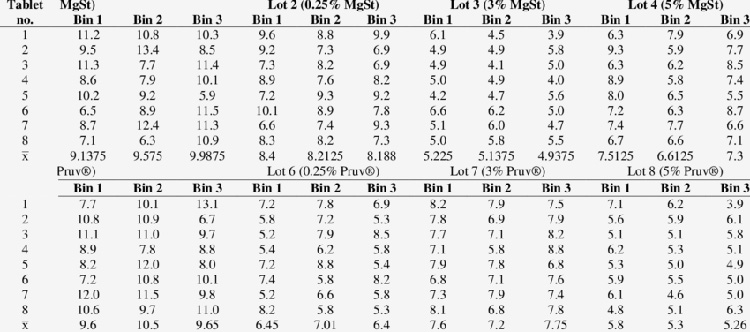

Hardness of Tablet Chart

From a pharmaceutical outlook, hardness of tablet is one of the quality control tests carried out to measure the ability of tablets to withstand mechanical pressures during its handling, packaging, storing and transportation. A tablet should not be hard enough that it’s difficult for it to disintegrate and neither it should be soft such that it disintegrates rapidly after ingestion.

There are certain tests that are performed on tablet to determine its breakage potential and there are few factors which control and affect a tablet’s hardness.

Let’s read the article ‘Hardness of Tablet Chart’ you’ll further get to know more about its significance.

1.What Is the Hardness Of Tablet?

Tablet hardness is the type of a physical property measurement used to identify the breaking point of a tablet and it’s ability to withstand mechanical pressures under situations like handling, packaging, storing and it’s transportation.

Testing the hardness of tablet is important parameter in medicinal production as a quality control method which suggests that the tablet must neither be too hard not too soft. Thus it can also be defined as the crushing strength or load which is required to crush the tablet into granules or powderous form.

However strangely the word ‘hardness’ is used misinterpretingly according to the pharmacopeias and the suitable word instead is said to be ‘crushing strength’ or ‘breaking strength’ .

2.Why Hardness Of Tablet Is Important To You?

As testing the hardness of a tablet is considered as a quality control checking parameter under laboratory pharmaceutical preparations, it is quite obvious the importance that the physical characteristics of any medicinal dosage form hold. Likewise, the hardness of tablet is important as this quality affects the normal disintegration timing of a tablet. If the tablet prepared becomes too hard, it will take more time to break down and disintegrate and therefore longer time to show the required action of the medicine. If the tablet prepared becomes soft, that means it will prematurely dissolve even before getting to the required site of action in the patient’s body.

We measure the hardness of the tablet to ensure the tablet’s consumer acceptance and also to determine the strength of crushing under pressure such as damage that might be faced during it’s after manufacturing processes.

3.What Is the Hardness Of Tablet Chart?

The hardness of a tablet chart indicates various criteria upon which a tablet’s crushable strength is found through laboratory research and noted in the form of numerical data in a table or a chart compared to the authentic values of those stated in BP and USP.

Measuring these criteria clearly shows how a tablet will crush and so these can be called ‘Tablet breaking characteristics' . Regardless of the force applied to break a tablet, or the type of material used to constitute a tablet or different methods applied to achieve the tablet granule sizes , the tablet will fracture irregularly and this is what is recorded in the form of a Hardness of tablet chart.

Different types of chart are drawn on the basis of the practical examination carried out for identifying a tablet’s hardness. For eg, in some charts simply the thickness and diameters of certain number of tablets are compared with their hardness and the deviation is assessed, in some charts tablet hardness is checked on addition of different granules sizes, etc.

Those criteria’s usually are as followed:

The Hardness Of Tablet Upon Addition Of Lubricants

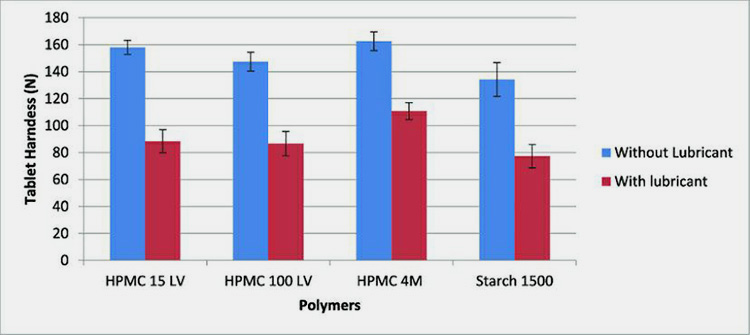

A figure illustrating effect of lubricant on the hardness of tablet chart- Photo Courtesy: Researchgate

Lubricants are used to minimize the occurrence of friction between tablet material and die metal of the tablet press. But along with this purpose, it also facilitates the ejection of tablet during the procedure of compression as well that’s indeed undesirable during production procedure. Therefore you must consider its amount within specification to keep hardness of tablet optimized.

In various research it was found that tablet hardness in different polymers increased without the addition of lubricants. In another study , upon addition of Magnesium Stearate (which is a lubricant) , the tablet hardness was found to be decreasing with increasing amount of lubricant.

The Hardness Of Tablets With Different Granules Sizes

Tablet hardness is greatly affected by changing granules size . Increasing granule size decreases the tablet hardness. Moreover, a decreased granular size may rise the electrostatic forces and high surface area that results in inter- particle or inter- granular friction and weight variation.

It is revealed that very small or very large granular size matter may not properly occupied void spaces and affect die fill due to insufficient compaction and affect overall hardness. It is recommended from various research report that 24C milled granules is better in order to producing the good tablet hardness instead high milled granules.

The Hardness of The Tablet When Different Forces Of Compression Are Applied.

You must know that compression force of tablet press have huge impact on the disintegration time of the tablet hardness. Moreover, for controlled release tablets compression force may produce extended effects for continuous supply of drug when ingested.Increasing compression force is shown to increase tablet hardness.

| Compression Force in Tons | Hardness in kg/cm3 | ||

| Tablet A | Tablet B | Tablet C | |

| 1 | 15.1 | 15.0 | 15.0 |

| 2 | 15.7 | 15.4 | 15.8 |

| 3 | 16.2 | 16.0 | 16.1 |

| 4 | 16.8 | 16.5 | 16.7 |

| 5 | 17.1 | 17.2 | 17.0 |

4.Why Do You Need the Hardness Of Tablet Chart?

In order to formulate a tablet that is perfect according to the manufacturer in terms of patient compliance, and its physicochemical properties which make it appropriate for handling and storing, data is required in the form of a chart that showcases different characteristics to identify whether a tablet is okay or not. Not only the hardness of tablet, but also weight, thickness, friability, tensile strength and disintegration and dissolution timings numerical data is recorded in charts and tables upon quality control analysis.

The tablet hardness chart is helpful for passing a tablet’s quality assurance which would ensure that a certain tablet is strong enough to bear compression under a limited force or that indicates the tablet would disintegrate rapidly or slowly inside the patient’s body. Different shapes and sizes of tablets also influence it’s breaking strength and therefore they can also be recorded in the form of chart.

5.How Do You Quantify Hardness Of Tablet Chart?

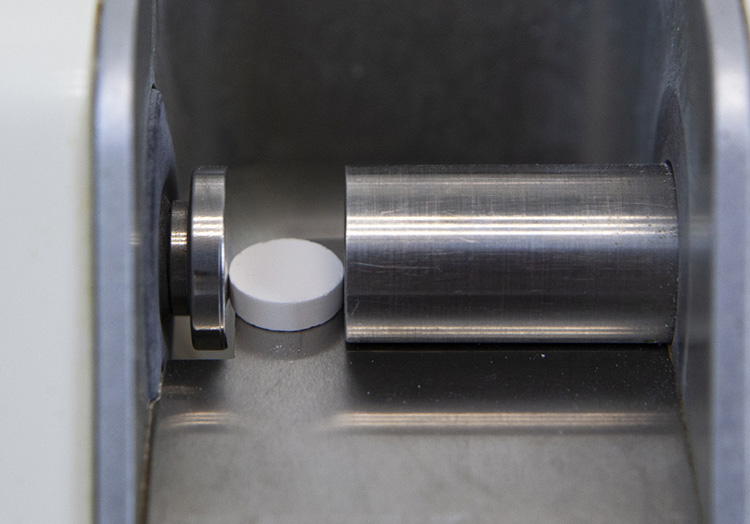

The hardness of the tablet is quantified by measuring it by placing it in between two platens (jaws) one of which is movable and the other is not, the breaking force applied crushes the tablet across diametrically. The breaking force of any tablet depends upon its shape and scoring.

There are different types of measuring tests used to check the hardness of tablets which can then be recorded in a chart. Crushing Test, Fracturing Test and Bending Test are employed to test the breaking strength of tablets.

Crushing Test

This is applied on round or capsule shaped tablet , and it’s compressed diametrically as the sample tablet is placed on a table base and force is applied through cylindrical probe.

Fracture Test

This is carried out by moving hemispherical ball probe onto a sample tablet.

Bending Test

Thisis performed on oval or round shaped tablet which is a little larger in size and is fractured with a knife like probe.

Official standard quantitative values for tablet hardness are: 5-8 kg/cm² for standard compressed tablet except few types of tablets such as effervescent tablet, Dispersible tablet ,Orodispersible tablet, Chewable tablet. Generally oral tablets and chewable tablets have a hardness range of 4-10 kg. More than 8-12 kg/cm² for sustained released tablet and controlled release tablets.

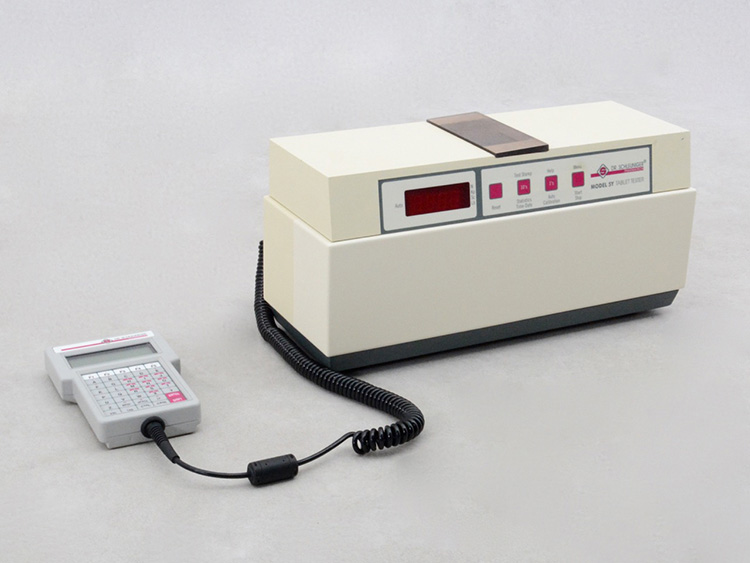

6.What Are The Tablet Hardness Testing Equipment Used?

There are various methods introduced and developed different types of hardness testers for tablets starting from the one that works manually to the one that is operated automatically and digitally.

Generally, the tablet is placed between two jaws of a tester and the force is applied to check when the tablet breaks.

Monsanto Hardness Tester

This equipment has two jaws, one which is moving and another that is fixed jaw. The pressure is applied with the help of movable screw knob. Tablet is placed between both jaws and force is applied. The scale on which tablet breaks can be recorded in kg/cm².

Pfizer Hardness Tester

A Pfizer Hardness Tester consists of a holding plier and a piston and knob which can be used for placing the tablet, where the force is applied by pressing the plier and the reading where the tablet breaks is recorded on force reading gauge. It is also recorded in kg/cm².

Strong Cobb Hardness Tester

This is one of the firstly introduced tester for measuring tablet hardness. The force applied was through manually operated air pump , upon crushing of tablet the value is recorded on pressure dial gauge.

Erweka Hardness Tester

Erweka Hardness Tester is operated digitally and have different models that consist of different tablet feeder system and testing station. Depending upon the type of model, various shapes and sizes of tablets are tested for their crushing strength.

Schleuniger Hardness Tester

This equipment is a tester used to measure diameter , hardness , weight and thickness of various shapes and sizes of tablets. The tester is operated by an electric motor which applies force on the anvil to compress the tablet until it breaks. The breaking point is recorded on a scale indicator.

7.What Are The Quality Standards For Tablet Hardness Testing?

There are some quality standards set for checking and evaluating a tablet hardness tester according to USP.

- Platens or Jaws of the tablet tester machine should be at the right angle to the direction of movement, must be precision ground and the surface must be broad and polished.

- The compression force applied and the rate of platen’s movement must be consistent to prevent uncontrollable crushing of tablet.

- The equipment used must be calibrated to the standard units of force which is in Newtons or kiloponds.

- Tablet hardness tester machine must be compliant with cGMP which would ensure proper functioning and manufacturing operations carried out through it. Pharmaceuticals devices must be regulated by FDA , Code of Federal Regulations (CFR 21).

8.What Are The Units For Testing Tablet Hardness?

Following the International System Of Units (SI), testing tablet hardness can be measured in different units mentioned below.

Kilogram: It is identified as one of the main units of measuring mass.

Newton: This is commonly known as unit of force. It is used by tablet hardness testers as a standardized calibration unit.

Pound: This is also recognized as a unit of force. North America uses this unit for testing tablet hardness, however, it is not an international unit.

Kilopond: It is used in some studies and research to measure tablet hardness, although it must not be considered as a standard unit.

Strong Cobbs:It’s one of the oldest used and discovered units for measuring tablet hardness, named after its device Strong Cobb’s tester. 1Sc equals about 7 N.

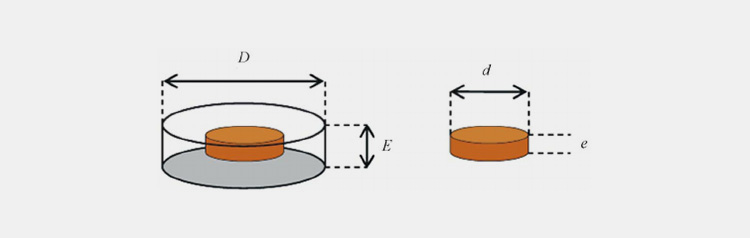

9.What is The Difference Between Testing the Hardness Of the Tablet VS Testing Thickness Of the Tablet?

The hardness of a tabletis tested when you need to check the crushing strength of certain tablets to further evaluate whether the tablet will withstand during its operation and handling. It is also used to assess whether the dissolution rate and disintegration timing will be according to the specification or not.

The thickness of the tabletis tested when you need to check the compressibility during tablet compression and to ensure effective packaging along with uniform tablet weight, die-filling granule size, and tablet hardness. These factors play a role in affecting the thickness of the tablet which overall affects the physical property of the tablet.

CONCLUSION

The production of tablets without compression force, lubricants, appropriate granular sizes, proper handling, and excellent tablet press is not possible. Although, keeping these parameters optimized must be the prime moto of any manufacturer to avoid picking, sticking, capping, cracking, or other relevant defects. Moreover, in the article Hardness of tablet chart,’ you also ended up with the idea that the higher the tablet hardness will lower the disintegration time, or if you increase the concentration of lubricant you will lower its hardness but more disintegration. For more queries or need to know excellent tablet press for your procedure, Please contact our expert team now.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours