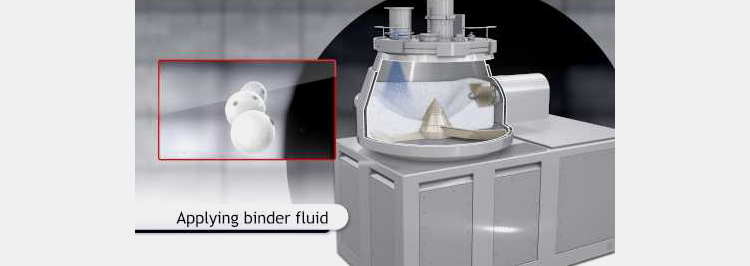

7.Spray Nozzle

Binder solution is sprayed with the help of more than one nozzle. The binder spray is scattered in the material by the combined action of impeller and chopper.

8.Compressed Air

Compressed air is provided from the underside to the impeller. The purpose of this compressed air is to avoid the stickiness of granules and it also reduces contamination in the material. The pressure of compressed air is about 5-6 kg.

9.Control Panel

The control panel is equipped with different options for controlling work parameters of the operations like temperature, dew point, and rotating velocity of impellers, chopper, etc

9.What are the different structural designs of high shear granulators?

High shear granulators of two main designs are available in the markets. These two different kinds of design are based on the location and direction of impellers.

- Vertical High Shear Granulator

- Horizontal High Shear Granulator

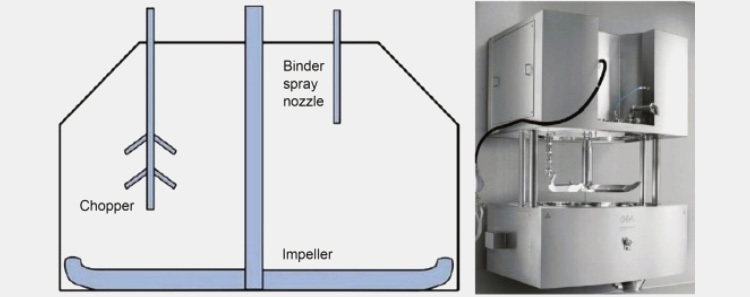

1.Vertical High Shear Granulator

In the vertical high shear granulator, impellers beams are rotated in the vertical direction. Based on the attachment position of the impeller and chopper to the mixing bowl, there are two types of vertical high shear granulators.

2.Bottom Driven Granulator

In this granulator, impellers are fixed to the bottom of the bowl and the grinders are placed at the edges of the bowl. It has a small space between the bowl and impellers. It has a 90% batch capacity.

vertical-bottom mounted high shear granulator

3.Top Driven Granulator

In top driven granulator, impellers and choppers are fixed at the top of the bowl. Bowls, choppers, and grinders are easily separated for cleaning in top driven granulator. It requires less working space for its operation.

Top Driven Granulator

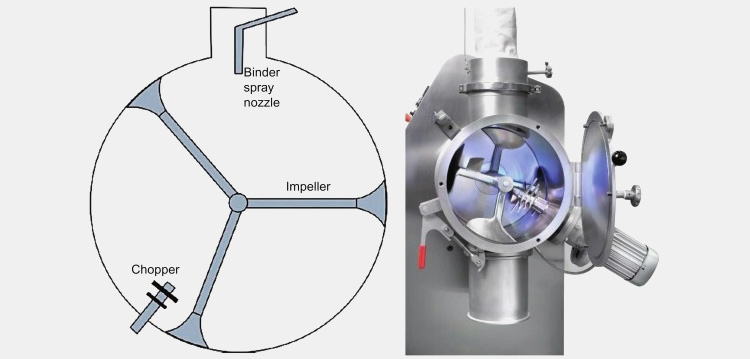

1.Horizontal High Shear Granulator

Impellers move in the horizontal plane in a horizontal shear granulator. The rotation of impellers is sideward. Impellers raise the powdery material and push it under the mist of the binder. The chopper is fixed to the bottom of the bowl in the horizontal high shear granulator.

Horizontal High-Shear Granulator

10.What is the high shear mixer granulator working principle?

The working principle of high shear mixing is based on the shaking of materials at moderate speed in the bowl. After those contents are mixed with the help of grinder blades at very high speed.

Broadly, the working of the high shear mixer is divided into three steps.

1.Dry Mixing

First, the powder is loaded into the bowl by the means of vacuum or gravity. The dry mixing of material takes place at high velocity. The powder is mixed utilizing an impeller and grinder. The time of dry mixing is around 3-5 minutes.

2.Addition of Binder

When a binder is added to the high shear granulator, its speed is decreased, and the impeller is rotated at a slow speed. Then materials are mixed for additional 5-10 minutes at a low speed. The impeller mixes the powder and binder liquid at 100-500 rpm. This helps in breaking materials and aggregating fragments into small pieces.

3.Wet Mixing

For wet mixing, the mixer is run at high speed. High shearing forces incorporation with a binder in the mixer break the granules and reduce their size. At the end of high shear wet granulation, small pellets having a size of 0.5-1mm in diameter are produced. This whole process takes about 5-10 minutes.

The wet granulation process usually depends upon the properties of preliminary material like its density and size, nature of binder, and acceleration of grinder. The construction and acceleration of grinder play a significant role in wet granulation and are crucial in producing granules of equal sizes. The speed of the grinder is about 1200 to 2000 rpm.

11.What factors affect the performance of high shear granulators?

You can choose good quality high shear granulator. But it is not sufficient to obtain excellent quality products. Several other parameters direct or in an indirect way impact the production of granules. Some of the important factors are mentioned below:

- Formulation variables

The kind and number of excipients also influence the performance of high shear granulators. The size of final granules is dependent upon the nature of excipients like their surface area and water content in it.

- Starting Material

Properties of starting material such as its size, diameter, conductivity, stability, viscosity, and color affect the process of granulation. If starting material is fragile then it deteriorates easily, and heat-sensitive material breaks down when the temperature is applied inside the granulator.

- Binder Solution

The idea behind the addition of binder solution is to improve the breakdown of large clusters of substances into small pieces.

Two properties of binder granulating liquids affect the process of granulation. These are

1.Amount

If a large amount of binder solution is added, then aggregates in materials are formed. If you little quantity of binder solution is added, then granules are not formed. The amount of binder solution has an impact on quality as well as the size of granules produced.

2.Viscosity

The viscosity of the binder also influences the size of granules. Binder solution of low viscosity produced granules of smaller size and vice versa.

- Design of Granulator Machine

Design construction of granulator impacts the relative volume of starting material. This also influences the compactness of end granules. The design of the impeller and mixing bowl has a major impact on the temperature of end granules and their cohesiveness.

High Shear Granulator

- Impeller and Chopper Speed

The flow of materials in the mixing bowl depends upon the impeller speed. When impeller speed is low then granules are smooth and have large distribution. At high impeller speed, the quality of granules is lost, and they have small distribution. You will observe a decrease in the size of granules with increasing the speed of the impeller. Chopper speed affects the granulation process when impeller speed is high around 700 rpm.

12.How to determine the endpoint in high shear granulators?

Endpoint determination is very necessary for controlling the size and distribution of granules. It also determines the viscosity and density of the granules.

A simple technique to determine the endpoint is as follows:

- Banana Breaking Method

Place a wet granule in the closed fist, afterward open the fist and try to break the fist by the thumb. If there is no dry powder, then the endpoint is reached. But this method requires the skill and expertise of working personnel.

- Load Ampere Method

It is the current consumed by the impeller and the copper for the rotation to produce granules. It has a high value when motors are consuming a lot of power and ultimately decreases when the endpoint is achieved.

13.How to determine the working capacity of high shear granulator?

For calculating the working capacity of high shear granulator, first, determine the bulk density of starting material. Suppose if the bulk density of the powder is 0.5 then the procedure of calculation is as follows:

high shear mixer granulator- Picture Courtesy- Pharma-trend

For a mixing bowl having a total volume of 600, the working volume of this bowl is 80% of the total volume, which means 480 liters.

So, working capacity in kilograms = working volume bulk density

=480x0.5=240 kg

You can make a batch having the load of 240 kg starting material for 600 liters high shear mixture.

14.How to operate high shear granulator?

Before operating the machine check the pre-startup guide. Please follow these steps.

- Always clean the working area before starting the machine.

- Ensure proper selection of materials for operating granulator.

Starting Granulator

- Wear gloves when loading the material inside the granulator.

- After opening the cover of the granulator, pour materials in the bowl as indicated by the Batch Manufacturing Record (BMR).

- Shut the lid and fasten two locking screws.

- Select the mixing velocity of dry mixing and time of operation as mentioned in BMR.

- Switch ‘ON’ the machine and initiate the working of the granulator.

- When you add a binder to the granulator, slow down the speed of the mixer. Binder is added using solution inlet port.

- Ensure the speed of the mixer for wet mixing is per guidelines of BMR. Then run the machine for a specific time.

- Raise the mixing velocity and increase granulation by adjusting the speed of the chopper accordingly.

- Continue checking the status for granulation after regular intervals.

- When granulation is completed, unlock the exhaust port and pour the wet load into a clean bowl. This bowl is present beneath the exhaust port.

Ending Operation

- First, halt the movement of the grinder and impeller.

- Afterward, uncover the lid of the granulator and get rid of leftover mixing material with scrappers.

- Ensure equipment is cleansed of all extra material.

- Turn off the energy supply.

15.What are the cleaning procedures of high shear granulators?

There are different cleaning procedures for a high shear granulator. These cleaning processes are carried out at different timings.

Batch Changeover Cleaning

It is noted that this cleaning procedure is done when the same products are mixed.

- Clean the granulator and working area of this machine.

- Take out the ‘clean’ label.

- And put the ‘in use’ label on the granulator.

Product Switch Cleaning

- Inspect the machine and the working area around the machine for any dust or waste material produced from the previous operation.

- Examine the wash report and fix it to BMR.

- Take out the ‘clean’ label.

- Record the temperature and dew point and mention them in BMR.

- If you note that temperature is not within a particular range and call the maintenance staff. DO NOT start the operation till the temperature and dew point is in the requisite range.

After Operation Cleaning

This cleaning procedure is carried out at the end of the operational day.

- Remove leftover powder with lint-free fabric.

- Take part machine components in the following order.

- shaker top

- grinder blades

- steel screw

- Use a clean cloth and scrub the removed parts.

- Wipe the machine with a sanitary cloth.

- Clean the working area according to the machine guidelines document.

- Reassemble the parts.

Maintenance Cleaning

- Scrub the machine and its external surface with a wet duster and then clean with a dry cloth.

- Pour water in the bowl and fill it to one-third of its loading capacity. Then cover the lid and run blender and chopper for 5 minutes.

- Uncover the lid and take part shaker blades by unscrewing the nuts.

- Then pull apart chopper blades. Wash agitator and grinder blades underwater. By using a brush, clean them of unwanted materials.

- Clean and wash the bowl with the help of a brush and water for removing powdery substances.

Ensure the instrument is clean by checking parts beneath the grinder blades, dome, exhaust gates, and nuts.

16. What protective procedures must be done while operating the high shear granulator?

You should consider following safety and protective measures when you are operating the high shear granulator.

- If the air pressure of the machine is below the threshold, first set the pressure to a specified value and then start the machine.

- Do not start the machine if the lid is open.

- If the discharge valve is open for cleaning do not start up the machine operation.

- The machine should not be switched on if the impeller is taken out due to cleaning.

- Ensure that all the belts, cranes, and conveyance systems are covered.

- Always handle machine while wearing protective equipment like gloves, overalls, goggles, etc

- Binder should be stored in the ground container and should be transported with non-inflammable tools.

Screws of sealing systems must be tightly closed.

17.What are maintenance recommendations of high shear granulators?

If you want your machine to have long working life, then you properly schedule maintenance of the machine. Few maintenance steps are given below:

- Electric motors should be kept free of dust and scratches.

- Electric motors must be oiled regularly.

- Impeller and chopper blades must be checked regularly for damage. If you see damage to their teeth, then they must be replaced instantly.

- Screws of impellers and choppers must be lubricated daily.

- Clean and lubricate the surface of the mixing bowl after work.

- Nozzles for spraying binder solution must be kept free of dust. Wash the spray nozzles with water.

18.What are important consideration factors when buying a high shear granulator?

If you want to purchase the high shear granulator for your business, then read this useful information. The following points should be kept in mind when procuring high shear granulators. These points will save time and money.

High Share Granulator

Ergonomic Design

When you are buying this machine, you should consider the efficiency of its design. Every component of the high shear granulator influences the operational time, effectiveness, safety, and dependability of the machine. For example, different designs of impellers have their advantages.

- If you purchase a three-blade impeller design, it will create granules of high density and rotate at high speed but consume a huge thermal power.

- If you buy a two-blade impeller design, it will perform rapid granulating at reduced speeds.

Bowl Configuration

When purchasing the high shear granulators, always purchase those machines which have flexible bowl designs. Bowl configuration has a major effect on efficiency and working volume. Working volume ranging from 30-90% depends upon bowl geometry. Many types of equipment have a maximum of 66-75% working volume.

The mixing bowl should be able to handle batches of different sizes. This feature will save your money. This will also save your effort in changing machine parts.

Position of Impeller and Chopper

Always inspect the location of the impeller and grinder. The performance efficiency of the granulating process depends upon the position of the impeller.

To ensure best performance buy those machines, whose impeller are at the bottom and chopper are at the sides. This will reduce the dead spots and maintain the uniformity of material. If the speed of the impeller tip is steady, then this will increase the production of granules.

High Shear Granulator- Impeller & Chopper

Automatic Cleaning

The machine should be provided with automatic cleaning in place system. These cleaning systems reduce a lot of time and effort. It saves the time spent on cleaning between batches processing.

Automatic Lift Tool

These tools automatically lift the impeller about 4-8 inches. It allows easy examination and cleaning beneath the impeller and bottom of the mixing bowl.

Hydraulic Drive System

Large scale machines equipped with hydraulic systems reduce the torque up to one-quarter rpm. This helps in saving break-out torque for extra mixing. This mixing occurs at decreased speeds after examination and ejection to wet grinding systems.

End Point Precision

Measurements in the granulating procedure help to determine the density, average size, and distribution of granules. These values help in calculating the endpoint of the process and its scalability. Machines that are automated with processors, records information like torque, power utilization, and amperes, are useful in determining the endpoint of the granulating process.

Loading and Unloading System

High shear granulators should have different loading and unloading systems. This helps in handling materials. High purge sealing systems do not allow exposure to dust while loading.

High Shear Mixer Granulator

Regulatory Requirements

These requirements are essential in proving that equipment follows a stringent quality production process. You should check that your selected machine should comply with cGMP regulations. It is an important prerequisite for every pharmaceutical instrument. These regulations ensure that the machine is tightly sealed to avoid dust exposure.

19.Can you troubleshoot the unexpected failure of the high shear granulator?

When you are operating any machine, you face any unexpected errors. The same is the case with a high shear granulator.

Don’t get too troubled as it is very easy to troubleshoot the failures that arise when operating high shear granulator. Some failures and their solutions are given below:

High ampere value

When the machine consumes much power, and you will get a high value of ampere.

Cause

- It is due to high environmental temperature

- Overload of motors.

Solution

- Try to decrease the temperature of the room.

- Check the cable to find signs of overload.

- Scratches on the Mixing Bowl

Sometimes the agitator scrapes the surface of the bowl.

Cause

- Old nut and screws

- Loose stators

- Dust particles on the surface of the magnet.

Solution

- Change the nut and screws

- Tauten the slack bearing

- Inspect the direction of rotation

- Wipe the particles from the surface of the magnet

Failure of Motor Rotation

Sometimes motor get struck and does not rotate

Cause

- It is due to the unavailability of the power

- Sometimes circuit breaker is switched off

- There are particles on the magnet.

Solution

- Check your power source.

- Check the room temperature and amp value.

- Remove dust particles from the magnet.

Density of Granules

The granules produced at the end of operation are too dense or they have very low density.

Cause

- The speed of the impeller is very high

- The optimum time is not given to produce granules.

Solution

- Check the speed of the impeller.

- Give optimum time for working.

Drying of Granules

Sometimes granules are too dried or they are over wet which causes sticking.

Cause

Timing and temperature for drying are not optimum.

Solution

- Temperature and timing for the drying process should be optimum.

- Check the nature of starting material.

Uniformity of Material

Sometimes granules do not have even consistency.

Cause

Mixing conditions are not proper.

Solution

Proper conditions such as time and amount of granulation material must be given for uniformity of granules.

Conclusion

To buy a right choice high shear granulator is time and energy consuming job. We hope this blog has developed your basic to advanced knowledge on how to select a high shear granulator according to your requirement to success your business.

Granulator Machine Related Products

Granulator Machine Related Posts

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machin

Tell us your material or budget,we'll reply you ASAP within 24 hours